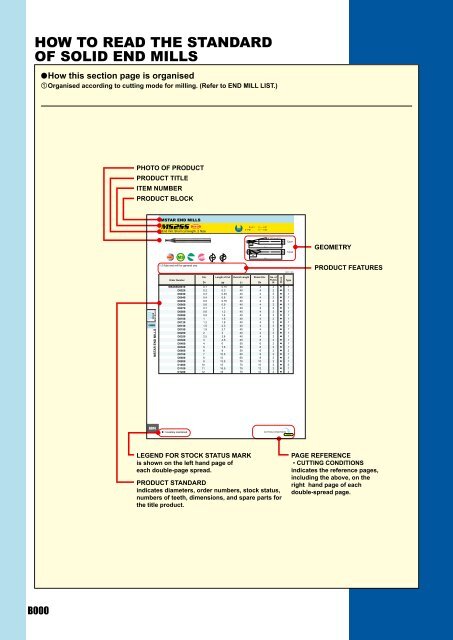

HOW TO READ THE STANDARD OF SOLID END MILLS

HOW TO READ THE STANDARD OF SOLID END MILLS

HOW TO READ THE STANDARD OF SOLID END MILLS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

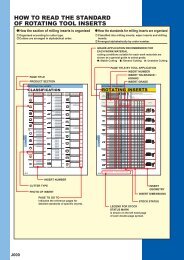

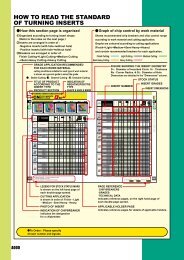

<strong>SOLID</strong> <strong>END</strong> <strong>MILLS</strong><strong>END</strong> <strong>MILLS</strong> SELECTION CHARTGroupTypeFeatureNo. of flutesCodeShapeCoatingSubstrateSize rangeCarbon steel, Alloy steelP H M S NAlloy steel(-40HRC)Work materialHardened steel(-55HRC)Hardened steel(55HRC-)Austenitic stainless steelTitanium alloy, Heat resistant alloyCopper alloyAluminium alloyGraphitePage numberDimensionsCuttingconditionsMSTAR / For General materialRadiusGeneral4MS4MRB aaaE &6MS UWC&16++ ++ ++B077B225IMPACT MIRACLE / For High hardened material (55HRC-)High speedNEWVF2SSBVF2SBVFVFUWCUWCR0.5R6R0.1R10++++ ++ +++ ++ +B079B080B227B227<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong><strong>END</strong> <strong>MILLS</strong> SELECTION CHARTSquare BallBall RadiusHard material High speedTough millingLongneckTaperball234662VFSDVFMDNEWVF2SDBNEWVF2SDBLNEWVF2XLBNEWVF3XBNEWVFSDRBNEWVFMDRBMIRACLE HARD / For High hardened material (55HRC-)VC2ESBVC2SSBVC2SBVFVFVFVFVFVFVFVFVCVCVCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCR0.5R10R0.5R10R0.1R3R0.4R2.5&1&12&1&25&3&12&3&20R0.15R6R0.5R6R0.15R10+++++++++++++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +++ ++ +B081B082B083B088B091B092B093B094B105B106B107B228B228B229B230B232B232B232B232B239B239B239VC4MBVCUWCR0.5R10+++ ++ +B121B2474VC4STBVCUWCR0.3R4+++ ++ +B145B258B004

GroupTypeFeatureNo. of flutesCodeShapeCoatingSubstrateSize rangeCarbon steel, Alloy steelP H M S NAlloy steel(-40HRC)Work materialHardened steel(-55HRC)Hardened steel(55HRC-)Austenitic stainless steelTitanium alloy, Heat resistant alloyCopper alloyAluminium alloyGraphitePage numberDimensionsCuttingconditionsCornerBall Square Ball SquareRadius BallSquareChamfer Taper RoughingroundingNon-ferrous GeneralGeneral General GeneralGeneral3424VCVCVC&22 VC2CVC UWCB147 B260&12++ ++ ++ + ++ ++3CRN / For CopperLongneckLongneckLongneck242DLC / For Aluminium22VCSFPRVC2MTVC4MTVCRCNEWCRN2MSCRN4JCCRN2XLCRN2MBCRN2XLBNEWCRN2MRBNEWCRN2XLRBDLC2MADLC2MBDIAMOND / For Graphite, Non-ferrous materialDC2MS3DC2MBNFVCCRNCRNCRNCRNCRNCRNCRNDLCDLCDCDCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCUWC&3&20&1&2.5&3&10R0.5R5&0.2&12&3&12&0.2&6R0.2R6R0.1R3&6&12&0.5&6&1&20R0.1R10&0.5&3R0.3R6++ ++ ++ + ++ ++++ ++ ++ + ++ ++++ ++ ++ + ++ ++++ ++ ++ + ++ ++++ +++ +++ +++ +++ +++ +++ ++ +++ ++++++++++B141 B256B142 B257B143 B257B148 B261B149 B262B152 B262B150 B263B153 B264B154 B265B157 B266B158 B267B160 B268B161 B269B162 B271B163 B270++ : 1st recommend / + : 2nd recommend<strong>END</strong> <strong>MILLS</strong> SELECTION CHART <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>B007

<strong>SOLID</strong> <strong>END</strong> <strong>MILLS</strong><strong>END</strong> <strong>MILLS</strong> SELECTION CHARTGroupTypeFeatureNo. of flutesCodeShapeCoatingSubstrateSize rangeCarbon steel, Alloy steelP H M S NAlloy steel(-40HRC)Work materialHardened steel(-55HRC)Hardened steel(55HRC-)Austenitic stainless steelTitanium alloy, Heat resistant alloyCopper alloyAluminium alloyGraphitePage numberDimensionsCuttingconditionsDIAMOND / For Graphite, Non-ferrous materialGraphiteDC2MBDC2LBDCDCUWCUWCR0.5R6R1R6+ +++ ++B166B167B271B271<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong><strong>END</strong> <strong>MILLS</strong> SELECTION CHARTRoughing RadiusSquare Ball BallBallLongneckTaperneck2223423DC2XLBDCXBCBN / For High hardened materialLongneckNEWCBN2XLBALIMASTER / For AluminiumGeneralAM2MBAM2MRAM2SCAM3SSAM3MFAM4MFNEWAM2SCRBNEWAM3SSRBAMSRAMMRDCDCUWCUWCCBNUWCUWCUWCUWCUWCUWCUWCUWCUWCUWCR0.2R3R0.2R3R0.2R1R0.5R10&3&25&3&20&12&25&6&16&20&25&3&20&12&25&10&25&3&25+ ++ +++ +++ +++ +++ +++ +++ +++ +++ +++ +++ +++ +++ ++B164B165B168B176B172B171B173B174B175B177B179B181B181B272B272B273B274B275B276B277B276B277B278B279B280B281RadiusAMSRRBUWC&10&25+ ++B182B280B008

Work materialPage numberGroupTypeFeatureNo. of flutesCodeShapeCoatingSubstrateSize rangeCarbon steel, Alloy steelP H M S NAlloy steel(-40HRC)Hardened steel(-55HRC)Hardened steel(55HRC-)Austenitic stainless steelTitanium alloy, Heat resistant alloyCopper alloyAluminium alloyGraphiteDimensionsCuttingconditionsCARBIDE / For General material, AluminiumSEE2SUWC&3&20++ ++ + +B183B2822Roughing BallSquareSquareHigh helixVariable helix424SEE2LSEE4LSZE4SSEG2SASEG4SAVIOLET / For General materialHigh helix GeneralGeneral2424246VA2SSVA2MSVA4MCVAMHVALHVA2MBVASFPRVAMFPRVAMRVVVVVVVVVUWCUWCUWCUWCUWCKHA SKHA SKHA SKHA SKHA SKHA SKHA SKHA SKHA S&3&20&3&25&3&25&6&25&6&25&3&20&3&40&3&30&5&30&5&30R6R15&5&50&5&50&5&50++ ++ + +++ ++ + +++ ++ + +++ + + +++ + + +++ + + +++ + + +++ + + +++ + + +++ + + +++ + + +++ + + ++ +++ ++B184B185B186B187B188B189B190B191B198B199B192B193B194B195B282B283B284B284B285B285B286B292B287B288B289B290<strong>END</strong> <strong>MILLS</strong> SELECTION CHART <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>VAJRVKHA S&10&50++ + + +B196B291VALRVKHA S&10&50++ + + +B197B291++ : 1st recommend / + : 2nd recommendB009

<strong>SOLID</strong> <strong>END</strong> <strong>MILLS</strong>PRODUCT CODE DESCRIPTIONSPRODUCT CODE <strong>OF</strong> <strong>END</strong> <strong>MILLS</strong>MS 2 M S D0100***PRODUCT CODE DESCRIPTIONS <strong>END</strong> <strong>SOLID</strong><strong>MILLS</strong>End mill namesNumber offlutesFlute length Features Dimensions Othersex.MS : Mstar end mills1 : 1flute ES : Extra shortS : General-useDiameterVF : Impact Miracle end mills 2 : 2flute S : ShortU : For stainless steel* Other types are available by special order. VC : Miracle end mills3 : 3flute M : MediumK : For keyway D0050 |&0.5CRN : CRN end mills4 : 4flute J : Semi longA : For light alloy D0500 |&5DLC : DLC coated end mills••• L : LongC : Centre cutDC : Diamond coated end millsXL : Long neckD : For deep cutRadius ofCBN : CBN end millsSX : Extra longB : Ball noseball noseAM : ALIMASTER end millsX : Taper neckR : Roughing ex.C : Carbide end millsMX : Extra longF : Semi-finishing R0050 | R0.5VA : Violet end millsH : High helix R0500 | R5T : TaperTB : Taper ball noseRB : Corner radiusSZ E 4 040 SSZ : Super squareSE : Square end millEnd mill names Helix angle Number of flutes DiameterShapeE : 45°G : Irregular spiralhelix angle(38°/41°)2 : 2flute4 : 4fluteex.D**** :S :**N*** :T**** :R**** :010 |&1050 |&5S : ShortL : LongShank diameterNeck lengthTaper angleone sideL : Flute length**Other types are available by special order.*B010

SYMBOL DESCRIPTIONSTool materialCoatingUWCUltra micro grain carbideUltra micro grain carbide is used as the substratematerial.MS(Al, Ti)N coating(Al,Ti)N offers higher versatility.CBNCubic boron nitrideMitsubishi’s original CBN is used.VFIMPACT MIRACLE CoatingSingle phase nano crystal coating technologyfor higher film hardness and heat resistance.KHA SHigh hardness powder metallurgy HSSHigh hardness powder metallurgy HSS is used as thesubstrate material.VCMIRACLE CoatingThe original Miracle (Al,Ti)N coating.Also suitable for dry cutting.TolerancesRRROutside diameter toleranceIndicates the diameter tolerance of the end mill.R toleranceIndicates the radial tolerance of a ball nose end mill.R toleranceIndicates the radial tolerance of an end mill with acorner radius.R toleranceIndicates the radial tolerance of an cutter with acorner radius.Tolerance of Taper angleIndicates the tolerance of the taper angle.Tolerance of Point angleIndicates the tolerance of the point angle.CRNDLCDCV30°P H M S N++ ++ + ++ ++ ++ ++ ++ ++ +++ ++ ++ + ++ ++++ ++ ++ ++ +++ ++ +++ ++++ + + +++ : 1st recommend / + : 2nd recommendCRN CoatingNewly developed CrN coating for CopperElectrodes machining.DLC CoatingHardness similar to that of CVD diamond coatingachieved with high adhesion strength.(Jointly developed with NAGATA SEIKI CO.,LTD.)Diamond CoatingPure Diamond high performance coating excellingin film adhesion to the substrate.Violet CoatingIncreased tool life of 23 times that of TiN coatedproducts.Angle and sharp corner edgeHelix angleIndicates the helix angle of the end mill.Sharp corner edgeIndicates the end mill has a sharp corner edge.COATING SELECTIONSeriesMSTARIMPACT MIRACLEMIRACLE HARDMIRACLECRNDLCDIAMONDCBNALIMASTERVIOLETCarbon steel,Alloy steelAlloy steel(-40HRC)Hardened steel(-55HRC)Work materialHardened steel(55HRC-)Austeniticstainless steelTitanium alloy,Heat resistant alloyCopper alloyAluminium alloyGraphiteSYMBOL DESCRIPTIONS / COATING SELECTION <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>B011

<strong>SOLID</strong> <strong>END</strong> <strong>MILLS</strong>COATING TECHNOLOGYCoatingFor higher hardness, higher speed and longer tool life!In comparison with the conventional coating single-phase nanocrystal coating technology offers higher coating hardness andheat resistance.When machining hardened steels it can be seen that theIMPACT MIRACLE coating offers a lower friction of coefficientand as such prevents abnormal damage such as chipping.FEATURES <strong>OF</strong> IMPACT MIRACLE COATINGHardness (HV)3700(Al,Ti,Si)N3200(Al,Ti)N2,800Oxidation Temperature (r)13001100840Adhesion (N) 1)1008080Wear Coefficient 2) (800r)0.480.530.581) Adhesion : Measured by critical load scratch test.2) Coefficient of friction : Mearsured by ball-on-disk method.(Counter gear : W.-nr. 1.2344(H13) 52HRC)COATING TECHNOLOGY <strong>END</strong> <strong>SOLID</strong><strong>MILLS</strong>Newly Developed MIRACLE CoatingMIRACLE coating evolution for high precision milling.To meet the needs of high precision milling, the "Newly Developed MiracleCoating" has improved its heat and wear resistance properties. It alsopossesses excellent lubrication properties that results in reduced cuttingforces against hardened steel due to the low friction coefficient at elevatedtemperatures. These excellent properties make it possible for smooth wearpatterns, rather than the usual uneven wear to be formed at the cutting edgeFEATURES <strong>OF</strong> DEVELOPED MIRACLE COATINGHardness (HV)Oxidation Temperature (r)Adhesion (N) 1)Wear Coefficient 2) (800r)Newly DevelopedMiracle Coating3,1001,1001000.42(Al,Ti)N2,800840800.53during long cutting operations. This new coating is applied to the new highprecision ball nose end mill "MIRACLE NOVA".SMOOTH WEAR PATTERNNewly Developed Miracle Coating10!m 10!mCoating WearNo Exposure ofthe SubstrateCoating Wear(Al,Ti)N CoatingExposedSubstrate1) Adhesion : Measured by critical load scratch test.2) Coefficient of friction : Mearsured by ball-on-disk method.(Counter gear : W.-nr. 1.2344(H13) 52HRC)Workpiece : W.-nr. 1.2344(H13) (52HRC), Cutting length : 20mMIRACLE Coating (Al,Ti)NMIRACLE coating for high speed milling.Miracle coating is produced by adding Al to an existing TiN coating.This new coating layer consists of a compound solid solution of (Al,Ti)N. Thiscoating has succeeded in improving heat resistance during cutting in addition toadding high hardness properties to the tool. The result is improved performancefor dry, high speed cutting of hardened materials.Oxidation Behavior Concept Chart of(Al,Ti)N Coating LayerHigh temperature zone of thecutting edge tip 8001,000rWorkMaterialOxygenAluminiumCoated Cutting Tool(Al,Ti)N Coating LayerNitrogenTitaniumWorkMaterialDiffusion ofOxygenDiffusion ofAluminiumTool Base MaterialB012Work MaterialTransition Layer(Al,Ti)NNon Crystalloid Aluminium Oxide Layer

CRN CoatingSpecially designed for milling of copper electrodeand copper alloy.CRN coating has been developed for copper alloy milling. It has superiorwear resistance and excellent adhesion strength by using Miracle coatingtechnology. The excellent anti adhesion properties needed for coppermachining has been achieved due to its low coefficient of friction at hightemperatures.FEATURES <strong>OF</strong> CRN COATINGHardness (HV)CRN2,000(Al,Ti)N2,800Carbide1,600Friction Coefficient against copper at thehigh temperature of 600rCoefficient of Friction0.600.550.500.45CRN0.480.55(Al,Ti)N0.52CarbideAdhesion (N)8080DLC CoatingNewly developed DLC coating.Hardness similar to that of CVD diamondcoating achieved with high adhesion strength.Mitsubishi Materials and NAGATA SEIKI have jointlydeveloped a unique DLC coating that has substantiallyincreased "adhesion strength" compared to previousDLC coatings.Diamond CoatingFEATURES <strong>OF</strong> DLC COATINGHardness (HV)Coefficient of FrictionMitsubishi’sDLC6,0007,000Diamond coating for non-ferrous and new non-metal materials.0.1Competitor’sDLC1,0007,000 7,00010,000Owing to Mitsubishi’s unique plasma chemical vapor deposition (CVD) coating technology, a great combination of coating hardnesssimilar to that of natural diamond has been combined with good adhesion to carbide substrates.0.1Diamond0.4TiN2,0000.4COATING TECHNOLOGY <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>VIOLET Coating(Al,Ti)N coating, excellentadhesion strength for HSS tools.Violet coating is the name of the technology ofsuccessfully applying a Miracle type coating to HSSsubstrate tools. The newly developed technology ofapplying (Al,Ti)N coating at the low temperaturesrequired for HSS substrates, means that Violet coatinghas the same level of adhesion strength as Miraclecoating. Additionally high film hardness and excellentoxidation resistance properties have also beenrealised.FEATURES <strong>OF</strong> VIOLET COATINGViolet CoatingHardness (HV)2,800Adhesion (N)80Oxidation Temperature (r)840TiN1,90060620B013

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2SSEnd mill, Short cut length, 2 fluteD1=0.10.1

MS2MSExpandEnd mill, Medium cut length, 2 fluteD1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MSExpandEnd mill, Medium cut length, 2 fluteD1

MS2JSEnd mill, Semi long cut length, 2 fluteD1=0.10.1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2LSEnd mill, long cut length, 2 flute0 -0.02øD1ap15°øD4Type1L1UWCMS30°øD1apL1øD4Type2D1

B019B2030 -0.010 -0.020.4

B0200 -0.010 -0.020.4

B021B203MS2XL D0200N200D0200N250D0200N300D0200N350D0200N400D0200N500D0200N600D0250N080D0250N120D0250N160D0250N200D0250N250D0250N300D0250N400D0250N500D0300N080D0300N120D0300N160D0300N200D0300N250D0300N300D0300N400D0300N500D0400N120D0400N160D0400N200D0400N250D0400N300D0400N350D0400N400D0400N450D0400N500D0400N600D0500N160D0500N250D0500N350D0500N500D0500N600D0600N200D0600N300D0600N400D0600N500D0600N6001.941.941.941.941.941.941.942.42.42.42.42.42.42.42.42.852.852.852.852.852.852.852.853.83.83.83.83.83.83.83.83.83.84.84.84.84.84.85.85.85.85.85.822222222.52.52.52.52.52.52.52.5333333334444444444555556666633333333.73.73.73.73.73.73.73.74.54.54.54.54.54.54.54.566666666667.57.57.57.57.599999202530354050608121620253040508121620253040501216202530354045506016253550602030405060607070809010011050506060707090100505060607070901005060607070809090100110607080110120809010011012044444444444444466666666666666666666666666662222222222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1 ap L1L3 D5 D4 N1111111111111111111111111111111111111122222Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDELength ofCutDia.Order NumberNo. ofFlutesShankDia.NeckLengthOverallLengthTypeStockNeckDia.

Unit : mmOrder NumberMS2XL6D0220N055D0220N110D0230N058D0230N115D0240N060D0240N120D0250N063D0250N125Dia. Length of Neck Neck Overall Shank No. ofCut Length Dia. Length Dia. FlutesD1 ap L3 D5 L1 D4 N2.22.22.32.32.42.42.52.53.33.33.53.53.63.63.83.85.5115.811.56126.312.52.102.102.202.202.302.302.402.4050605060506050606666666622222222aaaaaaaaTypeThe diameter tolerance is only applied to items produced after April 2005.Stock11111111MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDECUTTING CONDITIONSB204B023

MSTAR <strong>END</strong> <strong>MILLS</strong>MSSHDHigh power, Short cut length, 4 fluteD1< 1212

MSMHD0High power, Medium cut length, 4 fluteD1< 1212

MSTAR <strong>END</strong> <strong>MILLS</strong>MSMHD0High power, Medium cut length, 4 fluteD1< 1212

MSJHD0High power, Semi long cut length, 4 fluteD1< 1212

MSTAR <strong>END</strong> <strong>MILLS</strong>MSMHZD0ExpandEnd mill, Medium cut length, 3 fluteD1< 1212

MS4SC0End mill, Short cut length, 4 flute -0.0215°øD1 øD1apL1øD4øD4Type1Type2UWCMS30°apL1a4 flute end mill for general use.Unit : mmOrder NumberDia. Length of Cut Overall Length Shank Dia. No. ofFlutesD1 ap L1 D4 NStockTypeMS4SCD0100D0150D0200D0250D0300D0400D0500D0600D0800D1000D120011.522.53456810121.52.333.84.567.591215184040404050505050607075444466668101244444444444aaaaaaaaaaa11111112222MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDECUTTING CONDITIONSB208B029

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4MC0ExpandEnd mill, Medium cut length, 4 fluteD1

MS4JC0End mill, Semi long cut length, 4 flute -0.0215°UWCMS30°øD1 øD1apapL1L1øD4øD4Type1Type2D1

B032aMS4XLD0100N040D0100N060D0100N080D0100N100D0100N120D0100N160D0110N060D0110N100D0110N160D0120N060D0120N080D0120N100D0120N120D0120N160D0130N060D0130N120D0130N180D0140N060D0140N080D0140N100D0140N120D0140N140D0140N160D0140N220D0150N060D0150N080D0150N100D0150N120D0150N140D0150N160D0150N180D0150N200D0160N060D0160N080D0160N100D0160N120D0160N140D0160N1600.940.940.940.940.940.941.041.041.041.141.141.141.141.141.241.241.241.341.341.341.341.341.341.341.441.441.441.441.441.441.441.441.541.541.541.541.541.541111111.11.11.11.21.21.21.21.21.31.31.31.41.41.41.41.41.41.41.51.51.51.51.51.51.51.51.61.61.61.61.61.61111111.11.11.11.21.21.21.21.21.31.31.31.41.41.41.41.41.41.41.51.51.51.51.51.51.51.51.61.61.61.61.61.646810121661016681012166121868101214162268101214161820681012141650505050506050506050505050605050605050505060606050505050606060605050505060604444444444444444444444444444444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssssD1 ap L1L3 D5 D4 N11111111111111111111111111111111111111MS4XL 0 -0.02UWC 30°MSøD4L1L3D5apøD115°øD4L1L3D5apøD1MSTAR <strong>END</strong> <strong>MILLS</strong>End mill, 4 flute, Long neck4 flute long neck end mill.Unit : mmMSTAR <strong>END</strong> <strong>MILLS</strong><strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEType1Type2Length ofCutDia.Order NumberNo. ofFlutesShankDia.NeckLengthOverallLengthTypeStockNeckDia.s : Inventory maintained in Japan.

B033B210MS4XLD0160N180D0160N200D0160N260D0170N060D0170N140D0170N240D0180N060D0180N080D0180N100D0180N120D0180N140D0180N160D0180N180D0180N200D0180N250D0190N060D0190N160D0190N280D0200N060D0200N080D0200N100D0200N120D0200N140D0200N160D0200N180D0200N200D0200N250D0200N300D0250N080D0250N120D0250N160D0250N200D0250N250D0300N080D0300N120D0300N160D0300N200D0300N250D0300N300D0350N150D0350N250D0350N350D0400N120D0400N160D0400N200D0400N250D0400N300D0400N3501.541.541.541.641.641.641.741.741.741.741.741.741.741.741.741.841.841.841.91.91.91.91.91.91.91.91.91.92.42.42.42.42.42.92.92.92.92.92.93.43.43.43.93.93.93.93.93.91.61.61.61.71.71.71.81.81.81.81.81.81.81.81.81.91.91.922222222222.52.52.52.52.53333333.53.53.54444441.61.61.61.71.71.71.81.81.81.81.81.81.81.81.81.91.91.922222222222.52.52.52.52.53333333.53.53.54444441820266142468101214161820256162868101214161820253081216202581216202530152535121620253035606070506070505050506060606070506070505050506060606070705050606070505060607070607080506060707080444444444444444444444444444444444666666666666666444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssssssssssssssD1 ap L1L3 D5 D4 N111111111111111111111111111111111111111111111111Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDELength ofCutDia.Order NumberNo. ofFlutesShankDia.NeckLengthOverallLengthTypeStockNeckDia.

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4XL0End mill, 4 flute, Long neck -0.02D515°øD1øD4Type1apL3L1UWC MS 30°øD1D5øD4Type2a4 flute long neck end mill.apL3L1Unit : mmOrder NumberDia. Length of Neck Neck Overall Shank No. ofCut Length Dia. Length Dia. FlutesD1 ap L3 D5 L1 D4 NStockType<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>MS4XLD0400N400D0400N450D0400N500D0500N160D0500N250D0500N350D0500N500D0600N200D0600N300D0600N400D0600N500D0800N300D0800N500D0800N700D1000N400D1000N600D1000N800444555566668881010104445555666688810101040455016253550203040503050704060803.93.93.94.94.94.94.95.855.855.855.857.857.857.859.79.79.790901006070801108090100110901101301001201406666666666688810101044444444444444444sssssssssssssssss11111112222222222B034s : Inventory maintained in Japan.CUTTING CONDITIONSB210

MS2ES0End mill, 2 flute, For small automatic lathe -0.0215°øD1øD4Type1apL1UWCMS30°øD1apL1øD4Type2a2 flute end mill.øD1apL1øD4Type3Overall length 35mmUnit : mmOrder NumberDia. Length of Cut Overall Length Shank Dia. No. ofFlutesD1 ap L1 D4 NStockTypeMS2ESD0300L35S04D0350L35S04D0400L35S04D0500L35S05D0500L35S06D0600L35S05D0600L35S06D0700L35S07D0800L35S07D0800L35S08D1000L35S07D1000L35S10D1200L35S10Overall length 45mmOrder NumberMS2ESD0300L45S04D0350L45S04D0400L45S04D0500L45S06D0600L45S06D0700L45S07D0800L45S07D0800L45S08D1000L45S07D1000L45S10D1200L45S1033.54556678810101233.545678810101233.54556666666633.5456788101012353535353535353535353535354545454545454545454545444565677871010Dia. Length of Cut Overall Length Shank Dia. No. ofFlutesD1 ap L1 D4 N4446677871010222222222222222222222222sssssssssssssStocksssssssssss1122132232323Unit : mmType11212232323MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDECUTTING CONDITIONSB211B035

MSTAR <strong>END</strong> <strong>MILLS</strong>MS3ES0End mill, 3 flute, For small automatic lathe -0.0215°øD1øD4Type1apL1UWCMS30°øD1apL1øD4Type2a3 flute end mill.øD1apL1øD4Type3Overall length 35mmUnit : mmOrder NumberDia. Length of Cut Overall Length Shank Dia. No. ofFlutesD1 ap L1 D4 NStockType<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>MS3ESD0300L35S04D0350L35S04D0400L35S04D0500L35S05D0500L35S06D0600L35S05D0600L35S06D0700L35S07D0800L35S07D0800L35S08D1000L35S07D1000L35S10D1200L35S10Overall length 45mmOrder NumberMS3ESD0300L45S04D0350L45S04D0400L45S04D0500L45S06D0600L45S06D0700L45S07D0800L45S07D0800L45S08D1000L45S07D1000L45S10D1200L45S1033.54556678810101233.545678810101233.54556666666633.5456788101012353535353535353535353535354545454545454545454545444565677871010Dia. Length of Cut Overall Length Shank Dia. No. ofFlutesD1 ap L1 D4 N4446677871010333333333333333333333333sssssssssssssStocksssssssssss1122132232323Unit : mmType11212232323B036s : Inventory maintained in Japan.CUTTING CONDITIONSB211

MS4ECD1End mill, 4 flute, For small automatic lathe

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2SB0Ball nose, Short cut length, 2 fluteR±0.01 -0.02UWCMS30°øD1 øD1RRapapL1L115°øD4 øD4Type1Type2a2 flute ball nose end mill for general use.Unit : mmOrder NumberRadius ofBall NoseRDia.D1Length of Overall Shank No. ofCut Length Dia. Flutesap L1 D4 NStockType<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>MS2SBR0010S04R0010S06R0015S04R0015S06R0020S04R0020S06R0025S04R0025S06R0030S04R0030S06R0035S04R0040S04R0040S06R0045S04R0050S04R0050S06R0060S04R0060S06R0070S04R0070S06R0075S04R0075S06R0080S04R0080S06R0090S04R0090S06R0100S04R0100S06R0125S04R0125S06R0150S06R0200S06R0250S06R0300S06R0400S08R0500S10R0600S120.10.10.150.150.20.20.250.250.30.30.350.40.40.450.50.50.60.60.70.70.750.750.80.80.90.9111.251.251.522.534560.20.20.30.30.40.40.50.50.60.60.70.80.80.9111.21.21.41.41.51.51.61.61.81.8222.52.53456810120.30.30.50.50.60.60.80.80.90.91.11.21.21.41.51.51.81.82.12.12.32.32.42.42.72.7333.83.84.567.5912151845504550455045504550454550454550455045504550455045505050505070708080901001104646464646446446464646464646466666810122222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa1111111111111111111111111111111112222The diameter tolerance is only applied to items produced after July 2006.B038a : Inventory maintained.CUTTING CONDITIONSB212

<strong>END</strong> <strong>MILLS</strong>MS2MB0Ball nose, Medium cut length, 2 fluteR±0.01 -0.0215°UWCMS30°øD1 øD1RRapapL1L1øD4 øD4Type1Type2a2 flute ball nose end mill for general use.Unit : mmOrder NumberRadius ofBall NoseRDia.D1Length of Overall Shank No. ofCut Length Dia. Flutesap L1 D4 NStockTypeMS2MB R0025R0030R0040R0050R0060R0070R0075R0080R0090R0100R0125R0150S03R0150R0175R0200S04R0200R0250R0300R0400R0500R06000.250.30.40.50.60.70.750.80.911.251.51.51.75222.534560.50.60.811.21.41.51.61.822.5333.544568101211.21.62.52.53445668888812121418224545454545454545455050707070707080809010011044444444444366466681012222222222222222222222aaaaaaaaaaaaaaaaaaaaa111111111112112112222MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong>CARBIDEThe diameter tolerance is only applied to items produced after July 2006.CUTTING CONDITIONSB212B039

B040a13.7°14.1°13.8°12.9°13.6°12.5°13.3°12.2°13.1°11.9°12.8°11.6°12.6°11°10.5°13.8°12.9°13.6°13.4°12.2°13.1°11.5°12.6°11°10.4°9.5°12.9°13.6°13.4°12.2°13.1°11.5°12.6°10.9°12.1°10.4°11.7°9.9°MS2XLB R0010N005R0010N005S06R0010N008S06R0010N010R0010N010S06R0010N013R0010N013S06R0010N015R0010N015S06R0010N018R0010N018S06R0010N020R0010N020S06R0010N025R0010N030R0015N008S06R0015N010R0015N010S06R0015N012S06R0015N015R0015N015S06R0015N020R0015N020S06R0015N025R0015N030R0015N040R0020N010R0020N010S06R0020N012S06R0020N015R0020N015S06R0020N020R0020N020S06R0020N025R0020N025S06R0020N030R0020N030S06R0020N0350.10.10.10.10.10.10.10.10.10.10.10.10.10.10.10.150.150.150.150.150.150.150.150.150.150.150.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.20.20.20.20.20.20.20.20.20.20.20.20.20.20.20.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.170.170.170.170.170.170.170.170.170.170.170.170.170.170.170.270.270.270.270.270.270.270.270.270.270.270.360.360.360.360.360.360.360.360.360.360.360.360.50.50.8111.251.251.51.51.751.75222.530.8111.21.51.5222.534111.21.51.5222.52.5333.550505050505050505050505050505050505050505050505050505050505050505050505050504664646464646446466464644446646464646422222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N111111111111111111111111111111111111110.70.71.11.31.31.51.51.81.82.12.12.32.32.83.41.11.31.31.51.81.82.32.32.83.44.41.31.31.51.81.82.32.32.92.93.43.43.90.80.81.11.31.31.61.61.91.92.22.22.42.433.51.11.31.31.51.91.92.42.433.54.61.41.41.61.91.92.42.4333.53.540.90.91.21.51.51.71.7222.32.32.62.63.23.81.21.41.41.7222.62.63.23.74.91.51.51.7222.62.63.23.23.83.84.30.90.91.31.61.61.91.92.22.22.52.52.82.83.44.11.31.61.61.82.22.22.82.83.445.31.61.61.82.22.22.82.83.43.44.14.14.730' 1° 2° 3°B2MS2XLB ±0.01 0 -0.02******************************R30°UWCMSL1apL3D5øD4øD1RRøD4L1apL3øD115°D5B2MSTAR <strong>END</strong> <strong>MILLS</strong>a : Inventory maintained.2 flute long neck ball nose end mill.MSTAR <strong>END</strong> <strong>MILLS</strong><strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDETypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleInclined angleEffectivelengthEffective lengthfor inclined angleUnit : mmType1Type2Ball nose, Short cut length, 2 flute, Long neckExpand* Expand

B041B2139.5°9°8.7°8.3°8°12.2°13.1°11.5°12.6°10.9°12.1°10.3°11.7°9.8°11.3°9.4°10.9°9°10.5°8.6°10.2°8.3°9.9°7.9°9.6°7.4°9°6.9°8.6°6.1°7.7°12.8°11.5°12.6°10.9°12.1°10.3°11.7°9.8°11.2°9.3°10.9°8.9°10.5°8.5°10.2°7.9°9.5°MS2XLB R0020N040R0020N045R0020N050R0020N055R0020N060R0025N015R0025N015S06R0025N020R0025N020S06R0025N025R0025N025S06R0025N030R0025N030S06R0025N035R0025N035S06R0025N040R0025N040S06R0025N045R0025N045S06R0025N050R0025N050S06R0025N055R0025N055S06R0025N060R0025N060S06R0025N070R0025N070S06R0025N080R0025N080S06R0025N100R0025N100S06R0030N018S06R0030N020R0030N020S06R0030N025R0030N025S06R0030N030R0030N030S06R0030N035R0030N035S06R0030N040R0030N040S06R0030N045R0030N045S06R0030N050R0030N050S06R0030N060R0030N060S060.20.20.20.20.20.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.250.30.30.30.30.30.30.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.360.360.360.360.360.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.460.560.560.560.560.560.560.560.560.560.560.560.560.560.560.560.560.5644.555.561.51.5222.52.5333.53.5444.54.5555.55.566778810101.8222.52.5333.53.5444.54.55566505050505050505050505050505050505050505050505050505050505050505050505050505050505050505050505050444444646464646464646464646464664646464646464646222222222222222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N1111111111111111111111111111111111111111111111114.44.95.566.51.81.82.32.32.92.93.43.43.93.94.44.44.94.95.55.5666.56.57.57.58.68.610.610.62.12.32.32.92.93.43.43.93.94.44.44.94.95.55.56.56.54.65.15.66.26.71.91.92.42.4333.53.5444.64.65.15.15.65.66.26.26.76.77.87.88.98.911112.22.42.4333.53.5444.64.65.15.15.65.66.76.75.35.96.57.27.82.22.22.82.83.43.4444.74.75.35.35.95.96.56.57.17.17.87.89910.310.312.712.72.52.82.83.43.4444.74.75.35.35.95.96.56.57.87.84.95.56.16.67.2222.62.63.23.23.83.84.34.34.94.95.55.56.16.16.66.67.27.28.48.49.59.511.811.82.42.62.63.23.23.73.74.34.34.94.95.55.5667.27.230' 1° 2° 3°B2****************************************CUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDETypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank Angle* Expand Unit : mm

B0427.3°6.8°8.5°6.3°6°7.7°5.6°5.3°11.4°12.6°12.2°10.2°11.6°9.2°10.8°8.4°7.7°9.5°7.1°6.6°8.4°5.8°7.6°5.2°9.9°11.5°8.9°10.6°8.1°9.9°7.4°9.3°6.8°6.3°8.2°5.9°5.5°7.4°MS2XLB R0030N070R0030N080R0030N080S06R0030N090R0030N100R0030N100S06R0030N110R0030N120R0040N020R0040N020S06R0040N024S06R0040N030R0040N030S06R0040N040R0040N040S06R0040N050R0040N060R0040N060S06R0040N070R0040N080R0040N080S06R0040N100R0040N100S06R0040N120R0050N030R0050N030S06R0050N040R0050N040S06R0050N050R0050N050S06R0050N060R0050N060S06R0050N070R0050N080R0050N080S06R0050N090R0050N100R0050N100S060.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.8111111111111110.60.60.60.60.60.60.60.60.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.8111111111111110.560.560.560.560.560.560.560.560.760.760.760.760.760.760.760.760.760.760.760.760.760.760.760.760.940.940.940.940.940.940.940.940.940.940.940.940.940.94788910101112222.43344566788101012334455667889101050505050505050505050505050505050505050505050505050505050505050505050505050504464464446646464464464644646464644644622222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N111111111111111111111111111111111111117.58.68.69.610.610.611.712.72.32.32.83.43.44.44.45.56.56.57.58.68.610.610.612.73.53.54.64.65.65.66.76.77.78.78.79.810.810.87.88.88.89.9111112.113.12.42.42.93.53.54.64.65.66.76.77.88.88.8111113.13.73.74.74.75.85.86.96.97.99910.111.211.28.39.59.510.611.811.812.914.12.62.633.73.74.94.967.27.28.39.59.511.811.814.13.93.95.15.16.26.27.47.48.59.79.710.81212910.210.211.512.712.71415.22.82.83.3445.25.26.57.77.7910.210.212.712.715.24.24.25.45.46.76.77.97.99.210.410.411.712.912.930' 1° 2° 3°B2aMS2XLB ±0.01 0 -0.02**************************R30°UWCMSL1apL3D5øD4øD1RRøD4L1apL3øD115°D5B2TypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleMSTAR <strong>END</strong> <strong>MILLS</strong>a : Inventory maintained.Unit : mm<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDE2 flute long neck ball nose end mill.MSTAR <strong>END</strong> <strong>MILLS</strong>Inclined angleEffectivelengthEffective lengthfor inclined angleUnit : mmType1Type2Expand* ExpandBall nose, Short cut length, 2 flute, Long neck

B043B2134.9°6.7°4.4°4°5.7°3.7°3.4°4.9°10.9°7.2°9.2°6.1°8.1°5.3°7.3°4.7°6.6°4.2°3.8°5.6°3.5°2.8°5.9°4.5°3.6°10.1°6.9°9°8.2°5.8°8°5°7.1°4.4°6.4°3.9°5.8°3.5°5.4°3.2°3°4.6°2.8°2.1°5.7°4.3°3.4°2.9°MS2XLB R0050N120R0050N120S06R0050N140R0050N160R0050N160S06R0050N180R0050N200R0050N200S06R0060N036S06R0060N060R0060N060S06R0060N080R0060N080S06R0060N100R0060N100S06R0060N120R0060N120S06R0060N140R0060N160R0060N160S06R0060N180R0060N240R0070N080R0070N120R0070N160R0075N045S06R0075N060R0075N060S06R0075N075S06R0075N080R0075N080S06R0075N100R0075N100S06R0075N120R0075N120S06R0075N140R0075N140S06R0075N160R0075N160S06R0075N180R0075N200R0075N200S06R0075N220R0075N300R0080N080R0080N120R0080N160R0080N2000.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.60.60.60.60.60.60.70.70.70.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.80.80.80.8111111111.21.21.21.21.21.21.21.21.21.21.21.21.21.21.41.41.41.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.61.61.61.6111111111.21.21.21.21.21.21.21.21.21.21.21.21.21.21.41.41.41.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.51.61.61.61.60.940.940.940.940.940.940.940.941.141.141.141.141.141.141.141.141.141.141.141.141.141.141.341.341.341.441.441.441.441.441.441.441.441.441.441.441.441.441.441.441.441.441.441.441.541.541.541.5412121416161820203.66688101012121416161824812164.5667.588101012121414161618202022308121620505550556055556050505050505050505550556055655050555050505050505050505550555560555560607050505555464464466464646464464444464664646464646446444444222222222222222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N11111111111111111111111111111111111111111111111112.912.914.9171719.121.121.14.26.76.78.78.710.810.812.912.914.9171719.125.38.712.9175.16.66.68.28.78.710.810.812.912.914.914.9171719.121.121.123.231.58.712.91721.113.313.315.417.617.619.721.921.94.36.96.99911.111.113.313.315.417.617.619.726.1913.317.65.36.96.98.59911.111.113.313.315.415.417.617.619.721.821.82432.5913.317.621.815.415.417.920.420.422.825.325.34.97.97.910.410.412.912.915.415.417.820.320.322.810.415.320.367.97.99.710.310.312.812.815.315.317.817.820.320.322.825.310.315.320.314.314.316.618.918.921.223.523.54.67.37.39.69.611.911.914.214.216.518.818.821.1289.614.218.85.67.37.399.69.611.911.914.214.216.516.518.818.821.123.423.425.734.99.614.218.823.430' 1° 2° 3°B2**************************CUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDETypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleNointerferenceNointerferenceNointerferenceNointerferenceNointerference* Expand Unit : mm

B0445.4°4°3.2°2.7°7.8°10.2°6.1°8.7°5.1°7.6°4.3°6.7°3.8°6°3.4°5.5°3°5°2.7°4.6°2.5°4.3°2.3°2.1°3.6°1.8°3.1°1.5°2.8°8.4°7.5°6.3°5.5°4.6°3.9°3.3°2.8°2.5°MS2XLB R0090N080R0090N120R0090N160R0090N200R0100N040R0100N040S06R0100N060R0100N060S06R0100N080R0100N080S06R0100N100R0100N100S06R0100N120R0100N120S06R0100N140R0100N140S06R0100N160R0100N160S06R0100N180R0100N180S06R0100N200R0100N200S06R0100N220R0100N250R0100N250S06R0100N300R0100N300S06R0100N350R0100N350S06R0125N060S06R0125N075S06R0125N100S06R0125N125S06R0125N160S06R0125N200S06R0125N250S06R0125N300S06R0125N350S060.90.90.90.911111111111111111111111111.251.251.251.251.251.251.251.251.251.81.81.81.822222222222222222222222222.52.52.52.52.52.52.52.52.51.81.81.81.822222222222222222222222222.52.52.52.52.52.52.52.52.51.741.741.741.741.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.91.92.42.42.42.42.42.42.42.42.481216204466881010121214141616181820202225253030353567.51012.5162025303550505555505050505050505050555055556055606060606565707070805050505060606570804444464646464646464646446464666666666622222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N111111111111111111111111111111111111118.712.81721.14.64.66.76.78.88.810.910.912.912.9151517.117.119.119.121.221.223.326.426.431.531.536.736.76.78.310.813.41721.226.431.536.7913.317.521.84.84.86.96.99.19.111.211.213.313.315.515.517.617.619.819.821.921.92427.227.232.632.637.937.96.98.511.213.917.621.927.232.637.99.614.218.823.45.15.17.47.49.79.712.012.014.314.316.616.618.918.921.221.223.523.525.829.329.235.040.77.39.111.914.818.823.429.234.940.710.315.320.35.45.47.97.910.410.412.912.915.415.417.817.820.322.825.331.537.77.89.712.815.920.325.231.530' 1° 2° 3°B2aMS2XLB ±0.01 0 -0.02**********************R30°UWCMSL1apL3D5øD4øD1RRøD4L1apL3øD115°D5B2TypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleMSTAR <strong>END</strong> <strong>MILLS</strong>a : Inventory maintained.Unit : mm<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDE2 flute long neck ball nose end mill.MSTAR <strong>END</strong> <strong>MILLS</strong>Inclined angleEffectivelengthEffective lengthfor inclined angleUnit : mmType1Type2ExpandNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerference* ExpandBall nose, Short cut length, 2 flute, Long neck

B045B2136.8°5.9°5.2°4.6°4.2°3.5°2.9°2.5°2.2°2°4.7°4°3.5°3.2°2.6°2.1°1.8°1.6°1.4°1.3°1.1°1.5°1.2°1°0.9°MS2XLB R0150N080R0150N100R0150N120R0150N140R0150N160R0150N200R0150N250R0150N300R0150N350R0150N400R0200N100R0200N120R0200N140R0200N160R0200N200R0200N250R0200N300R0200N350R0200N400R0200N450R0200N500R0250N200R0250N250R0250N300R0250N350R0300N300R0300N5001.51.51.51.51.51.51.51.51.51.5222222222222.52.52.52.5333333333333444444444445555663333333333444444444445555662.92.92.92.92.92.92.92.92.92.93.93.93.93.93.93.93.93.93.93.93.94.94.94.94.95.855.858101214162025303540101214162025303540455020253035305060606060607070708090707070707070708090901007070808080120666666666666666666666666666222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N1111111111111111111111111228.810.812.9151721.226.331.536.741.810.812.9151721.226.331.536.741.84752.221.126.331.536.6911.213.315.417.621.927.232.637.943.311.113.315.417.521.827.232.537.943.248.653.921.827.110.312.715.217.720.225.212.615.117.620.19.611.914.216.518.823.429.134.940.611.814.116.418.723.329.130' 1° 2° 3°B2***CUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDETypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerference* Expand Unit : mmThe diameter tolerance is only applied to items produced after July 2006.

B047B214111111111111111111111111111111111111111111111111MS2XBR0025T0130L050R0025T0200L030R0025T0200L050R0030T0030L050R0030T0030L080R0030T0100L050R0030T0100L080R0030T0100L100R0030T0100L120R0030T0100L150R0030T0130L050R0030T0130L080R0030T0200L060R0030T0200L080R0040T0030L080R0040T0030L120R0040T0100L080R0040T0100L120R0040T0130L080R0040T0130L120R0040T0200L080R0040T0300L120R0050T0030L100R0050T0030L150R0050T0030L200R0050T0030L250R0050T0030L300R0050T0100L100R0050T0100L150R0050T0100L200R0050T0100L250R0050T0100L300R0050T0100L350R0050T0130L100R0050T0130L150R0050T0130L200R0050T0200L150R0050T0200L200R0050T0300L200R0050T0300L400R0050T0500L200R0060T0030L120R0060T0030L240R0060T0100L120R0060T0100L240R0060T0130L120R0060T0130L240R0060T0200L1200.250.250.250.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.50.50.50.60.60.60.60.60.60.60.60.60.60.60.80.80.80.80.80.80.80.811111111111111111111.21.21.21.21.21.21.21° 30'2°2°30'30'1°1°1°1°1°1° 30'1° 30'2°2°30'30'1°1°1° 30'1° 30'2°3°30'30'30'30'30'1°1°1°1°1°1°1° 30'1° 30'1° 30'2°2°3°3°5°30'30'1°1°1° 30'1° 30'2°0.50.50.50.60.60.60.60.60.60.60.60.60.60.60.80.80.80.80.80.80.80.811111111111111111111.21.21.21.21.21.21.25355858101215586881281281281210152025301015202530351015201520204020122412241224121.51.51.51.61.61.61.61.61.61.61.61.61.61.61.81.81.81.81.81.81.81.82.52.52.52.52.52.52.52.52.52.52.52.52.52.52.52.52.52.52.52.72.72.72.72.72.72.77.0°7.9°7.1°6.8°5.7°6.8°5.8°5.2°4.8°4.2°6.9°5.9°6.6°6.0°5.5°4.5°5.6°4.6°5.8°4.8°5.9°5.2°6.1°5.1°4.4°3.8°3.4°6.2°5.2°4.5°3.9°3.5°3.2°6.3°5.3°4.6°5.4°4.7°5.0°3.4°5.7°5.6°3.8°5.7°3.9°5.8°4.1°5.9°505050505050505050505050505050605060506060606060707070606070707080606070607070807060706070607060444444444444444444444466666666666666666666666666222222222222222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa5.38.38.312.310.415.420.425.430.412.424.45.68.75.48.410.412.415.48.713.08.412.410.916.221.526.832.010.515.520.525.530.535.513.125.712.524.55.83.55.56.29.86.09.411.613.917.25.89.06.68.69.814.59.413.99.013.28.612.218.224.130.035.911.817.423.028.634.239.811.316.621.915.820.814.628.814.027.513.426.212.86.64.06.37.111.16.810.713.215.819.66.610.27.49.711.116.510.715.810.215.09.712.813.920.727.434.241.013.419.826.232.639.045.412.818.924.918.023.721.241.216.632.815.931.315.229.814.60.650.570.710.620.680.680.790.860.931.030.740.900.871.010.870.940.981.121.091.301.201.831.081.161.251.341.421.211.381.561.731.912.081.341.601.861.822.172.784.884.011.311.521.471.891.632.261.79D3 30' 1° 2° 3°B1L2D1 ap L3 L1 ND4B2RStockTypeOrder NumberTaper AngleOne SideRadius ofBall NoseDia.Cutting Edge toShank AngleNo. ofFlutesEffective lengthfor inclined angleLength ofCutNeckLengthOverallLengthShankDia.Unit : mmLength ofStraight NeckNeckDia.CUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDE

B04811111111111111111111111111111111111111MS2XB R0060T0200L240R0075T0030L100R0075T0030L150R0075T0030L300R0075T0100L100R0075T0100L150R0075T0100L200R0075T0100L300R0075T0130L100R0075T0130L150R0075T0130L300R0075T0200L100R0075T0200L150R0075T0200L300R0100T0030L200R0100T0030L300R0100T0030L400R0100T0100L200R0100T0100L250R0100T0100L300R0100T0100L350R0100T0100L400R0100T0100L500R0100T0130L200R0100T0130L300R0100T0130L400R0100T0200L300R0100T0200L400R0100T0300L300R0100T0300L400R0100T0500L200R0100T0500L380R0150T0030L300R0150T0030L400R0150T0030L500R0150T0100L300R0150T0100L400R0150T0100L5000.60.750.750.750.750.750.750.750.750.750.750.750.750.751111111111111111111.51.51.51.51.51.51.21.51.51.51.51.51.51.51.51.51.51.51.51.52222222222222222223333332°30'30'30'1°1°1°1°1° 30'1° 30'1° 30'2°2°2°30'30'30'1°1°1°1°1°1°1° 30'1° 30'1° 30'2°2°3°3°5°5°30'30'30'1°1°1°1.21.51.51.51.51.51.51.51.51.51.51.51.51.522222222222222222233333324101530101520301015301015302030402025303540502030403040304020383040503040502.733333333333334444444444444444446666664.2°5.9°4.9°3.2°6.0°5.0°4.2°3.3°6.1°5.1°3.4°6.2°5.2°3.5°3.9°2.9°2.4°4.0°3.4°3.0°2.7°2.5°2.1°4.1°3.1°2.6°3.3°2.7°3.5°2.9°5.1°4.6°2.4°1.9°1.6°2.5°2.0°1.7°70606070606070706060706060706070806060708080906070807080708060807080907080906666666666666666666666666666666866666622222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa10.415.430.420.730.740.730.740.750.710.916.232.010.515.520.530.521.732.342.820.825.830.835.840.850.832.342.953.431.041.051.024.812.218.135.911.817.423.034.211.316.632.510.915.930.924.336.248.023.328.934.540.145.857.022.332.943.531.341.336.234.745.928.313.820.640.913.319.726.139.012.818.937.012.318.035.127.626.432.939.325.337.435.531.82.631.571.651.921.691.862.042.391.812.072.861.932.283.332.182.362.532.462.642.812.993.163.512.743.273.793.724.424.635.684.707.853.323.503.673.744.094.44D3 30' 1° 2° 3°B1L2D1 ap L3 L1 ND4B2RMS2XBae 0.01 0 -0.02R30°UWCMSøD4L1apøD1L3L2RB1B210°D3StockTypeOrder NumberTaper AngleOne SideRadius ofBall NoseDia.Cutting Edge toShank AngleNo. ofFlutesEffective lengthfor inclined angleLength ofCutNeckLengthOverallLengthShankDia.Unit : mmNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceType1Inclined angleEffectivelengthEffective lengthfor inclined angleMSTAR <strong>END</strong> <strong>MILLS</strong>Length ofStraight NeckNeckDia.MSTAR <strong>END</strong> <strong>MILLS</strong>a : Inventory maintained.<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDE2 flute taper neck ball nose end mill.Ball nose, 2 flute, Taper neck

Unit : mmOrder NumberMS2XBR0150T0130L300R0150T0130L400R0150T0130L500R0150T0200L300R0150T0200L480R0150T0300L300R0150T0300L500R0200T0030L600R0200T0100L600Radius ofBall NoseR1.51.51.51.51.51.51.522Dia. Taper Angle Length of Neck Length of Cutting Edge to Neck Overall Shank No. ofEffective lengthOne Side Cut Length Straight Neck Shank Angle Dia. Length Dia. Flutes for inclined angleD1 B1 ap L3 L2 B2 D3 L1 D4 N 30' 1° 2° 3°3 1° 30' 3 30 6 2.6° 4.16 70 6 2 a 1 33.13 1° 30' 3 40 6 2.1° 4.69 80 6 2 a 1 43.83 1° 30' 3 50 6 1.7° 5.21 90 6 2 a 1 Nointerference3 2° 3 30 6 2.7° 4.58 70 6 2 a 1 31.63 2° 3 48 6 1.9° 5.84 90 6 2 a 1 Nointerference3 3° 3 30 6 2.9° 5.42 70 6 2 a 1 3 3° 3 50 6 2.9° 7.52 90 8 2 a 1 4 30' 4 60 7 1.0° 4.83 110 6 2 a 1 60.8No64.0 interference4 1° 4 60 7 1.0° 5.76 110 6 2 a 1 61.1StockTypeNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDECUTTING CONDITIONSB214B049

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MRBExpandCorner radius end mill, Medium cut length, 2 flute0 -0.02<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>B050*D0800R020 816 60 8 0.2 2 a 2* Expand Type1RapL1Type2UWCR apMS 30°L1D1

Unit : mmOrder NumberDia. Length of Overall Shank Corner R No. ofCut Length Dia.FlutesD1 ap L1 D4 R NStockType***********************MS2MRBD0800R030D0800R050D0800R100D0800R150D0800R200D0800R250D0800R300D1000R020D1000R030D1000R050D1000R100D1000R150D1000R200D1000R250D1000R300D1200R020D1200R030D1200R050D1200R100D1200R150D1200R200D1200R250D1200R3008888888101010101010101012121212121212121616161616161620202020202020202424242424242424* Expand CUTTING CONDITIONS60606060606060707070707070707075757575757575758888888101010101010101012121212121212120.30.511.522.530.20.30.511.522.530.20.30.511.522.53The diameter tolerance is only applied to items produced after July 2006.22222222222222222222222aaaaaaaaaaaaaaaaaaaaaaa22222222222222222222222MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEB051B200

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2XLRBCorner radius end mill, Short cut length, 2 flute, Long neck0 -0.02Effective lengthfor inclined angleøD1RapL3D5L115°B2øD4Type1MSUWC30°D1

B053B216MS4MRBaMS4MRBD0300R010D0300R020D0300R030D0300R050D0300R100D0400R010D0400R020D0400R030D0400R050D0400R100D0500R010D0500R020D0500R030D0500R050D0500R100D0600R010D0600R020D0600R030D0600R050D0600R100D0600R150D0600R200D0800R020D0800R030D0800R050D0800R100D0800R150D0800R200D0800R250D0800R300D1000R020D1000R030D1000R050D1000R100D1000R150D1000R200D1000R250D1000R300333334444455555666666688888888101010101010101088888111111111113131313131313131313131319191919191919192222222222222222454545454545454545455050505050505050505050506060606060606060707070707070707066666666666666666666668888888810101010101010100.10.20.30.510.10.20.30.510.10.20.30.510.10.20.30.511.520.20.30.511.522.530.20.30.511.522.5344444444444444444444444444444444444444aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1 ap D4L1 R N11111111111111122222222222222222222222D1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4MRBCorner radius end mill, Medium cut length, 4 fluteD1

B055B217MSMHDRBaMSMHDRB D0200R020D0200R030D0300R020D0300R030D0300R050D0400R020D0400R030D0400R050D0500R020D0500R030D0500R050D0500R100D0600R030D0600R050D0600R100D0800R030D0800R050D0800R100D0800R150D1000R030D1000R050D1000R100D1000R150D1000R200D1200R050S10D1200R100S10D1200R150S10D1200R200S10D1200R300S10D1200R050D1200R100D1200R150D1200R200D1200R300D1600R100D1600R150D1600R200D1600R3002233344455556668888101010101012121212121212121212161616164488811111113131313131313191919192222222222262626262626262626263535353545454545454545455050505050505060606060707070707075757575757575757575909090904466666666666668888101010101010101010101212121212161616160.20.30.20.30.50.20.30.50.20.30.510.30.510.30.511.50.30.511.520.511.5230.511.52311.52344444444444444444444444444444444444444aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1 ap D4L1 R N111111111111222222222222333332222222220 -0.020 -0.03D1

MSTAR <strong>END</strong> <strong>MILLS</strong>MSMHDRBCorner radius end mill, High power, Medium cut length, 4 fluteD1

B057B218MS2MTaMS2MTD0020T0030D0020T0100D0020T0130D0020T0200D0020T0300D0020T0400D0020T0500D0020T0700D0020T1000D0030T0030D0030T0100D0030T0130D0030T0200D0030T0300D0030T0400D0030T0500D0030T0700D0030T1000D0040T0030D0040T0100D0040T0130D0040T0200D0040T0300D0040T0400D0040T0500D0040T0700D0040T1000D0050T0030D0050T0100D0050T0130D0050T0200D0050T0300D0050T0400D0050T0500D0050T0700D0050T1000D0060T0030D0060T01000.20.20.20.20.20.20.20.20.20.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.60.60.210.230.240.260.280.310.340.40.480.320.340.360.380.430.470.510.590.720.430.460.480.510.570.620.680.790.960.530.570.60.640.710.780.850.991.210.630.670.80.80.80.80.80.80.80.80.81.21.21.21.21.21.21.21.21.21.61.61.61.61.61.61.61.61.62222222222245454545454545454545454545454545454545454545454545454545454545454545454545454444444444444444444444444444444444444422222222222222222222222222222222222222ssssssssssssssssssssssssssssssssssssss30'1°1° 30'2°3°4°5°7°10°30'1°1° 30'2°3°4°5°7°10°30'1°1° 30'2°3°4°5°7°10°30'1°1° 30'2°3°4°5°7°10°30'1°D1 B7 D2 ap L1 D4 N11111111211111111211111111211111111211D1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MTTaper end mill, 2 flute, Medium cut lengthD1

B059B218MS2MTD0100T0130D0100T0200D0100T0230D0100T0300D0100T0400D0100T0500D0100T0700D0100T1000D0150T0030D0150T0100D0150T0130D0150T0200D0150T0230D0150T0300D0150T0400D0150T0500D0150T0700D0150T1000D0200T0030D0200T0100D0200T0130D0200T0200D0200T0230D0200T0300D0200T0400D0200T0500D0200T0700D0200T1000D0250T0030D0250T0100D0250T0130D0250T0200D0250T0230D0250T0300D0250T0400D0250T0500D0250T0700D0250T1000D0300T0030D0300T0100D0300T0130D0300T0200D0300T0300D0300T0400D0300T0500D0300T0700D0300T1000D0400T0030111111111.51.51.51.51.51.51.51.51.51.522222222222.52.52.52.52.52.52.52.52.52.533333333341.211.281.351.421.561.71.982.411.591.671.761.851.942.022.22.372.733.262.12.212.312.422.522.632.843.053.474.122.642.782.923.063.23.343.623.94.465.323.173.353.523.74.054.44.755.466.534.264444444455555555556666666666888888888810101010101010101015454545454545454545454545454545454545454545454545454545504545454545454545505050505050505050505050444444444444444444444444444644444444466666666666222222222222222222222222222222222222222222222222ssssssssssssssssssssssssssssssssssssssssssssssss1° 30'2°2° 30'3°4°5°7°10°30'1°1° 30'2°2° 30'3°4°5°7°10°30'1°1° 30'2°2° 30'3°4°5°7°10°30'1°1° 30'2°2° 30'3°4°5°7°10°30'1°1° 30'2°3°4°5°7°10°30'D1 B7 D2 ap L1 D4 N111111121111111112111111112211111122321111111231Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDESmallMill Dia.Order NumberNo. ofFlutesLength ofCutShankDia.OverallLengthLargeMill Dia.TypeStockTaper AngleOne Side

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MTTaper end mill, 2 flute, Medium cut lengthD1

MS4LTTaper end mill, Long cut length, 4 fluteD1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4LTTaper end mill, Long cut length, 4 fluteD1

B063B219MS4LTD0100T0130L12D0100T0130L16D0100T0200L06D0100T0200L08D0100T0200L10D0100T0200L12D0100T0200L16D0120T0015L06D0120T0015L10D0120T0015L12D0120T0015L16D0120T0030L06D0120T0030L10D0120T0030L12D0120T0030L16D0120T0100L06D0120T0100L10D0120T0100L12D0120T0100L16D0120T0100L20D0120T0130L06D0120T0130L10D0120T0130L12D0120T0130L16D0120T0130L20D0120T0200L06D0120T0200L10D0120T0200L12D0120T0200L16D0120T0200L20D0130T0030L12D0130T0100L12D0130T0130L12D0130T0200L12D0140T0030L12D0140T0100L12D0140T0130L12D0140T0200L12D0150T0015L06D0150T0015L08D0150T0015L10D0150T0015L12D0150T0015L16D0150T0015L20D0150T0030L06D0150T0030L08D0150T0030L10D0150T0030L1211111111.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.21.31.31.31.31.41.41.41.41.51.51.51.51.51.51.51.51.51.51.631.841.421.561.71.842.121.251.291.31.341.31.371.411.481.411.551.621.761.91.511.721.832.042.251.621.92.042.322.61.511.721.932.141.611.822.032.241.551.571.591.61.641.671.61.641.671.711216681012166101216610121661012162061012162061012162012121212121212126810121620681012505545454550554545505545455055454550555545455055554545505555505050505050505045454550555545454550444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssssssssssssss1° 30'1° 30'2°2°2°2°2°15'15'15'15'30'30'30'30'1°1°1°1°1°1° 30'1° 30'1° 30'1° 30'1° 30'2°2°2°2°2°30'1°1° 30'2°30'1°1° 30'2°15'15'15'15'15'15'30'30'30'30'D1 B7 D2 ap L1 D4 N111111111111111111111111111111111111111111111111Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDESmallMill Dia.Order NumberNo. ofFlutesLength ofCutShankDia.OverallLengthLargeMill Dia.TypeStockTaper AngleOne Side

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4LTTaper end mill, Long cut length, 4 fluteD1

B065B219MS4LTD0160T0200L20D0180T0015L08D0180T0015L16D0180T0015L24D0180T0030L08D0180T0030L16D0180T0030L24D0180T0100L08D0180T0100L16D0180T0100L24D0180T0130L08D0180T0130L16D0180T0130L24D0180T0200L08D0180T0200L16D0180T0200L24D0200T0015L08D0200T0015L10D0200T0015L12D0200T0015L16D0200T0015L20D0200T0015L25D0200T0030L08D0200T0030L10D0200T0030L12D0200T0030L16D0200T0030L20D0200T0030L25D0200T0030L30D0200T0100L08D0200T0100L10D0200T0100L12D0200T0100L16D0200T0100L20D0200T0100L25D0200T0100L30D0200T0130L08D0200T0130L10D0200T0130L12D0200T0130L16D0200T0130L20D0200T0130L25D0200T0130L30D0200T0200L08D0200T0200L10D0200T0200L12D0200T0200L16D0200T0200L201.61.81.81.81.81.81.81.81.81.81.81.81.81.81.81.82222222222222222222222222222222231.871.942.011.942.082.222.082.362.642.222.643.062.362.923.482.072.092.12.142.172.222.142.172.212.282.352.442.522.282.352.422.562.72.873.052.422.522.632.843.053.313.572.562.72.843.123.420816248162481624816248162481012162025810121620253081012162025308101216202530810121620554555604555604555604555604555604545505555604545505555606545455055556065454550555560654545505555444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssssssssssssss2°15'15'15'30'30'30'1°1°1°1° 30'1° 30'1° 30'2°2°2°15'15'15'15'15'15'30'30'30'30'30'30'30'1°1°1°1°1°1°1°1° 30'1° 30'1° 30'1° 30'1° 30'1° 30'1° 30'2°2°2°2°2°D1 B7 D2 ap L1 D4 N111111111111111111111111111111111111111111111111Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDESmallMill Dia.Order NumberNo. ofFlutesLength ofCutShankDia.OverallLengthLargeMill Dia.TypeStockTaper AngleOne Side

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4LTTaper end mill, Long cut length, 4 fluteD1

MS4LTBBall nose, 4 flute, Taper, For rib millingRe0.03 e5'RB7apD2L115°øD4Type1UWCMS20°a4 flute taper ball nose end mill for rib milling.Unit : mmOrder NumberRadius ofBall NoseRTaper Angle Large Mill Length of Overall Shank No. ofOne Side Dia. Cut Length Dia. FlutesB7 D2 ap L1 D4 NStockTypeMS4LTB R0030T0030L04R0030T0030L06R0030T0100L04R0030T0100L06R0030T0130L04R0030T0130L06R0030T0200L04R0030T0200L06R0040T0030L06R0040T0030L08R0040T0030L10R0040T0100L06R0040T0100L08R0040T0100L10R0040T0130L06R0040T0130L08R0040T0130L10R0040T0200L06R0040T0200L08R0040T0200L10R0050T0030L08R0050T0030L10R0050T0030L12R0050T0030L16R0050T0100L08R0050T0100L10R0050T0100L12R0050T0100L16R0050T0130L08R0050T0130L10R0050T0130L12R0050T0130L16R0050T0200L08R0050T0200L10R0050T0200L12R0050T0200L16R0060T0030L08R0060T0030L100.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.630'30'1°1°1° 30'1° 30'2°2°30'30'30'1°1°1°1° 30'1° 30'1° 30'2°2°2°30'30'30'30'1°1°1°1°1° 30'1° 30'1° 30'1° 30'2°2°2°2°30'30'0.660.700.730.800.790.900.861.000.900.930.971.001.071.141.091.201.301.191.331.471.131.171.201.271.261.331.401.541.391.501.601.811.521.661.802.081.331.36464646466810681068106810810121681012168101216810121681045454545454545455050505050505050505050505050505550505055505050555050505550504444444444444444444444444444444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssss11111111111111111111111111111111111111MSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDECUTTING CONDITIONSB220B067

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4LTBBall nose, 4 flute, Taper, For rib millingRe0.03 e5'RB7apD2L115°øD4Type1UWCMS20°a4 flute taper ball nose end mill for rib milling.Unit : mmOrder NumberRadius ofBall NoseRTaper Angle Large Mill Length of Overall Shank No. ofOne Side Dia. Cut Length Dia. FlutesB7 D2 ap L1 D4 NStockType<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>MS4LTB R0060T0030L12R0060T0030L16R0060T0100L08R0060T0100L10R0060T0100L12R0060T0100L16R0060T0130L08R0060T0130L10R0060T0130L12R0060T0130L16R0060T0200L08R0060T0200L10R0060T0200L12R0060T0200L16R0075T0030L08R0075T0030L10R0075T0030L12R0075T0030L16R0075T0030L20R0075T0100L08R0075T0100L10R0075T0100L12R0075T0100L16R0075T0100L20R0075T0130L08R0075T0130L10R0075T0130L12R0075T0130L16R0075T0130L20R0075T0200L08R0075T0200L10R0075T0200L12R0075T0200L16R0075T0200L20R0090T0030L08R0090T0030L10R0090T0030L12R0090T0030L160.60.60.60.60.60.60.60.60.60.60.60.60.60.60.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.750.90.90.90.930'30'1°1°1°1°1° 30'1° 30'1° 30'1° 30'2°2°2°2°30'30'30'30'30'1°1°1°1°1°1° 30'1° 30'1° 30'1° 30'1° 30'2°2°2°2°2°30'30'30'30'1.401.471.461.531.601.741.591.691.802.011.721.862.002.281.631.661.701.771.841.751.821.892.032.171.881.982.092.302.512.012.152.292.572.841.921.961.992.061216810121681012168101216810121620810121620810121620810121620810121650555050505550505055505050555050505560505050556050505055605050505560505050554444444444444444444444444444444444444444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssss11111111111111111111111111111111111111B068s : Inventory maintained in Japan.

B069B220RMS4LTBR0090T0030L20R0090T0100L08R0090T0100L10R0090T0100L12R0090T0100L16R0090T0100L20R0090T0130L08R0090T0130L10R0090T0130L12R0090T0130L16R0090T0130L20R0090T0200L08R0090T0200L10R0090T0200L12R0090T0200L16R0090T0200L20R0100T0030L10R0100T0030L12R0100T0030L16R0100T0030L20R0100T0030L25R0100T0030L30R0100T0100L10R0100T0100L12R0100T0100L16R0100T0100L20R0100T0100L25R0100T0100L30R0100T0130L10R0100T0130L12R0100T0130L16R0100T0130L20R0100T0130L25R0100T0130L30R0100T0200L10R0100T0200L12R0100T0200L16R0100T0200L20R0100T0200L25R0100T0200L300.90.90.90.90.90.90.90.90.90.90.90.90.90.90.90.91111111111111111111111112.132.052.122.192.332.472.172.282.382.592.802.302.442.582.863.132.162.192.262.332.422.512.312.382.522.662.843.012.472.582.793.003.263.522.632.773.053.333.684.03208101216208101216208101216201012162025301012162025301012162025301012162025306050505055605050505560505050556050505560656550505560656550505560656550505560656544444444444444444444444444444444664444664444444444444444444444444444444444444444ssssssssssssssssssssssssssssssssssssssss30'1°1°1°1°1°1° 30'1° 30'1° 30'1° 30'1° 30'2°2°2°2°2°30'30'30'30'30'30'1°1°1°1°1°1°1° 30'1° 30'1° 30'1° 30'1° 30'1° 30'2°2°2°2°2°2°B7 D2 ap L1 D4 N1111111111111111111111111111111111111111Unit : mmCUTTING CONDITIONSMSTAR <strong>END</strong> <strong>MILLS</strong> <strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDERadius ofBall NoseOrder NumberNo. ofFlutesLength ofCutShankDia.OverallLengthLarge MillDia.StockTypeTaper AngleOne Side

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MTBBall nose taper, Long cut length, 2 fluteRe0.01 e5'RB7apD215°øD4Type1L1UWCMS30°RB7apD2øD4Type2a2 flute taper ball nose end mill.L1Unit : mmOrder NumberRadius ofBall NoseRTaper Angle Large Mill Length of Overall Shank No. ofOne Side Dia. Cut Length Dia. FlutesB7 D2 ap L1 D4 NStockType<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEMSTAR <strong>END</strong> <strong>MILLS</strong>MS2MTBR0020T0300R0020T0500R0020T0700R0020T1000R0030T0300R0030T0500R0030T0700R0030T1000R0050T0030R0050T0100R0050T0130R0050T0200R0050T0300R0050T0500R0050T0700R0075T0030R0075T0100R0075T0130R0075T0200R0075T0300R0075T0700R0100T0030R0100T0100R0100T0130R0100T0200R0100T0300R0100T0400R0100T0500R0100T0700R0125T0030R0125T0100R0125T0130R0125T0200R0125T0300R0125T0400R0125T0500R0125T0700R0150T07000.20.20.20.20.30.30.30.30.50.50.50.50.50.50.50.750.750.750.750.750.75111111111.251.251.251.251.251.251.251.251.53°5°7°10°3°5°7°10°30'1°1° 30'2°3°5°7°30'1°1° 30'2°3°7°30'1°1° 30'2°3°4°5°7°30'1°1° 30'2°3°4°5°7°7°0.690.891.091.390.881.071.271.561.041.091.131.181.261.442.361.591.681.781.872.052.82.122.242.372.492.742.983.233.732.652.812.963.113.423.734.045.775.72333333333333336666666888888881010101010101014.512.540404040404040404040404040404540404040404045454545454545504545454545505060604444444444444444444444444444644444666622222222222222222222222222222222222222ssssssssssssssssssssssssssssssssssssss11111111111111111111111111111111111122B070a : Inventory maintained.s : Inventory maintained in Japan.CUTTING CONDITIONSB212

MS2MC aaa EEnd mill, Medium cut length, 2 flute, Centre cuttingD1< 33

MSTAR <strong>END</strong> <strong>MILLS</strong>MS3MC aaa EEnd mill, Medium cut length, 3 flute, Centre cuttingD1< 33

MS4MC aaa EEnd mill, Medium cut length, 4 flute, Centre cuttingD1< 33

MSTAR <strong>END</strong> <strong>MILLS</strong>MS4JC aaa EEnd mill, Semi long cut length, 4 flute, Centre cuttingD1< 33

MS2SB aaa EBall nose, Short cut length, 2 flute, Short shankRe 0.015D1

MSTAR <strong>END</strong> <strong>MILLS</strong>MS2MB aaa EBall nose, Medium cut length, 2 flute, Long shankRe 0.015D1

MS4MRB aaa EEnd mill, Medium cut length, 4 flute, Corner radiusD1 =66

MSTAR <strong>END</strong> <strong>MILLS</strong>MS6MH aaa E/MS8MH aaa EEnd mill, Medium cut length, 6/8 flutes, Centre cuttingD1 =66

IMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>VF2SSBBall nose, Short cut length, 2 flute, For hardened materialsRe0.005 0 -0.01øD1RapL3D5L115°øD4Type1UWCVF30°a2 flute ball nose end mill with Impact Miraclecoating for high hardened materials.øD1RapL3D5L1øD4Type2Unit : mmOrder NumberRadius of Dia. Length of Neck Neck Overall Shank No. ofBall NoseCut Length Dia. Length Dia. FlutesR D1 ap L3 D5 L1 D4 NStockTypeVF2SSBR0050S04R0050R0075S04R0075R0100R0150R0200R0250R0300R0400R0500R06000.50.50.750.7511.522.53456111.51.52345681012111.51.52345681012223346810121418220.940.941.441.441.92.93.94.95.857.859.711.740404040454545505060707546466666681012222222222222aaaaaaaaaaaa111111112222<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEIMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>CUTTING CONDITIONSB227B079

IMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>VF2SBExpandBall nose, Short cut length, 2 flute, For hardened materialsRR

VF2SDBBall nose, Medium cut length, 2 flute, Strong geometry typeRR

IMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>VF2SDBLBall nose, Medium cut length, 2 flute, Strong geometry type, Long shankRR

B083B229VF2XLBa±0.007±0.0100 -0.0211.2°11.5°10.9°10.7°11.1°10.4°10.2°10.8°10.0°9.7°9.3°10.7°11.1°10.4°10.2°10.8°10.0°9.7°10.4°9.3°8.9°8.2°10.7°11.1°10.2°10.8°9.7°10.4°9.3°10.1°8.9°9.8°8.2°7.6°10.2°10.8°9.7°10.4°0.10.10.10.10.10.10.10.10.10.10.10.150.150.150.150.150.150.150.150.150.150.150.20.20.20.20.20.20.20.20.20.20.20.20.250.250.250.250.20.20.20.20.20.20.20.20.20.20.20.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.50.50.50.50.160.160.160.160.160.160.160.160.160.160.160.240.240.240.240.240.240.240.240.240.240.240.320.320.320.320.320.320.320.320.320.320.320.320.40.40.40.40.170.170.170.170.170.170.170.170.170.170.170.270.270.270.270.270.270.270.270.270.270.270.360.360.360.360.360.360.360.360.360.360.360.360.460.460.460.460.50.50.75111.251.51.51.7522.5111.251.51.51.75222.534111.51.5222.52.533451.51.52250505050505050505050505050505050505050505050505050505050505050505050505050504644644644446446446444464646464644464622222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N111111111111111111111111111111111111110.70.71.01.31.31.51.81.82.12.32.81.31.31.51.81.82.12.32.32.83.44.41.31.31.81.82.32.32.92.93.43.44.45.51.81.82.32.30.80.81.11.31.31.61.91.92.22.43.01.31.31.61.91.92.12.42.43.03.54.61.41.41.91.92.42.43.03.03.53.54.65.71.91.92.42.40.90.91.21.51.51.82.12.12.42.73.31.51.51.82.12.12.42.72.73.23.85.01.51.52.12.12.72.73.33.33.93.95.16.32.12.12.72.71.01.01.31.61.61.92.32.32.62.93.61.61.61.92.32.32.62.92.93.64.35.61.61.62.32.32.92.93.63.64.34.35.66.92.32.32.92.930' 1° 2° 3°B2VF2XLB R0010N005S04R0010N005S06R0010N008S04R0010N010S04R0010N010S06R0010N013S04R0010N015S04R0010N015S06R0010N018S04R0010N020S04R0010N025S04R0015N010S04R0015N010S06R0015N013S04R0015N015S04R0015N015S06R0015N018S04R0015N020S04R0015N020S06R0015N025S04R0015N030S04R0015N040S04R0020N010S04R0020N010S06R0020N015S04R0020N015S06R0020N020S04R0020N020S06R0020N025S04R0020N025S06R0020N030S04R0020N030S06R0020N040S04R0020N050S04R0025N015S04R0025N015S06R0025N020S04R0025N020S06R

B084VF2XLBa±0.007±0.0100 -0.029.2°8.8°9.8°8.5°8.1°9.2°7.5°8.7°7.0°8.3°9.6°10.4°9.1°8.7°9.7°8.4°8.0°9.2°7.4°8.7°6.9°8.2°6.5°6.1°7.4°9.5°10.4°8.7°9.7°7.9°9.1°7.3°6.8°8.1°6.3°5.9°7.4°5.3°0.250.250.250.250.250.250.250.250.250.250.30.30.30.30.30.30.30.30.30.30.30.30.30.30.30.40.40.40.40.40.40.40.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.60.60.60.60.60.60.60.80.80.80.80.80.80.80.80.80.80.80.80.80.40.40.40.40.40.40.40.40.40.40.480.480.480.480.480.480.480.480.480.480.480.480.480.480.480.640.640.640.640.640.640.640.640.640.640.640.640.640.460.460.460.460.460.460.460.460.460.460.560.560.560.560.560.560.560.560.560.560.560.560.560.560.560.760.760.760.760.760.760.760.760.760.760.760.760.762.5333.5445566222.5333.54455667882233445667881050505050505050505060505050505050505050505050505060505050505050505050505050504464464646464464464646446464646446446422222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N111111111111111111111111111111111111112.93.43.43.94.44.45.55.56.56.52.42.43.03.53.54.04.54.55.65.66.66.67.78.78.72.42.43.53.54.54.55.66.66.67.78.78.710.83.03.53.54.14.64.65.75.76.86.82.52.53.13.63.64.24.74.75.85.86.96.98.09.19.12.52.53.63.64.74.75.86.96.98.09.19.111.33.33.93.94.55.15.16.26.27.47.42.82.83.44.04.04.65.25.26.46.47.67.68.810.010.02.82.84.04.05.15.16.37.57.58.79.99.912.33.64.34.34.95.65.66.96.98.28.23.13.13.74.44.45.05.75.77.07.08.48.49.711.011.03.03.04.34.35.75.77.08.38.39.711.011.013.630' 1° 2° 3°B2VF2XLB R0025N025S04R0025N030S04R0025N030S06R0025N035S04R0025N040S04R0025N040S06R0025N050S04R0025N050S06R0025N060S04R0025N060S06R0030N020S04R0030N020S06R0030N025S04R0030N030S04R0030N030S06R0030N035S04R0030N040S04R0030N040S06R0030N050S04R0030N050S06R0030N060S04R0030N060S06R0030N070S04R0030N080S04R0030N080S06R0040N020S04R0040N020S06R0040N030S04R0040N030S06R0040N040S04R0040N040S06R0040N050S04R0040N060S04R0040N060S06R0040N070S04R0040N080S04R0040N080S06R0040N100S04R

B085B2296.7°8.3°9.5°7.6°8.9°7.0°8.4°6.5°7.9°6.0°5.6°7.2°5.3°5.0°6.5°4.5°6.0°4.1°3.7°5.1°3.4°3.2°4.5°6.3°7.9°5.5°7.1°4.8°6.4°4.3°5.9°3.9°3.6°5.0°5.3°4.1°3.4°6.0°7.7°5.2°6.9°4.5°6.3°4.0°5.7°3.6°5.3°3.3°0.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.60.60.60.60.60.60.60.60.60.60.60.70.70.70.750.750.750.750.750.750.750.750.750.750.750.811111111111111111111111.21.21.21.21.21.21.21.21.21.21.21.41.41.41.51.51.51.51.51.51.51.51.51.51.50.640.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.960.960.960.960.960.960.960.960.960.960.961.121.121.121.21.21.21.21.21.21.21.21.21.21.20.760.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.940.941.141.141.141.141.141.141.141.141.141.141.141.341.341.341.441.441.441.441.441.441.441.441.441.441.44103344556678891010121214161618202066881010121214161681216668810101212141416605050505050505050505050505050506060607060607050505050505050506060705050605050505050505050505060646464646446446464464464646464644644446464646464222222222222222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N11111111111111111111111111111111111111111111111110.83.83.84.94.95.95.97.07.08.09.19.110.111.211.213.213.215.317.417.419.521.621.67.07.09.19.111.211.213.213.215.317.417.49.113.217.47.07.09.19.111.111.113.213.215.315.317.411.34.04.05.15.16.26.27.37.38.49.59.510.611.611.613.813.816.018.218.220.422.522.57.37.39.59.511.611.613.813.816.018.218.29.413.818.27.37.39.49.411.611.613.813.816.016.018.212.34.44.45.65.66.86.88.08.09.210.310.311.512.712.715.115.117.519.919.922.324.724.77.97.910.310.312.712.715.115.117.519.919.910.315.119.97.97.910.310.312.712.715.115.117.517.519.913.64.84.86.16.17.57.58.88.810.111.411.412.814.114.116.716.719.422.122.124.727.427.48.78.711.411.414.114.116.716.719.422.022.011.416.722.08.78.711.411.414.014.016.716.719.319.322.030' 1° 2° 3°B2VF2XLB R0040N100S06R0050N030S04R0050N030S06R0050N040S04R0050N040S06R0050N050S04R0050N050S06R0050N060S04R0050N060S06R0050N070S04R0050N080S04R0050N080S06R0050N090S04R0050N100S04R0050N100S06R0050N120S04R0050N120S06R0050N140S04R0050N160S04R0050N160S06R0050N180S04R0050N200S04R0050N200S06R0060N060S04R0060N060S06R0060N080S04R0060N080S06R0060N100S04R0060N100S06R0060N120S04R0060N120S06R0060N140S04R0060N160S04R0060N160S06R0070N080S04R0070N120S04R0070N160S04R0075N060S04R0075N060S06R0075N080S04R0075N080S06R0075N100S04R0075N100S06R0075N120S04R0075N120S06R0075N140S04R0075N140S06R0075N160S04Unit : mmCUTTING CONDITIONS<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEIMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>TypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank Angle

B087B2292.7°2.4°6.0°5.2°4.7°4.2°3.9°3.3°2.8°2.4°2.1°1.9°3.4°2.9°2.4°2.1°1.8°1.6°4.2°3.7°3.3°3.0°2.5°2.1°1.8°1.5°1.4°1.2°1.1°1.4°1.2°1.0°0.9°0.0°0.0°0.0°1.251.251.51.51.51.51.51.51.51.51.51.51.751.751.751.751.751.75222222222222.52.52.52.53332.52.533333333333.53.53.53.53.53.5444444444445555666222.42.42.42.42.42.42.42.42.42.42.82.82.82.82.82.83.23.23.23.23.23.23.23.23.23.23.244444.84.84.82.42.42.92.92.92.92.92.92.92.92.92.93.43.43.43.43.43.43.93.93.93.93.93.93.93.93.93.93.94.94.94.94.95.855.855.853035810121416202530354016202530354010121416202530354045502025303530405080806060606060707070809060707080809070707070707070809090100707080808090100666666666666666666666666666666666666222222222222222222222222222222222222aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaD1R ap D5L3 L1 D4 N11111111111111111111111111111111122232.137.39.111.213.315.417.521.626.932.137.342.517.521.626.832.137.342.511.213.315.417.521.626.832.137.342.547.752.921.626.832.037.233.538.99.511.713.816.018.222.528.033.438.944.318.222.528.033.438.944.311.613.816.018.122.528.033.438.844.349.755.222.527.936.642.610.312.715.117.419.824.630.636.642.619.824.630.636.512.615.017.419.724.530.511.213.916.519.221.927.221.813.716.419.030' 1° 2° 3°B2VF2XLB R0125N300S06R0125N350S06R0150N080S06R0150N100S06R0150N120S06R0150N140S06R0150N160S06R0150N200S06R0150N250S06R0150N300S06R0150N350S06R0150N400S06R0175N160S06R0175N200S06R0175N250S06R0175N300S06R0175N350S06R0175N400S06R0200N100S06R0200N120S06R0200N140S06R0200N160S06R0200N200S06R0200N250S06R0200N300S06R0200N350S06R0200N400S06R0200N450S06R0200N500S06R0250N200S06R0250N250S06R0250N300S06R0250N350S06R0300N300S06R0300N400S06R0300N500S06Unit : mmCUTTING CONDITIONS<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEIMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>TypeStockRadius ofBall NoseOrder NumberDia.Length ofCutNeckDia.NeckLengthOverallLengthShankDia.No. ofFlutesEffective lengthfor inclined angleCutting Edge toShank AngleNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerferenceNointerference

B088VF3XBaD3 30' 1° 2° 3°B1L2D1 ap L3 L1 ND4B2RVF3XBR0040T0024L006R0040T0024L008R0040T0024L012R0040T0054L008R0040T0054L012R0040T0054L016R0050T0024L008R0050T0024L010R0050T0024L012R0050T0024L016R0050T0024L020R0050T0024L025R0050T0024L030R0050T0024L035R0050T0054L008R0050T0054L012R0050T0054L016R0050T0054L020R0050T0054L025R0050T0054L030R0050T0054L035R0050T0054L040R0050T0054L050R0050T0054L060R0050T0054L070R0050T0130L012R0050T0130L016R0050T0130L020R0050T0130L025R0050T0130L030R0050T0130L035R0075T0024L010R0075T0024L015R0075T0024L020R0075T0024L030R0075T0054L015R0075T0054L020R0075T0054L0300.40.40.40.40.40.40.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.50.750.750.750.750.750.750.750.80.80.80.80.80.811111111111111111111111111.51.51.51.51.51.51.50.40.40.40.90.90.90.40.40.40.40.40.40.40.40.90.90.90.90.90.90.90.90.90.90.91.51.51.51.51.51.50.40.40.40.40.90.90.90.50.50.50.50.50.50.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.80.81.31.31.31.31.31.31.3681281216810121620253035812162025303540506070121620253035101520301520301.51.51.51.51.51.52.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.32.82.82.82.82.82.82.88.9°7.5°5.7°7.6°5.8°4.7°9.6°8.5°7.6°6.3°5.4°4.6°4.0°3.5°9.7°7.7°6.4°5.5°4.7°4.0°3.6°3.2°2.7°2.3°2.0°7.9°6.5°5.6°4.8°4.1°3.7°8.1°6.2°5.0°3.7°6.3°5.1°3.7°60606060606060606070707080806060707070808080110110110607070708080606070806070804444446666666666666666666666666666666633333333333333333333333333333333333333aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa6.38.412.48.510.512.616.620.625.730.735.710.615.620.630.76.68.612.78.412.416.58.810.913.017.121.226.331.536.68.612.616.720.725.730.835.840.850.960.971.010.916.021.231.515.720.730.86.99.113.48.913.117.39.311.413.618.022.327.733.138.69.113.317.621.827.132.437.743.053.664.174.713.017.121.226.331.536.611.416.922.333.116.521.832.47.39.514.19.313.818.39.812.114.418.923.529.335.040.79.614.118.523.028.634.239.845.413.718.022.427.833.238.612.017.823.535.017.423.034.20.820.850.910.961.091.221.021.051.081.131.191.261.331.401.121.241.371.501.651.811.972.122.442.753.071.451.661.872.132.392.651.541.611.681.821.821.982.29111111111111111111111111111111111111110 -0.02e 0.0130°UWCVFøD4L1apøD1L3L2RB1D3B220°Ra : Inventory maintained.Ball nose, 3 flute, Taper neck, For hardened materialsUnit : mm<strong>SOLID</strong><strong>END</strong> <strong>MILLS</strong>CARBIDEIMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>IMPACT MIRACLE <strong>END</strong> <strong>MILLS</strong>Inclined angleEffectivelengthEffective lengthfor inclined angleStockTypeOrder NumberTaper AngleOne SideRadius ofBall NoseDia.Cutting Edge toShank AngleNo. ofFlutesEffective lengthfor inclined angleLength ofCutNeckLengthOverallLengthShankDia.Length ofStraight NeckNeckDia.Type1NointerferenceNointerferenceNointerference3 flute ball end mill, high rigid taper neck type.