ltd â summer 2011/12 - CablePrice

ltd â summer 2011/12 - CablePrice

ltd â summer 2011/12 - CablePrice

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

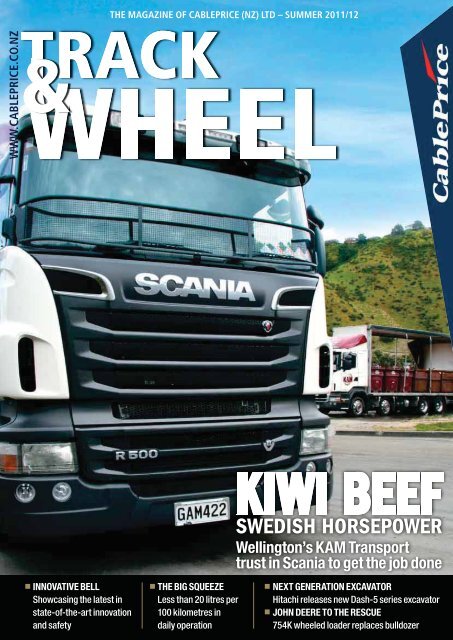

THE MAGAZINE OF CABLEPRICE (NZ) LTD – SUMMER <strong>2011</strong>/<strong>12</strong>WWW.CABLEPRICE.CO.NZKIWI BEEFSWEDISH HORSEPOWERWellington’s KAM Transporttrust in Scania to get the job doneINNOVATIVE BELLShowcasing the latest instate-of-the-art innovationand safetyTHE BIG SQUEEZELess than 20 litres per100 kilometres indaily operationNEXT GENERATION EXCAVATORHitachi releases new Dash-5 series excavatorJOHN DEERE TO THE RESCUE754K wheeled loader replaces bulldozer

Cover image: Wellington based KAMTransport Ltd has grown its business withthe assistance of 14 Scania trucks suppliedby Cable Price.Track & Wheel is designed and published on behalfof <strong>CablePrice</strong> (NZ) Ltd, and produced by theMarketing Department.DESIGN & PRINTINGTraderGroup (a division of ACP Media)Please direct any feedback or suggestions tomarketing@cableprice.co.nz; or mail:<strong>CablePrice</strong> Track&Wheel magazinePO Box 38040Wellington Mail CentreNew ZealandWhat’s a QR code?Throughout this magazine, you’ll find QR codes that look like this:The Track & Wheel staff would like to thank all of thecustomers who made this issue possible. This issuewas brought to you by the letter R and the number 3.<strong>CablePrice</strong> (NZ) Ltd41-51 Bell Road South, Gracefield,Lower Hutt, New Zealand.T (04) 568 4289F (04) 568 4283sales@cableprice.co.nzTo receive your free copy of Track & Wheel , visitwww.cableprice.co.nz and select “about us” then“track&wheel”.They’re there to offer you even more information about themachines or vehicles you’re reading about.How it works:1. Download a QR code reader to your smartphone2. Launch the QR code reader application on your phone3. Scan or snap this QR code to view the websiteCopyright: <strong>CablePrice</strong> (NZ) Ltd <strong>2011</strong>/<strong>12</strong>, all rights reserved. Reproduction in whole or in partis forbidden except with the written permission of the publisher. The opinions and thoughtsexpressed in this publication, whether factual or otherwise, are those of the individual writerresponsibility for inaccuracies or omissions.

CONTENTSNEWSNew Scania dealer locator iPhone application…….......................................... 5<strong>CablePrice</strong> moves to new multi-million dollar facility in Wellington………..…6Recently appointed staff members… .......................................................…….7Hitachi’s Top Technician… ............................................................................….7<strong>CablePrice</strong> donates to Canterbury earthquake relief fund… ..................……..8Introducing Bell Articulated Dump Trucks… ................................................….9Long-service recognition awards ...................................................................... 9Training students using John Deere simulators .............................................. 10Staff on six-month foreign exchange……… ...............................................….11COMMERCIAL VEHICLE FOCUSA lot of steak at stake for KAM Transport……… ............................................ .<strong>12</strong>It’s time to deliver for Key Carriers’ new Isuzus............................................... 23The big fuel squeeze……… ........................................................................….24NEW HITACHI DASH-5Hitachi Dash-5… .....................................................................................…….17EXCAVATOR FOCUSFirst new Hitachi EX2500-6 delivered in New Zealand…… ...................…….26The right tools for the job in Christchurch…… ....................................……..30OFF-ROAD DUMP TRUCK FOCUSJohn Deere to the rescue in the Hutt Valley .................................................... 20Bell’s reputation rings true .............................................................................. 36AFTER HOURSColouring competition ................................................................................... 40Merchandise .................................................................................................... 42RECENT DELIVERIESTruck deliveries ............................................................................................... 44Equipment deliveries ...................................................................................... 48SPECIFICATIONSHitachi / Bell specifications ............................................................................. 55John Deere specifications ............................................................................... 60

TRACK & WHEELGM’S ADDRESSThis year has flown by, and at the time of publishing,I have enjoyed the challenge of being in the roleof general manager sales and marketing with suchan enterprising company for almost a year. <strong>2011</strong>has been a year of challenges and changes for<strong>CablePrice</strong> (NZ) Ltd, ranging from the devastatingearthquake in Christchurch to earthquakes and tsunamis in Japan,all having a major impact on the running of our company.Business confidence continues to be volatile globally: justwhen one newspaper is reporting that confidence is improving,another comes out reporting confidence has dipped. <strong>CablePrice</strong>has successfully moved on from this and we see a confidentorder book. Our customers are judging the reports themselves,just getting on with business.We are proud of the new Hitachi EX 2500-6 excavator thatis up and running at OceanaGold’s East Otago mine site. Manythanks to our experienced, specialised mining support staff fortheir involvement. Also, the new Bell Articulated Dump Trucks atthe Solid Energy New Vale mine are making their mark. The JohnDeere product is growing from strength to strength, showinggood sales across the board, particularly in forestry equipmentand wheel loaders. Scania V8 truck orders are positive after oursuccessful V8 road show that was complimented by recent salesin milk, forestry, line haul and distribution. All up, these salesfurther cement our confidence in our clients and upcomingproduct lines, such as our new Hitachi Dash-5 due to come online very soon. As such, <strong>CablePrice</strong> is placing customers firstwith reliability, lowest fuel consumption, lowest environmentalimpact combined with highest brand image in the market, all ofwhich is complimented with a wide range of service supportand service contracts.On the head office front, we have had a couple of senior staffchanges, and with those come renewed energy, new ideas, freshthinking and forward visionWe appreciate our customers for continuing to invest in<strong>CablePrice</strong>’s products, despite the turbulent economic times, andas a result, <strong>CablePrice</strong> has decided to further invest in the NewZealand economy. After 16 years at our current location, we havedecided to move head office and regional workshop operationsto a new purpose-built facility in Bell Road South, Lower Hutt,some 500 metres from our present site.As our customer base continues to grow, we needed a moremodern workshop, administration and warehouse building tofuture-proof our business so that we can continue to provide aprofessional service to our ever growing list of clients and fleets.To put it briefly, “we’ve simply outgrown our present location”.We look forward to serving all our customers in a refreshedapproach in 20<strong>12</strong>.I wish you all a very merry Christmas, and a happy and safenew year.Alfons ReitsmaGeneral Manager Sales and Marketing4 <strong>CablePrice</strong>

TRACK & WHEELCABLEPRICELONG-SERVICE RECOGNITION<strong>CablePrice</strong> takes pride in acknowledging those who haveachieved long-service milestones. The company’s long-servicescheme is designed to recognise those who have 10, 20, 30and 40 years of service, displaying loyalty, dedication and highlevels of performance.In <strong>2011</strong>, eight additional staff achieved milestones as part ofthe company’s scheme of recognising long service.Special recognition must also go to Peter Johnson fromAuckland, for achieving a milestone of 30 years of service. Peterhas been a dedicated employee at <strong>CablePrice</strong> since April 1981.<strong>CablePrice</strong> would like to thank all of its employees for theircommitment and loyalty, and looks forward to the growingpool of experience in the coming years.10-year long-service achievementTony ScharviCraig HamiltonPeter AitchesonStuart ThornleyAucklandAucklandChristchurchGreymouth20-year long-service achievementWayne HanrahanPeter DochertyTrish FretheyChristchurchChristchurchHead officeSCANIA DEALER LOCATORWith the Scania dealer locator app in your smartphone,you can easily find the Scania dealers and workshops that areclosest to your current location, anywhere in the world.Wherever you need Scania, the dealer locator app is thereto help. You can call Scania assistance or workshops directlyfrom the app, or find them on a map with route descriptions.You can also save your favorites for quick access and planyour stops in advance with a global list of Scania locations.Available both for iPhone and Android.<strong>CablePrice</strong> 5

TRACK & WHEEL - NEWSTHE MOVE IS ON<strong>CablePrice</strong>, New Zealand’s importer and distributor of Hitachiconstruction equipment, Scania trucks and buses, John Deereforestry equipment and Bell dump trucks, boosts its commitmentto the Wellington region in the form of a new multi-million dollarfacility in Bell South Road, Gracefield. This purpose-built buildingwill encompass the head office, Wellington branch, national partswarehouse and distribution centre, all on one site.Soon to enter its 60th year in business, <strong>CablePrice</strong> has alwayscalled Wellington “home”. In a time when many businesses areeither downsizing or relocating to other regions, <strong>CablePrice</strong> isproud to show its continued commitment to its customers andthe Wellington region.“We’ve outgrown Tunnel Grove. It’s served us well over thepast 16 years, but we now need a modern facility with moreroom, and a head office worthy of a company like <strong>CablePrice</strong>,one that does justice to the products we represent. We also needa branch workshop facility that aptly suits the customers whohave purchased our products, and we feel this move will deliverthese factors, and then some,” says Pat Ward, <strong>CablePrice</strong> generalmanager of finance and administration.The new facility will be built in three stages over the next 9 to<strong>12</strong> months: stage one, due for completion in early December, willbe the Wellington branch and workshops; stage two, the headoffice, is due to be completed by April next year; and the thirdand final stage, a national parts and distribution warehouse, is tobe completed before November 20<strong>12</strong>.“We look forward to providing our Wellington branch withstate-of-the-art workshop facilities. The new building will bebigger with more capacity for trucks: five full-length, 32-metrelong bays, plus two specialist construction and forestryequipment bays. In addition, we will be using the latest Skyliftsnot the old-fashioned, hole in the ground pit. Skylifts make iteasier for technicians to work on heavy gear, so that means nomore climbing up and down from the pit. Mobile lifting gear andtools etc can be wheeled straight under the equipment beingworked on. This will be a lot safer, cleaner and more user-friendly,”says Ward.Another way that <strong>CablePrice</strong> is investing in the future isthrough technical training. In this ever-changing world, thecompany says that “knowledge is power”. The trucks andmachinery sold by <strong>CablePrice</strong> are some of the most, if not themost, up to date and sophisticated in their class found anywherein the world, and to maintain them at peak performance requiresskilled technicians.“Part of this new head office facility will include a purposebuilttheory training room complete with its own fullyoperationalworkshop, where we will be training techniciansfrom all over New Zealand with the latest tools to a world classlevel,” says Ward.New location effective November 28, <strong>2011</strong>.41-51 Bell South Road, Gracefield, Lower Hutt.Phone, fax, email and website details all remain unchanged.6 <strong>CablePrice</strong>

NEWS - TRACK & WHEELHITACHI’S TOPTECHNICIANAfter his success in New Zealand’s local competition,Sam Rowan was selected to represent <strong>CablePrice</strong>, and NewZealand, in the fourth annual Hitachi Regional Top Techniciancompetition. Rowan, who works for the company’s North Shorebranch, travelled to Singapore in April to compete against fourother national champions from the Asia-Pacific region, includingAustralia, Malaysia, Thailand and Indonesia.The competition consisted of both theory and practicalelements. The theory examination was to be completed withoutthe assistance of manuals or other external resources. For thepractical component of the competition, each contestant had todiagnose and solve identical faults in a specially prepared Hitachiexcavator. The main fault, being hydraulic, had to be identified, aswell as two electrical faults, all within a pressured time frame ofone hour and fifteen minutes – no mean feat!Competing against highly-trained technicians from aroundthe region – a challenge in its own right – Rowan also had toendure temperatures in excess of 34 degrees while undertakingthe practical element of the competition. Working in scorchingheat and high humidity in full safety gear, Rowan displayed bothstamina and determination, representing <strong>CablePrice</strong> admirably.NEW PRODUCT MANAGER FORJOHN DEERE CONSTRUCTIONTo a lot of you, the name Riki Corley will be a familiar one,as he has worked at the head office of <strong>CablePrice</strong> for the pastfour years.Recently moving to a new role as equipment productmanager from the position of equipment product coordinator,Corley’s core responsibilities were the purchase ordering, salesadministration and logistical processes for new equipment.Corley’s new role will see him continue to develop JohnDeere’s smaller product ranges, while also taking responsibilityfor the management of the growing market for John Deereconstruction equipment, including wheel loaders, graders,dozers and the newly-introduced D-series skid steer loaders.“Corley brings anextensive workingknowledge of ourconstruction andforestry range to his newposition,” says <strong>CablePrice</strong>national equipment salesmanager, Andrew Crane.And with an ability tohit the ground runningwhile maintaining astrong focus on product,sales and post-salessupport, Corley will be areal asset to John Deere’scustomers and salesteam alike.Demonstrating impeccable skill, Rowan was the onlycompetitor to accurately identify and solve the three faults, aswell as reassemble the machine completely in the time framespecified. This, combined with the theory element of thecompetition, resulted in Rowan achieving the highest overallscore, winning him the title of “Top Technician” for the HitachiAsia-Pacific region.Following on from his win at the Asia-Pacific competition,Rowan will have the opportunity to really test his skills againstHitachi’s top technicians from around the globe at the worldfinals which are to be held in Japan later this year.Well done!NEW SCANIA SALES MANAGERFOR CABLEPRICE<strong>CablePrice</strong> has recentlyintroduced Garry Leitch to itstruck sales team. Coming on-boardas the national commercial vehiclesales manager, Leitch says thathe’s “dedicated to ensuring Scaniaremain a market leader in themedium and in the heavy-dutytruck range,” a position that Scaniaare well known for.Born in Scotland, Leitch is no stranger to the commercial vehicleand construction equipment industries. He started out within theautomotive industry with a main Ford (England) dealership, beforemoving to New Zealand in 1989 where he took up various roleswithin Mitsubishi Motors (New Zealand). From 1999, he filledvarious management roles within Titan Plant Services, with Volvotruck, bus, construction and forestry equipment.Leitch will compliment an already experienced and motivated<strong>CablePrice</strong> truck sales team that is dedicated to delivering a highstandard of customer service in all facets of the business.“Leitch’s professionalism and commitment to customersatisfaction will ensure clients receive real value for money, aswell as priority attention and care throughout the lifecycle oftheir truck, not just during the purchase,” says Alfons Reitsma,<strong>CablePrice</strong> general manager of marketing and sales.Leitch advises, “A real point of difference with the Scania rangeis that we can customise client requirements to suit their transportneeds, provided they meet Scania’s technical dependencies onperformance, fuel efficiency and driver comfort.”<strong>CablePrice</strong> 7

TRACK & WHEEL - NEWS$100,000 DONATION TOEARTHQUAKE RELIEF FUNDNew Zealand heavy machinery dealer <strong>CablePrice</strong> hasrecently announced a $100,000 donation to the PrimeMinister’s Christchurch Earthquake Appeal Fund. The donationencompasses a financial contribution from <strong>CablePrice</strong> keybusiness partner Scania AB, along with a further contributionfrom <strong>CablePrice</strong> owners Hitachi Construction Machinery(HCM) and fellow HCM subsidiaries Hitachi ConstructionMachinery Australia and Hitachi Construction Machinery Asiaand Pacific.<strong>CablePrice</strong> general manager of sales and marketing AlfonsReitsma says that while images of the firm’s Hitachi excavatorsand Scania trucks and fire engines have become synonymouswith scenes from the rescue and recovery effort, the company iscommitted to supporting the rebuild of the Garden City.“The earthquake affected everybody throughout the country,but it also pulled us much closer together to support those whohave been directly affected by this event.“Since the earthquake, we have focused on supporting our40 Christchurch staff and their families, together with ourcustomers in Canterbury, who have been affected by the quakeand involved in the rescue and recovery efforts,” Reitsma says.While the company’s office in Hornby wasn’t badly affectedby the February earthquake, a number of staff members’homes were severely damaged. Reitsma says that customersinvolved in the rescue and recovery efforts had also relied onthe company’s support service to ensure excavators and trucksremained operational throughout the time-critical rescue andrecovery phases.“Christchurch is now moving into the rebuilding phase,and we stand alongside the city and its people as they work tore-establish their services, infrastructure, buildings and their wayof life,” Reitsma adds.8 <strong>CablePrice</strong>

<strong>CablePrice</strong> has announced a change to the distribution ofHitachi articulated dump trucks in New Zealand. Branding ofthe trucks has changed from Hitachi to Bell, the originalequipment manufacturer.This change to Bell significantly improves machine and partsavailability thanks to direct access to manufacturers stock.Customers will also receive enhanced support and reduced leadtimes, matching machine availability with market demand.Andrew Crane, national equipment sales manager, says,“The change from Hitachi to Bell trucks provides significantimprovements in supply chain efficiency, and aligns our salesof articulated dump trucks with the global distribution of theBell brand”.<strong>CablePrice</strong> has had an excellent start with this announcement,achieving recent success with the deliveries of three Bell B50Dsto the Solid Energy New Vale Mine in Southland, and a furtherNEWS - TRACK & WHEELINTRODUCING BELL ARTICULATED DUMP TRUCKSunit to the Birchfield Coal Mine on the West Coast to add to theexisting fleet of three Hitachi brand trucks.“We’re really impressed. They’re carrying 25 percent more thanour other trucks yet only using one-litre per hour more fuel. Asfor working in the wet, again, they’re much better than the othertrucks, and are more stable thanks to the wider track,” says SolidEnergy’s New Vale Mine manager, Antony Stodart.“We are confident that most customers are aware that Hitachiand Bell articulated dump trucks are essentially the sameproduct, with the only difference being the decals and colour.Features, capabilities and specifications are identical between thebrands,” he continues.With the growing population of trucks, <strong>CablePrice</strong>’s nationalparts and service network for both Hitachi and Bell articulateddump trucks has been strengthened for the current numbers,with more units on the way.<strong>CablePrice</strong> 9

TRACK & WHEEL - NEWSJOHN DEERE SIMULATORS:A COST-EFFECTIVE TRAINING TOOLThanks to the support of <strong>CablePrice</strong> and John DeereForestry Equipment, Waiariki Institute of Technology in Rotoruatook delivery of the very first John Deere E-series operatortraining simulator in the southern hemisphere, at the beginningof September.To help reduce traditional training costs and prevent unskilledoperators from using equipment in the field, John DeereForestry has produced this state-of-the-art simulator for E-seriesmachines, complete with new technology that enhances thevirtual environment.John Deere’s operator training simulator is a cost-effective, safeand efficient way for students to learn how to correctly operatea highly-sophisticated forwarder in a controlled environment,before they ever step foot towards a real machine. Highlydetailed and realistic lessons teach proper operator technique,machine controls and safe operation in a virtual job site.“We saw this as the perfect opportunity to support thefuture of the forestry industry in New Zealand, giving the nextgeneration the opportunity to learn how to get the most fromthe state-of-the-art equipment that they will soon be operatingin the field,” says Andrew Crane, <strong>CablePrice</strong> equipmentproduct manager.Waiariki Institute of Technology showcased the simulator tomedia and invited guests at the opening of the school’s newbuilding and gasification plant, before moving the simulator tothe <strong>CablePrice</strong> stand at this year’s Forest Industry Expoin Rotorua.“We see this as very significant for Waiariki Institute. We’llbe incorporating the use of this simulator into two of ourcourses: the first, a high-level diploma in forest management;and the second, our practical logging course that has over 200students per year. Primarily, it is a chainsaw based course, butwe also want to provide students with hands-on experienceof operating a forwarder,” says Jeremy Christmas, director ofWaiariki School of Forestry and Primary Industries.Pictured is National MP for Rotorua Todd McClay guided by<strong>CablePrice</strong> equipment sales specialist Terry Duncan, right. Photokindly supplied by Waiariki Institute of Technology.STAY ON THE RIGHT ROADTHERE’S STILL MORE WORKTO BE DONETRUCK AND BUSTECHNICIANS REQUIREDWe’re Cable Price and we’re looking forskilled technicians. We’ve got plenty onso this is a great time to be joining us.As part of our team you’ll enjoy themachinery, training, support, variety andcompetitive remuneration we offer. We’vebeen trading in New Zealand for 60 yearsand we’re proud of the reputation we’vebuilt. We have 13 branches nationwide,so you don’t need to travel far to accessworld class opportunities. Just check outour website to learn more.cableprice.co.nz0800 555 288www.cableprice.co.nz10 <strong>CablePrice</strong>

TRACK & WHEELA FIRST FORCABLEPRICEAND SCANIAStaffan Kollander recently arrived in New Zealand,on loan from Scania CV AB, Sweden. In what is afirst for <strong>CablePrice</strong>, Kollander will be working at<strong>CablePrice</strong> head office in Wellington, as part ofScania’s PEP (personnel enhancement programme).PEP is a program set up by Scania in Sweden,making it possible for employees within the Scania organisationto go on short-term assignments in other markets or countriesaround the world, gaining experience and assisting Scania indeveloping products and services for a global market.Kollander is on an exchange basis for a period of 6 to <strong>12</strong>months. For this program to be fully beneficial to both Scania,Sweden, and <strong>CablePrice</strong>, New Zealand, <strong>CablePrice</strong> will alsobe sending an exchange employee to Sweden. Lauren Calvert,marketing coordinator at head office, has been given theopportunity to be the first employee from <strong>CablePrice</strong> to moveto Sweden as part of this program. Calvert will live and work inSödertälje, a municipality of Stockholm and the home of Scania’shead office. On a six month exchange commencing in January20<strong>12</strong>, she will be working in the sales and marketing departmentat Scania.While at <strong>CablePrice</strong>, Kollander will be the marketingcoordinator responsible for Scania trucks in New Zealand. Hisprime responsibility will be to analyse and support upcomingmarket changes in the New Zealand truck market, and assist invarious other head office marketing activities.Kollander comes to <strong>CablePrice</strong> with a Masters of Sciencedegree in Business Administration, and has been workingfor Scania for almost five years. Among some of his formerresponsibilities, he has worked with sales from Scania head officetowards the European region. Before that, he worked in the presalesdepartment with sales systems and commercial questions.“I come from Stockholm in Sweden and really enjoy travelling,so it’s really a plus going overseas for work. It is wonderful tocome here during the New Zealand spring time. I also enjoysports. Golf is one of my big interests, and I’ve got myself a setof clubs so I will definitely try some of the courses while here. Iwill also try to see as much of New Zealand as possible. I thinkthat this will be a fantastic experience for me,” says Kollander.“This is the first upcoming exchange opportunity arrangedbetween Scania CV AB and <strong>CablePrice</strong>. I’m sure everyone willjoin with me in welcoming Kollander to New Zealand and makehim feel right at home,” says Alfons Reitsma, general manager ofsales and marketing at <strong>CablePrice</strong>.<strong>CablePrice</strong> 11

TRACK & WHEELA LOT OF STEAK AT STAKEIn recent years, the export meat business has been booming in this country,with New Zealand farmers developing a reputation for producing goodquality beef and lamb. But it takes more than just great farming to delivergreat products – transportation also plays a big role.For more information scan this tag.For full instructions, see page 2.<strong>12</strong> <strong>CablePrice</strong>

TRACK & WHEEL<strong>CablePrice</strong> 13

TRACK & WHEELFor Wellington-based KAM Transport Ltd, the meatindustry forms the foundations of its operations, aswell as its management and ownership team.Owners Rod and Scot Preston are part of a familythat has been in the butchery business for morethan a century. The brothers took over the companyin 1989, growing the business from a small local delivery firmthat serviced the Wellington City Council abattoir, into one thatnow has operations in both islands.The Prestons also form a large part of Taylor Preston MeatProcessors, which is where the majority of KAM Transport’swork comes from.“The company was running three little trucks around townwith the odd run up the line to New Plymouth, but, basically, allthe action was down here,” says transport manager Chris Mooney.“In 1989, when Rod and Scot Preston took over, we started to14 <strong>CablePrice</strong>

TRACK & WHEELget into the export side of things alongside Taylor Preston. Wethen started to do their container work, and we’ve grown sincethen, now doing their export coolstore work and by-productscartage. We’ve stuck around the meat trade – that’s what weknow best – but we’ve also got into general freight and all sortsof stuff. We will basically cart everything and anything rightnow. You have to be into a bit of everything, so we do containerhandling, swinglift, refrigerated and some bulk units in the SouthIsland,” Mooney continues.He adds, “Although we’ve predominantly been in the bottomhalf of the North Island, at the start of this year, we began toventure into the South Island with some bulk trucks and tipperunits.” Indeed, an alliance with Canterbury Meat Packers (CMP)has allowed the company to take on the extra work, runningbeef hides up from the South Island and beef by-products on thereturn leg. Mooney says, “They’re pretty big in the South Islandand we had the opportunity to get involved with them, so wenow have six trucks running around down there – Blenheim,Greymouth and Ashburton.”The increased transport business has seen the overall fleetgrow to 16 trucks, 14 of which are Scanias. Despite the size ofthe fleet, it’s actually a fairly modern line-up, with the oldestof the trucks being a 2003 R<strong>12</strong>4 420h – originally a tipper, it isnow a refrigerated unit. The most recent additions are three newR500 units powered by Scania’s DC16 Euro IV V8 engine. In 8x4bulk tipper configuration, the trio is perfect for coping with theexpanded KAM Transport business.Mooney says the line-up of Scanias has a range of benefits,many of those due to the operating costs of the powerful15.6-litre engine: “They’re a very reliable, efficient andprofessional vehicle. The running costs we’ve got from themhave always been good and they’ve given us very few problems,”he says. “We’re really pretty happy with what we’ve got.”But it’s not just return on investment that makes Scania sucha good choice for KAM Transport, as they also keep the drivershappy, something that gives the business a consistent baseof employees.Renowned for their driver comfort, Scania has set abenchmark with an air-suspended cab, comfortable drivingposition and the aesthetically-designed cabin layout, all ofwhich plays a major part in ensuring drivers are working in acomfortable environment. Other features, such as the electronicbraking system, ABS anti-lock braking and cab constructionbased around driver protection, also mean that safety is a bigpart of Scania’s design.“Good gear does keep the drivers around. If they’re drivingrubbish, then someone can offer them a job driving somethingelse and off they go…there’s no allegiance,” Mooney says. “If youcan supply them with a good, comfortable truck, that’s evenbetter – you can hold onto your drivers a bit better.”KAM Transport has thrived on developing long-termrelationships with its clients, something that has paid off asthe company has developed. It’s a company that has alsobenefited from its relationship with Scania, and <strong>CablePrice</strong> isextraordinarily proud of being associated with it.<strong>CablePrice</strong> 15

TRACK & WHEEL16 <strong>CablePrice</strong>

THE NEW DASH-5 SERIES EXCAVATORSMore movedwith less effortFor more information scan this tag.For full instructions, see page 2.<strong>CablePrice</strong> 17

5NEWZXSERIESTHE NEW ZAXIS 5 SERIES EXCAVATORS HAVE ARRIVEDMany will remember the Hitachi EX-5 as being “the complete” machine for reliability and performanceof its era. Initial response to the first machine in New Zealand is that the ZAXIS-5 range will once againput Hitachi Excavators at the peak.Loaded with numerous, customer-driven enhancements, all models deliver superior productivity anddurability, while keeping operating costs low. With more dig force, slew torque and lift capacity, ZX-5excavators get more work done in a day, so you can stay on schedule. Their powerful and proven Isuzu6BG1T and 6HK1X diesel engines go reliably about their business wherever you put these machinesto work.The larger operator environment features a more comfortable air suspension, heated high-back seatand a new operator friendly multifunction monitor.Other standard features, such as rear-view camera, ROPS cabs (ISO <strong>12</strong>117) and FOPS (Level II) roofand front window guards, further enhance the machine applications and operator safety.18 <strong>CablePrice</strong>

The first ZX200-5 arrived in New Zealandin September and since then TaylorsContracting in Nelson have been testing themachine, clocking up 300 hours with ChrisDonavan, a skilful operator who appreciatesa good machine. Having operated a widerange of excavators in his career, Chris hadan open minded view when he was given thenew ZX200-5.When asked for his opinions of the machine’sperformance, Chris comments.“I found it’s very powerful in the slew andhas excellent multi-function ability andtrack drive. The productivity of the newmodel is also better when loading trucks, Iam consistently a minute faster than othersame sized machines on the job. Also, for theamount of extra work the machine does, fuelconsumption is very good, and I only have tofuel up every three days”.When asked for his opinions of the new cabin“It’s got great leg room and a comfortableseat, I like the monitor with its larger screenand controls all within one close area, makingit extremely easy to change settings withouttaking my eyes off the job. I like to do my jobsin the shortest amount of time possible andit really allows me to do just that thanks to itsvery smooth and responsive controls”.Hitachi has also improved durabilityfor the new Dash-5 series with severalimprovements made to the undercarriageand front attachment.The new Zaxis Dash 5 is available in fivemodels between 20 and 35 tonne from early20<strong>12</strong>, and will able to be seen at a <strong>CablePrice</strong>branch near you.<strong>CablePrice</strong> 19

TRACK & WHEEL20 <strong>CablePrice</strong>

TRACK & WHEELDEERE TOTHE RESCUEUsing a bulldozer to push waste arriving at alandfill was turning the ground to mud. Butbuying a John Deere wheeled loader to dothe work has quickly solved the problem.Thanks to its ruggedversatility, a John DeereK-series wheeledloader has permanentlysupplanted a bulldozerin a waste-moving taskat a major landfill, as well as being ableto perform other roles on the site.The Silverstream landfill in the HuttValley has been operating since 1972,serving a population of more than<strong>12</strong>5,000. Eighteen months ago, withthe original area filled and capped, apurpose-built phase two of the landfillwas opened.This phase has a lifespan of 50years and its class-A rating enablesit to take the widest range of wastematerial, holding up to 105,000tonnes annually. TranspacificIndustries Group (TPI) (a leadingprovider of comprehensive waste andenvironmental services) contracts tothe Hutt City Council to operate andmanage the site, alongside the originallandfill team that has managed thesite for approximately 11 years,gaining an in-depth knowledge of theoperational requirements.Four months ago, the companypurchased a 20-tonne John Deere724K wheeled loader to add to itsmachinery fleet, currently consistingof a 35-tonne refuse compactor, a20-tonne D6 bulldozer, an 11-tonnefront-end loader, a 30-tonne excavatorand two dump trucks.Landfill manager James Blair saysthe primary reason for the purchaseof the 724K was for use on the truck’smanoeuvring and tipping pad insteadof the bulldozer, as the latter wasbreaking up the pad in winter andturning the surface to mud.All trucks arriving with waste atthe landfill must deposit their loadson the pad. The waste is then pushedoff the pad to the compactor, a task<strong>CablePrice</strong> 21

TRACK & WHEELnow permanently transferred from thebulldozer to the 724K wheeled loader.“With its foam-filled rubber tyres,the John Deere is sealing up the truckmanoeuvring pad so it doesn’t get muddy,and being a 20-tonne loader, it can pushrefuse quite readily,” Blair says. “We alsouse it for small jobs like ‘blading out’ ofearth on the pad, because we’re alwaysprogressing forward with the earth.”He says that, in addition, the loaderwill be employed to stockpile gravel andmove it into position for placing on topof the landfill’s plastic liner and fabricoverlay to further protect the liner.Blair continues that when TPI realisedit would have to buy a wheeled loaderto use on the pad, it surveyed whatcould be obtained locally. The JohnDeere not only came up to spec withall other comparable loaders but “itwas there – it was readily available. And<strong>CablePrice</strong>’s service and parts are locallysourced – you don’t have to look outsideof New Zealand”.The Silverstream landfill’s long,planned life is matched by that of theJohn Deere 724K. Its turbocharged 9-litre,197kw, wet sleeve diesel engine deliversan impressive 1169Nm of torque, and itsall-round rugged reliability, durability andheavy-duty mainframe equip it to thriveon waste-handling and tough transferstation tasks.An innovative Quad-Cool (coolingon demand) system with proportional(reversible) fan ensures that everythingstays cool in dusty conditions. Extensiveguarding minimises debris build-upand helps to avoid close encounterswith obstacles from slowing downthe machine. A solid-state electricaldistribution centre, durable sealed-switchmodule and state-of-the-art diagnosticmalfunction monitor further boostuptime and productivity.Other features include inboard,planetary, wet-disc brakes that help toensure longer service life.While Blair has yet to fully assessthe 724K’s operating costs, he says thewheeled loader has been performingwell, fulfilling TPI’s expectations. It hasan ideal weight-to-power ratio and hisoperators have praised its accessibility,simplicity, cab comfort and ease ofhandling.“We’ve been through snow and a wetsix weeks and we’ve found that havingthe loader has been an asset. It was agood choice – we made a good decision,”Blair says.22 <strong>CablePrice</strong>

TRACK & WHEELTIME TO DELIVERHave you ever thought of joining the growing fuel efficient, easy to drive and safe. Another important fact wasnumber of people doing online shopping? that it had to have a narrow cab/body to fit the new purposebuiltbodies. The Isuzu NLR250 that Teariki decided on ticked allIt appears that more and more of us aredoing our weekly shop online, and why not?! the right boxes.You get your own personal shopper, exactly Delivering in Wellington’s CBD, with its narrow alleyways, iswhat you order and not just your pre-packed always going to be a challenge. But if you think that’s difficult,goods (bread, tinned foods and cleaning products) – it caters you want to try some of the steep, tight driveways in the suburbs,for all your shopping needs, including fresh fruit and vegetables, like up the top of Mt Victoria, where a good street has room formeat and frozen goods – all delivered to your door at a time just two cars, let alone a truck. Its times like these that a truckthat suits you.with the narrow body of the Isuzu NLR is appreciated, not toSuch is the professionalism of the service offered bymention the inclusion of hill start assist.Countdown that couriers are not considered to be good enough The NLR250 is powered by a Euro IV, three-litre, four-cylinder,to deliver your order: Countdown has a contracted fleet of16-valve, DOHC, turbocharged Isuzu diesel engine. This isspecialised, refrigerated carriers to deliver your online orders. capable of producingLike any time-critical business, reliability is key. Without110kW with 375Nm ofreliability, everything else becomes secondary. Deliveringtorque. With a GVM ofonline orders for Countdown is a time-critical business, one that 4500kg, a narrow bodyWellington-based Key Carriers has been contracted for, delivering and a list of modernto customers in Khandallah, Wellington CBD and southernsafety features – ABS,regions for over five years.EBS, driver’s air bag andKey Carriers’ managing director Ki Teariki and his team arehill start assist – theresponsible for ensuring that online shopping orders (in their Isuzu NLR250 is theregion) are delivered in pristine condition, on time, every time. ideal delivery truck.What started less than six years ago with a used HiAce van, hasIf Teariki andnow grown into the business we see today, employing 10 staff Countdown continue to(six full-time and four part-time), and, with the two new Isuzu experience the growthNLR250s, a full fleet of five.seen over the past fiveWith an ageing fleet, maintenance costs on the increase and years, Key Carriersa need to fit new, purpose-built bodies, it was time to upgrade. will be sure to get itsTeariki says: “Initially, I was looking for a couple of used imports, money’s worth from thebut on closer inspection and after talking with <strong>CablePrice</strong>, there new Isuzus.was actually little to be gained from buying used over new. Also,with new, you get the advantages like full dealer support and a Visit Countdownknown history of the truck.”online atTeariki knew exactly what he needed in a truck: it had to be www.countdown.co.nz<strong>CablePrice</strong> 23

TRACK & WHEELTHE BIG SQUEEZEFuel consumption in heavy, long-haul traffic can be reduced to less than 20 litres per100 kilometres in daily operation. The Scania transport laboratory reveals how.Words by Per-Ola KnutasImages Kjell Thorsson and Carl-Erik AnderssonWith the right vehicles, an uncompromisingfocus on driver behaviour and use of thecomputer-based Scania driver supportsystem, fuel consumption can be reducedto very low levels. This is the assertion ofthe Scania transport laboratory, and it’sdone the research to prove it.“On our best trips between Sweden and the Netherlands, wehave reached 18.2L/100km, a level that many say is impossible,”says Anders Gustavsson, managing director of the Scaniatransport laboratory.The laboratory is a wholly-owned Scania subsidiary that testsand evaluates vehicle properties and performance in commercialroad haulage. It also trains and coaches drivers in the use ofeconomical and safe driving techniques.Today, the company consists of 65 drivers, 20 tractor units and24 <strong>CablePrice</strong>75 semi-trailers. The fleet includes competitors’ trucks as well,providing relevant comparisons in real-life conditions.The practical assignment of the transport laboratory is to beresponsible for part of Scania’s European production flow byhauling freight and components between the production units inSödertälje in Sweden, and Zwolle in the Netherlands.“From the start in 2007, we wanted the lab to facilitatecommunications between Scania’s product development andthe daily operations of a haulage company,” says Gustavsson.“The dialogue works very well. Virtually every week, our driversare visited by employees of Scania’s research and developmentdepartments who want to talk about concrete ideas andimprovement opportunities.”One result is that the laboratory now operates tractor units thatare configured with a faster rear-axle gear ratio. This leads to lowerengine revs at cruising speed, something that can reduce fuel

TRACK & WHEEL7TIPSFORBETTEROPERATINGECONOMYConsistent driver training: repeat and reinforcedriver training for real and lasting fuel savings. Findmethods and processes for coaching drivers regularly,preferably in real time using the tools in the Scania fleetmanagement portal.Correct vehicle specification: devote time to determiningthe correct vehicle specifications for your operations. Afaster rear-axle gear ratio leads to lower engine revs atcruising speed, and can lower fuel consumption by 3 to 10percent. Correct specifications may also mean not havingtoo much of a powerful an engine.Scania ecocruise: this is an intelligent cruise controlsystem that can save up to 4 percent on fuel.Scania driver support: this computerised supportsystem guides the driver in real time by providing tipsand feedback.Properly adjusted air deflectors: ask your Scaniaworkshop to help adjust air deflectors properly. Animproperly adjusted deflector will increasefuel consumption.Regular vehicle checks: check the axle and wheelalignment regularly, and adjust tyre pressure.Regular trailer checks: check axle alignment and brakesettings regularly in order to avoid traction losses.Source: Scania transport laboratoryconsumption by 3 to 10 percent.Another result is a new rear air deflector,known as a “boat-tail” spoiler, mounted atthe back of the company’s semi-trailers. Thespoiler increases the length of the vehiclecombination by 30cm, which is equivalent tothe extra length permitted by the EuropeanUnion. The results are very promising.“The fuel savings are close to four percent,”Gustavsson says. “For our trucks that run360,000km per year and consume an averageof 26 litres of fuel per 100km, this representsan annual saving of nearly 4000 litres of fuelper truck, as well as lower CO2 emissions.”But the biggest improvements in termsof fuel consumption and vehicle wear andtear are still achieved by means of consistentefforts to train and coach drivers, along withsystems such as Scania fleet management andScania driver support, Gustavsson says.“These are the most important steps forus to achieve our target of fuel consumptionaveraging 22 litres per 100km,” he adds.“ On our besttrips, wehave reached18.2L/100km”Anders Gustavsson,Scania transport laboratoryFACTS ABOUT THE SCANIATRANSPORT LABORATORYAverage annual mileage: 360,000km pervehicle20 tractor units (4x2)65 drivers75 three-axle semi-trailers13 daily trips: Sweden to the Netherlandsto SwedenVolume: 100 m³/semi-trailerLoad factor: 92%Average gross weight of each rig: 37 tonnesen route to Zwolle, 32 tonnes returningAverage fuel consumption: 26L/100km(target: 22L/100km)Most of this traffic goes via Denmark.<strong>CablePrice</strong> 25

TRACK & WHEELDELIVERY OF FIRST HITACHI EX2500-6MINING EXCAVATOR IN NEW ZEALANDLocated in East Otago, some 80km north of Dunedin and 2km to the east of the Macraes Flattownship, the OceanaGold mine site actually consists of two mines – the Macraes Open Cut andFrasers Underground – with a total anticipated production of around 210,000 ounces per annum26 <strong>CablePrice</strong>

TRACK & WHEELWhen OceanaGold, New Zealand’slargest gold producer, look for earthmoving equipment, it needs unbeatableperformance from proven suppliers.Hitachi and <strong>CablePrice</strong> are suchsuppliers. Having been a large excavatorsupplier to OceanaGold for a number of years, Hitachi hasproven it knows how to build safe, solid and reliable miningexcavators, and <strong>CablePrice</strong> knows just how best to support themining company with its specialised mining support group.So, when OceanaGold made the decision to purchase anotherexcavator for their Macraes Flat operation, it was no surprisethat it once again looked to Hitachi. This time, it chose theHitachi EX2500-6 to add to its fleet, which already includes two359-tonne Hitachi EX3600 excavators, one a 2005 vintage withmore than 35,000 hours on the clock and the other a 2010vintage with 7000 hours.While the new EX2500-6 may be bit smaller than its twobrothers, weighing in at just 250 tonnes, it is by no means asmall machine. As a backhoe configuration excavator, it is bothpowerful and efficient. With a 50-litre, 1400hp Cummins QSKseries, 16-cylinder, turbocharged and after-cooled diesel engine,it has more than eight times the power of the average family car.<strong>CablePrice</strong> 27

TRACK & WHEELThe operator of the EX2500-6 sits on an air-suspendedseat in a cab some six metres above the ground. The cabitself is roomy, pressurised with three air-conditioningunits to keep dust out and the operator cool in <strong>summer</strong>and warm in winter. Access to the cab is via hydraulicallyoperatedfolding stairs, for both safety and easy access.Additional safety comes from a Sandvik fire suppressionsystem, installed by Fire Suppression Systems.This excavator is a real workhorse with six hydraulicpumps, a peak oil flow of 2450 litres per minute and a15-cubic metre bucket, all of which means it is capableof collecting 27 tonnes of earth in each pass. Workingaround the clock, the average pass only takes 25 seconds,so this is an excavator that can load over 2500 tonnes perhour, or 60,000 per day.Having been fully assembled and tested at Hitachi’smining factory in Japan, the EX2500-6 was dismantled28 <strong>CablePrice</strong>

TRACK & WHEELinto transportable sized components and shipped to NewZealand, arriving at Wellington’s Centre Port on October 1. Fromthere, with the assistance of Orbit Heavy Haulage, 11 transporterswere used to move the components to the assembly site atMacraes Mine.Since arriving at Macraes Flat, the 250-tonne miningexcavator spent two weeks being assembled and tested by the<strong>CablePrice</strong> mining support group that consists of 10 techniciansand is led by Invercargill branch service manager Roger Hunt.The machine was then handed over to OceanaGold to beofficially commissioned on October 18.“While we had a few delays early on, partly due to theearthquake and tsunami in Japan, everything came togetherjust right, and the team did an excellent job reassembling themachine in two weeks. Given the size, shape and weight of theparts that the team were assembling, we couldn’t have done thiswithout the assistance of A V Martin and Co crane hire for theheavy lifts,” says Paul Laird, <strong>CablePrice</strong> mining product manager.STAY ON THE RIGHT TRACKTHERE’S STILL MOREWORK TO BE DONEHEAVY EQUIPMENTTECHNICIANS REQUIREDWe’re Cable Price and we’re looking forskilled technicians. We’ve got plenty onso this is a great time to be joining us.As part of our team you’ll enjoy themachinery, training, support, variety andcompetitive remuneration we offer. We’vebeen trading in New Zealand for 60 yearsand we’re proud of the reputation we’vebuilt. We have 13 branches nationwide,so you don’t need to travel far to accessworld class opportunities. Just check outour website to learn more.cableprice.co.nz0800 555 288www.cableprice.co.nz<strong>CablePrice</strong> 29

TRACK & WHEELTHE RIGHT TOOLSFOR THE JOBOne of the many new words to pepper conversation in Christchurch over thepast year has been “deconstruction”, effectively meaning carefully controlleddemolition. At the vanguard of that activity in the Garden City is Auckland-basedNikau Contractors Ltd, a firm of deconstruction engineering specialists.For more information scan this tag.For full instructions, see page 2.30 <strong>CablePrice</strong>

TRACK & WHEEL<strong>CablePrice</strong> 31

TRACK & WHEELThe company initially came to Christchurch toanswer a call for demolition equipment, as JohnPaul Stil, senior estimator for the company, explains:“We were in Wellington at the time and one ofour operations managers got a call from someonein USAR (Urban Search and Rescue) asking us tobring some gear down. We just bought down a couple of 40-tonnediggers to begin with. But then we bought a lot of other machinesdown, and the rest is history …”However, none of it was big enough for some of the challengesthe earthquakes presented.A few months ago, the company bought a new 63-tonneHitachi ZX470LCH-3 excavator, a specialist demolition machinewith a three-piece boom and crusher capable of reaching 26metres, used primarily on buildings of five to six storeys. It’s oneof only a few in the country, and Nikau has been operating it inChristchurch since its arrival in mid-<strong>2011</strong>.The Zaxis-3 LCH-series excavators are well suited to thiskind of work, with features such as a large undercarriageand strengthened boom cylinders. However, strength doesnot compromise efficiency in these machines: clean-burningcommon rail diesel engines and an exhaust gas recirculationsystem are just two of a number of their cost-saving andenvironment-respecting assets.Advanced Hitachi hydraulic technologies also abound inthese excavators. Two examples include the enhanced boomrecirculation systems and a new regenerative oil circuit, both ofwhich effectively store hydraulic energy when the load on thecrusher or bucket is light.Nikau Contractors Ltd was formed in 1980, having grownout of a husband-and-wife lawn mowing company that wasasked to shift an old garden shed. Two sons and two daughtersof founders Diane and John Paul Stil manage the company’soperations in the field today, and it is now one of New Zealand’sleaders in deconstruction, recycling and salvage techniques, withclients ranging from government agencies, regional councilsand iwi, to property developers and general contractors withdemolition, site works and environmental projects on hand.You’d have to say that Nikau Contractors was always a prime32 <strong>CablePrice</strong>

TRACK & WHEELcandidate to help beleaguered Christchurch, thanks to itsextensive experience in the safe and efficient removal of multistoreybuildings, bridges, underwater structures, service stationsand underground storage tanks.And it has plenty of gear. In fact, it has New Zealand’s largestrange of high-reach excavators, heavy-duty rock breakers andmulti-task attachments. Its extensive plant inventory includes 35excavators all up, 21 of them carrying the Hitachi nameplate, 14of those from the Zaxis range.Mostly at work in Christchurch, these machines are fitted witha wide range of rock breakers, rippers, pulverisers and shears,with two of those shear attachments being capable of delivering1400 tonnes of cutting force.But Stil is quite matter-of-fact about the high proportion ofHitachis in their excavator fleet: “They’re good and reliablemachines. They’re really great value…and the back-up service<strong>CablePrice</strong> 33

TRACK & WHEELand support from <strong>CablePrice</strong> is really good, too.”The company also specialises in environmentally sensitiveprojects, having a subsidiary, Nikau Environmental Ltd, to dealwith sampling, testing, removal, clean-up and remediation ofasbestos and other hazardous materials. These specialist skillshave proved invaluable in Christchurch, where the companyhas been called upon to salvage materials and items of historicalimportance at several sites.Nikau places a very high degree of importance on safety,going to the extent of employing two members of staff as “safetychampions”, patrolling its numerous work sites that are mannedby 50 staff, nearly half of them recruited locally.So, with its host of safety and environmental features, theZX470LCH suits the ethos of Nikau down to the ground.There’s plenty of work in Christchurch for the Nikau team andthe many other companies helping the city with the clean-up.The numbers being reported change every day, but one recentcount had 650 buildings in the CBD demolished. By the time thejob’s done, it’s expected some 1500 buildings will have been fullyor partly demolished -- sorry, deconstructed.34 <strong>CablePrice</strong>

TRACK & WHEEL<strong>CablePrice</strong> 35

TRACK & WHEELFor more information scan this tag.For full instructions, see page 2.36 <strong>CablePrice</strong>

TRACK & WHEELBELLREPUTATIONRINGING TRUEInnovative Bell MkVI ADT upgradeshowcases the latest in safety and innovation<strong>CablePrice</strong> is the national distributor of BellArticulated Dump Trucks (ADTs) in NewZealand. Since early 2010, customers havebenefited from the many industry-leadingfeatures and benefits of the Bell D-Series MkVIADTs, which provide significant advantages interms of ADT innovation and technology.The MkVI upgrade focuses largely on enhancements to theelectronics and the operator station in order to further improvesafety, ease of operation, noise level reduction and vehicleprotection.State-of-the-art operating environmentThe most recognisable change to the Bell MkVI ADT is locatedin the cab where the gear selection and bin-tip lever are nowincorporated into a fully-sealed switch module. This arrangementnot only reduces wear and tear, it also optimises the cab’sergonomics by placing important controls within easy reach ofthe operator, thus creating an efficient operating environment.The Bell MkVI ADT includes a keyless start which is protectedby a numerical code that must be entered by the operatorprior to starting the truck. Different options can be set to allowfor easy on-site management and automatic expiry of codes,something that provides site management with greater controlof who can operate a specific vehicle and when.The keyless engine stop includes a standard turbo spin-downfeature to regulate spin downtime according to how hard theengine has been working.Safety features are becoming increasingly important, and theBell MkVI ADT incorporates industry-leading improvements. Forexample, the park brake application is automatic when selectingneutral, and neutral cannot be selected above a speed of 5kph.A pitch and roll measurement device has been fitted to therear chassis to enable additional technology to be integrated intothe machine’s software. This allows for the inclusion of numerousinnovations, such as the hill assist feature. The inclinometermeasures the angle of the vehicle and cross-references this withthe exclusive on-board weighing feature. This results in the parkbrake only being released once a pre-programmed engine torquehas been reached in order to ensure a controlled pull away withno rollback, even on the steepest of inclines.Similarly, the machine angle and payload are cross-referencedon pull away, so if the vehicle is unladen and on relatively flatterrain it will automatically pull away in second gear. Apart fromguaranteeing a smooth pull away and shifting, this feature alsosaves fuel by removing the unnecessary shift from first to<strong>CablePrice</strong> 37

TRACK & WHEELsecond gear.The roll detector can also be used on-site to set limits forwhen the bin-tip function can be activated. If the vehicle ispositioned at an angle where lifting the bin may cause instability,the software will prevent the bin from tipping and the operatorwill be warned of the potentially dangerous action on the displaymonitor.Along with the standard OEM features of the MkVI upgrade,<strong>CablePrice</strong> has further enhanced safety by including, as standard,a number of safety-related options: an in-cab emergency stop;lockout kits; hi-visibility mirrors; additional work lights; anddeluxe seating.Operator comfort reaches a new high in the Bell MkVI ADTs.In addition to the improved ergonomics and inclusion of deluxeseating, CD player and sunvisor, comfort is further enhanced bya significant reduction in noise levels. This is achieved throughfocused changes that include a new headliner, hydraulic damperand additional strategically placed insulation in the cab.Fleetm@tic – the next generationCoupled to the electronic innovations are enhancements toBell Equipment’s global fleet tracking system, Fleetm@tic. Thesecond generation Fleetm@tic system provides customers withsignificantly improved reporting, to the extent that reportson individual shifts and operators are possible. The standardfunctions of geofencing, fault warnings and service notificationshave also been retained.Features included in the Mark VI upgrade, coupled withthe existing advantages of low fuel burn, low daily operatingcosts and high productivity, reaffirm Bell as the safest and mostinnovative ADT on the market.For more information on this product, ph 0800 555 456 orvisit www.cableprice.co.nz38 <strong>CablePrice</strong>

TRACK & WHEEL<strong>CablePrice</strong> 39

This issue <strong>CablePrice</strong> will begiving away two prizes of $50 ToyWorld Vouchers.0-5yearoldsDID YOU KNOW...?Larry is a large wheel loader who weighs as much as 20 hippos! He can be foundin yards full of sand, stone and rocks, and loads these materials on to trucks.To enter, simply colour in the picture as best you can, then post it to us at:TRACK & WHEELCOLOURING COMPETITIONMarketing DepartmentPO Box 38-040Wellington Mail Centre 5045NAME: ...................................................................................AGE: ............ EMAIL ..............................................................ADDRESS: ............................................................................................................................................................................PHONE: .................................................................................Terms & Conditions: Entrants contact information will not be used for any other activity and will not be passed on to any third parties. Information is gathered purely for the purpose of contacting the winner(s)and delivering prizes. <strong>CablePrice</strong> (NZ) Ltd staff and their direct families are not eligible for entry. Final day for entries is 31 January 20<strong>12</strong>. The winning drawings will be selected by a panel of judges. The judges’decision is final and no correspondence will be entered into. The prize is not redeemable for cash or other items. Only one entry per individual. Winners will be advised by email and/or phone and prizes willbe delivered to the address supplied on the form. Prizes can not be couriered to a PO Box or Private Bag.40 <strong>CablePrice</strong>

There are two age categories: 0-5 and 6-<strong>12</strong>. How to enter: Simply colour in thepicture for your age group and send your entries toColouring Competition<strong>CablePrice</strong> Marketing DepartmentPO Box 38-040, Wellington Mail Centre 5045Remember to complete all the details on the colouring competition to be eligible.Final date for entries will be 5pm, January 31, 20<strong>12</strong>. Winners will be notified by phone and prizes will be courieredto the address supplied on the entry form. Note: Prizes can only be sent by courier to physical address, not PO Boxesor Private Bags. Note: The colouring competition will be available for download from www.cableprice.co.nz for anyentrants not wishing to colour in on the gloss paper of the magazine.6-<strong>12</strong>yearoldsSam has a short-tail, which enables him to swing around without hitting walls or otherobstacles. This makes his job on the building site much safer and easier to complete.DID YOU KNOW...?To enter, simply colour in the picture as best you can, then post it to us at:TRACK & WHEELCOLOURING COMPETITIONMarketing DepartmentPO Box 38-040Wellington Mail Centre 5045NAME: ...................................................................................AGE: ............ EMAIL ..............................................................ADDRESS: ............................................................................................................................................................................PHONE: .................................................................................Terms & Conditions: Entrants contact information will not be used for any other activity and will not be passed on to any third parties. Information is gathered purely for the purpose of contacting the winner(s)and delivering prizes. <strong>CablePrice</strong> (NZ) Ltd staff and their direct families are not eligible for entry. Final day for entries is 31 January 20<strong>12</strong>. The winning drawings will be selected by a panel of judges. The judges’decision is final and no correspondence will be entered into. The prize is not redeemable for cash or other items. Only one entry per individual. Winners will be advised by email and/or phone and prizes willbe delivered to the address supplied on the form. Prizes can not be couriered to a PO Box or Private Bag.<strong>CablePrice</strong> 41

MERCHANDISEScania belt , $81.88Scania hi-vis jersey, $54.95Scania kids hoodie, $41.20Scania RLX jeans, $154.50Scania dark chromesunglasses, $87.55Scania womens polo, $30.00Scania R60 highline1:25, $<strong>12</strong>8.75Scania hat, $10.00Scania vacuumflask, $26.52John Deere work wear, $49.95John Deere polo, $23.50John Deere multitool,$13.50John Deerebackpack, $43.5042 <strong>CablePrice</strong>John Deere hat,$19.20

MERCHANDISEHitachi white ringer tee, $8.69Hitachi polos, $8.69Hitachi black & grey tees, $8.69Hitachi hi-vis jersey, $54.95Hitachi polos, $8.69Hitachi 3-in-1 jacket, $90.00Hitachi hat, $17.951:30 ZX35U model excavator, $<strong>12</strong>8.75John Deere / Hitachi hi-vis tee, $38.00ORDER TODAYTO PLACE AN ORDER FOR THESE AND OTHER GREAT MERCHANDISEPRODUCTS, CONTACT YOUR LOCAL CABLEPRICE BRANCH TODAY!All prices exclude GST. Products are subject to availability and prices may change without notice. Items displayed are for promotionalpurposes only and may or may not include optional extras. Offers valid while stock last. Stock may vary between branches.<strong>CablePrice</strong> 43

TRACK & WHEELRECENT TRUCK DELIVERIESSouth Wairarapa livestock and general cartage company, Martinborough Transport Limitedrecently added this exceptionally well-presented new Scania R620 8x4 with sleeper cab to itslivestock transport fleet.Proudly driven by Marc Kumeroa, the Scania, with its distinctive green-on-green paintfinish, will become a familiar site, primarily transporting beef out of the Wairarapa butultimately travelling nationwide.With 620hp, “the two-pedal opticruse with retarder is just magic” says Kumeroa. And asfor the power, he’s already impressed, saying “just think what it’ll go like when it’s got a fewmore kms – it’ll be humming.”Other features include Jackson mono four-axle trailer and deck, and Total stock crates.44 <strong>CablePrice</strong>

TRACK & WHEELCustomer: Reefton HireModel: Scania P420After being blown away by the performance and exceptional run achieved withtheir first Scania R620 8X4, Marty and John have purchased a second Scania fortheir operation in Reefton. A P420CA6X4MHZ has the perfect specification fortheir requirements: with 420hp 6X4, three-pedal opticruise, hub reductions andspring suspension the job of carting the special bins from the mine to the railwayis done with unbelievable ease. Marty is quietly impressed with the care taken andthe quality of workmanship involved in getting this truck ready for delivery.Customer: Tussock Log CartageModel: Scania R620Jason Stewart, owner of Tussock Log Cartage, has a new620 logger in Gisborne, which joins his existing Scania R470.The operator is Mike Bond. Bond has come from a livestockbackground but enjoys the logging scene. On visiting Bond,he had a very nice packed lunch and seemed to be gettinglooked after at home almost as much as he is at work! Thetruck has been fitted out with Patchell logging gear.Customer: Transworld Roxburgh LimitedModel: Scania R560Transworld Roxburgh has recently put this very sharp lookingR560LB8X4MSA Euro 5 to work. With 560hp, 2700Nm of torque and the allnewtwo-pedal opticruise, it pulls a five-axle trailer through the South Islandwith ease. Transworld is most impressed with the Scania’s comfort, fueleconomy and retarder.Customer: Pete SargisonModel: Scania R620Pete Sargison has recently taken delivery of a new Scania R620. The truck hasbeen set-up with Patchell’s logging gear, and has been put to work in the HawkesBay with Pan Pac.<strong>CablePrice</strong> 45

TRACK & WHEELCustomer: SouthfuelsModel: Scania G480Southfuels has recently put this new, smart-looking Scania G480LB8X4MSAtruck and trailer on the road. Hosting 480hp with two-pedal opticruise, the jobof fuel delivery around Southland is done with ease.This unit is also used extensively for delivery to the ski fields in thewinter time. The truck also delivers to the Mossburn 24/7 fuel stop, with theoccasional rural delivery. Having 25,000-litre capacity on the trailer and 18,000litres on the truck, with the correct permit, this unit will be able to go to 54tonnes. Tank fitting and trailer were done by Tanker Solutions.Customer: Amuri Transport LimitedModel: Scania P360Based in North Caterbury, Amuri Transport Limited has recently taken delivery of anew Scania P360CB4X4HHZ spreader, which has been fitted with a Bredal Fertiliser Bin.With the addition of this new truck, the company now runs seven Scanias in its fleet.Customer: Tony PyeModel: Scania R620Tony and Dianne Pye have put their first of two Scania R620s on the road. This newScania will join their G480 on the job in Hawkes Bay.In keeping with their usually impressive murals on the cab, the company has delivereda fire breathing Grim Reaper on his wild stead, dressed with a V8 chain bridle to theforests of Hawkes Bay. The mural was painted by Darryn Caulfield in Rotorua.The sleeper cab has been brought back in, after a couple of trucks with rest cabs. Pyesays, “It just rides so smooth with the slightly bigger cab, with only about 140kg difference.”Customer: DouglasLogging LimitedModel: Scania G440Douglas Logging Limited has recently takendelivery of a new Scania G440CB8X8HHZ fortheir logging operation in Northland. The unitis 8WD and is fitted with a Scania six-cylinder440hp, Euro 5 engine, Allison automatic gearboxand hub reduction axles, with cross-axledifferential locks. The new unit will be operatingin Northland and is set-up for shifting logs fromthe harvester to their super skid, along with thecompany’s other Scania, which is a 6X6 unit.46 <strong>CablePrice</strong>

TRACK & WHEELRECENTEQUIPMENTDELIVERIESIn pushing forward with their mechanised operation, Lars & Fiona Rosewarne haveintroduced a new John Deere 2154D log Loader into their Northland operation.The 30 tonne Log Loader is the first of John Deere’s new D Series delivered into NewZealand. These units are factory built and feature beefy new structures and next-size upcomponents; “purpose built to perform”.Their powerful swing systems, 6 cylinder John Deere engines and hydraulic systems allpromise increased productivity. Visibility and comfort for the operator are outstanding fromthe secure and roomy near–entry cab. Even the ride itself can’t be beaten.This is the 6th new John Deere to be delivered to Rosewarnes by <strong>CablePrice</strong> (NZ) Ltd<strong>CablePrice</strong> 47

TRACK & WHEELCustomer: James Drainage LtdModel: Hitachi ZX<strong>12</strong>0-3Allan James, from James Drainage Limited, has recently added a new HitachiZX<strong>12</strong>0-3 to his fleet. The machine comes complete with JB power tilt andwedgelock thumb, and will be put to work in the Coromandel.Customer: Broughton Contracting LimitedModel: Hitachi ZX<strong>12</strong>0-3Broughton Contracting Limited has taken delivery of a new Hitachi ZX<strong>12</strong>0-3.The machine comes with quick hitch, thumb and tilting bucket and has been putto work in northern Waikato.Customer: J Swap Contractors LtdModel: Hitachi ZX160LC-3 & ZX210LCH-3J Swap Contractors Limited has added two more machines to their fleet: aHitachi ZX160LC-3 and ZX210LCH-3. The machines come with tilting quick hitch,thumb, auto lube system and external ROPS.Customer: Kerry Dines LtdModel: Hitachi ZX200LC-3 & ZX270-3Kerry Dines Limited has taken delivery of two new machines: a ZX200LC-3 andZX270-3. These are the latest Hitachis to be added to its fleet. The machines comecomplete with hydraulic quick hitch, and will be working in the Auckland area.48 <strong>CablePrice</strong>

TRACK & WHEELCustomer: VolcanicPlateau LoggingModel: Hitachi ZX250L-3Volcanic Plateau Logging, based inTaupo, has taken delivery of a new HitachiZX250L-3. Coming direct from the factorywith a high and wide chassis, the machinewill be focused on a forestry application.The rest of the forestry conversionwas carried out by Shultz Engineeringin Taupo. Steven Yeoman finished thepackage off with a 1500-series Ensigngrapple. Crew foreman Paul Kora(pictured) has worked with Yeoman forfive years, and will be operating the newmachine, fleeting, loading and bunchingfor the crew. VPL is a ground base crewcontracted to Kaingaroa Timberlands.Customer: Tom Harrison& SonsModel: Hitachi ZX250L-3Tom Harrison and Sons from Keri Keri hastaken delivery of its first new Hitachi ZX250L-3.The high and wide package is factory-fitted,while other features such as the cab guard weredone at Morgan Engineering in Whangarei,with the Ensign grapple being supplied byEngineering Services. The sale was made byDavid Smith.Customer: Stokes Logging LtdModel: Hitachi ZX250L-3Steven Stokes of Stokes Logging Limited is seen here with Murray Stokes, takingdelivery of his second Hitachi ZX250L-3 log loader, for his Northland operations. Withthe performance of the first ZX250L-3, it was an easy decision to purchase a secondmachine. A factory-fitted high and wide undercarriage makes the machine suitablefor both skid and cut-over duties. Sold by Phil McKenzie, the machine is seen here in ablock near Kaikohe. From left, Steven Stokes and Murray Stokes.<strong>CablePrice</strong> 49

TRACK & WHEELCustomer: Kimberly Contractors LimitedModel: Hitachi ZX280L-3Kimberly Contractors has recently taken delivery of a new Hitachi log loader,pictured here working on the skid site. The machine was guarded by Pro SteelEngineering in Hamilton, and the grapple is an Ensign. The machine is another in theGisborne region, and is going really well at present. The machine will be joined byanother ZX280L later in the month.Customer: Anderson Forest Harvesting LtdModel: Hitachi ZX280L-3Working in the Marlborough area for Nelson Forests Limited, Anderson ForestHarvesting Limited has taken delivery of its second Hitachi ZX280L-3. This one hasbeen set-up for felling and shovelling, and is fitted with a Trinder felling head – aproduct you’ll surely hear more about in the future. Karl Anderson says he was happyto purchase a second Hitachi due to the performance, service back-up and qualityof his first ZX280L-3. The guarding package was completed by Waimea EngineeringLimited, Nelson, and the felling head was built and installed by Trinder EngineeringLimited. The machine was sold by Todd Blackwood of <strong>CablePrice</strong>, Nelson.Customer: Havard LoggingModel: Hitachi ZX330-3Havard Logging, Wairarapa, has taken delivery of another new Hitachi. Joe Tozer,pictured in front of his new machine, has worked for Havard Logging for four years,specialising in machine operation. The machine has a Gary Douglas Engineering logbuild, a live heel and an Ensign 1700-series grapple. The machine is pictured here in theNgamu Forest.Customer: John Coates Earthmovers LtdModel: Hitachi ZX330-3John Coates Earthmovers has recently taken delivery of a new Hitachi. JohnCoates and operator Steve stand in front of their new Zaxis 330-3. The machinehas been fitted with Hitachi FOPS roof guard and front FOPS grill by HTEngineering, Napier.The machine will be put to work on new forestry roading projects around thebooming Gisborne forestry scene.50 <strong>CablePrice</strong>

TRACK & WHEELCustomer: Havard LoggingModel: Hitachi ZX330LC-3A new Hitachi ZX330LC-3 has been delivered to operation in Pipiwai, Northland.Rick McGlashan, team boss of Havard Loggings’ “Thunderbird” crew, says theoperator, David McNally, is very happy with his new Hitachi, which is the secondnew Hitachi delivered to McGlashan’s crew in the last few months.Customer: Kelly Logging LtdModel: Hitachi ZX400LCH-3Kelly Logging have taken delivery of a new ZX400LCH excavator, fitted with aWaratah 626 big wood head.This machine was guarded by Trinder Engineering in Nelson and would be “one ofthe best packages I have seen,” says Nigel Kelly, who had a lot of input in the design andfunctionality of it. The package is strong and light, maintaining all of the Hitachi factoryrequirements for air flow cooling and serviceability in a secure shell.The machine operator, Chris Flanagan, says, “it’s early days, but it is performing reallywell. I love the cabin layout, and it has plenty of slew power so it should be real quickwhen I get use to the new controls.”Working in NFL Golden Downs forest, Nelson, at time of the photo.Customer: StraconModel: Hitachi ZX520LCH-3Stracon has recently taken delivery of two new Hitachi ZX520LCHexcavators, which were bought to complete a large restoration job atthe Ohai coal mine. Both the Hitachi ZX520LCH excavators have a 6.3mBE boom and a 2.5m BE arm. The buckets were built by Northland SteelProducts and are of 3.1m capacity, while both machines are fitted withgreasing systems.Customer: Hollands ExcavationModel: Hitachi ZX80LCK-3Andrew Hollands, from Hollands Excavation, has recently takendelivery of a Hitachi ZX80LCK-3 with a 4m K boom and a 2.<strong>12</strong>m K arm.Hollands is based in Mosgiel, and carries the majority of his work in andaround this area. the Hollands Excavation’s partnership is comprised ofHollands, his wife Sarah and his brother.Andrew is also five-time regional winner of the Otago ExcavatorDriving Competition and came second this year in the nationals.<strong>CablePrice</strong> 51

TRACK & WHEELCustomer: Solid Energy New Zealand LtdModel: Hitachi ZX870LCH-3 & ZX470H-3Solid Energy New Zealand Limited has purchased two new excavators from<strong>CablePrice</strong>, Invercargill: a Hitachi ZX870LCH-3 and a ZX470H-3. The ZX870LCH-3 hasa 7.1m BE boom and a 2.95m BE arm. The two buckets for this machine are built byNorthland Steel Products, the coal bucket is of a 5m capacity, and the hard diggingbucket is of 4.3m capacity. This machine will predominately be used for overburdenremoval, while the ZX470H-3 will be used for coal extraction. The ZX470H-3 has a 7mH boom and a 2.9m BE arm with an NSP-built 2.1m bucket. Both machines have extrasafety guard rails, fire suppression systems, gas discharge work lights and auto lubesystems fitted. Pictured is the Hitachi ZX870LCH-3 on its first day digging coal.Customer: Douglas LoggingModel: John Deere 1910E ForwarderThe second new John Deere 1910E forwarder, sold in Northland,has gone to Douglas Logging Limited, based in Dargaville. This newunit replaces an older John Deere 1710D and will operate just north ofDargaville. The sale was made by David Smith.Customer: A H Gillespie LtdModel: John Deere 648H SkidderA H Gillespie Limited owner, Ralph Gillespie, has taken delivery of his second JohnDeere 648H grapple skidder. This will be working with his swing yarder, two-stagingdown to a processor landing. Ralph has used John Deere skidders for some years now,still talking about his old 640E and just how reliable his John Deere skidders are, as wellas productive. The skidder, although the same model, has had some big improvementsmade: among others, a new control module and an auto shift transmission, which onlong hauls can really improve cycle times and fuel consumption.A H Gillespie works in Blenheim for Nelson Forests Limited.Customer: Endurance Logging LtdModel: John Deere 648H SkidderHayden Barnes, owner of Endurance Logging Limited, Nelson, standsin front of his new John Deere 648H grapple skidder. Barnes works forNelson Forests Limited in Nelson and uses the skidder to two-stage fromhis swing yarder.When Barnes was looking around at all the options, he had one mainrequirement: the ability for the machine to be used to cable log as well asgrapple. The John Deere machine has a 4000-series winch, the same as onthe 540 cable skidder, and it has heaps of line pull and is a true cable option.The machine has great visibility and is well appointed in the cab. The autoshift is also a great new feature for the long, downhill drags.52 <strong>CablePrice</strong>