Product Data Sheet - Valspar Coil & Extrusion

Product Data Sheet - Valspar Coil & Extrusion

Product Data Sheet - Valspar Coil & Extrusion

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

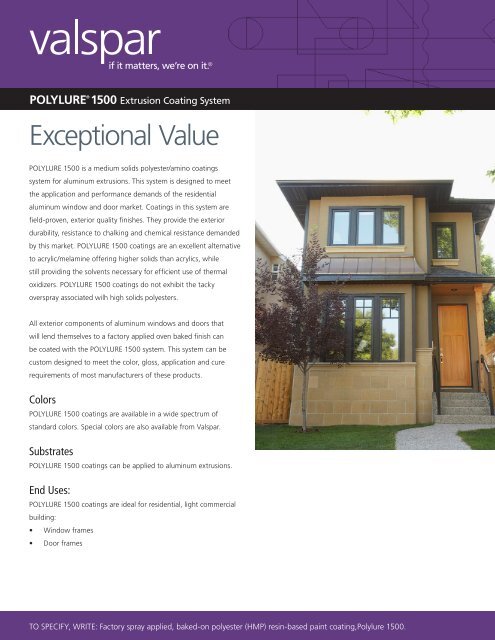

POLYLURE ® 1500 <strong>Extrusion</strong> Coating SystemExceptional ValuePOLYLURE 1500 is a medium solids polyester/amino coatingssystem for aluminum extrusions. This system is designed to meetthe application and performance demands of the residentialaluminum window and door market. Coatings in this system arefield-proven, exterior quality finishes. They provide the exteriordurability, resistance to chalking and chemical resistance demandedby this market. POLYLURE 1500 coatings are an excellent alternativeto acrylic/melamine offering higher solids than acrylics, whilestill providing the solvents necessary for efficient use of thermaloxidizers. POLYLURE 1500 coatings do not exhibit the tackyoverspray associated wilh high solids polyesters.All exterior components of aluminum windows and doors thatwill lend themselves to a factory applied oven baked finish canbe coated with the POLYLURE 1500 system. This system can becustom designed to meet the color, gloss, application and curerequirements of most manufacturers of these products.ColorsPOLYLURE 1500 coatings are available in a wide spectrum ofstandard colors. Special colors are also available from <strong>Valspar</strong>.SubstratesPOLYLURE 1500 coatings can be applied to aluminum extrusions.End Uses:POLYLURE 1500 coatings are ideal for residential, light commercialbuilding:• Window frames• Door framesTO SPECIFY, WRITE: Factory spray applied, baked-on polyester (HMP) resin-based paint coating,Polylure 1500.

POLYLURE ® 1500 <strong>Extrusion</strong> Coating SystemP H Y S I C A L P R O P E R T I E SPROPERTY RESULTS TEST DESIGNATION60° Specular Gloss: 15 - 90 ASTM D-523Pencil Hardness H - 3H ASTM D-3363Film AdhesionWetDryAcceptable (B)AAMA 2603Acceptable (B) AAMA 2603Impact Resistance (direct) Acceptable (C) AAMA 2603CHEMICAL RESISTANCE TESTS RESULTS TEST DESIGNATIONMuriatic Acid Resistance Acceptable (D) AAMA 2603Mortar Resistance Acceptable (E) ASTM C-207Detergent Resistance Acceptable (F) AAMA 2603ACCELERATED TESTS RESULTS TEST DESIGNATIONHumidity Resistance100% relative humidity @ 100° F1,500 hours exposureAcceptable (G) ASTM D-2247, ASTM D-714Salt Spray Resistance5% salt solution @ 95°-100° F1,500 hours exposureAcceptable (G) ASTM B-117, ASTM D-1654NOTES:(A)(B)(C)(D)(E)(F)(G)Applied in accordance with <strong>Valspar</strong> technical specification sheet on properly treated aluminum surfaces.One-sixteenth inch cross-hatch-no removal of film by tape and no blistering on wet test.One-tenth inch deformation. No removal of film from substrate.Fifteen minutes spot test of 10% solution cover with watch glass (convex side up) conducted at 6S-70°F. No blistering or visual change in appearance.Twenty-four hours exposure to 100% relative humidity at 100°F. Mortar easily dislodges with no Joss of adhesion or visual change in appearance.Immerse at least two specimens in 3% solution at 100°F. for 72 hours. No loss of adhesion to substrate. No blistering and no significant visual changein appearance.Conforms to AAMA 2603 performance specifications.POLYLURE 1500 COATING SYSTEMPolylure 1500 is a one-coat polyester resin systemwith a total Dry Film Thickness (DFT) of 1.2 mils total system.Color Coat(1) American Architectural Manufactures Association’s ten year superior performing specification withincreased performance to AAMA 2603. (2) Applied in accordance with <strong>Valspar</strong> technical specification sheeton properly pretreated aluminum surfaces. (3) American Society for Testing and Materials. (4) Recommendedfor most colors.For details and health, safety and handling information, Material Safety <strong>Data</strong> <strong>Sheet</strong>s (MSDS) are available atwww.valsparcoilextrusion.com.Polylure is a registered trademark of The <strong>Valspar</strong> Corporation.VALSPAR MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND DISCLAIMS ALL IMPLIED WARRANTIESINCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. VALSPAR WILL NOTBE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.Color Coat: 0.8 -1.2 milsPretreatedAluminum<strong>Valspar</strong> <strong>Coil</strong> and <strong>Extrusion</strong> Coating DivisionPhone: 866-351-6900Email: extrusionhelp@valpsar.comwww.valsparcoilextrusion.comVAL No. 171/15000March 2013 / Printed in the USA©2000 The <strong>Valspar</strong> Corporation.