Large Diameter Piping - Victaulic

Large Diameter Piping - Victaulic

Large Diameter Piping - Victaulic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

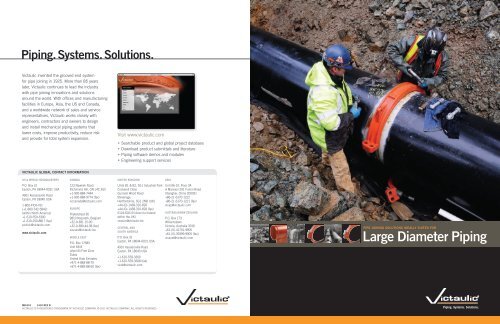

<strong>Piping</strong>. Systems. Solutions.<strong>Victaulic</strong> invented the grooved end systemfor pipe joining in 1925. More than 85 yearslater, <strong>Victaulic</strong> continues to lead the industrywith pipe joining innovations and solutionsaround the world. With offices and manufacturingfacilities in Europe, Asia, the US and Canada,and a worldwide network of sales and servicerepresentatives, <strong>Victaulic</strong> works closely withengineers, contractors and owners to designand install mechanical piping systems thatlower costs, improve productivity, reduce riskand provide for total system expansion.Visit www.victaulic.com• Searchable product and global project database• Download product submittals and literature• <strong>Piping</strong> software demos and modules• Engineering support servicesVICTAULIC GLOBAL CONTACT INFORMATIONUS & WORLD HEADQUARTERSCANADAUNITED KINGDOMASIAP.O. Box 31Easton, PA 18044-0031 USA4901 Kesslersville RoadEaston, PA 18040 USA1-800-PICK-VIC(+1-800-742-5842)(within North America)+1-610-559-3300+1-610-250-8817 (fax)pickvic@victaulic.comwww.victaulic.com123 Newkirk RoadRichmond Hill, ON L4C 3G5+1-905-884-7444+1-905-884-9774 (fax)viccanada@victaulic.comEUROPEPrijkelstraat 369810 Nazareth, Belgium+32-9-381-15-00+32-9-380-44-38 (fax)viceuro@victaulic.beMIDDLE EASTP.O. Box 17683Unit XB 8Jebel Ali Free ZoneDubaiUnited Arab Emirates+971-4-883-88-70+971-4-883-88-60 (fax)Units B1 & B2, SG1 Industrial ParkCockerell CloseGunnels Wood RoadStevenageHertfordshire, SG1 2NB (UK)+44-(0)-1438-310-690+44-(0)-1438-310-699 (fax)0124-60219 (direct to Irelandwithin the UK)viceuro@victaulic.beCENTRAL ANDSOUTH AMERICAP.O. Box 31Easton, PA 18044-0031 USA4901 Kesslersville RoadEaston, PA 18040 USA+1-610-559-3300+1-610-559-3608 (fax)vical@victaulic.comUnit 06-10, Floor 3AA Mansion 291 Fumin RoadShanghai, China 200031+86-21-6170-1222+86-21-6170-1221 (fax)vicap@victaulic.comAUSTRALIA/NEW ZEALANDP.O. Box 173WilliamstownVictoria, Australia 3016+61-(0)-41701-9905+61-(0)-39399-9905 (fax)vicaust@victaulic.comPIPE JOINING SOLUTIONS IDEALLY SUITED FOR<strong>Large</strong> <strong>Diameter</strong> <strong>Piping</strong>MB-010 1410 REV BVICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2011 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

VICTAULIC LARGE DIAMETER PIPING SYSTEMSVersatile and ReliableThe <strong>Victaulic</strong> grooved piping system is the most versatile, economicaland reliable piping system available. It is up to three times faster to installthan welding, easier and more reliable than flanging, resulting in lowertotal installed cost.The system is designed for ANSI, ISO, DIN and other black or galvanizedsteel pipe. Pipe end preparation is fast and easy either in the shop or onthe job site with the variety of <strong>Victaulic</strong> grooving tools available.In addition to speed and ease of assembly, the <strong>Victaulic</strong> system offersvaried mechanical benefits to the designer, installer and owner.FEATURESExaggerated for clarityEACH JOINT IS A UNIONWelded systems require specially installedunions while flanged systems have twicethe number of bolts of grooved systems.EASY SYSTEM OR EQUIPMENT ACCESSRemoval of couplings provides access forcleaning, maintenance, system expansionor changes.NO FIRE HAZARDAs a fully mechanical, bolted system,<strong>Victaulic</strong> products present no fire hazard.It is far safer and requires no shieldingor fire watch.ALIGNMENT EASEThe grooved system allows full rotationof pipe, valves, fittings or couplingsbefore tightening for easy alignment.This compensates for some alignmenterrors and eliminates the “twoholing”required with flanges. Fitting in tightplaces is eased.Request publication 26.03The <strong>Victaulic</strong> AdvancedGroove System conceptis the strongest and mostreliable way to mechanicallyjoin large diameter pipe.ContractionDeflectionFLEXIBILITYThe <strong>Victaulic</strong> system is unique in the abilityto accommodate expansion/contraction/deflection. Elimination or reduction ofspecial vibration accessories, expansionloops and settlement allowance are amongthe inherent benefits of the grooved system.Request publication 26.01EndLoadEndLoadSELF-RESTRAINED JOINTThe full engagement of the housingkeys into grooves around the full pipecircumference provides significantpressure restraint and end loadcapabilities to withstand pipe movementfrom varied internal and external sources.Request publication 26.05ELIMINATES RE-COATING AND RE-LININGSince <strong>Victaulic</strong> couplings do not requireheat to join the piping system no damageis done to either coatings or linings duringthe assembly process. Eliminating the costlystep of re-lining and re-coating the pipedramatically reduces project completion times.ELIMINATES CONFINED SPACE ENTRYBecause <strong>Victaulic</strong> couplings areassembled on the outside of the pipethe need to re-coat, re-line or weldthe inside of the pipe is eliminated.This creates a safer working environmentand increases productivity.[ 4 ] www.victaulic.comwww.victaulic.com[ 3 ]

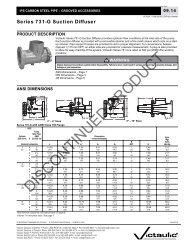

VICTAULIC LARGE DIAMETER PIPING SYSTEMS IMPROVES PRODUCTIVITYVersus Flanged/Welded SystemsVICTAULIC GROOVEDVICTAULIC GROOVED LARGE DIAMETER VIC› Grooved piping can pass through wall sleeves› Special design considerations eliminated› Compression type couplings not required› No side space needed for bolts; No two-holing required› 1⁄3 the weight of flanged systems› Number of bolts greatly reduced› No radiographic inspection requiredFLANGEDFLANGED LARGE DIAMETER FLG› Require special design considerations› Flanging must be made-on loose or have couplingadapter added to pass through a wall sleeve› Side space needed for bolts; Two-holing required› Heavier, more costly to install› More bolts, longer installation timeWELDED<strong>Victaulic</strong> systems rotate for alignmentand can pass through wall sleeves<strong>Victaulic</strong>Flanged<strong>Victaulic</strong>Flanged must be “two holed” and must bemade-on loose or have coupling adaptersadded to pass through a wall sleeveFlangedNominalSizeinchesmminchesmmWidthSAVES SPACE... LIGHTER... FEWER BOLTS.inchesmmOutside<strong>Diameter</strong>inchesmminchesmmlbs.kgWeightlbs.kg24 4.50 10.4 32.3 32.0 107 260600 114 264 821 813 48.5 117.928 5.68 10.5 37.2 36.0 220 400700 144 267 945 914 99.8 181.432 5.68 10.8 41.7 42.5 242 560800 144 274 1060 1080 109.8 254.036 5.68 11.0 45.7 46.0 268 640900 144 279 1161 1168 121.6 290.342 6.50 11.5 52.5 53.0 360 8301050 165 292 1334 1346 163.3 376.548 6.50 12.1 58.5 59.5 425 9801200 165 307 1485 1511 192.8 444.554 10.00 12.7 65.2 66.3 648 14001375 254 323 1655 1684 293.9 635.060 10.00 13.2 72.1 73.0 720 17501525 254 335 1832 1854 326.6 793.8Numberof Bolts2 204 244 284 324 364 444 444 48VIC FLG VIC FLG VIC FLG VIC FLGWELDED LARGE DIAMETER› Emits harmful noxious fumes› Over 10× longer to install than grooved› Requires skilled welder and welding equipment› No visual method for ensuring joint integrity<strong>Victaulic</strong> systems can reduce direct andindirect installed costs by 50% or morewhen compared to other joining methods.NUMBER OF MEN ON SITEShift MaximumManpower Line<strong>Victaulic</strong>Peak Man-PowerWeldedPeak Man-PowerMeet or BeatProject ScheduleMECHANICAL CONSTRUCTION WEEKS[ 6 ] www.victaulic.com www.victaulic.com [ 7 ]

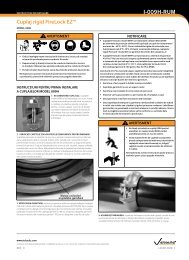

VICTAULIC LARGE DIAMETER PIPING SYSTEMSMethods for Joining <strong>Large</strong> <strong>Diameter</strong> PipeThe Direct Grooved MethodThe AGS Vic-Ring MethodThe concept of rolling a groove into pipe withoutremoving metal was developed by <strong>Victaulic</strong> in 1955.The concept was first used for light-wall pipe whichdid not have sufficient wall thicknesses to permit cutgrooving. Technological developments now permitroll grooving of standard weight steel pipe, up to60"/1525 mm.Style W07 Rigid CouplingStyle W77 Flexible Coupling<strong>Victaulic</strong> offers the AGS (Advanced Groove System)Vic-Ring piping method for joining large diameterpipe which does not lend itself to direct grooving.The adaptation of pipe with Vic-Ring adapters andthe selection of a suitable <strong>Victaulic</strong> coupling canpresent individual considerations which are besthandled by <strong>Victaulic</strong> engineers, who are experiencedin these applications. Contact <strong>Victaulic</strong> for assistance.Style W07 Rigid Couplingwith AGS RingStyle W77 Flexible Couplingwith AGS RingType BRingHousingGasketPipeDIRECT GROOVED PIPE PREPARATION<strong>Piping</strong> from 14 – 60"/350 – 1525 mm can now be directroll grooved to receive AGS (Advanced Groove System)large diameter couplings. This capability brings the speedand ease of bolted mechanical assembly to large diameterpipe assembly.Roll grooving removes no metal, cold forming a groove by theaction of an upper male roll displacing the pipe wall as thepipe is rotated by a lower female drive roll forming the groove.<strong>Victaulic</strong> shop roll groovers can roll groove up to ½"/13 mmwall thickness carbon steel pipe.LARGE DIAMETER PIPE ROLL GROOVING TOOLThe <strong>Victaulic</strong> <strong>Large</strong> <strong>Diameter</strong> Roll Groover is a fully motorized,automated shop tool for continuous production grooving. It issupplied in several variations to accommodate the needs of rollgrooving pipe above 14"/350 mm.The VE436 is a fully automated shop tool for roll grooving pipe in thefollowing sizes: 22 – 24"/550 – 600 mm and 30 – 36"/750 – 900 mm upto maximum wall thickness of ½"/13 mm. These rolls are standardsupply with this tool. Other roll sets can be provided upon request.The VE-460 is our most versatile tool; capable of grooving ½"/13 mmwall pipe up to 60"/1525 mm. This heavy duty tool is capable ofproduction grooving over the entire range of large diameter products.TYPE B RING CONFIGURATIONA short grooved nipple, buttwelded to the pipe end. The nipplesmay be cut from standard pipe and joined using standard AGSrigid or flexible couplings.Type DRingHousingTYPE D RING CONFIGURATIONGasketA heavy duty collar typically for large diameter pipe — 30"/750 mmand up — providing special pipe end reinforcement and rigidity.Standard Style W07 rigid or Style W77 flexible couplings may beused with Type "D" ring configurations.Pipe[ 8 ] www.victaulic.comwww.victaulic.com[ 9 ]