REFERENCE MANUAL FOR U.S. WHEY AND LACTOSE PRODUCTS

REFERENCE MANUAL FOR U.S. WHEY AND LACTOSE PRODUCTS

REFERENCE MANUAL FOR U.S. WHEY AND LACTOSE PRODUCTS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

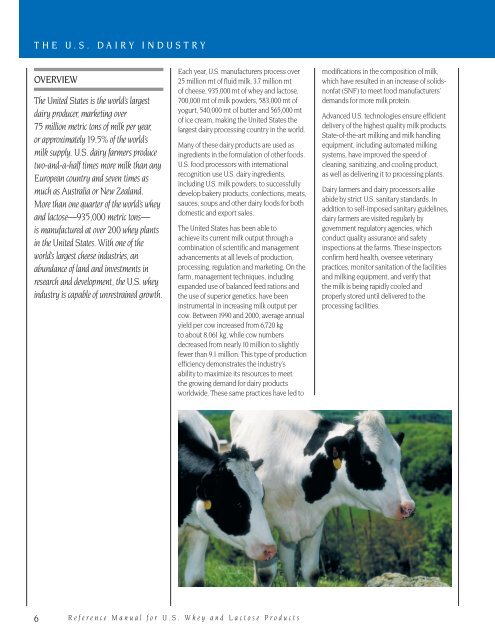

THE U.S. DAIRY INDUSTRYOVERVIEWThe United States is the world’s largestdairy producer, marketing over75 million metric tons of milk per year,or approximately 19.5% of the world’smilk supply. U.S. dairy farmers producetwo-and-a-half times more milk than anyEuropean country and seven times asmuch as Australia or New Zealand.More than one quarter of the world’s wheyand lactose—935,000 metric tons—is manufactured at over 200 whey plantsin the United States. With one of theworld’s largest cheese industries, anabundance of land and investments inresearch and development, the U.S. wheyindustry is capable of unrestrained growth.Each year, U.S. manufacturers process over25 million mt of fluid milk, 3.7 million mtof cheese, 935,000 mt of whey and lactose,700,000 mt of milk powders, 583,000 mt ofyogurt, 540,000 mt of butter and 565,000 mtof ice cream, making the United States thelargest dairy processing country in the world.Many of these dairy products are used asingredients in the formulation of other foods.U.S. food processors with internationalrecognition use U.S. dairy ingredients,including U.S. milk powders, to successfullydevelop bakery products, confections, meats,sauces, soups and other dairy foods for bothdomestic and export sales.The United States has been able toachieve its current milk output through acombination of scientific and managementadvancements at all levels of production,processing, regulation and marketing. On thefarm, management techniques, includingexpanded use of balanced feed rations andthe use of superior genetics, have beeninstrumental in increasing milk output percow. Between 1990 and 2000, average annualyield per cow increased from 6,720 kgto about 8,061 kg, while cow numbersdecreased from nearly 10 million to slightlyfewer than 9.1 million. This type of productionefficiency demonstrates the industry’sability to maximize its resources to meetthe growing demand for dairy productsworldwide. These same practices have led tomodifications in the composition of milk,which have resulted in an increase of solidsnonfat(SNF) to meet food manufacturers’demands for more milk protein.Advanced U.S. technologies ensure efficientdelivery of the highest quality milk products.State-of-the-art milking and milk handlingequipment, including automated milkingsystems, have improved the speed ofcleaning, sanitizing, and cooling product,as well as delivering it to processing plants.Dairy farmers and dairy processors alikeabide by strict U.S. sanitary standards. Inaddition to self-imposed sanitary guidelines,dairy farmers are visited regularly bygovernment regulatory agencies, whichconduct quality assurance and safetyinspections at the farms. These inspectorsconfirm herd health, oversee veterinarypractices, monitor sanitation of the facilitiesand milking equipment, and verify thatthe milk is being rapidly cooled andproperly stored until delivered to theprocessing facilities.6 Reference Manual for U.S. Whey and Lactose Products