Vacu-Blot - Biometra

Vacu-Blot - Biometra

Vacu-Blot - Biometra

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Vacu</strong>-<strong>Blot</strong> System (Order No. 053-000/090/091)<strong>Vacu</strong>-<strong>Blot</strong> (Order No. 053-100)ManualJuly 2003!! Warning !!Please read these instructions carefullybefore using this apparatus!<strong>Biometra</strong> GmbHRudolf-Wissell-Str. 30D-37079 Göttingen Service DepartmentPostfach 1544 Rudolf-Wissell-Str. 14-16D-37005 Göttingen D-37079 GöttingenTel: ++49 – (0)5 51 / 50 68 6-0 Tel.: ++49 – (0)5 51 / 50 88 1-10 + 12Fax: ++49 – (0)5 51 / 50 68 6-66 Fax.: ++49 – (0)5 51 / 50 88 1-11e-mail: <strong>Biometra</strong>.info@whatman.com e-mail: <strong>Biometra</strong>.service@whatman.cominternet: http://www.biometra.de

Contents:1 Intended Uses And Specifications ............................................................................................. 22 Systems and Accessories Available........................................................................................... 33 Ordering Information................................................................................................................ 44 Safety and Operating Informations ............................................................................................ 55 Set Up ..................................................................................................................................... 55.1 Unpack and Check...........................................................................................................56 Location................................................................................................................................... 67 Assembling the Transfer Unit..................................................................................................... 68 Disassembling the unit ............................................................................................................... 89 Application Information............................................................................................................. 99.1 Southern <strong>Blot</strong> with the <strong>Vacu</strong>-<strong>Blot</strong> and <strong>Vacu</strong>-<strong>Blot</strong> System...................................................99.2 Northern <strong>Blot</strong> with the <strong>Vacu</strong> <strong>Blot</strong> and <strong>Vacu</strong>-<strong>Blot</strong>.............................................................1010 Service................................................................................................................................. 1111 Notes................................................................................................................................... 131

1 Intended Uses And SpecificationsThe <strong>Vacu</strong>-<strong>Blot</strong> enables the scientist to perform rapid and reliable transfer of nucleic acids (DNAand RNA) from agarose gels onto membranes. This technique is superior to any other way of nucleicacid transfer because of its speed. Compared with the usual capillary transfer the vacuum-blottingdemonstrates an enhanced detection limit of nucleic acids 1 . The size of the <strong>Vacu</strong>-<strong>Blot</strong> is adequate formedium-sized up to large-sized agarose gels (max. 20 x 20 cm) as routinely used in molecularbiology laboratories.The efficiency of transfer of nucleic acids mainly depends on the vacuum. The filter plate holder hastherefore been optimised to ensure an homogeneous vacuum over the entire filter area. The size ofthe collecting tank has been designed in order to guarantee an appropriate vacuum but is also largeenough for collecting the entire flow through during a 1 h transfer. By using a vacuum pump (includedin the <strong>Vacu</strong>-<strong>Blot</strong> System), which can be regulated, the transfer of nucleic acids becomes a simpleand reproducible procedure with a superior degree of efficiency 1 . A simple water jet pump is notadequate for the vacu-blot method.The rubber mats, which are delivered together with the apparatus, are used for sealing. In the centreof one mat a piece is cut out, which is slightly smaller than the agarose gel. The transfer membrane,which lies on the filter plate, is covered by the rubber frame and the agarose gel placed above theempty central hole of the frame. The cover plate (filled with transfer buffer) presses the rubber matonto the filter plate. Therefore, after applying vacuum, the entire surface of the filter plate is sealed bythe rubber frame with the exception of the central hole. The buffer is forced to migrate through theagarose gel and to transport the nucleic acid fragments onto the membrane.The collecting tank and the cover plate are manufactured from durable acrylic, which withstandsmost reagents.1 Olszewska, E. and Jones, K. (1988). <strong>Vacu</strong>um blotting enhances nucleic acid transfer. TIG 4:92-94.2

2 Systems and Accessories Available<strong>Vacu</strong>-<strong>Blot</strong> (Order No. 053-100)• Transfer unit, consisting ofCollecting tank (volume: 3400 ml)Porous filter plateFilter plate holder (23.7 x 23.7 cm)Cover plate with buffer reservoir (volume: 3000 ml)• 9 clips (3 x Order No. 010-007)• 3 Rubber masks (27.5 x 27.5 cm) (Order No. 053-002)• 1 Tube adapter (<strong>Vacu</strong>um connector) for the collecting tank• 1 <strong>Vacu</strong>um tube (Order No. 049-001)• 1 Instruction Manual<strong>Vacu</strong>-<strong>Blot</strong> System 230V (Order No. 053-000)115V, 60Hz (Order No. 053-090)100V, 50/60Hz (Order No. 053-091)• <strong>Vacu</strong>-<strong>Blot</strong> (complete transfer unit with accessories)• <strong>Vacu</strong>um pump MP86 with manometer and adjustable vacuum gauge3

3 Ordering InformationItem:Order No.:<strong>Vacu</strong>-<strong>Blot</strong> System with vacuum pump (20 x 20 cm gel size), 230 V 053-000<strong>Vacu</strong>-<strong>Blot</strong> System with vacuum pump (see above), 115 V, 60 Hz 053-090<strong>Vacu</strong>-<strong>Blot</strong> System with vacuum pump (see above), 100 V, 50/60 Hz 053-091<strong>Vacu</strong>-<strong>Blot</strong> without vacuum pump 053-100<strong>Vacu</strong>um pump MP86 with manometer and adjustable vacuum gauge(max. delivery 6 l/min, end vacuum 100 mbar), 230 V 049-000<strong>Vacu</strong>um pump MP86 with manometer and adjustable vacuum gauge(max. delivery 6 l/min, end vacuum 100 mbar), 115 V, 60 Hz 049-090<strong>Vacu</strong>um pump MP86 with manometer and adjustable vacuum gauge(max. delivery 6 l/min, end vacuum 100 mbar), 100 V, 50/60 Hz 049-091Accessories:Porous filter plate for <strong>Vacu</strong>-<strong>Blot</strong>/System 053-004Rubber mat (3 pieces) for <strong>Vacu</strong>-<strong>Blot</strong>/System 053-002Clips (3 pieces) 010-007Whatman filter paper 25 pieces, 29,7 cm x 21 cm (thickness: 0.9 mm) 092-002Whatman 3MM Chr 100 pieces, 46 cm x 57 cm (thickness: 0.34 mm) 3030917Whatman 3MM Chr 100 pieces, 58 cm x 68 cm (thickness: 0.34 mm) 3030931Nitrocellulose membrane 15 pieces, 10 cm x 12 cm (pore size: 0.45 µm) 090-008Nitrocellulose membrane 15 pieces, 16 cm x 20 cm (pore size: 0.45 µm) 090-009Nitrocellulose membrane 10 pieces, 20 cm x 20 cm (pore size: 0.45 µm) 090-010Nitrocellulose membrane 1 piece, 30 cm x 3 m (pore size: 0.45 µm) 090-002Nitrocellulose membrane 15 pieces, 10 cm x 12 cm (pore size: 0.20 µm) 090-011Nitrocellulose membrane 15 pieces, 16 cm x 20 cm (pore size: 0.20 µm) 090-004Nitrocellulose membrane 10 pieces, 20 cm x 20 cm (pore size: 0.20 µm) 090-012Nitrocellulose membrane 1 piece, 30 cm x 3 m (pore size: 0.20 µm) 090-0054

4 Safety and Operating InformationsCaution!Do not use organic solvents or solvents with chaotropic ions for cleaning.Solvent resistance: Use neither organic solvents (e.g.: acetone, chloroform), nor >30%ethanol;Use no chaotropic ions (e.g. urea, guanidine hydrochloride)Cleaning: A detergent solution or0.1 N NaOH solution ora dilute alcohol solution (≤ 30 %)<strong>Vacu</strong>um:Max. gel sizeMaximum 500 mbar less than atmospheric pressure20 x 20 cm5 Set Up5.1 Unpack and CheckUnpack and carefully examine the electrophoresis unit. Report any damage to BIOMETRA. Do notattempt to operate this device if physical damage is present. Save all packing material if damage isfound.Do not attempt to operate this device if physical damage is present.!! Attention !!Please fill out and send back the warranty registration card. This isimportant for you to claim to full warranty.5

6 LocationPlace the chamber in proximity to the vacuum pump with which it is to be connected. Be sure toplace the chamber in a safe, dry location away from the edge of the working surface.7 Assembling the Transfer UnitPrior to use, ensure that the filter plate and the filter plate holder are not clogged.Before inserting a membrane into the <strong>Vacu</strong>-<strong>Blot</strong>, please read the information aboutpre-treatment of the desired filter material given by the manufacturer.1. Screw the tube adapter into the housing of the collecting tank. The vacuum pump can either beconnected directly to the <strong>Vacu</strong> <strong>Blot</strong> or indirectly via an intermediate wash bottle.The use of a wash bottle is advisable when working with radioactive substances or veryconcentrated saline solutions (e.g.: 10 x SSC).2. Place the filter plate holder into the collecting tank and place the porous filter plate on it.3. Place a piece of Whatman 3MM filter paper, which has been cut to the size of the filter plateand equilibrated in the transfer buffer (e.g.: 2xSSC-buffer), on the filter paper.Note: Eliminate all air bubbles between the filter paper and the filter plate byrolling a glass pipette or a similar object across the filter paper.4. The membrane, which has been pre-cut to fit your sample needs and equilibrated in buffersolution, is laid on the filter paper.Note: Eliminate all air bubbles between the membrane and filter paper byrolling a glass pipette or a similar object across the membrane.5. Place a wet rubber mat, from which the centre has been cut out (see note), on the filter plate.This rubber frame covers the entire surface of the filter plate with the exception of the cut outcentre.Note: The size of the cutting in the rubber mat should be slightly smaller thanthe agarose gel (maximum size of agarose gel 20 x 20 cm). Eliminate all airbubbles between the rubber mat and the membrane by rolling a glass pipette ora similar object across the rubber mat.6. Place the agarose gel on the central hole of the rubber frame. There should be about 5 - 10 mmof the agarose gel on each side lying on the rubber mat. The sample slots must lie on the rubbermat otherwise inhomogenity of the vacuum around the slots could occur during transfer.6

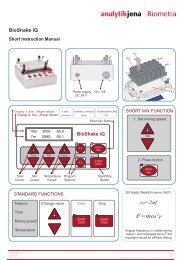

Note: Eliminate all air bubbles between the agarose gel, the membrane andthe rubber frame by rolling a glass pipette or a similar object across the gel.7. Place the cover plate with the buffer reservoir on the filter plate so that it corresponds to theorientation of the guide pins.8. Tighten both parts of the <strong>Vacu</strong> <strong>Blot</strong> by using the clips.9. Apply vacuum to the transfer unit before pouring transfer buffer into the upper reservoir.Otherwise your agarose gel might float up.10. Transfer time of nucleic acid fragments from an 0.8 % concentrated agarose gel to themembrane is about 1 h to 2 h (when applying a vacuum of 50 to 100 mbar below ambient).These values are only guideline for transferring nucleic acids from 0.5 kb - 10 kb.Cover plate with buffer reservoirAgarose gelRubber sheetMembraneWhatman 3MM filter paperPorous filter plateSupportClipTankStabilizer<strong>Vacu</strong>um connectorFig. 1: Set up of a vacuum blotting sandwich7

8 Disassembling the unit1. First interrupt the vacuum before opening the clips. When using the vacuum pump delivered withthe system (Order-No.: 053-000/090/091) you can apply ambient pressure by opening the flowvalve.2. Remove the transfer buffer from the upper buffer reservoir. Afterwards the apparatus can bedisassembled in reverse order to assembling.3. The membrane can be further processed as usually, e.g. by UV-light crosslinking or by bakingat 80 o C.4. Please rinse all parts of the <strong>Vacu</strong> <strong>Blot</strong> after use with deionised water. Pay attention to the guidelines for cleaning given in chapter “4 Safety and Operating Informations”.8

10 ServiceShould you have any problems with this unit, please contact our service department or your local<strong>Biometra</strong> dealer:<strong>Biometra</strong> GmbHService DepartmentRudolf-Wissell-Straße 14 - 16D-37079 GöttingenPhone: ++49 – (0)5 51 / 50 88 1 – 10 + 12Fax: ++49 – (0)5 51 / 50 88 1 – 11e-mail: <strong>Biometra</strong>.service@whatman.comIf you would like to send the unit back to us, please read the following returninstructions.Instructions for return shipment• Return only defective devices. For technical problems which are not definitively recognisable asdevice faults please contact the Technical Service Department at <strong>Biometra</strong> (Tel.-No.: 0551 / 5088 1 – 10 and 12).• Use the original box or a similarly sturdy one.• Label the outside of the box with “CAUTION! SENSITIVE INSTRUMENT!”• Please enclose a precise description of the fault, which also reveals during which proceduresthe fault occurred, if possible.• Important: Clean all parts of the instrument from residues, and of biologicallydangerous, chemical and radioactive contaminants. Please include a writtenconfirmation that the device is free of biologically dangerous and radioactivecontaminants in each shipment. If the device is contaminated, it is possible that<strong>Biometra</strong> will be forced to refuse to accept the device.• The sender of the repair order will be held liable for possible losses resulting from insufficientdecontamination of the device.• Please enclose a note which contains the following:a) Sender’s name and address,b) Name of a contact person for further inquiries with telephone number.11

Equipment Decontamination CertificateTo enable us to comply with german law (i.e. §71 StrlSchV, §17 GefStoffV and §19 ChemG) and to avoidexposure to hazardous materials during handling or repair, will you please complete this form, prior to theequipment leaving your laboratoryCOMPANY / INSTITUTEADDRESS______________________________________________________________________________________________________________________________TEL NO _______________________________ FAX NO_______________________________E-MAIL______________________________________________________________________________EQUIPMENT Model Serial No________________________________________________________________________________If on loan / evaluation Start Date: _______________ Finish Date ___________________Hazardous materials used with this equipment___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Method of cleaning / decontamination___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________The equipment has been cleaned and decontaminated:NAME ________________________________(HEAD OF DIV./ DEP./ INSTITUTE / COMPANY)SIGNED ______________________________POSITION ___________________________DATE _______________________________PLEASE RETURN THIS FORM TO BIOMETRA GMBH OR YOUR LOCAL BIOMETRA DISTRIBUTORTOGETHER WITH THE EQUIPMENT.PLEASE ATTACH THIS CERTIFICATE OUTSIDE THE PACKAGING. INSTRUMENTS WITHOUT THISCERTIFICATE ATTACHED WILL BE RETURNED TO SENDER.12

11 Notes________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________13

WarrantyThis laboratory instrument is produced with the highest practical standards of materials,workmanship, and design. The design and manufacture of parts have been conceived with onepurpose - to produce units which will give satisfactory service.<strong>Biometra</strong> GmbH guarantees this unit to be free from defects in materials or workmanship undernormal use or service for 12 month from date of shipment. If, during this time, this unit provesdefective in materials or workmanship, <strong>Biometra</strong> GmbH will repair or replace it free of charge ifreturned to us prepaid. This guarantee does not cover damage in transit, damage caused bycarelessness, misuse or neglect, or unsatisfactory performance as a result of conditions beyond ourcontrol; or consequential losses as a result of failure of our product.___________________________________________________________________________<strong>Biometra</strong> GmbHRudolf-Wissell-Str. 30D-37079 Göttingen Service DepartmentPostfach 1544 Rudolf-Wissell-Str. 14-16D-37005 Göttingen D-37079 GöttingenTel: ++49 – (0)5 51 / 50 68 6-0 Tel.: ++49 – (0)5 51 / 50 88 1-10 or -12Fax: ++49 – (0)5 51 / 50 68 6-66 Fax.: ++49 – (0)5 51 / 50 88 1-11e-mail: <strong>Biometra</strong>.info@whatman.com e-mail: <strong>Biometra</strong>.service@whatman.cominternet: http://www.biometra.de14