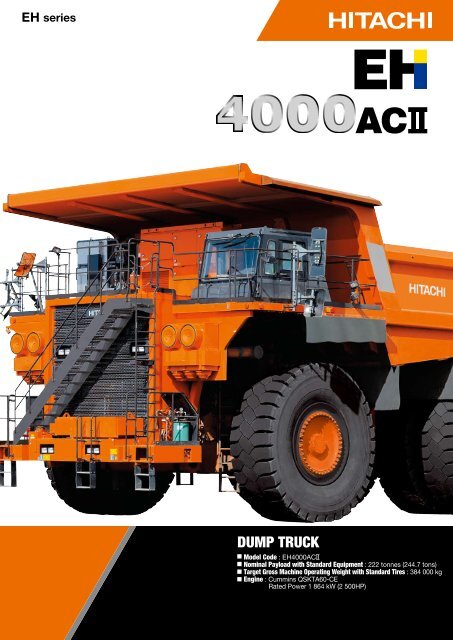

EH4000ACII - Hitachi Construction Machinery

EH4000ACII - Hitachi Construction Machinery

EH4000ACII - Hitachi Construction Machinery

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AC Drive Advantage<strong>Hitachi</strong> AC drive technology providessuperior truck performance with highertop speeds, better gradeability andstronger retardation.<strong>Hitachi</strong> inverter modules provide highrigid truck controlability and efficiency.The <strong>Hitachi</strong> AC wheel motors do nothave commutators and brushes,which improves truck performance byproviding reduced maintenance costs,higher truck availability and highertravel speeds. These advantages resultin more productivity and lower costsper tonne.<strong>Hitachi</strong> AC drive systems also powerelectric train locomotives world wide.Water Cooling PumpAC Control CabinetGrid MotorRetarding Grid BoxAlternator BlowerWheel Motor BlowerAlternatorAC Wheel MotorFull Retarding CapabilityThe AC Drive Wheel MotorsAC Drive ControlRimpullRimpullDrivingAC DriveDrivingRetardingSpeedRetardingBrake Blending, which combinesservice braking with electric retarding,is applied automatically through the ACdrive control system to stop the haulerwhen travel speed is below 0.5 km/hr.Therefore, with the exception ofemergencies, the driver can stop thetruck using the retarder pedal only,resulting in easy machine operationand longer time between brake serviceintervals.Auto Cruise Control keeps vehiclespeed constant within the set range bylimiting the minimum vehicle speed.DC DriveSpeed<strong>Hitachi</strong> AC drive systems provide morerimpull than comparable DC systems.Full retarding capability means the truckcan be fully stopped without applyingthe service brake pedal.The <strong>Hitachi</strong> Dual Path Epicyclic Planetarydesign provides high efficiency and easymaintenance.Allowing the 1st (outer) planetary carrierto travel at wheel speed provides loweroperating temperatures.Better component and lubricant life is theresult of an inverter controlled lubricantcirculation system that includes lubricantcooling and filtration.Auto Retarding Control keeps vehicledownhill speed constant within the setrange by limiting the maximum vehiclespeed.

Ease of OperationSuperior SuspensionThe <strong>Hitachi</strong> trailing arm suspensionsystem delivers excellentmaneuverability, even at higher speeds.The trailing arm layout offers greaterease of servicing while improving truckperformance compared to suspendedking-pin designs. The pivot mountingof the trailing arm design allows onlyaxial input to the strut and allows wheelmovement to the vertical plane only.Features:• Lateral forces that act on the frontwheels are minimized, resulting inreduced tire scuffing.• Dynamic friction (side-wall force)within the strut is low due tothe features of the trailing armsuspension design, allowing theuse of a lighter strut engineered to asmaller diameter and longer stroke.• The necessary frame bulk (horsecollarstructure) needed to mount asuspended king-pin is non-existent.• The elimination of the “horse-collar”member provides greater engineaccess.• The NEOCON strut used with thetrailing arm suspension, improvesoperator and component isolation,provides better hauler stability andpredictable operational control.• Locating the king-pin close to thewheel assembly and at a slight angleresults in low “Dry Park Steering”effort.• Development of the compressiblemedia, NEOCON- E TM fluid(proprietary, silicone based,environmentally friendly) for use inthe suspension strut with Heliumgas, results in an improved energyabsorption (isolation) systemand an improved energy release(stability) system that respondsfavorably whether traveling empty orloaded in a wide range of ambienttemperatures.The trailing arm suspension designallows the front struts to be removedand installed without removing thefront brakes or tires. This means fewertools and less labor time are required,resulting in less downtime and higherproductivity.THE FAST FILLING SYSTEM12453Trailing Arm Suspension (Front)1. Hydraulic oil2. Coolant 13. Coolant 24. Grease5. Engine oilBoth Struts at normal heightThe fast filling system, providedstandard on the left side of the radiator,allows direct access at ground levelfor fast feeding of coolant, grease,hydraulic oil and engine oil.(Couplers are optional.)NEOCON Strut (Front/Rear)Both struts in compressionHelium gasNEOCON-E TM fluidHI-TECH ROPS/FOPS CabThe new HI-TECH ROPS/FOPS cab has been newly equippedwith a <strong>Hitachi</strong> controller and a large centrally mounted, colorLiquid Crystal Display (LCD) as used in <strong>Hitachi</strong> large sizedexcavators. Double wall construction of 11 gauge inner and outersteel panels produces a more structurally sound cab. A threepointrubber isolation-mount arrangement minimizes vibration tothe operator compartment.Drivers Side Strut in compression,other strut in extensionWith no horizontal deflectionImpactSpindleEach controlled by a hydraulic steering cylinder, rotates around the king-pin and the outer end of the trailingarm to position the wheels for steering. The spindles are attached by one simple tie-rod.Trailing ArmMain suspension member to which other suspension components are attached. The trailing arms hinge ona cross tube that is clamped to the front of the frame.Neocon StrutThe energy absorption and release component of the trailing arm suspension system. Pinned to ballbushings at the frame and at the top of each trailing arm to prevent bending movements from transferring tothe strut. Receives only axial input.

SPECIFICATIONSEQUIPMENTFRAMEFull fabricated box section main rails with section height tapered fromrear to front. Narrow at the rear to support the load and wider at thefront allowing truck stability and excellent engine access for servicing.One piece top and bottom flanges that eliminate cross member tiein joints and provide a large exposed center area for access to majorcomponents. Large radii at frame junctions are blended and ground tominimize stress concentrations. Weld joints are oriented longitudinally tothe principal flow of stress for greater durability and more strength.The new "bolt-on" HighArch Design requiresless assembling timeand no welding. Thedesign provides higherstructural quality andbetter serviceabilityduring engineoverhaul.Bolt FastenedBODYAn extended canopy protectsthe service deck area. Hightensile strength 400 BHNabrasion and impact resistantalloy steel is used for the plateindicated below:Floor......................... 16 mmFront ........................ 9 mmSides ........................ 9 mmCanopy .................... 6 mmCorners .................... 12 mmHigh strength 690 N/mm 2 (100000 psi) alloy steel is also usedfor the canopy side membersand floor stiffeners. The body isrubber cushioned on the frame.Optional Body LinersFloor & Corners ........................................................................ 12 mmSides & Front ........................................................................... 6 mmCanopy .................................................................................... 6 mmSpecial plate thicknesses and partial plates are available.SERVICE CAPACITIESMain Accumulator ..................................................................Crankcase (includes filters) .....................................................Engine Cooling System ..........................................................Fuel Tank (Standard) ..............................................................Fuel Tank (Optional)................................................................Hydraulic System ...................................................................Brake cooling system .............................................................Planetary Drives (L&R) ............................................................Front Wheels (L&R).................................................................Windshield Washer ................................................................85 L260 L619 L2 680 L4 620 L750 L250 L300 L34 L20 LPERIMETER VISIBILITYThe addition of mirrors and cameras to the base model make the truck compliant to the perimeter viewing requirement of standards ISO 5006 and ISO 14401.STANDARD EQUIPMENTGENERALAC drive systemAuto cruise controlAuto retarding controlBrake blending controlControl cabinetpressurized/liquid cooled/lockableAutomatic lubrication system(Lincoln)Battery isolation switchBody prop pinsDeck mounted mufflerDeck mounted stone guardsDiagonal front stairwayElectric controlled hoist systemElectric horns (4)Engine access ladders (2)Engine shutdown switchBeside engine (2)Ground level, on bumper (1)Inside rear axle (1)Fan and belt guardsFan clutchFast fluid filling systemFast fuel filling system provisionFinal drive lubricant coolingFinal drive lubricant filtrationFront view mirror, LHS/RHSCABAir conditionerAM-FM radioAuxiliary outlet, 12 voltCamera monitorEngine shutdown switchHeater and defrosterIntegral ROPS/FOPS cabLCD system monitorLoad and dump brake switchOverride switchFuel/Water separatorFuel tank, 2 680 LGround level battery boxGround level relay boxIGBT controlled blower fan motors (2)IGBT controlled final drive lubricantmotor (1)IGBT controlled grid fan motors (5)Load weighing systemNEOCON suspension strutsOperator arm guardRear view cameraRear view mirrors (4)Rims, available for 40.00R57 &46/90R57 tiresSide view camera (RHS)Suction port shut off valve athydraulic tankSupplementary front brakingsystem, accumulatorsSupplementary rear brakingsystem, accumulatorsSupplementary steering system,accumulatorsTow hooks, frontTow lugs, rearSeat with 2-point, 50 mm widthseat beltFull size operator's seat, airsuspension & 6 positionRegular size trainer's seat,mechanical & adjustableTinted safety glass, with roll-downwindows12 volt accessory connectionOPTIONAL EQUIPMENTAuxiliary dump connectionAuxiliary steer connectionBody liners (400BHN)Body prop cableBody sizes **Cold weather package **includes Kim Hot coolant and oilpan heaterContinuous heated bodyFast fluid filling system couplers **Fast fuel filling system coupler **Fuel tank, 4 620 LFuel tank inlet access ladderFull size operator's seat, airsuspension & 6 position, with3-point, 50 mm width seat beltFull size trainer's seat, airsuspension & 6 position, with2-point, 50 mm width seat beltGridbox guardHalogen front tire lights (2)Heated mirrorsHID headlights (8)Loadweight display (1) or (2)Sound attenuation package **Spare rimTire guardsTrolley assist configulation **** : Engineered on requestOPTIONAL EQUIPMENT WEIGHTBody liners (400BHN) plates including floor & corners (12 mmthicknesses), sides & front and canopy (6 mm thicknesses)....... 8 200 kg4620 L fuel tank with 100 % fuel (additional weight to thestandard tank with 100 % fuel) ............................................... 1 954 kgGridbox guard............................................................................... 128 kgLoadweight display (1)..................................................................... 75 kgTire guard (2)................................................................................. 248 kgFront view mirror (LHS)Mirror Camera MonitorFront view mirror (RHS)INDICATORS AND GAUGES SHOWN ON MONITOR DISPLAYBrake/steering hydraulic oil HCM codepressure gaugeMessageCentral warning indicatorSAE codeClockLight indicatorsCoolant temperature gauge Load meterDrive related warning indicator Shift lever position indicatorEngine oil pressure gaugeSpeedometer with odometerEngine related warning indicators Stop valve warning indicatorEngine stop warning indicator TachometerFuel gaugeTurn signal indicatorHour meterWheel motor temperature gaugeHydraulic related warningindicatorsSide view mirrors (LHS)CameraMACHINE LIGHTSBackup lights (2)Clearance lights (4)Combination stop and tail lights (2)Deck lights (2)Diagonal front stairway lightEngine compartment lights (2)Halogen headlights (8)Payload external indicators, 2locations of 2 lights eachRear axle compartment lightSide view mirror and camera (RHS)Camera monitorRear view camera10 11

DIMENSIONSUnit: mm9 0607 3601 6906 1302 35013 86050.5°6 0909904 7904 240 6 0603 9806 0507 29014 2809 5408 2708 1207 7608402 3404 9607 580NOTES:Dimensions shown are for an empty machine with 46/90R57 tires.These specifications are subject to change without notice.Illustrations and photos show standard models, and may or may not include optional equipment,accessories, and all standard equipment with some differences in color and features.Before use, please read and understand the Operator’s Manual for proper operation.<strong>Hitachi</strong> <strong>Construction</strong> <strong>Machinery</strong> Co.,Ltd.www.hitachi-c-m.comKR-EN030P10.12 (KA/KA, MT3)Printed in Japan