You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The elevator system consists of three main components:<br />

• Platform<br />

• Cantilever beam with wheel, slewing ring and swing gear<br />

• Guiding column<br />

• Hoisting machinery<br />

• Hydraulic system<br />

• El. control system<br />

The platform is built as an open construction with solid top plate and<br />

stiffener reinforced for the slewing ring in the centre.The outside<br />

edge of the platform is protected with hard rubber.The cantilever<br />

beam is of box construction to enable it to take bending and torsion<br />

forces.The outer end if arranged for housing the swing gear with<br />

electric motor and brake.The cantilever beam has six driving wheels<br />

fitted with double roller bearings in a completely sealed system.The<br />

axle is of stainless steel.<br />

The swing of the platform is controlled by limit switches and<br />

rubber stoppers for accurate positioning, while double lifting wires<br />

<strong>TTS</strong> <strong>Review</strong> June <strong>2003</strong> 11<br />

are connected to a lever in front of the vertical cantilever beam.<br />

The guiding column is delivered as a complete unit with rail for<br />

elevator, lifting equipment, lever for hinges, cylinder for swing,<br />

locking arrangement for column in inner position and hydraulic<br />

stopper for elevator in TD level.<br />

<strong>TTS</strong>’s contract also calls for the design and supply of:<br />

• Extension splash covers for each side door<br />

• Pontoon hatch covers arranged in the top of each side door<br />

tower to provide access to the cargo hold for FLTs<br />

• Wheel stoppers (5)<br />

• Hydraulic barriers on each deck/elevator (10)<br />

• Side-hinged bulkhead doors (3)<br />

• Top-hinged bulkhead doors (8)<br />

• Hydraulic and electrical system<br />

The lead vessel in the Spliethoff’s newbuilding series in Poland is due<br />

for delivery in 2004, followed by the remaining vessels at abt 4<br />

month intervals.The Dutch operator also has an option on a further<br />

four vessels of the same type and size.<br />

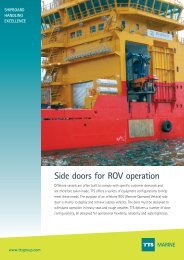

The principal of the <strong>TTS</strong> side loading system is based on the<br />

premise that the best way to load or discharge cargo is by the shortest<br />

possible path – through the ship’s side. Key benefits of side loading<br />

systems are:<br />

• Compact stowage of cargo<br />

• Low cargo damage rates<br />

• Cargo handling operations independent of tidal variations<br />

• Small demand on port facilities<br />

• Increased turnaround times in port<br />

Depending on the intended use and specified degree of automation,<br />

<strong>TTS</strong> can deliver any system perfectly adjusted to suit specific needs.

![2012.MasterPresentation_final [Compatibility Mode] - TTS Group ASA](https://img.yumpu.com/4612021/1/190x146/2012masterpresentation-final-compatibility-mode-tts-group-asa.jpg?quality=85)