Chaseling Company.pdf - Land Locomotion â Mechanical Vehicle ...

Chaseling Company.pdf - Land Locomotion â Mechanical Vehicle ...

Chaseling Company.pdf - Land Locomotion â Mechanical Vehicle ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

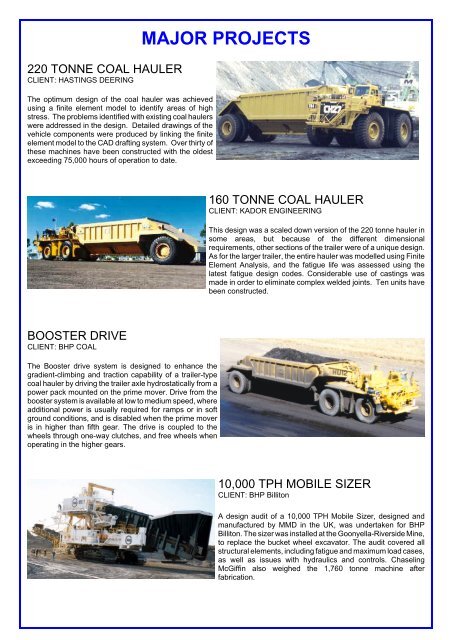

220 TONNE COAL HAULERCLIENT: HASTINGS DEERINGThe optimum design of the coal hauler was achievedusing a finite element model to identify areas of highstress. The problems identified with existing coal haulerswere addressed in the design. Detailed drawings of thevehicle components were produced by linking the finiteelement model to the CAD drafting system. Over thirty ofthese machines have been constructed with the oldestexceeding 75,000 hours of operation to date.MAJOR PROJECTS160 TONNE COAL HAULERCLIENT: KADOR ENGINEERINGThis design was a scaled down version of the 220 tonne hauler insome areas, but because of the different dimensionalrequirements, other sections of the trailer were of a unique design.As for the larger trailer, the entire hauler was modelled using FiniteElement Analysis, and the fatigue life was assessed using thelatest fatigue design codes. Considerable use of castings wasmade in order to eliminate complex welded joints. Ten units havebeen constructed.BOOSTER DRIVECLIENT: BHP COALThe Booster drive system is designed to enhance thegradient-climbing and traction capability of a trailer-typecoal hauler by driving the trailer axle hydrostatically from apower pack mounted on the prime mover. Drive from thebooster system is available at low to medium speed, whereadditional power is usually required for ramps or in softground conditions, and is disabled when the prime moveris in higher than fifth gear. The drive is coupled to thewheels through one-way clutches, and free wheels whenoperating in the higher gears.10,000 TPH MOBILE SIZERCLIENT: BHP BillitonA design audit of a 10,000 TPH Mobile Sizer, designed andmanufactured by MMD in the UK, was undertaken for BHPBilliton. The sizer was installed at the Goonyella-Riverside Mine,to replace the bucket wheel excavator. The audit covered allstructural elements, including fatigue and maximum load cases,as well as issues with hydraulics and controls. <strong>Chaseling</strong>McGiffin also weighed the 1,760 tonne machine afterfabrication.