eurodrives - Sew-Eurodrive

eurodrives - Sew-Eurodrive

eurodrives - Sew-Eurodrive

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

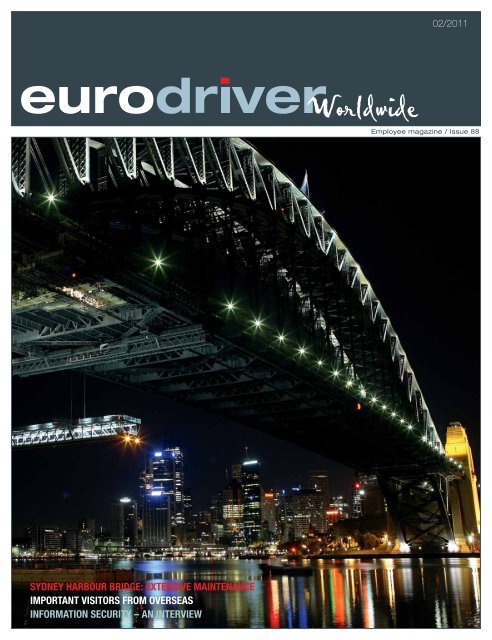

SYDNEY HARBOUR BRIDGE: EXTENSIVE MAINTENANCE<br />

IMPORTANT VISITORS FROM OVERSEAS<br />

INFORMATION SECURITY – AN INTERVIEW<br />

02/2011<br />

Employee magazine / Issue 88

Dear colleagues,<br />

There could not have been a better start to 2011, the year in<br />

which SEW-EURODRIVE celebrates its 80th anniversary, or a<br />

better birthday present to mark the occasion. Turnover in the<br />

last business year surpassed 2 billion euros, breaking the record<br />

set before the crisis – and this, against all expectations,<br />

in only the fi rst year after the crisis.<br />

This is a remarkable success, but it is one that has demanded<br />

enormous dedication from our entire team of employees in<br />

Germany and overseas, not to mention outstanding performance.<br />

This deserves appreciation and recognition and therefore,<br />

in the name of the management, I would like to take this<br />

opportunity to thank each of our colleagues sincerely. Based<br />

on the fact that the number of orders received remained above<br />

average for the fi rst half of 2011, we anticipate further growth<br />

of 10% in our anniversary year.<br />

Despite all the necessary efforts that will be required to expand<br />

our capacity and resources in order to ensure prompt<br />

delivery times and high-quality services for our customers,<br />

we must not forget that an economic slowdown is imminent,<br />

even if we cannot know exactly when this will happen. Especially<br />

when considered against the present background<br />

of global economic instability (the European debt crisis, the<br />

American budget defi cit, a slowdown in China's growth, and<br />

so on), this slowdown could happen sooner than we would<br />

like. First business climate indicators show that the situation<br />

is not alarming yet; however, if the crisis escalates in countries<br />

such as Italy, the same indicators could signal a downward<br />

trend for the European economy.<br />

Further risks of a downturn are the scarcity of resources and<br />

raw materials and the resulting increase in the cost of inputs,<br />

and a declining population in Europe, which has led to the<br />

specifi c problem of a shortage of skilled workers in Germany<br />

and Europe. The trend of a regional migration of revenue<br />

and growth from Europe towards the BRIC countries is set to<br />

continue. However, this does not represent a threat because<br />

2<br />

we are securing the continued existence of all our offi ces by<br />

building and expanding the global SEW network following a<br />

platform strategy with the goal of being as close as possible to<br />

the customer. A number of factors will determine our sustainable<br />

growth in the coming years. These are all on our agenda<br />

and covered in the “3F” corporate project (f it for future). To<br />

mention just the most important factors concerned:<br />

– Technology, innovation and cost leadership<br />

– Flexibility and adaptability for shorter economic cycles in<br />

the future with greater fl uctuations<br />

– Establishing business models and new fi elds of operation<br />

oriented towards mega trends (environment and recycling,<br />

energy effi ciency, electric mobility, system solutions, etc.)<br />

– Success in gaining market shares in the BRIC countries<br />

(Brazil, Russia, India and China)<br />

– Defending key markets, especially against Chinese competition,<br />

by expanding the product portfolio in the high volume<br />

market sector (basic sector)

Implementing the measures required by this project will inevitably<br />

result in changes and adaptive processes in our organizational<br />

structures. I am aware that it is diffi cult to convince<br />

people that change is necessary, especially in times when<br />

things are going well. It has to be clear for everyone, though,<br />

that the future is determined by change and that those who<br />

recognize this in good time and who adapt fastest will lead<br />

the way in their fi eld. We must strive to be a leader and for<br />

this we need your support, dear colleagues, because you are<br />

at the heart of our business activities and will have a decisive<br />

infl uence on the success or failure of this process of change.<br />

eurodriver EDITORIAL<br />

You have my every confi dence and I rely on your willingness<br />

to adapt so that we can remain successful while steering our<br />

SEW-EURODRIVE unerringly towards its 90th birthday. In<br />

this spirit<br />

Happy Birthday SEW-EURODRIVE<br />

Hans Sondermann<br />

SUCCESSFUL ACROSS BORDERS – THE “EURODRIVES”<br />

Customer proximity, partnership and confi dence – across any<br />

borders. The past and future of SEW is closely connected with<br />

the success of our global "<strong>Eurodrive</strong> network". Since the foundation<br />

of the fi rst assembly plant in Sweden in 1968 until the<br />

so far latest overseas production plant in Brazil in 2010, our<br />

international branches, plants and competence centers have<br />

contributed signifi cantly to our success and are the key to an<br />

economically stable future.<br />

The fi rst international assembly plant: 1968 Jonköping in Sweden One of the latest plants of SEW-EURODRIVE: 2010 Joinville in Brazil<br />

3

CONTENTS<br />

4

EDITORIAL<br />

CONTENTS<br />

IN THE FOCUS<br />

6 • Ernst Blickle Prize Ceremony<br />

LOCATION, MARKET AND WORLD<br />

10 • Sydney Harbour Bridge: Extensive Maintenance<br />

12 • Important Visitors From Overseas<br />

14 • Lean Production at SEW Italy<br />

15 • <strong>Eurodrive</strong>s Under New Management<br />

CUSTOMERS, PROJECTS AND PRODUCTS<br />

20 • SLAP – Standardized Processes Increase Effi ciency<br />

22 • Moving News From The Netherlands<br />

24 • Inductive Drive Technology for Rector Lesage<br />

26 • Industrial Gear Unit for Turbine Welding Systems<br />

27 • Imprint<br />

WORLDWIDE – EDITORIAL AND ABSTRACTS<br />

28 • French<br />

32 • Spanish<br />

36 • Portuguese<br />

40 • Chinese<br />

eurodriver CONTENTS<br />

FROM THE GROUP<br />

16 • Information Security –<br />

An Interview<br />

18 • Purchasing Departments<br />

F and GER – Working Together<br />

5

eurodriver IN THE FOCUS<br />

6

AWARD-WINNING<br />

Dr. Michael Rogowski Receives Ernst Blickle Prize<br />

At fi rst it appeared to be the same as every other time, but this time something<br />

was different. Badische Neueste Nachrichten, a regional newspaper, called it a “family<br />

gathering”, which sums up this year’s awards ceremony for the Ernst Blickle Prize rather<br />

well. It could be that this year more former award winners took part than in<br />

recent years, or that the winner was used to being at the center of attention.<br />

Nevertheless, he was visibly moved as he addressed the graduate award winners in<br />

his speech. Bottom line: It was a successful event, but let us start at the beginning.<br />

7

eurodriver IN THE FOCUS<br />

Once again, the Bruchsal castle was an<br />

excellent backdrop for the award ceremony,<br />

for the Ernst Blickle Prize. The<br />

weather was also on the bright side, paving<br />

the way for the occasion. Fortunately,<br />

there were no traffi c jams or worse.<br />

Starting right on time, Rainer Blickle<br />

welcomed the participants to this year’s<br />

award ceremony, the 15th. He has known<br />

the prize winner for at least 30 years, and<br />

their paths have crossed on many occasions,<br />

said Blickle, such as at German<br />

Employers' Association (BDA), at the<br />

Federation of German Industries (BDI)<br />

or at the German Engineering Federation<br />

(VDMA). He was especially pleased<br />

to welcome 14 out of the 15 graduate prize<br />

winners; among them one woman.<br />

In his speech, Professor Sigmar Wittig<br />

spoke of the life and career path of<br />

Rogowski. He pointed out that Rogowski<br />

had already worked on valuation and<br />

8<br />

measurement methods at an early stage<br />

of his career, and that these methods<br />

are still relevant today. His dissertation<br />

at the Technical University of Karlsruhe<br />

in 1969 was on the topic of rationalizing<br />

corporate accounting using external data<br />

management based on examples from<br />

the trades. Professor Wittig painted a<br />

very complete and personal picture of the<br />

award winner, acknowledging the phases<br />

and achievements of his life.<br />

Dr. Rogowski, clearly moved by the<br />

speech, accepted the award from Rainer<br />

Blickle. Rogowski directed his speech to<br />

the winners of the graduate student prize<br />

and gave them advice on their future professional<br />

and career paths. He advised<br />

them to let themselves be guided by solid<br />

values and to lead with responsibility –<br />

greed was a value they should not adhere<br />

to. He also advised them to be committed<br />

and dedicated; professional success is<br />

5% genius and 95% hard work, he said.<br />

It is important to fi nd the right balance<br />

between courage and taking risks. After<br />

all, every decision is connected with<br />

a risk. Dr. Rogowski suggested that the<br />

award-winning graduate students should<br />

always remain curious and authentic.<br />

Being and staying credible means following<br />

your course. Remaining true to<br />

yourself can help you to climb up a notch<br />

on the career ladder. However, Rogowski<br />

summed up “a career can’t be planned;<br />

most often, it’s a matter of coincidence<br />

and twists of fate.” In his conclusion,<br />

Rogowski thanked his wife for her years<br />

of support, critical questioning and reliability<br />

in all aspects of life.<br />

The guest speaker of the award ceremony<br />

was Dr. Nagel, board member of<br />

the Deutsche Bundesbank. Dr. Joachim<br />

Nagel, who had received a stipend from<br />

the SEW-EURODRIVE Foundation to

study in Washington D.C., gave his guest<br />

lecture on the topic of the crisis in the<br />

fi nancial markets and its management.<br />

His speech was eloquent and easy to follow,<br />

even for those who are not familiar<br />

with trends in the fi nancial markets.<br />

He described how the crisis began, pointing<br />

out what really happened to the markets,<br />

and then presented a way out of the<br />

crisis, including potential risks of consequences.<br />

One conclusion he drew was<br />

that we are not going to experience what<br />

we experienced before the crisis. “The<br />

years of plenty are irrevocably over,” said<br />

Dr. Nagel.<br />

After awarding the prizes to the graduate<br />

students, a lively discussion ensued while<br />

everybody enjoyed the excellent buffet.<br />

Later at the DriveAcademy ® , there were<br />

additional lectures and a tour of the electronics<br />

production facilities.<br />

Author: Stefan Brill / SEW Germany<br />

9

EXTENSIVE MAINTENANCE AT<br />

LOFTY HEIGHTS<br />

The Sydney Harbour Bridge connects Milson Point in Sydney to the north coast, making it a<br />

major traffi c artery in the city. It has eight traffi c lanes, two train tracks, a pedestrian walkway<br />

and a bike path. Completed in 1932, the Harbour Bridge is subject to regular inspection<br />

and maintenance so as to ensure structural safety and to preserve its outward appearance.<br />

10

For simplifying these maintenance<br />

tasks, the Harbour Bridge is equipped<br />

with numerous moving service bridges<br />

that are located under the traffic lanes<br />

and rail level – and 50 meters above the<br />

natural harbor of Port Jackson. These<br />

service bridges run on rails, giving the<br />

repair and maintenance teams safe access<br />

to areas on the underside of the<br />

bridge that would otherwise be barely<br />

accessible.<br />

While the bridge was being modernized,<br />

the New South Wales Roads and<br />

Traffic Authority decided to replace<br />

the existing pneumatic-hydraulic drive<br />

system with a state-of-the-art electric<br />

motor-driven drive system having variable<br />

speed drive (VSD). The Authority<br />

commissioned SAGE Automation,<br />

the largest, independent company for<br />

integrating automation and control<br />

systems in Australia, with integrating<br />

the system. SAGE decided to use a<br />

comprehensive solution package from<br />

SEW-EURODRIVE – the experts in<br />

drive solutions.<br />

“Our decision to use a complete drive<br />

package including motion control,<br />

VSD, geared brakemotors, encoders<br />

and HMI from SEW-EURODRIVE allowed<br />

us to significantly reduce the<br />

amount of equipment for each service<br />

bridge,” explains Robert Craig, Business<br />

Manager of SAGE Group.<br />

The biggest challenge presented by<br />

this project was in accessing the bridge<br />

itself. The majority of the drive system<br />

was not assembled at the project site,<br />

so that this difficulty could be worked<br />

out. All controls and drive components<br />

were sent to SAGE, where the control<br />

cabinets were assembled and configured<br />

before they were installed at their<br />

place of use. The geared brakemotors<br />

were installed directly on site.<br />

Not to mention that all work was carried<br />

out while the bridge was in operation.<br />

“Due to the tremendous importance as<br />

a traffic junction, it was impossible to<br />

close the Sydney Harbour Bridge completely<br />

at any time,” says Craig. “The<br />

Road and Traffic Authority’s coordinated<br />

and strategic closing of individual<br />

lanes was limited to an absolute minimum<br />

for carrying out the installation,<br />

as were the number and duration of<br />

closed lanes. Lanes were closed only<br />

to allow the correct positioning of the<br />

equipment. In this way, traffic impairments<br />

could be effectively curtailed.”<br />

For inhabitants of the city, the Sydney<br />

Harbour Bridge has been one of the<br />

most important traffic arteries for al-<br />

eurodriver LOCATION, MARKET AND WORLD<br />

most the past 80 years and is also a<br />

world-famous landmark for the city.<br />

Thanks to the updated and improved<br />

infrastructure on the hard-to-access<br />

underside of the bridge, it will be possible<br />

to inspect, maintain, paint and repair<br />

important structural elements in a<br />

simple and effective way. The bridge’s<br />

future can now be ensured for at least<br />

another 80 years.<br />

Author: Ash Vague / SEW Australia<br />

11

Tour: Philip D. Murphy<br />

eurodriver LOCATION, MARKET AND WORLD<br />

12<br />

Brazilian delegation

IMPORTANT VISITORS at the Graben Plant<br />

Twice in May, the Graben-Neudorf site welcomed important visitors. On May 17, the<br />

ambassador of the United States of America, and in the following week on May 24, a<br />

German-Brazilian delegation visited the plant.<br />

Graben-Neudorf's city council is wellconnected.<br />

Graben-Neudorf belongs to<br />

the constituency of Axel Fischer (CDU),<br />

member of the German Bundestag, who<br />

is friends with US ambassador Philip D.<br />

Murphy in Berlin. As ambassadors have<br />

to get to know the country they work in<br />

and politicians need to be present in their<br />

electoral district, visiting constituencies<br />

is common. Fischer invited ambassador<br />

Murphy to one of these tours, during<br />

which they visited SEW-EURODRIVE.<br />

Rainer Blickle welcomed the distinguished<br />

visitor, who was accompanied<br />

with nine security people in four limousines.<br />

Of course, Graben-Neudorf’s<br />

mayor, Hans D. Reinwald, and city council<br />

members were there to welcome the<br />

guests. Ambassador Murphy’s fi rst act<br />

was to sign Graben-Neudorf’s Golden<br />

Book. Following the obligatory photo<br />

session for the press, Dr. Klaiber gave the<br />

participants a quick overview on the history,<br />

the range of products and solutions,<br />

and the worldwide activities of SEW-<br />

EURODRIVE. Dr. Klaiber explained<br />

that SEW-EURODRIVE is a family-run<br />

company with strong activities abroad,<br />

including North America.<br />

Murphy thanked him very much and<br />

explained that the success of Germany<br />

was due to its fantastic medium-sized<br />

companies, such as SEW-EURODRIVE,<br />

which is a perfect example. He thanked<br />

Rainer Blickle, in particular, for his<br />

time, for the information, and for the<br />

opportunity to visit SEW. Afterwards,<br />

the ambassador took the time for a short<br />

tour of the plant. Rainer Blickle and Dr.<br />

Klaiber guided Murphy through the<br />

individual manufacturing steps, such<br />

as worm gear production. Murphy expressed<br />

his satisfaction and thanked all<br />

participants before continuing his tour,<br />

High security level Golden Book<br />

heading towards Oberderdingen to visit<br />

the Blanco plant.<br />

On May 24, the following Tuesday, Rainer<br />

Blickle and Dr. Klaiber welcomed a<br />

delegation from the German-Brazilian<br />

Society of Santa Catarina to the Graben<br />

plant. District administrator, Dr.<br />

Schnaudigel, the mayor of Karlsdorf-<br />

Neuthard, Mr. Weigt, Bruchsal’s mayor,<br />

Ms. Petzold-Schick, and the former mayor<br />

of Karlsdorf-Neuthard, Mr. Klefenz,<br />

who organized the tour, were guests of<br />

the delegation.<br />

After Rainer Blickle welcomed the delegation<br />

in Portuguese, Dr. Klaiber introduced<br />

SEW-EURODRIVE, its products<br />

and gave a detailed account of SEW’s<br />

activities in Brazil and South America.<br />

Then the participants took advantage<br />

of enjoying an interesting and insightful<br />

tour of the plant. Many discussions<br />

in German and Portuguese made for a<br />

lively exchange.<br />

Author: Stefan Brill / SEW Germany<br />

13

14<br />

Maurizio Mojoli, Managing Director SEW Italy, pointed out the importance of this implementation on the Italian<br />

production system, which was connected to radical changes to the assembly plant: up to 90% of the hardware was<br />

replaced, machines were modernized, new structures were drawn up and basic criteria were changed.<br />

The most important innovation is represented by the so-called “CELLS”, new U-shaped working areas that<br />

resemble a horse shoe. The motors are assembled on the right side, and the gear units on the left. Both<br />

components are combined at the end, which signifi cantly reduces the assembly time.<br />

Up to four qualifi ed workers are able to operate on a single cell. Each tool has been set-up in the ideal<br />

position and the pickers are able to fi nd gearmotor parts easily and quickly.<br />

LEAN PRODUCTION<br />

for Best Results<br />

Another SEW Group highlight: SEW-EURODRIVE Italy has implemented<br />

the Lean Production concept as well. One Piece<br />

Flow, job rotation and enhanced communication for all have<br />

proved to be the key for immediate success.<br />

Last but not least special software optimizes the picking process to provide the individual cells with<br />

the required materials; this is based on the assembly to order principle.<br />

The process is subject to constant analysis for further improvements. The latest innovation at the beginning<br />

of this year was the integration of the R27 gear unit assembly on the very cell that already produced<br />

R47 and R57, which reduced the assembly time by 50%. All this happened without any throughput<br />

reduction, and the 2000 hours saved are now free for other assembly functions.<br />

Lean Production not only enhances the process operation, it also improves the working environment and<br />

reduces the stress for employees.<br />

At the end the result speaks for itself: more EFFICENCY and more SUCCESS.<br />

Author: Marina Cornero / SEW Italy

South Africa<br />

Ute Bormann assumed<br />

the position of Managing<br />

Director at SEW South Africa<br />

on March 1, 2011. This<br />

is the first time that the<br />

company has had a female managing director<br />

in South Africa. Ute Bormann began her career<br />

as a marketing coordinator in 2003. Later, she<br />

went on to become head of marketing and marketing<br />

director before taking on the role of sales<br />

and marketing manager in 2006.<br />

FOUR OVERSEAS EURODRIVES<br />

under new<br />

management<br />

Malaysia<br />

Lep Ming Soh started as Managing<br />

Director in Malaysia<br />

on March 1, 2011. He began<br />

his career with SEW in 1992,<br />

starting as a sales engineer<br />

before moving on to work<br />

as product manager for IG.<br />

After an intermediate position as<br />

Country Manager at Siemens/Flender (2000<br />

to 2010), Mr. Soh returned to SEW Malaysia<br />

in his new function as Managing Director.<br />

eurodriver FROM THE GROUP<br />

Singapore<br />

Anthony Tan has been<br />

running the SEW subsidiary<br />

in Singapore<br />

since March 1, 2011. Prior<br />

to this, he was senior<br />

sales manager at Elektrim<br />

Motors, ABB, and<br />

Danfoss in the ASEAN region. From 2006<br />

to the beginning of this year, Mr. Tan was responsible<br />

for the frequency inverter division<br />

at Rockwell Automation Asia Pacific.<br />

In the last few months, there have been some changes in the<br />

management of the <strong>Eurodrive</strong>s in South Africa, Singapore, Malaysia<br />

and South Korea. <strong>Eurodrive</strong>r would like to present the<br />

colleagues concerned.<br />

South Korea<br />

At the beginning of the year, James Park took<br />

over the head position at the <strong>Eurodrive</strong> in<br />

South Korea. James Park began his career as a<br />

sales engineer 15 years ago. He subsequently<br />

worked as an application<br />

and TASC engineer before<br />

assuming the role of head<br />

of sales for SEW South<br />

Korea. After H.S. Park retired<br />

at the end of 2010,<br />

James Park became the<br />

new Managing Director.<br />

We would like to congratulate these four colleagues and wish<br />

them all the best in their new positions.<br />

15

eurodriver FROM THE GROUP<br />

ON VIRUSES, WORMS AND SPIES ...<br />

Editorial team: Mr. Haungs, what is currently<br />

your biggest challenge in the job?<br />

Mr. Haungs: That would be the rapid<br />

technological progress in mobile devices<br />

such as the iPhone, iPad, etc. – our security<br />

measures have to keep up with these<br />

changes.<br />

Ed.: What exactly do we need to protect<br />

ourselves against?<br />

H: In particular, we have to protect<br />

ourselves against the intentional and<br />

accidental leakage of confi dential and<br />

business-related company information.<br />

We have worked hard on developing our<br />

product and process know-how, and this<br />

is what ensures that we all have jobs. We<br />

are certain that attempts are being made<br />

to steal data and sell it to competitors,<br />

particularly those abroad.<br />

16<br />

Ed.: Is it possible to guarantee 100% protection?<br />

H: No, it’s not. We have a number of different<br />

technical tools available, such as<br />

encryption systems, access controls, passwords,<br />

fi rewalls and so on, but the weak<br />

est link is always the human element.<br />

The most powerful weapon for battling<br />

industrial espionage is a knowledgeable<br />

and attentive team of SEW employees.<br />

Ed.: What does that mean?<br />

H: It means that SEW employees should<br />

be on the lookout for anything unusual.<br />

They should not pass on business in-<br />

It is important to make all SEW<br />

employees aware of issues<br />

concerning information security<br />

and to remind them of the<br />

importance of following our<br />

security policy on a regular basis.<br />

For this reason, the EURO-<br />

DRIVER editorial team spoke to<br />

Bernhard Haungs, who is responsible<br />

for information security<br />

at SEW-EURODRIVE.<br />

formation to unauthorized persons, not<br />

open suspicious e-mails, wear their SEW<br />

ID card openly, dispose of confi dential<br />

documents in the shredder and not in<br />

the trash, not pass on PIN numbers and<br />

passwords, and they should also pay attention<br />

to what happens around them.<br />

“In 2010, 253,000 viruses, worms, Trojan horses and undesirable<br />

software were discovered on 8,200 SEW IT systems<br />

(PCs, notebooks, servers) in SEW country organizations”<br />

Ed.: Monitor their colleagues?<br />

H: No, not at all monitor. But they can<br />

offer help and advice if they notice that<br />

confi dential data is being handled with<br />

insuffi cient care.

Ed.: Is “Information security” simply protecting<br />

against industrial espionage?<br />

H: No – in addition to maintaining<br />

confi dentiality, the availability of the IT<br />

systems is extremely important. When<br />

networks, applications and servers malfunction,<br />

it immediately causes more<br />

extensive damage, since almost all processes<br />

in the company are supported by<br />

IT. This is why we are aiming for 100%<br />

availability.<br />

Ed.: How can that be achieved?<br />

H: “Redundancy” and “change management”<br />

are the key factors. As far as possible,<br />

all business-critical IT systems are<br />

laid out redundantly. Changes to the pro-<br />

gram code or to technical components<br />

can only be carried out once a test has<br />

ensured that they are “compatible” with<br />

other systems and functions.<br />

Ed.: So, SEW employees cannot directly<br />

contribute to ensuring “availability”?<br />

H: Yes they can! The network is jeopardized<br />

whenever unauthorized software is<br />

run on individual PCs or notebooks, for<br />

example, or if viruses enter the system<br />

via mobile data storage devices (e.g. USB<br />

sticks/fl ash drives). Many viruses are programmed<br />

to make systems malfunction<br />

rather than to steal data; this is called a<br />

“denial-of-service attack” in IT jargon.<br />

Ed.: These issues must affect every company<br />

– are there standard procedures for<br />

this?<br />

H: Yes, the ISO 27001 standard for information<br />

security; SEW-EURODRIVE<br />

has held this certifi cation in Germany<br />

and France since 2006. This means that<br />

information security is established as a<br />

management process, with around three<br />

employees working at it constantly.<br />

Ed.: For SEW in Germany?<br />

H: Not only in Germany: we have been<br />

offering consultation to the <strong>Eurodrive</strong>s<br />

regarding security matters and helping<br />

them implement the appropriate measures.<br />

“In 2010, SEW received 12.5 million e-mails,<br />

9.5 million of which were SPAM”<br />

Ed.: So we are well organized in terms of<br />

data protection?<br />

H: “Data protection” is something else –<br />

it’s a common mistake. Information security<br />

– that is, data security – ensures<br />

the availability of data and systems,<br />

whereas data protection is the protection<br />

of the personal rights of a company’s employees.<br />

It’s inevitable that these terms<br />

are mixed up; the term “privacy”, which<br />

is used more often in English, may make<br />

more sense.<br />

Ed.: Thank you, Mr. Haungs, for sharing<br />

this information with us. Is there<br />

anything else you would like to add?<br />

“1,300 notebooks<br />

used within SEW are<br />

encrypted”<br />

H: It’s important to mention that according<br />

to the security policy, which the<br />

management established in 2004, every<br />

employee – and in particular every manager<br />

– is responsible for taking security<br />

measures. There is no higher-level body<br />

that can judge the criticality of all data;<br />

SEW-EURODRIVE is simply too big and<br />

complex. However, my team and I are always<br />

ready to provide technical consultation<br />

should anyone require it.<br />

“Social engineering”<br />

describes the process of deceiving authorized users of an information and communication<br />

system into sharing sensitive or confi dential data (e.g. password or<br />

user authorizations) by providing a false identity or other fraudulent information.<br />

The attacker can then use this information to hack the system or pass on data<br />

from the system immediately without authorization.<br />

17

“WE’RE STRONGER WHEN WE<br />

WORK TOGETHER!”<br />

From 24-25 March 2011, the DriveAcademy ® hosted a workshop with the theme,<br />

“we’re stronger when we work together”, to which, for the first time, all<br />

purchasing representatives from France and Germany were invited. The<br />

focus of the workshop was on getting to know each other better, resolving<br />

any cultural obstacles, and intensifying cooperation despite the distance.<br />

The right amount of curiosity and the capacity<br />

to understand others are essential ingredients<br />

for achieving synergy effects in multicultural<br />

collaborations. Synergy effects are a<br />

creative potential for the joint development<br />

of innovative ideas, while cross-cultural<br />

competence is also crucial to the success of<br />

international purchasing activities. Developing<br />

in this way was the challenge facing the<br />

participants over the two days of the workshop.<br />

18<br />

The themes “close cooperation” and “joint<br />

action” between the purchasing organizations<br />

were also discussed, with the aim of<br />

strengthening the market position with<br />

the suppliers. Here, willingness for international<br />

collaboration and interpersonal<br />

communication beyond cultural borders is<br />

required; only this way it is possible to position<br />

oneself, with all the necessary opportunities<br />

and risks, when it comes to globalization.<br />

Role plays in mixed working groups<br />

provided a starting point.

Despite a few small linguistic hurdles, participants<br />

of the workshop were able to form<br />

a solid foundation of trust through team<br />

work and tasks over the two days. “It was<br />

great that we could help develop solutions”,<br />

said one participant, “we are all highly motivated!”<br />

Another participant praised the great<br />

sense of community. The intensive activities<br />

during the workshop resulted in an essential<br />

understanding of the others’ behavior, and<br />

any issues were immediately resolved. At the<br />

end of the workshop, a list of measures was<br />

eurodriver FROM THE GROUP<br />

drawn up and their implementation sorted<br />

according to priority. The first measures<br />

have already been initiated or have already<br />

been put in place.<br />

All participants agreed that the event was a<br />

resounding success and are looking forward<br />

to seeing each other next time!<br />

Author: Bernd Kohring / SEW Germany<br />

19

In 2009, we carried out a benchmark* study within the<br />

European logistics and assembly strategy in the European<br />

<strong>Eurodrive</strong> plants. This formed the basis for the SLAP project.<br />

Based on this study, we determined that in relation to the<br />

sizes of the <strong>Eurodrive</strong>s, there were substantial differences<br />

in the administrative work required for supporting operative<br />

processes. The differences are in part due to local circumstances,<br />

but we recognized a significant potential for<br />

increasing efficiency.<br />

20<br />

L A<br />

STANDARDIZED PROCESSES<br />

INCREASE EFFICIENCY<br />

SLAP – Standardize administrative Logistic and Assembly Processes<br />

in European <strong>Eurodrive</strong>s<br />

In the subsequent analysis, we also discovered that the level<br />

of utilization of IT systems in the individual <strong>Eurodrive</strong>s differed<br />

greatly. Even existing “best practice” processes were<br />

not being implemented in all sites.<br />

After doing a cost/benefit analysis, we launched the SLAP<br />

project with the goal of realizing the efficiency potential that<br />

had been identified. This was to be accomplished by standardizing<br />

business processes as well as by optimally reproducing<br />

these new standards in the IT system environment.

In December 2009, one of the first<br />

workshops was held with participants<br />

from core teams from <strong>Eurodrive</strong>s in<br />

Finland, Italy, the Netherlands, Poland,<br />

and Spain. The entire administrative<br />

logistics and assembly process was split<br />

into the following four sub-processes,<br />

for which the appropriate standards<br />

were defined:<br />

– Receiving process<br />

– Order picking process for assembly<br />

– Assembly documents & capacity<br />

planning<br />

– Packaging & shipping processes<br />

In 2010, we added more details to<br />

the standards that had been defined,<br />

and then we consulted with the twelve<br />

<strong>Eurodrive</strong> plants that were affected.<br />

During the definition phase, we discovered<br />

points of intersection between the<br />

DriveTag and VARIOLUTION ® projects.<br />

The requirements that these two projects<br />

place on the logistics processes in<br />

the <strong>Eurodrive</strong>s were integrated into the<br />

SLAP going live Team & <strong>Eurodrive</strong> Experts:<br />

SEW BE, ES, FI, IT, NL, PL<br />

SLAP standards in collaboration with<br />

the respective project leaders. This synergy<br />

effect means that with the launch of<br />

SLAP, the DriveTag and VARIOLUTION ®<br />

functions necessary for logistics are also<br />

available for each <strong>Eurodrive</strong> plant. By the<br />

end of 2010, after completing the definition<br />

phase and creating the IT concept,<br />

the processes were implemented<br />

within the new SAP ERP environment<br />

on the basis of the newest techniques.<br />

In early April, the first system went live<br />

at SEW Poland. By the end of November<br />

2011, the roll-out will take place in the<br />

other eleven European <strong>Eurodrive</strong>s using<br />

SAP. At the EURODRIVER’s editorial<br />

deadline, the processes were successfully<br />

implemented in four additional<br />

<strong>Eurodrive</strong>s (the Netherlands, Finland,<br />

Sweden, and Spain). The estimated<br />

efficiency improvements have been<br />

verified in practice.<br />

It has already become apparent that the<br />

processes defined in the SLAP project<br />

and the related IT system functions can<br />

eurodriver CUSTOMERS, PROJECTS AND PRODUCTS<br />

*BENCHMARK STUDY<br />

denotes a comparative analysis with a<br />

defi ned reference value.<br />

Process Benchmarking compares the processes<br />

within companies during internal<br />

benchmarking as well as the involved<br />

companies through external benchmarking.<br />

The results are then analyzed, and<br />

the processes are subsequently optimized.<br />

be used as the basis for future optimization<br />

projects in countries outside of<br />

Europe.<br />

Even though the project has not yet<br />

been completed, the SLAP project<br />

team would like to take the opportunity<br />

to thank all parties concerned for<br />

their assistance. With the successful<br />

conclusion of the project at the end of<br />

this year, the European logistics and<br />

assembly network will once again have<br />

moved a significant step ahead.<br />

Author: Robbert Molendijk / SEW Germany<br />

SLAP going live Team & <strong>Eurodrive</strong> Experts:<br />

SEW AT, DK, NO, PT, SE, UK<br />

21

eurodriver CUSTOMERS, PROJECTS AND PRODUCTS<br />

22<br />

MOVING NEWS FROM THE NETHERLANDS<br />

MUSICAL SUCCESS THANKS TO<br />

SEW DRIVE TECHNOLOGY<br />

The Dutch musical Soldier of Orange is based on the true experiences of one of the<br />

country’s greatest resistance fi ghters, Erik Hazelhoff Roelfzema. What is more, the<br />

play is being performed in one of the most unusual theaters in the Netherlands, an<br />

aircraft hangar between 60 and 70 m in length, situated at the former Valkenburg air<br />

force base between Wassenaar, Katwijk and Leiden.<br />

There is no other auditorium like it. It rotates 360 degrees with the audience, moving<br />

up to 1,100 people from one scene to the next. It weighs 225 metric tons, and the<br />

revolving base has a diameter of 33 m. Twenty SEW-EURODRIVE helical-worm gear<br />

units drive the rotary base and fi ve MOVIDRIVE ® frequency inverters control a cluster<br />

of four motors each.<br />

Audiences of this theater production have responded very enthusiastically. Our drive technology,<br />

meanwhile, continues to make a silent contribution to the musical’s success.<br />

Source: M-Xposure Marc Vreenegoor

Source: Productie Soldaat van Oranje<br />

365 DAYS OF ENERGY<br />

FOR CANCER SUFFERERS<br />

SEW-EURODRIVE Netherlands is supporting<br />

the Wheel of Energy, a striking<br />

treadmill that has been erected in front<br />

of the main entrance to Amsterdam Airport<br />

on Schiphol Plaza. In this location,<br />

it captures the attention of hundreds of<br />

thousands of travelers. Using the wheel,<br />

which has a diameter of 7 m and a width<br />

of 3 m, Foundation Marathon365 hopes<br />

to contribute to making this world one<br />

in which cancer is no longer a life-threatening<br />

illness. The initiative strives to<br />

increase public awareness and sensitivity<br />

towards people suffering from cancer<br />

and to give hope to them and their<br />

families.<br />

The wheel converts muscle power into<br />

electrical energy via a dynamo installed<br />

on the axle. This is the fi rst dynamo in<br />

the world to be driven continuously by<br />

man power alone over 365 days. SEW-<br />

EURODRIVE Netherlands supported the<br />

client’s engineering project and supplied<br />

a number of drive components.<br />

Author: Louis Duijser / SEW Netherlands<br />

23

INDUCTIVE DRIVE TECHNOLOGY<br />

IMPROVES EFFICIENCY<br />

in Rector Lesage’s Plant for Pre-Cast Concrete Components<br />

24 36

MOVITRANS<br />

Rector Lesage is one of France’s leading<br />

manufacturers of pre-stressed concrete<br />

components. The company has about<br />

800 employees working at its 20 sites.<br />

At the Weyersheim plant in Alsace,<br />

the company produces pre-fabricated<br />

concrete ceilings. Vollert Anlagenbau<br />

(Weinsberg/Germany) supplied the pallet<br />

conveyor system for the Weyersheim<br />

site. As the plant was being modernized,<br />

Vollert received the contract to modify<br />

the loading equipment for finished and<br />

pre-picked concrete components at the<br />

plant.<br />

Between four and six components, with<br />

a total weight of up to 24 tons, are assembled<br />

on a support frame. A run-off<br />

lifting carriage transports the concrete<br />

components out of the factory building<br />

and places them in the correct position<br />

on 50-meter long double-T tracks<br />

at a height of 50 centimeters. A forklift<br />

picks up the components and loads<br />

them on a truck.<br />

Through the modernization of the plant<br />

and implementation of the run-off lifting<br />

carriage, Rector Lesage intended<br />

to make work processes more efficient<br />

and reduce operational costs at the site.<br />

Normally, trailing cables or conductor<br />

rails are used for the power supply.<br />

However, there is a drawback in using<br />

them, as from time to time the sliding<br />

contacts or worn-out lines need to be<br />

replaced. With this kind of machinery,<br />

components such as motor-driven cable<br />

reels carrying reeled-up power and data<br />

cables are especially prone to malfunction.<br />

One alternative would have been<br />

to use a battery-operated carriage. However,<br />

outages may occur when the bat-<br />

tery simply fails, such as in cold winters.<br />

Moreover, high follow-up costs<br />

arise because the battery needs to be<br />

replaced every five to six years. The running<br />

costs are very high with both of<br />

these conventional technologies.<br />

Vollert developed a solution, in close<br />

collaboration with their customer,<br />

where the energy transfer to the run-off<br />

lifting carriage is based on our inductive<br />

MOVITRANS ® system. The electromagnetic<br />

connection is made across an<br />

air gap. It is not subject to wear; making<br />

it maintenance-free, and it is resistant<br />

to dirt. Using a mobile voltage supply,<br />

MOVIDRIVE ® moves a 4 kW SEW<br />

gearmotor for the forward and back-<br />

eurodriver CUSTOMERS, PROJECTS AND PRODUCTS<br />

ward movement and two 2.2 kW hydraulic<br />

pumps, which lift and lower the<br />

load. The run-off lifting carriage uses a<br />

S7 control system from Siemens, which<br />

was installed by Unitechnik (Wiehl/<br />

Germany), a control system specialist.<br />

The plant technicians use wireless controls<br />

to operate the run-off lifting carriage.<br />

Vollert’s next project will be to do a<br />

similar modernization of Rector Lesage's<br />

plant in Nantes, France. However,<br />

the solution for Nantes will include automatic<br />

operation. The run-off lifting<br />

carriage will be controlled wirelessly,<br />

transferring the data from a computer<br />

to the carriage using the DATAEAGLE<br />

and PROFIsafe systems “The use of an<br />

inductive energy supply in the pre-cast<br />

concrete industry is groundbreaking.<br />

This helps us increase our system availability<br />

and reduce maintenance costs at<br />

the same time,” explains Francis Brogle,<br />

project manager of Rector Lesage. Manufacturers<br />

already using this technique<br />

confirm that plant maintenance costs<br />

can be reduced by up to 80%; whereby,<br />

in many cases a return on investment<br />

(ROI) can be achieved in a short time.<br />

Due to the good collaboration between<br />

SEW-EURODRIVE and SEW-USOCOME /<br />

Haguenau, this project was successfully<br />

implemented. The system was taken into<br />

operation by colleagues of USOCOME.<br />

Author: Steve Geiger / SEW Germany<br />

25

eurodriver CUSTOMERS, PROJECTS AND PRODUCTS<br />

INDUSTRIAL GEAR UNIT FOR<br />

TURBINE WELDING SYSTEMS<br />

Turning with power and precision

Power plants use turbines in order to meet the global energy<br />

demand. On these systems, the quality of the welded connections<br />

in particular has to meet rigorous standards. Deuma, a<br />

custom machine manufacturer based in the Siegerland region<br />

of Germany, specializes in welding equipment. The company<br />

places its trust in reliable and precise drive technology from<br />

SEW-EURODRIVE.<br />

Deuzer Maschinenfabrik (Deuma) is an international leader in the construction<br />

of machines and devices for welding operations and welding robot systems. The<br />

company received an order for turbine welding equipment from China. Their<br />

cooperation partner ESAB contributed to production by manufacturing the portal.<br />

Deuma manufactured the rotator device while SEW-EURODRIVE delivered<br />

the complete drive technology.<br />

The turbine rotors are first pre-welded before being completely attached, which<br />

happens through a process of submerged arc welding. Since this procedure<br />

occurs with the turbine in a horizontal position, it requires a portal with two<br />

frames to support the turbine and a rotator device. The rotors to be welded have<br />

different shaft diameters, so it is necessary to adjust the height. The technical<br />

challenge posed by this solution is that the rotors must lie in a perfectly horizontal<br />

position while also allowing for adjustments. Each of the two support<br />

frames can carry 200 tons. The third fastening element for the turbines – the<br />

positioner – does not bear a load, but it is designed to withstand tensile forces<br />

in an axial direction. The drive machinery has to be positioned so that its center<br />

of rotation is exactly at the center of the rotor’s axis of rotation. This is why<br />

the shaft of the welding equipment is flexibly suspended over a cardan shaft.<br />

At the end of the shaft is the slewing drive, an industrial gear unit from SEW-<br />

EURODRIVE. This is a PHF042/T planetary gear unit with a torque arm and a<br />

KF107 bevel-helical gear unit with a DRL132 AC motor at the front.<br />

“It must be possible to lift and move the turbine with a load of 400 tons. This<br />

is why, here too, we selected drive solutions from SEW-EURODRIVE,” explains<br />

Dr. Gerhard Honig, CEO of Deuma. The positioning drives are mounted on the<br />

same side as the support frames. These are parallel shaft helical gearmotors<br />

from SEW-EURODRIVE. For the welding work, the turbine also has to be adjusted<br />

with precision in a horizontal direction. This is why it is possible to slide<br />

the entire support frame on rails. SEW-EURODRIVE type FAZ77 drives with<br />

DR63L4 standard gearmotors connected upstream function as travel drives. The<br />

gearmotors are controlled by SEW frequency inverters of the MOVIDRIVE ®<br />

MDX61B series.<br />

Author: Gunthart Mau / SEW Germany<br />

Imprint<br />

Publisher:<br />

SEW-EURODRIVE GmbH & Co KG<br />

Ernst-Blickle-Str. 42,<br />

76646 Bruchsal, Germany<br />

Phone +49 7251 75-0<br />

Fax +49 7251 75-1970<br />

www.sew-eurodrive.com<br />

sew@sew-eurodrive.com<br />

Founded on September 23, 1988<br />

under the patronage of Edeltraut Blickle †<br />

This edition was compiled by:<br />

Rainer Blickle, Andrea Balser, Wilma<br />

Berweiler, Stefan Brill, Marina Cornero,<br />

Louis Duijser, Steve Geiger, Bernhard<br />

Haungs, Bernd Kohring, Gunthart Mau,<br />

Robbert Molendijk, Harald Sälzler,<br />

Hans Sondermann, Ash Vague, René Will.<br />

Editorial journalist:<br />

MECM, Bruchsal<br />

Contact person: Stefan Brill<br />

Realization, design and printing:<br />

MECP, MECV<br />

Editorial deadline for<br />

edition no. 89 / edition no. 90:<br />

31 October 2011 / 29 February 2012<br />

Suggested topics for<br />

edition no. 90 / edition no. 91:<br />

5 January 2012 / 4 May 2012<br />

27

Chers collaboratrices et chers collaborateurs,<br />

Pouvions-nous espérer un meilleur démarrage pour le jubilé<br />

2011, un plus beau cadeau d’anniversaire pour les 80 ans<br />

d’existence du groupe SEW ? Contre toute attente, nous avons<br />

clôturé l’exercice 2010 en franchissant la barre des deux milliards<br />

de chiffre d’affaires ; en dépassant le niveau record<br />

d’avant la crise, et ce dès la première année post-crise.<br />

Un succès remarquable qui a nécessité l’investissement et<br />

l’implication maximale de tous les collaborateurs en Allemagne,<br />

mais aussi dans toutes les fi liales du groupe SEW à<br />

travers le monde. A toutes et à tous, je tiens à exprimer ici et<br />

au nom du conseil d’administration, notre profonde estime et<br />

notre reconnaissance.<br />

La projection du niveau d’entrée de commandes hors pair que<br />

nous avons connu jusqu’à fi n juin 2011 laisse entrevoir une<br />

croissance de 10 % pour cette année-anniversaire. Mais il ne<br />

faut pas que l’augmentation de nos capacités et ressources,<br />

consentie pour garantir à nos clients le respect des délais et le<br />

standard de qualité de nos prestations, nous fasse perdre de<br />

vue l’imminence d’un ralentissement de la conjoncture, dont<br />

nous ne pouvons cependant prévoir la date. Du fait de l’instabilité<br />

actuelle de l’environnement économique mondial (crise<br />

fi nancière européenne, budget des Etats-Unis, affaiblissement<br />

de la croissance en Chine, etc.), ce ralentissement pourrait<br />

intervenir beaucoup plus vite que nous le pensons. Bien<br />

qu’ils ne soient pas encore alarmants, les premiers signes de<br />

morosité sont pourtant apparus. Une propagation de la crise<br />

à des pays comme par exemple l’Italie, pourrait amplifi er la<br />

dynamique négative en Europe.<br />

La pénurie de matériaux et de matières premières, et donc la<br />

hausse des coûts d’approvisionnement qui en découle, ainsi<br />

que l’érosion démographique, et notamment le manque de<br />

personnel qualifi é en Allemagne et en Europe, sont autant de<br />

déclencheurs d’un ralentissement conjoncturel.<br />

La tendance au transfert géographique du chiffre d’affaires<br />

et de la croissance de l’Europe vers les pays de la zone BRIC<br />

va se poursuivre. Pour nous, ce scénario ne constitue pas une<br />

menace puisque l’implantation et l’extension de notre réseau<br />

SEW global, basé sur une stratégie de plate-forme pour être<br />

28<br />

au plus près du client, garantit la pérennité et l’existence de<br />

tous les sites.<br />

Dans les prochaines années les facteurs suivants seront décisifs<br />

pour une croissance durable. Ils fi gurent d’ailleurs sur<br />

notre plan d’action et sont déclinés dans notre projet d’entreprise<br />

« 3F » (f it for future). Parmi les plus importants on notera :<br />

– Le leadership en matière de technologie, d’innovation et de<br />

coûts<br />

– La fl exibilité et l’adaptabilité aux cycles économiques de demain,<br />

qui seront plus courts, avec des marges de fl uctuation<br />

plus importantes<br />

– L’élaboration de modèles économiques et la création de domaines<br />

d’activité axés sur les tendances majeures (environnement<br />

/ recyclage, effi cacité énergétique, électromobilité,<br />

solutions système, etc.)<br />

– La prise de parts de marchés dans les pays de la zone BRIC<br />

(Brésil, Russie, Inde, Chine)<br />

– La défense de nos parts sur les marchés traditionnels, en<br />

particulier face à la concurrence chinoise, grâce à l’extension<br />

de notre palette de produits pour les segments de marché<br />

à fort volume (gammes Basic).

Pour réussir à transposer les mesures défi nies dans ce projet<br />

il nous faudra forcément modifi er et adapter nos structures<br />

organisationnelles.<br />

Je sais qu’il est diffi cile de convaincre que le changement est<br />

nécessaire, en particulier dans les périodes où tout va pour<br />

le mieux. Mais tous ensemble, nous devons cependant nous<br />

rendre à l’évidence que l’avenir est fait de changement et que<br />

celui qui en perçoit la nécessité suffi samment en amont et<br />

qui s’y prépare, se positionnera en leader. C’est précisément<br />

cet objectif-là que nous visons. Pour y parvenir, nous avons<br />

besoin de vous, chères collaboratrices et chers collaborateurs,<br />

car c’est vous qui êtes au cœur de notre action entrepreneu-<br />

UNE RÉUSSITE SANS FRONTIÈRES – LES « EURODRIVES »<br />

Proximité avec les clients, partenariat et confi ance – au-delà<br />

des frontières. Le passé et le futur de SEW sont étroitement<br />

liés à la réussite de notre « réseau <strong>Eurodrive</strong> » global. Depuis<br />

la création de la première usine de montage en Suède en<br />

1968 jusqu’au lancement de notre dernier site de production<br />

riale et c’est vous qui déterminerez la réussite ou l’échec des<br />

processus de changement.<br />

Vous avez toute ma confi ance, et je compte sur votre volonté<br />

d’évoluer pour propulser notre entreprise sans hésitation et<br />

avec succès jusqu’à son 90è anniversaire.<br />

Joyeux anniversaire SEW-EURODRIVE<br />

Hans Sondermann<br />

eurodriver<br />

d'outre-mer au Brésil en 2010, nos fi liales, nos usines et nos<br />

centres de compétences internationaux ont considérablement<br />

contribué à la réussite et sont les garants d’un avenir économique<br />

stable.<br />

La première usine de montage à l’étranger : 1968, Jonköping en Suède L’une des dernières usines de SEW-EURODRIVE : 2010, Joinville au Brésil<br />

29

30<br />

Remise de prix<br />

Le prix Ernst Blickle attribué au docteur Michael Rogowski<br />

Une fois de plus, le château de Bruchsal a servi de cadre pour la remise du prix Ernst Blickle de<br />

100. 000 euros, dotation à une personne parmi les plus élevées en Europe. M. Blickle a ainsi<br />

réuni tous les participants à cette 15è édition. Lors de la remise du prix, il a souligné connaître<br />

personnellement le lauréat depuis 30 ans au moins. En effet, leurs routes se sont croisées à<br />

de multiples occasions, au cours de rencontres dans les instances patronales, au BDI ou au<br />

VDMA. M. Blickle était particulièrement heureux d’accueillir 14 sur les 15 diplômés.<br />

Prix de l’ingénierie de<br />

l’environnement du<br />

Bade-Wurtemberg 2011<br />

Mercredi le 6 juillet 2011, SEW-EURO-<br />

DRIVE s’est vu décerner la deuxième<br />

place dans la catégorie « Effi cacité énergétique<br />

» et la troisième place dans la<br />

catégorie « Technologie de mesure, de pilotage<br />

et de régulation » lors de la cérémonie<br />

de remise des prix de l’ingénierie de<br />

l’environnement du Bade-Wurtemberg.<br />

Dans la catégorie « Effi cacité énergétique<br />

», c’est le système d’accumulation<br />

d’énergie à courte durée pour applications<br />

industrielles qui a permis à SEW<br />

de se hisser à la deuxième place. Dans<br />

la catégorie « Technologie de mesure, de<br />

pilotage et de régulation », l’unité d’entraînement<br />

mécatronique décentralisée<br />

MOVIGEAR ® nous a propulsés à la troisième<br />

place.

« Plus forts tous ensemble »<br />

C’est la devise choisie pour le séminaire<br />

qui s’est déroulé du 24 au 25.03.2011 à la<br />

DriveAcademy ® où étaient réunis pour<br />

la première fois tous les acheteurs et une<br />

acheteuse de France et d’Allemagne.<br />

Apprendre à mieux se connaître, surmonter<br />

rapidement les éventuelles barrières<br />

interculturelles et intensifi er la coopération<br />

malgré l’éloignement géographique<br />

sont parmi les objectifs premiers de ce<br />

séminaire.<br />

SLAP – « Standardize administrative Logistic and Assembly<br />

Processes » dans les <strong>Eurodrive</strong>s européens<br />

Le point de départ du projet fut une étude Benchmark en<br />

2009 auprès des sites <strong>Eurodrive</strong> européens, dans le cadre de<br />

la stratégie de logistique et de montage Europe. Cette étude a<br />

notamment démontré les importantes divergences au niveau<br />

des tâches administratives supports aux processus opération-<br />

En effet, être curieux afi n de comprendre<br />

les faits et gestes des autres permet d’utiliser<br />

effi cacement les synergies existantes<br />

de la coopération multiculturelle. Elles<br />

sont la base d'un fort potentiel pour le développement<br />

commun d’idées innovantes.<br />

La compétence interculturelle est également<br />

un facteur de réussite primordial<br />

dans le cadre des achats internationaux.<br />

Les deux journées de séminaires ont permis<br />

d’aborder et d’approfondir successivement<br />

tous ces points.<br />

eurodriver<br />

Des processus standardisés pour améliorer l’effi cacité<br />

nels. Ces différences sont dues en partie à des spécifi cités<br />

locales, mais des potentiels d’amélioration signifi catifs ont<br />

néanmoins été décelés.<br />

Une autre étape de l’analyse a permis de démontrer que le<br />

niveau d’utilisation des services informatiques varie énormément<br />

dans les différents <strong>Eurodrive</strong>. Certains processus « Best<br />

Practice » n’ont en effet pas été mis en place sur tous les sites.<br />

31

Estimados empleados:<br />

No podría haber habido un mejor inicio del año de aniversario<br />

2011, ni un mejor regalo de cumpleaños para los 80 años de<br />

SEW. El pasado año económico, el volumen de negocio ha superado<br />

la marca de los dos mil millones, superando el nivel<br />

record antes de la crisis; y esto en contra de todas las previsiones<br />

para el primer año después de la crisis.<br />

Un notable éxito, que también ha requerido un gran nivel de<br />

compromiso y máxima efi ciencia por parte de todo el personal,<br />

tanto dentro como fuera de nuestras fronteras, lo que merece<br />

nuestro reconocimiento y consideración, y por lo que les<br />

doy las gracias a todos los empleados en nombre de la junta<br />

directiva. En vista del desproporcionado número de pedidos<br />

que hemos recibido hasta fi nales de junio de 2011, puede deducirse<br />

y anticiparse un crecimiento de un 10% más para este<br />

año de aniversario.<br />

Junto a los esfuerzos necesarios para garantizar tanto los<br />

tiempos de entrega como la calidad de nuestros servicios en<br />

lo relacionado con los clientes por medio de la ampliación de<br />

nuestra capacidad y nuestros recursos, no debemos perder de<br />

vista que, aunque no sabemos el momento exacto, nos espera<br />

una ralentización de la economía. A la vista de la inestabilidad<br />

de la economía mundial (crisis de la deuda europea,<br />

presupuesto estadounidense, ralentización del crecimiento<br />

en China, etc.), esta podría producirse antes de lo que nos<br />

gustaría. Ya se divisan nubarrones en el horizonte, que no<br />

son preocupantes todavía, pero que en el caso de que la crisis<br />

se propague a otros países, como por ejemplo Italia, podrían<br />

hacer entrar a Europa en una dinámica negativa.<br />

Otras amenazas que podrían llevar a una recesión económica<br />

vienen dadas por los temas de escasez de materias primas y<br />

recursos, y el consiguiente aumento de los costes de los materiales,<br />

así como por aspectos negativos del desarrollo demográfi<br />

co, en este caso sobre todo la falta de mano de obra especializada<br />

en Alemania y Europa. La tendencia de transferir el<br />

volumen de negocio y el crecimiento desde Europa hacia los<br />

países BRIC continuará. Esto no supone por supuesto ninguna<br />

amenaza, porque el desarrollo y la expansión de nuestra<br />

red global SEW basada en estrategias de plataforma, con el<br />

32<br />

objetivo de estar lo más cerca posible del cliente, garantizan<br />

la continuidad y la permanencia de todas nuestras sedes.<br />

En los próximos años, los siguientes factores serán decisivos<br />

para un crecimiento sostenido. Todos ellos están en nuestra<br />

agenda, y se tratarán en el proyecto empresarial «3F» (f it for<br />

future). Lo siguiente es un extracto de los más importantes:<br />

– liderazgo en tecnología, innovación y costes;<br />

– fl exibilidad y capacidad de adaptación a los ciclos económicos<br />

futuros, más cortos y con márgenes de fl uctuación<br />

más amplios;<br />

– establecimiento de modelos y áreas de negocio orientados<br />

a las megatendencias (medioambiente/reciclaje, efi ciencia<br />

energética, electromovilidad, negocio sistemático, etc.);<br />

– obtención de una cuota de mercado en los países BRIC<br />

(Brasil, Rusia, India, China);<br />

– defensa de los mercados clave, especialmente contra la<br />

competencia china a través de una ampliación de la cartera<br />

de productos para los segmentos de mercado de gran volumen<br />

(área Basic).

La implantación de las medidas contempladas en este proyecto<br />

tendrá obligatoriamente como consecuencia cambios y<br />

reajustes en nuestra estructura organizativa. Soy consciente<br />

de que cuando las cosas van bien es difícil convencer a las personas<br />

de que hay que realizar cambios. Pero todos nosotros<br />

debemos tener claro que el futuro viene defi nido por los cambios,<br />

y que aquellos que los reconozcan de antemano y más<br />

rápidamente se adapten a los mismos serán los que ocuparán<br />

los primeros puestos. Exactamente esta es nuestra pretensión,<br />

y para ello les necesitamos a ustedes, estimados empleados,<br />

porque ustedes constituyen el centro de nuestra actividad<br />

UN ÉXITO SIN LÍMITES: LOS «EURODRIVES»<br />

La orientación al cliente, la colaboración y la confi anza superan<br />

todas las fronteras. La historia y el futuro de SEW están<br />

estrechamente ligados al éxito de nuestra «Red <strong>Eurodrive</strong>»<br />

global. Desde la fundación de la primera planta de montaje<br />

en Suecia en 1968 hasta la puesta en marcha de la que de<br />

empresarial, e infl uyen de forma decisiva en el éxito o el<br />

fracaso de los procesos de cambio.<br />

Confío en ustedes y en su buena disposición a la hora de<br />

afrontar cambios para que podamos conducir SEW de forma<br />

certera y con éxito hasta su 90 cumpleaños. Teniendo todo<br />

esto presente:<br />

Feliz cumpleaños, SEW-EURODRIVE<br />

Hans Sondermann<br />

eurodriver<br />

momento constituye la planta de producción de ultramar más<br />

nueva en Brasil en 2010, nuestras sedes, nuestras fábricas y<br />

nuestros centros de competencia internacionales han contribuido<br />

decisivamente a conseguir el éxito y son garantes de un<br />

futuro económicamente estable.<br />

La primera planta de montaje en el extranjero: 1968, Jonköping en Suecia Una de las plantas más recientes de SEW-EURODRIVE: 2010, Joinville en Brasil<br />

33

34<br />

Máxima excelencia<br />

Dr. Michael Rogowski galardonado con el premio Ernst Blickle<br />

Este año, el Palacio de Bruchsal, en el estado de Baden-Wurtemberg, Alemania, ha vuelto a ser el marco<br />

para la celebración de la entrega del premio personal de mayor cuantía de toda Europa (100. 000 euros).<br />

Con el tiempo también a la altura del evento, todos los astros se alinearon para que este se celebrase;<br />

afortunadamente tampoco hubo retenciones de tráfi co ni otros impedimentos. Así, el Sr. Blickle pudo dar<br />

puntualmente la bienvenida a los participantes de la edición número 15 de esta entrega de premios. El Sr.<br />

Blickle comentó que conocía al galardonado desde hace por lo menos 30 años. Años durante los que sus caminos<br />

se han cruzado frecuentemente en distintas situaciones: en la patronal, la BDI o la VDMA. Especialmente<br />

se alegró de poder saludar a 14 de los 15 futuros graduados, entre los cuales se encontraba una mujer.<br />

Premios de Técnica<br />

Medioambiental<br />

Baden-Wurtemberg 2011<br />

El miércoles 6 de julio de 2011, SEW-EURO-<br />

DRIVE fue galardonada con el segundo puesto<br />

en la categoría «Efi ciencia energética» y<br />

el tercer puesto en la categoría «Técnicas de<br />

medición, control y regulación» en el certamen<br />

Premios de Técnica Medioambiental de<br />

Baden-Wurtemberg, Alemania, en el que se<br />

distinguen los productos que contribuyen a la<br />

conservación del medio ambiente y un mejor<br />

aprovechamiento de los recursos.<br />

SEW-EURODRIVE pudo convencer en<br />

la categoría «Eficiencia energética» con<br />

el sistema de acumulación de energía a<br />

corto plazo para aplicaciones industriales<br />

y alzarse con el segundo premio. En la<br />

categoría «Técnicas de medición, control<br />

y regulación», SEW-EURODRIVE puntuó<br />

con el sistema de accionamiento descentralizado<br />

MOVIGEAR ® , logrando el<br />

tercer puesto.

«La unión hace la fuerza»<br />

Bajo el lema «la unión hace la fuerza», los<br />

días 24 y 25 de marzo de 2011 se celebró<br />

un taller en la DriveAcademy ® , en el<br />

que por primera vez se reunieron todos<br />

los compradores, y una compradora, de<br />

Francia y Alemania.<br />

El objetivo era conocerse mejor, superar<br />

posibles barreras interculturales rápidamente<br />

e intensifi car la cooperación, a pesar<br />

de la separación física.<br />

SLAP – Standardize administrative Logistic and Assembly<br />

Processes en las sedes <strong>Eurodrive</strong> europeas<br />

El punto de partida del proyecto fue una evaluación comparativa<br />

de las plantas <strong>Eurodrive</strong> realizada en el 2009 dentro del<br />

marco de la estrategia de logística y montaje en Europa. Una<br />

de las conclusiones, entre otras muchas, fue que tomando<br />

como referencia el tamaño de las distintas sedes <strong>Eurodrive</strong>,<br />

estas presentaban diferencias considerables en lo que se refería<br />

a la complejidad administrativa para apoyar los procesos<br />

Solo la curiosidad de comprender la forma<br />

de hacer las cosas de los demás permite<br />

aprovechar los efectos sinergia de la<br />

cooperación multicultural.<br />

Representan un potencial creativo para el<br />

desarrollo conjunto de ideas innovadoras.<br />

La competencia intercultural es a su vez<br />

también un factor importante del éxito de<br />

las actividades de compra. Todo esto se<br />

iba a tratar durante los dos días del taller.<br />

eurodriver<br />

Procesos estandarizados para aumentar la efi cacia<br />

operativos. Estas diferencias se deben en parte a condicionantes<br />

locales, aunque también se identifi có un potencial<br />

signifi cativo para aumentar la efi ciencia.<br />

En el análisis posterior se determinó que también había diferencias<br />

importantes en el grado de aprovechamiento de los<br />

sistemas de tecnología de la información entre las distintas<br />

sedes <strong>Eurodrive</strong>. Los procesos «Best Practice» ya implantados<br />

no se estaban llevando a la práctica en todos los emplazamientos.<br />

35

Prezados colegas e colaboradores,<br />

não poderia haver uma melhor entrada no ano de comemoração<br />

de 2011 nem um melhor presente de 80° aniversário<br />

de existência da SEW. No ano comercial fi ndo, o volume de<br />

vendas ultrapassou a marca de 2 mil milhões de euros, quebrando<br />

o recorde do nível antes da crise – e isto contra todas<br />

as expectativas já no primeiro ano do pós crise.<br />

Um sucesso louvável que exigiu de toda a equipa, nacional e<br />

internacional, um enorme empenho e que, por tal, merece o<br />

maior reconhecimento e estima e pelo qual eu, em nome da<br />

administração, gostaria de agradecer a todos os colegas e colaboradores.<br />

Do extraordinário elevado número de encomendas<br />

registadas até fi nais de Junho de 2011, espera-se, neste ano de<br />

comemoração, um crescimento adicional de 10%.<br />

Nos esforços necessários para assegurar os prazos de fornecimento<br />

e a qualidade dos serviços prestados aos nossos clientes<br />

através das respectivas ampliações das capacidades e recursos,<br />

não devemos, no entanto, perder de vista que enfrentaremos<br />

uma redução da velocidade da conjuntura, mesmo se<br />

ainda não se conhece exactamente quando isto irá acontecer.<br />

Especialmente, devido à actual situação económica instável<br />

(crise devido às dívidas dos Estados Europeus, orçamento<br />

EUA, enfraquecimento do crescimento na China, etc.), isto<br />

poderá acontecer mais cedo do que nos é desejável. Já se sente<br />

um ligeiro abrandamento dos ânimos que, apesar de ainda<br />

não preocupante, poderá ganhar uma dinâmica negativa para<br />

a Europa, se a situação de crise em países, como por exemplo,<br />

a Itália, se agravar.<br />

Outros perigos para uma regressão da conjuntura são a escassez<br />

de materiais e matérias primas e o resultante aumento<br />

dos preços dos mesmos, bem como o desenvolvimento demográfi<br />

co negativo, em particular, a falta de especialistas na Alemanha<br />

e na Europa. Continuará a tendência da transferência<br />

da facturação e do crescimento regionais da Europa para os<br />

países BRIC. No entanto, esta situação não representa um<br />

cenário ameaçador, pois a ampliação e o aperfeiçoamento da<br />

rede da SEW baseada em estratégias globais e de plataforma,<br />

com o objectivo de acompanhar o cliente o mais perto possível,<br />

36<br />

assegura a continuidade e a existência de todos os centros de<br />

produção.<br />

Nos próximos anos, os seguintes factores sãos decisivos no<br />

que respeita ao crescimento sustentável. Estes factores estão<br />

incluídos na nossa agenda e são tratados no projecto “3F” (f it<br />

for future) da empresa. Entre outros, são de mencionar os<br />

seguintes:<br />

– Liderança tecnologia, de inovação e de custos<br />

– Flexibilidade e adaptabilidade face aos futuros ciclos económicos<br />

mais curtos com maiores oscilações<br />

– Implementação de modelos e áreas comerciais orientadas<br />

para as megatendências (ecologia/reciclagem, efi ciência de<br />

energia, mobilidade eléctrica, vendas de sistemas, etc.)<br />

– Aumento das parcelas de mercado nos países BRIC (Brasil,<br />

Rússia, Índia, China)<br />

– Protecção dos mercados permanentes, em particular, face<br />

aos competidores chineses através da complementação do<br />

leque de produtos nos segmentos de mercado de grande<br />

volume (área básica)

A implementação das medidas tratadas neste projecto causará,<br />

inevitavelmente, alterações e adaptações na nossa estrutura<br />

organizatória. É-me claro que, particularmente, nas alturas<br />

em que tudo corre bem, é extremamente difícil convencer as<br />

pessoas da necessidade de mudanças. No entanto, temos que<br />

estar conscientes que o futuro é determinado por mudanças,<br />

e que aquele que é capaz de detectá-las de antemão e se adapta<br />

rapidamente a estas, assumirá um papel de liderança. Esta<br />

ideia tem de ser a nossa meta. E para alcançá-la, precisamos<br />

de si, prezados colegas e colaboradores, pois vós sois o ponto<br />

central da nossa actividade empresarial e infl uenciam, decisivamente,<br />

o sucesso ou insucesso de processos de mudança.<br />

Confi o em si e conto com a sua disposição a mudanças para<br />

que posamos levar a nossa SEW com sucesso ao 90° aniversário.<br />

Neste âmbito:<br />

Feliz Aniversário SEW-EURODRIVE<br />

Hans Sondermann<br />

eurodriver<br />

SUCESSO SEM FRONTEIRAS – OS “EURODRIVES”<br />

Proximidade ao cliente, parceria e confi ança – sem fronteiras.<br />

A história e o futuro da SEW estão estreitamente ligados<br />

ao sucesso da nossa rede global de EURODRIVES. Desde a<br />

fundação da primeira fábrica de montagem na Suécia, em<br />

1968, até ao nosso até agora mais recente centro de produção<br />

A primeira fábrica de montagem no estrangeiro: em Jonköping, na Suécia,<br />

em 1968<br />

transatlântico no Brasil em 2010, as nossas fi liais, fábricas e<br />

centros de competência internacionais têm vindo a contribuir<br />

fortemente para o sucesso da empresa e são uma garantia de<br />

um futuro economicamente estável.<br />

Uma das mais recentes fábricas da SEW-EURODRIVE: em Joinville, no Brasil,<br />

em 2010<br />

37

38<br />

Condecorado!<br />

Prémio Ernst Blickle atribuído ao Dr. Michael Rogowski<br />

O palácio de Bruchsal voltou a brilhar este ano no âmbito da condecoração do prémio dotado de 100.000<br />

Euros, um dos prémios pessoais mais dotados na Europa. O tempo contribuiu bastante e, com isso, estava<br />

tudo preparado para este evento – felizmente não houve congestionamentos nem situações piores. O<br />

senhor Blickle pode então dar as boas vindas sem atrasos a todos os participantes nesta já 15a atribuição<br />

de prémios. Segundo as declarações do senhor Blickle, ele já conhece os condecorados há, pelo menos, 30<br />