Series 731-G Suction Diffuser - Victaulic

Series 731-G Suction Diffuser - Victaulic

Series 731-G Suction Diffuser - Victaulic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

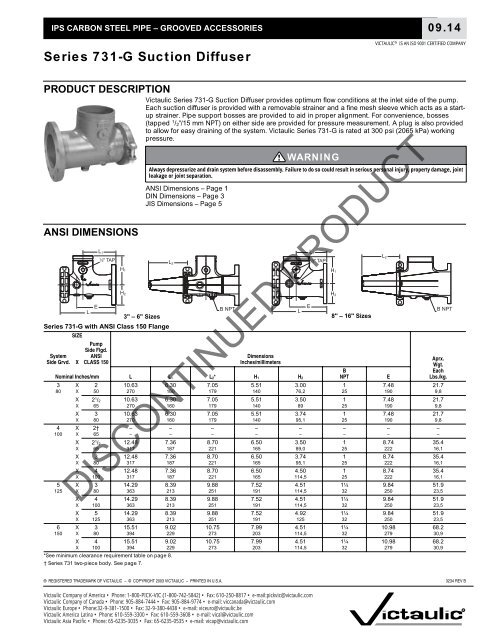

09.14JIS DIMENSIONSL1L112,7 mm3/88.9TAPH1L28/219.1mm12,7 mmTAPH1L23-1508-150H2H2<strong>Series</strong> <strong>731</strong>-G with JIS 10K FlangeSystemSide Grvd.SIZEXLEPumpSide Flgd.10KDN80A – 165,1 mm SizesDimensionsmillimeters/Inchesmillimeters L L 1 L 2* H 1 H 2 BSPTBDN80A X 50A 270 160 179 140 77,5 25 190 9,8X 10.63 6.30 7.05 5.51 3.05 1 7.48 21.7X 65A 270 160 179 140 87,5 25 190 9,8X 10.63 6.30 7.05 5.51 3.44 1 7.48 21.7X 80A 270 160 179 140 92,5 25 190 9,8X 10.63 6.30 7.05 5.51 3.64 1 7.48 21.7DN100A X 50A – – – – – – – –X – – – – – – – –X 65A 317 187 221 165 87,5 25 222 16,1X 12.48 7.36 8.70 6.50 3.44 1 8.74 35.4X 80A 317 187 221 165 92,5 25 222 16,1X 12.48 7.36 8.70 6.50 3.64 1 8.74 35.4X 100A 317 187 221 165 105 25 222 16,1X 12.48 7.36 8.70 6.50 4.13 1 8.74 35.4139,7 X 100A 363 213 251 191 105 32 250 23,5X 14.29 8.39 9.88 7.52 4.13 1¹⁄₄ 9.84 51.9X 125A 363 213 251 191 125 32 250 23,5X 14.29 8.39 9.88 7.52 4.92 1¹⁄₄ 9.84 51.9165,1 X 100A 394 229 273 203 105 32 279 30.4X 15.51 9.02 10.75 7.99 4.13 1¹⁄₄ 10.98 68.2X 125A 394 229 273 203 125 32 279 30.4X 15.51 9.02 10.75 7.99 4.92 1¹⁄₄ 10.98 68.2X 150A 394 229 273 203 140 32 279 30.415.51 9.02 10.75 7.99 5.51 1¹⁄₄ 10.98 68.2216,3 X 150A 464 260 323 229 140 32 318 54,7X 18.27 10.24 12.72 9.02 5.51 1¹⁄₄ 12.52 120.6X 200A 464 260 323 229 165 32 318 54,7X 18.27 10.24 12.72 9.02 6.50 1¹⁄₄ 12.52 120.6267,4 X 200A 561,5 315 398 279 165 32 395 87,3X 22.11 12.40 15.67 10.98 6.50 1¹⁄₄ 15.55 192.5X 250A 561,5 315 398 279 200 32 395 87,3X 22.11 12.40 15.67 10.98 7,87 1¹⁄₄ 15.55 192.5318,5 X 250A 668 392 474 335 200 32 472 131,7X 26.30 15.48 18.66 13.19 7.87 1¹⁄₄ 18.58 290.4X 300A 668 392 474 335 222,5 32 472 131,7X 26.30 15.48 18.66 13.19 8.78 1¹⁄₄ 18.58 290.4DN350A X 250A 727 410 532 365 212,5 40 540 150,7X 28.62 16.14 20.94 14.37 8.37 1¹⁄₂ 21.26 332.3X 300A 727 410 532 365 230 40 540 150,7X 28.62 16.14 20.94 14.37 9.06 1¹⁄₂ 21.26 332.3X 350A 727 410 532 365 260 40 540 150,7X 28.62 16.14 20.94 14.37 10.24 1¹⁄₂ 21.26 332.3DN400A X 300A – – – – – – – –X – – – – – – – –X 350A 839 497 643 403 222,5 40 639 180,6X 33.03 19.57 25.31 15.87 8.78 1¹⁄₂ 25.16 398.2X 400A – – – – – – – –X – – – – – – – –*See minimum clearance requirement table on page 8.(BSPT)LE216,3 – DN400A mm SizesDISCONTINUED PRODUCTE(BSPT)Aprx.Wgt.Eachkg/Lbs.<strong>Series</strong> <strong>731</strong>-G <strong>Suction</strong> <strong>Diffuser</strong> 5

09.14JIS DIMENSIONSL1L112,7 mm3/88.9TAPH1L28/219.1mm12,7 mmTAPH1L23-1508-150H2H2<strong>Series</strong> <strong>731</strong>-G with JIS 20K FlangeSystemSide Grvd.SIZEXLEPumpSide Flgd.10KDN80A – 165,1 mm SizesDimensionsmillimeters/Inchesmillimeters L L 1 L 2* H 1 H 2 BSPTBDN80A X 50A 270 160 179 140 77,5 25 190 9,8X 10.63 6.30 7.05 5.51 3.05 1 7.48 21.7X 65A 270 160 179 140 87,5 25 190 9,8X 10.63 6.30 7.05 5.51 3.44 1 7.48 21.7X 80A 270 160 179 140 100,0 25 190 9,8X 10.63 6.30 7.05 5.51 3.94 1 7.48 21.7DN100A X 50A – – – – – – – –X – – – – – – – –X 65A 317 187 221 165 87,5 25 222 16,1X 12.48 7.36 8.70 6.50 3.44 1 8.74 35.4X 80A 317 187 221 165 100,0 25 222 16,1X 12.48 7.36 8.70 6.50 3.94 1 8.74 35.4X 100A 317 187 221 165 112,5 25 222 16,1X 12.48 7.36 8.70 6.50 4.43 1 8.74 35.4139,7 X 100A 363 213 251 191 112,5 32 250 23,5X 14.29 8.39 9.88 7.52 4.43 1¹⁄₄ 9.84 51.9X 125A 363 213 251 191 135,0 32 250 23,5X 14.29 8.39 9.88 7.52 5.82 1¹⁄₄ 9.84 51.9165,1 X 100A 394 229 273 203 112,5 32 279 30.4X 15.51 9.02 10.75 7.99 4.43 1¹⁄₄ 10.98 68.2X 125A 394 229 273 203 135,0 32 279 30.4X 15.51 9.02 10.75 7.99 5.82 1¹⁄₄ 10.98 68.2X 150A 394 229 273 203 154 32 279 30.415.51 9.02 10.75 7.99 6.06 1¹⁄₄ 10.98 68.2216,3 X 150A 464 260 323 229 152,5 32 318 54,7X 18.27 10.24 12.72 9.02 6.00 1¹⁄₄ 12.52 120.6X 200A 464 260 323 229 175 32 318 54,7X 18.27 10.24 12.72 9.02 6.89 1¹⁄₄ 12.52 120.6267,4 X 200A 561,5 315 398 279 175 32 395 87,3X 22.11 12.40 15.67 10.98 6.89 1¹⁄₄ 15.55 192.5X 250A 561,5 315 398 279 215 32 395 87,3X 22.11 12.40 15.67 10.98 8.47 1¹⁄₄ 15.55 192.5318,5 X 250A 668 392 474 335 215 32 472 131,7X 26.30 15.48 18.66 13.19 8.47 1¹⁄₄ 18.58 290.4X 300A 668 392 474 335 240 32 472 131,7X 26.30 15.48 18.66 13.19 9.95 1¹⁄₄ 18.58 290.4DN350A X 250A 727 410 532 365 212,5 40 540 150,7X 28.62 16.14 20.94 14.37 8.37 1¹⁄₂ 21.26 332.3X 300A 727 410 532 365 230 40 540 150,7X 28.62 16.14 20.94 14.37 9.06 1¹⁄₂ 21.26 332.3X 350A 727 410 532 365 260 40 540 150,7X 28.62 16.14 20.94 14.37 10.24 1¹⁄₂ 21.26 332.3DN400A X 300A – – – – – – – –X – – – – – – – –X 350A 839 497 643 403 270 40 639 180,6X 33.03 19.57 25.31 15.87 10.63 1¹⁄₂ 25.16 398.2X 400A – – – – – – – –X – – – – – – – –*See minimum clearance requirement table on page 8.(BSPT)LEDN200A – DN400A mm SizesE(BSPT)Aprx.Wgt.Eachkg/Lbs.DISCONTINUED PRODUCT6 <strong>Series</strong> <strong>731</strong>-G <strong>Suction</strong> <strong>Diffuser</strong>

09.14ANSI DIMENSIONS<strong>Series</strong> <strong>731</strong> Two-Piece<strong>Suction</strong> <strong>Diffuser</strong>C - ESIZESystemSide Grvd. XPumpSide Flgd.DimensionsInches/millimetersNominal InchesActual mm C - E C - O OAL OAH OAW<strong>Series</strong> <strong>731</strong> with ANSI Class 150 FlangeDIN DIMENSIONS<strong>Series</strong> <strong>731</strong> Two-Piece<strong>Suction</strong> <strong>Diffuser</strong>C - OAprx.Wgt.EachLbs./kg4 X 2 5.00 8.30 14.44 8.97 6.75 30.0100 X 50 127 211 367 228 172 13,616 X 12 12.00 26.00 39.50 23.00 27.12 525.0400 X 300 305 661 1003 584 689 238,116 X 16 15.50 30.50 47.50 27.50 29.00 700.0400 X 400 394 775 1207 699 737 317,5NOTE: <strong>Series</strong> <strong>731</strong> two piece body utilizes 3 / 16" (4,8 mm) diameter holes.C - EC - OOALOAHRemovable Strainer& Flow StraightenerSIZESystem PumpDimensionsAprx.Side Grvd. X Side Flgd.millimeters/InchesWgt.Actual mmNominal Inches C - E C - O OAL OAH OAWEachkg/Lbs.<strong>Series</strong> <strong>731</strong> with PN10 and PN16 Flange100 X 50 127 211 367 228 172 13,64 X 2 5.00 8.30 14.44 8.97 6.75 30.0400 X 300 305 661 1003 584 689 238,116 X 12 12.00 26.00 39.50 23.00 27.12 700.8400 X 400 394 775 1207 699 737 317,516 X 16 15.50 30.50 47.50 27.50 29.00 700.0NOTE: <strong>Series</strong> <strong>731</strong> two piece body utilizes 4,8 mm ( 3 / 16") diameter holes.OALOAHRemovable Strainer& Flow StraightenerDISCONTINUED PRODUCTABABOAWOAW<strong>Series</strong> <strong>731</strong>-G <strong>Suction</strong> <strong>Diffuser</strong> 7

MATERIAL SPECIFICATIONSHousing (body, coupling, end cap): Ductile iron conforming to ASTM A-395.Coupling Gasket: (specify choice)*Standard09.14• Grade “E” EPDMEPDM (Green color code). Temperature range –30°F to +230°F (–34°C to +110°C). Recommended forcold and hot water service within the specified temperature range plus a variety of dilute acids, oil-freeair and many chemical services. UL classified in accordance with ANSI/NSF 61 for cold +86°F (+30°C)and hot +180°F (+82°C) potable water service. NOT RECOMMENDED FOR PETROLEUM SERVICES.Optional - Special Order• Grade “T” nitrileNitrile (Orange color code). Temperature range –20°F to +180°F (–29°C to +82°C). Recommended forpetroleum products, air with oil vapors, vegetable and mineral oils within the specified temperaturerange. Not recommended for hot water services over +150°F (+66°C) or for hot dry air over +140°F(+60°C).*Services listed are General Service Recommendations only. It should be noted that there are services forwhich these gaskets are not recommended. Reference should always be made to the latest <strong>Victaulic</strong>Gasket Selection Guide for specific gasket service recommendations and for a listing of services whichare not recommended.<strong>Diffuser</strong>: Stainless steel, type 304, frame and perforated sheet with 5 / 32" (4 mm)# diameter holes.#<strong>Diffuser</strong>s on two-piece body sizes 4 X 2" (100 X 50 mm) , 16 X 12" (400 X 300 mm) and 16 X 16" (400 X400 mm) have 3 / 16" (4,8 mm) diameter holes.Start-up Pre-filter: 20 mesh Stainless steel, type 304.Bolts/Nuts: Heat treated carbon steel, track head conforming to physical properties of ASTM A-183minimum tensile 110,000 psi (758340 kPa).Support: Boss for support. See table above for size. (Support not supplied).DISCONTINUED PRODUCT<strong>Series</strong> <strong>731</strong>-G <strong>Suction</strong> <strong>Diffuser</strong> 9

09.14PERFORMANCE DATAPressure loss values for flow of water at 60°F (+16°C) shown below.Pressure Drop - psi<strong>Series</strong> <strong>731</strong>-G1010.10.01Flow Rate - GPMJIS AND DIN FLOW DATA<strong>Series</strong> <strong>731</strong>-G10.10.010.00110 100 1000 10000Flow Rate - m3/hr1 psi/1 bar equals C v/K vPressure Drop - bar88,9 ✕ DN50, DN65, DN80IMPERIAL FLOW DATA3 ✕ 2, 2¹⁄₂, 310 100 1000 10000114,3 ✕ DN65, DN80, DN1004 ✕ 2¹⁄₂, 3, 4168,3 ✕ DN100, DN125, DN150141,3 ✕ DN80, DN100, DN1255 ✕ 3, 4, 56 ✕ 4, 5, 6219,1 ✕ DN125, DN150, DN2008 ✕ 5, 6, 810 ✕ 6, 8, 10273,0 ✕ DN150, DN200, DN250323,9 ✕ DN200, DN250, DN300355,6 ✕ DN250, DN300, DN350406,4 ✕ DN300, DN350, DN40012 ✕ 8, 10, 1214 ✕ 10, 12, 1416 ✕ 12, 14, 16DISCONTINUED PRODUCTAll products shall be installed in accordance with current <strong>Victaulic</strong> installation/assembly instructions.<strong>Victaulic</strong> reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.10 <strong>Series</strong> <strong>731</strong>-G <strong>Suction</strong> <strong>Diffuser</strong>