WHEEL LOADER - Hitachi Construction Machinery

WHEEL LOADER - Hitachi Construction Machinery

WHEEL LOADER - Hitachi Construction Machinery

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

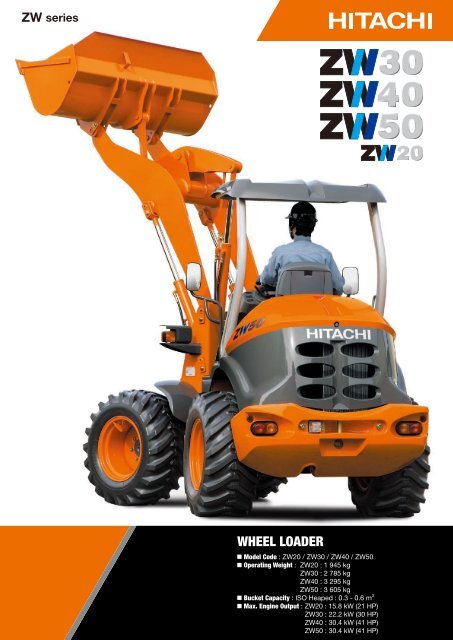

With Emphasis onFunctional BeautyPractical Compact-Wheel LoaderPleasantto DriveThe ZW Compact Series features comfortableand reliable Compact-wheel loaders for usein a wide variety of fields. The strong andindividual body of these Compact-machines wasdesigned with functionality and mobility in mind.The graceful silhouette is a result of thoroughresearch into the full range of basic functions.Try the ZW Compact Series of wheel loadersequipped with a diverse range of high-qualityfunctions demanded of versatile Compactmachinery,including comfortable operability,high-level safety, easy maintenance andenvironmentally friendly design.The new engine complieswith the Emission RegulationsU.S EPA Interim Tier 4 andEU Stage III AThe advanced low noisedesign complies withthe coming EU noiseregulation 2000 / 14 / EC,STAGE IINote: The illustrations and photos used in thisbrochure include optional equipment.

Subtle Functional Beauty for Greater Work PerformanceHeavy load performance that supports powerful digging, excellent stability, and strong traction force.Steering performance that improves work efficiency in tight job site. All part of greater work performance.Excellent StabilityHigh-Powered EngineHighly Original Large CounterweightThe use of a large counterweight lowersthe center of gravity and protects thebody, as well as improves stability.Easy-to-Use Towin PinBy lowering the towin pin position, thetroublesome need to raise loads bystraining on a heavy wire rope has beeneliminated, enabling much more stabletowin performance.The high-powered engine, mountedon the ZW40 or ZW50, allows formore powerful, smoother operationwith less fuel consumption evenat low engine rpm, assisted by its new4-cylinder configuration with increaseddisplacement and suppressed vibration.Reinforced MainframeWe have carefully researched the center of gravity to maintain the weight balancebetween the front and rear, upper and lower, and left and right of the machine so thatnot only is excellent stability maintained.Great Dumping Clearance and ReachSmall Turning Radius for Tight SpacesDumpingClearanceZW30ZW40ZW50DumpingReachDumpingClearance2 155 mm2 445 mm2 500 mmDumpingReach775 mm800 mm870 mmAchieves ample dumping and reach.Dumping into a hopper or loading intoan 11 t dump truck is possible due tothe excellent stability.ZW30ZW40ZW50Total Length(in Driving Mode)4 165 mm4 460 mm4 630 mmTurningRadius3 550 mm3 740 mm3 815 mmNote: The turning radius is the value of theoutermost bucket.In order to improve turning performance,such as the distance and position fromthe front axle to center pin and centerpin to rear axle, great improvementshave been made to this latest model.In this way, the Compact-wheel loaderis now easier to use in town and citystreets and other confined work spaces.To reinforce the front and rear frames,a box-section structure has beenintroduced. This improves durability,which results in greater reliability.

Functional Beauty That Promotes Skillful Operationand ComfortCan be operated skillfully by operators without great experience.Further, this quiet and comfortable operating environment is part of basic ZW concept.HST Auto TransmissionContinuously adjustable speed can beachieved by operating the accelerationpedal - enabling start, acceleration, andstopping to be performed automatically.Travel is made easy with smoothautomated speed changesPrecision operations possible usingextremely low speedsExcellent mechanical operations withhighly responsive accelerationSmooth startup on inclines using HSTbrake operationsExcellent rim pull at all speeds rangeSimple and Secure Front Control LeverPanoramic Cab for Good Field of Vision (Optional)Sun Visor (Optional)Suppresses glare from thesnow and sun.AM/FM Radio + 2 Speakers(Optional)A secure and easy-to-use front operationlever that controls the lifter smoothly andspeedily.Suspension Seat(Optional)A suspension seat is availableto lessen vibrations and shockduring operation.Convenient Forward and Reverse LeverSwitch easily between forward andreverse operations using the fingers ofyour left hand while holding onto thehandle.Good Visibility MonitorSpecial Handrail and Large Step forMounting and AlightingComfortable Seat to Reduce FatigueUses a large sliding sash for the door and a pillar-less designgives an unobstrusted view of the front. The cab enablespanoramic views via the addition of a lower window, which wasabsent in existing models, the removal of the rear corner pillar,and the use of a new and improved defroster nozzle,etc., providing a wide field of vision.An easy-to-read transparent meter panelenables you to determine the machine'sstatus at a glance. Instruments feature acompact layout for easy checking.Walkthrough Type CabinA walkthrough type cabin enablesmounting and alighting from either theright or left.There are handrails and large stepsmounted on both the left and right of thecabin for easy access.Electric Switch Parking Brake thatPrevents Pulling Friction DamageSuppresses scorching due to pullingfriction. Further, when the engine isstopped, the brake is automaticallyapplied.A comfortable seat to relieve operatorfatigue has been adopted. Absorbsunpleasant vibrations, reducespsychological and physical burdens,and reduces fatigue due to long timeoperations.Glove Box BehindSeatA convenient glovebox is locatedbehind the seat forstoring documents,etc.Quiet Cab InteriorQuiet interior design for operator comfort.Cab interior noise has been greatlysuppressed to achieve quiet travelingrubber-mounted hydraulics, a tightly-sealedcan operator frame anda new low-noise engine.

Functional Beauty Safety and EnvironmentallyFriendlyAchieving a high-level of safety in the working environment with an array of advanced mechanisms.Functional Beautyto Reduce CostsCentralized Rear MaintenanceIn pursuit of functional beauty, models featuring this new design are not just beautiful,but also easy and reduced running costs.Full-Open Cover Easy Day-to-Day InspectionsHN Bush* Extends Lubrication IntervalsGreasetroughHN bushes boasting superior lubricationcharacteristics are used in the loaderjoints to extend the lubrication interval to250 hours.Note: For the lubrication interval from the start ofoperation to 50 hours, refer to the user manual.Improved Cab CleaningROPS* / FOPS** Cab (Optional)The ROPS / FOPS cab is provided toprotect the operator from injury in anaccident.* ROPS: Roll-Over Protective Structure: ISO3471** FOPS: Falling-Object Protective Structure: ISO3449Neutral Engine Start Mechanism toImprove SafetyUnless the forward and reverse lever isin neutral, this safety feature inhibits theengine from being started.Lever LockKey Lock to Prevent VandalismThis key lock prevents damage causedby vandalism to the fuel inlet cap andengine cover.Reduced Environmental ImpactSubstancesAluminum RadiatorLead-Free WiringDaily maintenance is even easier with the incorporation of a large full-open cover andlowest counterweight. The cover opens at a touch, and is supported by tow gasdampers. The engine room, which can be fully open, enables maintenance such asinspections, replacements and filling to be carried out with ease.Replacement Friendly Filter LayoutCompact Electrics LayoutElectrical device relays are locatedtogether for easy maintenance.Easy Remote LubricationThe area around the door has beenredesigned to produce a flat, even floorinside the cab. This allows for easy ofcleaning.This safety mechanism locks the frontcontrol lever. Lever locks can be fittedoptionally to third function levers.The layout enables easy replacementof the fuel and hydraulic systemfilters. These fuel filters are integratedcombining water separator functions.The filters, including the engine oiland operating oil tank return filters,are cartridge type filters for easyreplacement.Lubricator(Grease nipple)Remote tubeSuspensionBecause the rear suspension can belubricated remotely, there is no need tocrawl under the machine to performthis task.

SPECIFICATIONSENGINESTEERING SYSTEMZW30 ZW40 ZW50Model KUBOTA D1803-M-DI KUBOTA V2403-M-DI KUBOTA V2403-M-DIType4-cycle water-cooled,direct injectionNo. of cylinders 3 4 4MaximumpowerBore and strokeISO 9249, netEEC 80/1269,without Fan netSAE J1349, net22.2 kW (30 HP)at 2 200 min-1 (2 200 rpm)22.5 kW (30 HP)at 2 200 min-1 (2 200 rpm)22.2 kW (30 HP)at 2 200 min-1 (2 200 rpm)30.4 kW (41 HP)at 2 200 min-1 (2 200 rpm)30.7 kW (41 HP)at 2 200 min-1 (2 200 rpm)30.4 kW (41HP)at 2 200 min-1 (2 200 rpm)87 mm x 102.4 mm30.4 kW (41 HP)at 2 200 min-1 (2 200 rpm)30.7 kW (41 HP)at 2 200 min-1 (2 200 rpm)30.4 kW (41HP)at 2 200 min-1 (2 200 rpm)Piston displacement 1.826 L 2.434 L 2.434 LBatteriesAir cleanerPOWER TRAIN12V×490 CCA, 123-min.rated reserve 12V×490 CCA, 123-min.rated reserve 12V×490 CCA, 123-min.rated reserveDouble stage dry type with restrictuin indicatorTypeSteering mechanismZW30 ZW40 ZW50Articulated frame steeringFull hydraulic power steering with orbitrolSteering angle Each direction 41°; total 82° Each direction 41°; total 82° Each direction 41°; total 82°Relief pressure 17.2 MPa (175 kgf/cm 2 ) 17.2 MPa (175 kgf/cm 2 ) 17.2 MPa (175 kgf/cm 2 )CylindersDouble-acting piston typeNo. x Bore x Stroke 1 × 55 mm × 228 mm 1 × 60 mm × 228 mm 1 × 60 mm × 228 mmMinimum turning radius at thecenterline of outside tireHYDRAULIC SYSTEMArm and bucket are controlledby mechanical single controllever arm controls3 010 mm 3 125 mm 3 125 mmZW30 ZW40 ZW50Four position valve; Raise, hold, lower, floatTransmissioncontrolsTravel speed :Forward & ReverseZW30 ZW40 ZW50Hydrostatic (HST) transmission automatically controls power and speed with electrically controlled15 km/hWith 12.5/70-16-6PR (L2) tires15 km/hWith 15.5/60-18-8PR (L2) tires15 km/hWith 15.5/60-18-8PR (L2) tiresBucket controls with automaticbucket return-to-dig controlThree position valve; Roll back, hold, dumpMain pump (Load & steer) Gear type 34.9 L/min Gear type 39.5 L/min Gear type 48.3 L/min2 200 min -1 (rpm) at 20.6 MPa(210 kgf/cm 2 )2 200 min -1 (rpm) at 20.6 MPa(210 kgf/cm 2 )2 200 min -1 (rpm) at 20.6 MPa(210 kgf/cm 2 )AXLE AND FINAL DRIVEZW30 ZW40 ZW50Drive systemFour-wheel drive systemFront & rear axleSemi-floatingFrontfixed to the front frameRearCenter pivotOscillation angle total 16° (±8°) total 16° (±8°) total 16° (±8°)Final drivesHeavy-duty, planetary final driveTIRES (tubeless, nylon body)ZW30 ZW40 ZW50Standard 12.5/70-16-6PR(L2) 15.5/60-18-8PR(L2) 15.5/60-18-8PR(L2)BRAKESZW30 ZW40 ZW50Service brakesInboard mounted fully hydraulic wet diskParking brakeSpring applied hydraulic released wet diskRelief pressure setting 20.6 MPa (210 kgf/cm 2 ) 20.6 MPa (210 kgf/cm 2 ) 20.6 MPa (210 kgf/cm 2 )HydrauliccylindersFiltersHydrauliccycle timesTypeNo. x Borex StrokeTwo arm and one bucket,double acting typeArm: 2 × 65 mm × 450 mmBucket : 1 × 65 mm × 364 mmTwo arm and one bucket,double acting typeArm : 2 × 65 mm × 539 mmBucket: 1 × 70mm × 431 mmFull-flow 10 micron return filter in reservoirTwo arm and one bucket,double acting typeArm: 2 × 70 mm × 531 mmBucket: 1 × 70 mm × 450 mmArm raise 5.0 s 5.0 s 5.0 sArm lower 3.0 s 3.0 s 3.0 sBucket dump 1.0 s 1.0 s 1.0 sSERVICE REFILL CAPACITIESZW30 ZW40 ZW50Fuel tank 45 L 45 L 45 LEngine coolant 4.5 L 6.5 L 6.5 LEngine oil 5.6 L 7.6 L 7.6 LFront axle differential & wheel hubs 4.5 L 4.5 L 4.5 LRear axle differential & wheel hubs 4.5 L 4.5 L 4.5 LHydraulic reservoir tank 38 L 38 L 38 L10 11

STANDARD & OPTIONAL EQUIPMENTNote: ○ Standard equipment ● Optional equipment Note: ○ Standard equipment ● Optional equipmentZW30 ZW40 ZW50ZW30 ZW40 ZW50 ZW30 ZW40 ZW50 ZW30 ZW40 ZW50ENGINEELECTRICALBUCKETS AND ATTACHMENTSBUCKETS AND ATTACHMENTSCoolant recovery tank ○ ○ ○Environmentally friendly engine oil drain ○ ○ ○Quick-release fuel filter and water separator ○ ○ ○Glow system (for cold start) ○ ○ ○Double-element air cleaner ○ ○ ○Clog prevention net and fan ● ● ●POWER TRAINHydrostatic (HST) transmission, electronicshift control, hydrostatic oil cooler,inching pedal, and forward and reverseHYDRAULIC SYSTEM○ ○ ○Automatic bucket return-to-dig control ○ ○ ○Operator warning lights: Brake oil /Engine oil pressure / Alternator voltage(charge)○ ○ ○Indicator lights: Turn signals / forward /Reverse ○ ○ ○Parking brake (negative) ○ ○ ○12-volt AM/FM radio (for cab model only) ● ● ●OPERATOR’S STATIONCanopyFRP roof ○ ○ ○ROPS ※ / FOPS ※※ ● ● ●CabSteel cab (with ROPS / FOPS) ● ● ●Full line of <strong>Hitachi</strong> pin on buckets with selection of bolt-on cuttingedgesWide (daily &livestock) bucket withbolt on cutting edges0.65 m 3 (ISO heaped) ●0.8 m 3 (ISO heaped) ●Quick-coupler and mechanical controlsystem for quick-coupler locking pins, lines,and valves.0.9 m 3 (ISO heaped) ●● ● ●Full line of <strong>Hitachi</strong> buckets for quick coupler with selection of bolt-oncutting edgesGeneral purposebucket with bolt oncutting edges0.4 m 3 (ISO heaped) ●0.5 m 3 (ISO heaped) ●0.6 m 3 (ISO heaped) ●Manure forkRoll grabMax load 500 kg(for quick coupler)Max load 550 kg(for quick coupler)Max load 550 kg(for quick coupler)Max load 550 kg(for quick coupler)Max load 700 kg(for quick coupler)Max load 800 kg(for quick coupler)●●●●●●Hydraulic filters, vertical mounting ○ ○ ○Two-function hydraulic valve with joystickcontrol (mechanical controlled)Three-function hydraulic valve with joystickcontrol and auxiliary lever for third function(mechanical controlled)ELECTRICAL○ ○ ○● ● ●Heater / Defroster (Cab model only) ● ● ●Seat belt, 50mm ● ● ●Seat, vinyl covered, mechanical suspension,adjustable for weight-height, fore-aft position,backrest tiltSeat, vinyl covered, adjustable for fore-aftposition, backrest tilt● ● ●○ ○ ○Light materialhandling bucket withbolt on cutting edgesWide (daily &livestock) bucket withbolt on cutting edges0.5 m 3 (ISO heaped) ●0.6 m 3 (ISO heaped) ●0.7 m 3 (ISO heaped) ●0.65 m 3 (ISO heaped) ●0.8 m 3 (ISO heaped) ●0.9 m 3 (ISO heaped) ●TIRES12.5/70-16-6PR (L2) ○Bias ply15.5/60-18-8PR (L2)○15.5/60-18-8PR (L2)○Tire chain (H type) ● ● ●Spare tire with rim ● ● ●12-volt electrical system ○ ○ ○Rubber floormat ○ ○ ○Full line of construction utilityforks, pallet forks, and attachments ※※※Spare rim ● ● ●Standard batteries (1), 12 volt with 490 CCA,123-min. rated reserve○ ○ ○Steering wheel, textured with spinner knob ○ ○ ○Rear view mirrors, outside (2) ○ ○ ○Max load 700 kg(pin on type)●Solid tires with rims per machine ● ● ●Spare solid tire with rim ● ● ●Alternator, 60 amps and 12 volts ○ ○ ○LightsDriving with guards / Turn signals/ Stop, tail and buck-up lights /(Conform to SAE 99)○ ○ ○Handholds, steps, and slip resistant ○ ○ ○<strong>LOADER</strong> LINKAGEZ-bar loader linkage provides "high bucketbreakout"○ ○ ○Lumber and pallet forkMax load 860 kg(pin on type)Max load 980 kg(pin on type)●●Standard tires and galvanized rims permachine● ● ●Spare standard tire and galvanized rim ● ● ●Spare galvanized rim ● ● ●Work lights on cab, front (2) (Cab model only) ● ● ●Work lights, rear (2) (Cab model only) ● ● ●Horn, with push button in center of steeringwheel (Conforms to SAE J994, J1446)○ ○ ○Buckup alarm ○ ○ ○Monitor and warning system, multi-functionelectronic analog instruments: Engine coolanttem-perature / Fuel level / Hour-meter○ ○ ○BUCKETS AND ATTACHMENTSFull line of <strong>Hitachi</strong> pin on buckets with selection of bolt-on cutting edgesGeneral purposebucket with bolt oncutting edgesLight materialhandling bucket withbolt on cutting edges0.4 m 3 (ISO heaped) ○0.5 m 3 (ISO heaped) ○0.6 m 3 (ISO heaped) ○0.5 m 3 (ISO heaped) ●0.6 m 3 (ISO heaped) ●0.7 m 3 (ISO heaped) ●Lumber and pallet forkMax load 650 kg(for quick coupler)Max load 810 kg(for quick coupler)Max load 920 kg(for quick coupler)●●●OTHERSVandal protection, includes lockable engineenclosure, and fuel fill○ ○ ○Counter weight, built-in ○ ○ ○Power steering ○ ○ ○Lifting lig (4-point support) ○ ○ ○※ : ROPS (Roll Over Protective Structure) Conforms to ISO 3471;1994.※※ : FOPS (Falling Objects Protective Structure) Conforms to ISO 3449;1992 Level ll.※※※ : Contact your <strong>Hitachi</strong> dealer for further information.12 13

NNDIMENSIONS & SPECIFICATIONSZW30ZW4045°45°41°41°ILILG F CJKBG F CJKB41°H'HMADE41°H'HMADEStandard boomStandard boom with quick-couplerStandard boomStandard boom with quick-couplerBucket typeGeneralpurposeLight materialhandlingWide (dairy &livestock)GeneralpurposeLight materialhandlingWide (dairy &livestock)Bucket typeGeneralpurposeLight materialhandlingWide (dairy &livestock)GeneralpurposeLight materialhandlingWide (dairy &livestock)bolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesBucket capacity ISO heaped m 3 0.4 0.5 0.65 0.4 0.5 0.65ISO struck m 3 0.38 0.42 0.58 0.38 0.42 0.58A Overall length mm 4 140 4 270 4 410 4 275 4 405 4 545B Overall height, bucket on ground (with FRP canopy) mm 2 415Overall height, bucket on ground (with Rops cab) mm 2 480C Width over tires mm 1 505D Wheel base mm 1 780E Ground clearance mm 255F Tread mm 1 180G Bucket width mm 1 570 1 570 1 690 1 570 1 570 1 690H Turning radius (centerline of outside tire) 3 010H' Loader clearance circle, bucket in carry position mm 3 550 3 610 3 700 3 635 3 650 3 740I Overall operating height mm 3 420 3 435 3 515 3 420 3 525 3 610J Height to hinge pin, fully raised mm 2 685K Dump clearance 45 degree, full height mm 2 155 2 065 1 965 2 060 1 965 1 865L Reach, 45 degree dump, full height mm 775 865 965 870 960 1 060M Digging depth (horizontal digging angle) mm 40N Max. roll back at carry position deg 53Static tipping load * straight kgf 1 700 1 650 1 580 1 555 1 505 1 420Full 41 degree turn kgf 1 400 1 360 1 300 1 280 1 240 1 170Breakout force kN 29.3 23.3 19.1 22.8 18.5 15.4(kgf) (2 990) (2 380) (1 950) (2 330) (1 890) (1 570)Operating weight * kg 2 785 2 800 2 835 2 870 2 890 2 900Notes: 1. All dimensions, weight and performance data based on ISO 6746-1:1987, ISO 7131:1997 and ISO 7546:19832. Static tipping load and operating weight marked with * include 12.5/70-16-6PR (L2) tires (no ballast) with lubricants, coolant, full fuel tank andoperator.Machine stability and operating weight depend on counterweight, tire size and other attachments.bolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesbolt-oncutting edgesBucket capacity ISO heaped m 3 0.5 0.6 0.8 0.5 0.6 0.8ISO struck m 3 0.42 0.52 0.65 0.42 0.52 0.65A Overall length mm 4 435 4 515 4 635 4 570 4 650 4 770B Overall height, bucket on ground (with FRP canopy) mm 2 495Overall height, bucket on ground (with Rops cab) mm 2 560C Width over tires mm 1 660D Wheel base mm 1 850E Ground clearance mm 295F Tread mm 1 260G Bucket width mm 1 690 1 690 1 890 1 690 1 690 1 890H Turning radius (centerline of outside tire) 3 125H' Loader clearance circle, bucket in carry position mm 3 740 3 765 3 885 3 780 3 800 3 920I Overall operating height mm 3 795 3 865 3 895 3 885 3 955 3 990J Height to hinge pin, fully raised mm 3 030K Dump clearance 45 degree, full height mm 2 445 2 390 2 305 2 350 2 295 2 210L Reach, 45 degree dump, full height mm 800 855 940 895 955 1 035M Digging depth (horizontal digging angle) mm 50 51 52 50 51 52N Max. roll back at carry position deg 54Static tipping load * straight kgf 2 100 2 050 1 955 1 905 1 855 1 710Full 41 degree turn kgf 1 720 1 680 1 600 1 560 1 520 1 440Breakout force kN 35.8 31.6 26.9 28 25 21(kgf) (3 650) (3 220) (2 750) (2 850) (2 550) (2 150)Operating weight * kg 3 295 3 310 3 335 3 375 3 390 3 425Notes: 1. All dimensions, weight and performance data based on ISO 6746-1:1987, ISO 7131:1997 and ISO 7546:19832. Static tipping load and operating weight marked with * include 15.5/60-18-8PR (L2) tires (no ballast) with lubricants, coolant, full fuel tank andoperator.Machine stability and operating weight depend on counterweight, tire size and other attachments.14 15

SPECIFICATIONSA high-performance, compact wheel loader that is gentle to the environment while operating in urban areasand conducting night work.ZW20ENGINEModelKUBOTA D1105-K3ASTEERING SYSTEMTypeArticulated frame steeringType4-cycle water-cooled,direct injectionSteering mechanismFull hydraulic power steering with orbitrolNo. of cylinders 3Steering angle Each direction 42°; total 84°MaximumpowerBore and strokePiston displacementISO 9249, netSAE J1349, net15.8 kW (21 HP)at 2 500 min -1 (2 500 rpm)15.8 kW (21 HP)at 2 500 min -1 (2 500 rpm)78 mm × 78.4 mm1.123 LRelief pressureCylindersNo. x Bore x StrokeMinimum turning radius at thecenterline of outside tire17.2 MPa (175 kgf/cm 2 , 2 490 psi)Double-acting piston type1 × 50 mm × 233 mm2.545 mBatteriesAir cleanerPOWER TRAINTransmissioncontrolsTravel speed : Forward & Reverse12V×490 CCA, 123-min.rated reserveSingle stage dry type with restrictionindicatorHydrostatic (HST) transmissionautomatically controls power andspeed with electrically controlled15Km/h With 10-16.5-4PR (L2) tiresHYDRAULIC SYSTEMArm and bucket are controlledby mechanical single controllever arm controlsBucket controls with automaticbucket return-to-dig controlFour position valve; Raise, hold,lower, floatThree position valve; Roll back,hold, dumpMain pump (Load & steer) Gear type 25 L/min2 500 min -1 (rpm) at 20.6 MPa(210 kgf/cm 2 )AXLE AND FINAL DRIVEDrive systemFront & rear axleFrontRearFour-wheel drive systemSemi-floatingfixed to the front frameCenter pivotOscillation angle total 16° (±8°)Final drivesHeavy-duty, planetary final driveRelief pressure setting 20.6 MPa (210 kgf/cm 2 )HydrauliccylindersFiltersHydrauliccycle timesTypeNo. x Borex StrokeArm raiseArm lowerTwo arm and one bucket,double acting typeArm: 2 × 55 mm × 385 mmBucket: 1 × 60 mm × 262 mmFull-flow 10 micron return filter inreservoir4.6 s3.2 sHST Auto TransmissionContinuously adjustable speed can beachieved by operating the axle pedalenabling start, acceleration, andstopping to be performed automatically.Driving is made easy with smoothautomatically speed changesDifficult operations possible usingextremely slow speedsExcellent mechanical operations withhighly responsive accelerationSmooth startup on inclines using HSTbrake operationsExcellent rim pulling effects manifestedat all speedsA Single-Speed Locking Mechanism toImprove PerformanceThis switches the operation mode for thetravel speed between work mode anddrive mode.LOW : When the switch is set to LOW,the speed is fixed and workmode is selected.AUTO : When the switch is set toAUTO, work mode is releasedand the vehicle enters drive(automatic variable speed) mode.High-Output Engine15.8 kW(21 HP)Top-Class Traction Force17.2 kW(1 750 kgf)Improved Starting PerformanceWhen the outside air temperature islow and starting the engine is difficult,starting performance can be improvedby turning the key switch to the HEAT(preheat) ON position.OtherEnclosed wet-disc brakeElectric parking brakeFull safety featuresEasy maintenanceEquipped with HN bushLarge fuel tank (33 L capacity)Cab Specifications (Optional)Wide panorama cab(without ROPS / FOPS)Wider foot space and lever operationarea with stylishly-spacious design,improved operability and interiorcomfortTIRES (tubeless, nylon body)StandardBRAKESService brakesParking brake10-16.5-4PR (L2)Inboard mounted fully hydraulicwet diskSpring applied hydraulic releasedwet diskBUCKET SELECTION GUIDEZW20Standard lift armStanderd lift arm withquick-couplerGeneralpurposeLight materialhandlingWide (dairy &livestock)GeneralpurposeLight materialhandlingWide (dairy &livestock)With bolt-oncutting edgesWith bolt-oncutting edgesWith bolt-oncutting edgesWith bolt-oncutting edgesWith bolt-oncutting edgesWith bolt-oncutting edgesBucket dumpSERVICE REFILL CAPACITIESFuel tankEngine coolantEngine oilFront axle differential & wheel hubsRear axle differential & wheel hubsHydraulic reservoir tank1.0 s33 L5.5 L3.6 L3.5 L3.5 LBucketMaterial density kg/m 3Capacity m 3 0.8 1.0 1.2 1.4 1.6 1.80.30.40.50.30.40.523 L110% 100% 95%%=Bucket Fill Factor18 19

STANDARD & OPTIONAL EQUIPMENTDIMENSIONS & SPECIFICATIONSZW20ZW20Note: ○ Standard equipment● Optional equipmentENGINEOPERATOR’S STATIONCoolant recovery tank○Rubber floormat○Environmentally friendly engine oil drain○Steering wheel, textured with spinner knob○Quick-release fuel filter and water separator○Rear view mirrors, outside (2)○Glow system (for cold start)Single-element air cleanerClog prevention net and fanPOWER TRAINHydrostatic (HST) transmission, electronic shift control,hydrostatic oil cooler, inching pedal, and two speedsforward and reverseHYDRAULIC SYSTEMAutomatic bucket return-to-dig controlHydraulic filters, vertical mountingTwo-function hydraulic valve with joystick control(mechanical controlled)Three-function hydraulic valve with joystick control andauxiliary lever for third function (mechanical controlled)ELECTRICAL12-volt electrical systemStandard batteries (1), 12 volt with 490 CCA,123-min. rated reserveAlternator, 40 amps and 12 voltsLightsDriving with guards / Turn signals / Stop, tail and buck-uplights / (Conform to SAE 99)Work lights on cab, front (2) (Cab model only)Work lights, rear (1) or (2) (Cab model only)Horn, with push button in center of steering wheel(Conforms to SAE J994, J1446)Buckup alarmMonitor and alarm system, multi-function electronicanalog instruments: Engine coolant tem-perature /Fuel level / Hour-meterOperator warning lights: Brake oil / Engine oil pressure /Alternator voltage (charge)Indicator lights: Turn signals / forward /ReverseParking brake (negative)12-volt AM/FM radio (for cab model only)OPERATOR’S STATIONCanopyCabFRP roofROPS ※ / FOPS ※※Steel cab (without ROPS / FOPS)Heater / Defroster (Cab model only)Seat belt, 50mmSeat, vinyl covered, mechanical suspension, adjustablefor weight-height, fore-aft position, backrest tiltSeat, vinyl covered, adjustable for fore-aft position,backrest tilt○○●○○○○●○○○○●●○○○○○○●○●●●●●○Handholds, steps, and slip resistant<strong>LOADER</strong> LINKAGEZ-bar loader linkage provides "high bucket breakout"BUCKETS AND ATTACHMENTSFull line of <strong>Hitachi</strong> pin on buckets with selection of bolt-on cutting edgesGeneral purpose bucket with bolt on cuttingedges : 0.3 m 3 (ISO heaped)Light material handling bucket with bolt on cuttingedges: 0.4 m 3 (ISO heaped)Wide (daily & livestock) bucket with bolt oncutting edges : 0.5 m 3 (ISO heaped)Quick-coupler and mechanical control system forquick-coupler locking pins, lines, and valvesFull line of <strong>Hitachi</strong> buckets for quick coupler with selection of bolt-oncutting edgesGeneral purpose bucket with bolt on cuttingedges : 0.3 m 3 (ISO heaped)Light material handling bucket with bolt on cuttingedges : 0.4 m 3 (ISO heaped)Wide (daily & livestock) bucket with bolt on cuttingedges : 0.5 m 3 (ISO heaped)Full line of construction utilityforks, pallet forks, and attachments ※※※Lumber and pallet fork : Max load 500 kg (pin on type)Lumber and pallet fork : Max load 450 kg(for quick coupler)Manure fork : Max load 450 kg (for quick coupler)Roll grab : Max load 400 kg (for quick coupler)TIRESBias ply : 10-16.5-4PR (L2)Tire chain (H type)Spare tire with rimSpare rimSolid tires with rims per machineSpare solid tire with rimStandard tires and galvanized rims per machineSpare standard tire and galvanized rimSpare galvanized rimOTHERSVandal protection, includes lockable engine enclosure,and fuel fillCounter weight, built-inPower steeringLifting lig (4-point support)※ : ROPS (Roll Over Protective Structure) Conforms to ISO 3471;1994.※※ : FOPS (Falling Objects Protective Structure) Conforms to ISO 3449;1992 Level ll.※※※: Contact your <strong>Hitachi</strong> dealer for further information.○○○●●●●●●●●●●○●●●●●●●●○○○○G42°42°Bucket typeH'HGeneralpurposebolt-oncutting edgesStandard boomLight materialhandlingbolt-oncutting edgesWide (dairy &livestock)bolt-oncutting edgesStandard boom with quick-couplerGeneralpurposebolt-oncutting edgesLight materialhandlingbolt-oncutting edgesWide (dairy &livestock)bolt-oncutting edgesBucket capacity ISO heaped m 3 0.3 0.4 0.5 0.3 0.4 0.5ISO struck m 3 0.24 0.35 0.43 0.24 0.35 0.43A Overall length mm 3 440 3 555 3 695 3 555 3 675 3 815B Overall height, bucket on ground (with FRP canopy) mm 2 350Overall height, bucket on ground (with Rops cab) mm 2 395C Width over tires mm 1 335D Wheel base mm 1 500E Ground clearance mm 215F Tread mm 1 065G Bucket width mm 1 350 1 405 1 570 1 350 1 450 1 570H Turning radius (centerline of outside tire) 2 545H' Loader clearance circle, bucket in carry position mm 2 970 3 025 3 140 3 000 3 060 3 175I Overall operating height mm 3 005 3 085 3 030 3 085 3 170 3 115J Height to hinge pin, fully raised mm 2 335K Dump clearance 45 degree, full height mm 1 850 1 765 1 665 1 765 1 680 1 580L Reach, 45 degree dump, full height mm 570 650 755 650 740 840M Digging depth (horizontal digging angle) mm 55N Max. roll back at carry position deg 51F CStatic tipping load * straight kgf 1 350 1 290 1 250 1 240 1 180 1 150Full 42 degree turn kgf 1 100 1 050 1 020 1 000 950 930Breakout force kN 21 16 13 16 13 10(kgf) (2 100) (1 650) (1 300) (1 600) (1 300) (1 050)Operating weight * kg 1 945 1 935 1 960 1 965 1 985 2005Notes: 1. All dimensions, weight and performance data based on ISO 6746-1:1987, ISO 7131:1997 and ISO 7546:19832. Static tipping load and operating weight marked with * include 10-16.5-4PR (L2) tires (no ballast) with lubricants, coolant, full fuel tank andoperator.Machine stability and operating weight depend on counterweight, tire size and other attachments.IJKNML45°AEDB20 21

MEMOMEMO22 23

ZW seriesThese specifications are subject to change without notice.Illustrations and photos show the standard models, and may or may not include optional equipment,accessories, and all standard equipment with some differences in color and features.Before use, read and understand the Operator’s Manual for proper operation.<strong>Hitachi</strong> <strong>Construction</strong> <strong>Machinery</strong> Co., Ltd.www.hitachi-c-m.comKL-EN01808.09 (CD/NB,GT3)