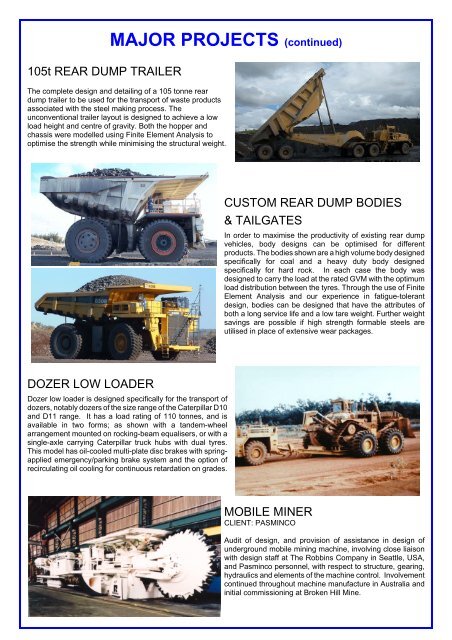

105t REAR DUMP TRAILERMAJOR PROJECTS (continued)The complete design and detailing of a 105 tonne reardump trailer to be used for the transport of waste productsassociated with the steel making process. Theunconventional trailer layout is designed to achieve a lowload height and centre of gravity. Both the hopper andchassis were modelled using Finite Element Analysis tooptimise the strength while minimising the structural weight.CUSTOM REAR DUMP BODIES& TAILGATESIn order to maximise the productivity of existing rear dumpvehicles, body designs can be optimised for differentproducts. The bodies shown are a high volume body designedspecifically for coal and a heavy duty body designedspecifically for hard rock. In each case the body wasdesigned to carry the load at the rated GVM with the optimumload distribution between the tyres. Through the use of FiniteElement Analysis and our experience in fatigue-tolerantdesign, bodies can be designed that have the attributes ofboth a long service life and a low tare weight. Further weightsavings are possible if high strength formable steels areutilised in place of extensive wear packages.DOZER LOW LOADERDozer low loader is designed specifically for the transport ofdozers, notably dozers of the size range of the Caterpillar D10and D11 range. It has a load rating of 110 tonnes, and isavailable in two forms; as shown with a tandem-wheelarrangement mounted on rocking-beam equalisers, or with asingle-axle carrying Caterpillar truck hubs with dual tyres.This model has oil-cooled multi-plate disc brakes with springappliedemergency/parking brake system and the option ofrecirculating oil cooling for continuous retardation on grades.MOBILE MINERCLIENT: PASMINCOAudit of design, and provision of assistance in design ofunderground mobile mining machine, involving close liaisonwith design staff at The Robbins <strong>Company</strong> in Seattle, USA,and Pasminco personnel, with respect to structure, gearing,hydraulics and elements of the machine control. Involvementcontinued throughout machine manufacture in Australia andinitial commissioning at Broken Hill Mine.

AREAS OF EXPERTISE<strong>Mechanical</strong> DesignThe range of design work undertaken is wide, varying from finemechanical devices, to large mining structures such asdraglines, weighing several thousand tonnes. The firm is veryexperienced in design for high fatigue environments where useof castings may be necessary to avoid complex weldedfabrications, as well as being experienced in design of itemslikely to be subjected to high overloads.Extensive use is made of 3D CAD modeling throughout thedesign process. A complete virtual model is produced andaspects such as clearances and locii of mechanisms can betested. In most cases, the 2D workshop drawings aregenerated from 3D solid models, which ensures thatcomponents will correctly fit together to form the assembly.Design Audits andDesign/Construction SpecificationsThe firm is experienced in the undertaking of Design Audits,either in a close co-operative relationship with design firmsduring the course of design, or in a more independentapproach as required by the client. The firm also developsdetailed specifications for use in the construction of largeitems of machinery such as draglines.Testing Services<strong>Chaseling</strong> McGiffin has the capability to undertake straingaugingas well as vibration measurements and to provide athorough analysis of the data, involving such techniques as"Rainflow" analysis to assess fatigue loading, spectralanalysis of vibrations, online reduction of strain gauge rosettedata to principal stresses and strains.Finite Element AnalysisWith the latest computer software, <strong>Chaseling</strong> McGiffin can rapidly undertake finite element analysis of structures ormachinery to analyse stress or thermal problems, including non-linear analysis. Specialised Finite Element CAD is usedto develop the model, but if CAD drawings are supplied, these can be converted to a form compatible with the FEA CADsystem. Both static and dynamic analysis can be undertaken, with the latter being used to identify potential troublesomevibration modes, and to assess the effect of structural modifications on vibration levelsFailure Analysis<strong>Chaseling</strong> McGiffin can carry out a complete analysis of the cause of failure of most equipment. The firm has experiencewith a wide range of machines, including vehicles, aircraft, opencut and underground mining machines, materials handlingequipment, and manufacturing machinery. Types of failure examined include structural overload or fatigue, failure withgearing, failure of drives or hydraulics, or problems involving electro-mechanical systems. Fatigue analysis may includethe use of "Fracture Mechanics" to assess the potential life of items with known defects present.Product DevelopmentOften truly revolutionary concepts fail in the market place because of a lack of professional engineering analysis anddesign. <strong>Chaseling</strong> McGiffin has considerable experience in assisting clients in the development of innovative products.This assistance includes various forms of analysis and modelling as well as material selection and manufacturing processadvice. Computer simulation of electro-mechanical and control systems is part of our armoury.Accident Investigation<strong>Chaseling</strong> McGiffin can offer advice on the cause of various accidents including such as industrial accidents and vehiclecollisions. A report based on expert analysis will be prepared and if necessary expert testimony can be provided.