Equipment/ functions - Process Valve Solutions

Equipment/ functions - Process Valve Solutions

Equipment/ functions - Process Valve Solutions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISO 9001<br />

ISO 14001<br />

Certificate Registration No.<br />

12 100 4269<br />

12 104 4269<br />

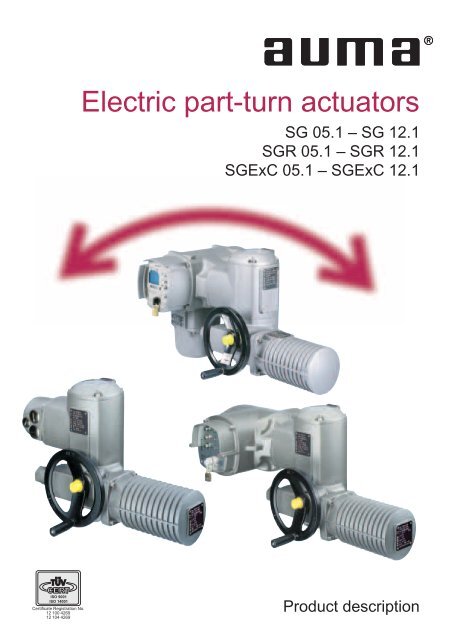

Electric part-turn actuators<br />

SG 05.1 – SG 12.1<br />

SGR 05.1 – SGR 12.1<br />

SGExC 05.1 – SGExC 12.1<br />

Product description

2<br />

Part/turn valves find applications in<br />

many industries as shut-off devices<br />

and increasingly to control the flow.<br />

Without automation the smooth function<br />

of industrial processes would be<br />

impossible. AUMA’s electric<br />

part-turn actuators play an important<br />

role in this case. For part-turn valves<br />

with a nominal diameter of approx.<br />

DN 40 and above, AUMA part-turn<br />

actuators from the SG 05.1 –<br />

SG 12.1 range are the best automation<br />

solution.<br />

AUMA is a leading manufacturer of<br />

electric actuators. More than 40<br />

years’ experience in conjunction with<br />

the innovative spirit of our engineers<br />

are the sound basis for constant<br />

improvement and further developments.<br />

AUMA offer a wide range of actuators<br />

which fulfils all the usual requirements<br />

of valve automation.<br />

Multi-turn actuators from 10 to<br />

32,000 Nm, part-turn actuators from<br />

25 to 360,000 Nm or linear thrust<br />

units from 4 to 217 kN. All kinds of<br />

valves can be automated and operated<br />

by rotary and linear movement.<br />

Sales support and after sales service<br />

are provided worldwide by regional<br />

offices, service centres, AUMA subsidiaries<br />

and representatives. This<br />

ensures that experienced sales<br />

engineers and qualified service technicians<br />

are close to the customer.<br />

They are prepared for responding to<br />

enquiries, executing orders or furnishing<br />

after-sales service.<br />

Table of contents<br />

Applications 3<br />

<strong>Equipment</strong>/ Summary of <strong>functions</strong> 5<br />

<strong>Equipment</strong>/ <strong>functions</strong> 6<br />

Type designation 6<br />

Open-close duty 6<br />

Modulating duty 7<br />

Comparison short-time and intermittent duty 7<br />

Adjustable swing angle 8<br />

Seating 8<br />

Adjustable torques 9<br />

Overload protection against torque peaks 9<br />

DUO limit switching/ intermediate position switches (option) 10<br />

Limit and torque switches 10<br />

Magnetic limit and torque transmitter (MWG) (option) 11<br />

Non-intrusive setting (option) 12<br />

Position/ torque feedback signal (option) 12<br />

Running indication (option) 13<br />

Heater 13<br />

Design principle 14<br />

<strong>Equipment</strong>/ <strong>functions</strong> 16<br />

Motors 16<br />

Operating times 16<br />

Motor protection 17<br />

Interfaces 18<br />

Electrical connection 18<br />

Wiring diagrams 20<br />

<strong>Valve</strong> attachment 20<br />

Coupling 20<br />

Integral controls 21<br />

Integral controls (option) 21<br />

Which type of controls? 22<br />

Advantages of integral controls (option) 23<br />

Ambient conditions 24<br />

Enclosure protection 24<br />

Corrosion protection/ Colour 24<br />

Ambient temperatures 24<br />

Explosion protection 25<br />

Lifetime 25<br />

Mounting positions 25<br />

Other information 26<br />

EU-Directives 26<br />

Functional tests 26<br />

Further literature 26<br />

Index 27<br />

We reserve the right to alter data according to improvements made.<br />

Figures and diagrams are not binding.

AUMA part-turn actuators are<br />

employed wherever an automated<br />

rotatry movement of 360° or less<br />

driven by an electric motor is<br />

required. Examples are valves such<br />

as butterfly valves and ball valves.<br />

Chemical<br />

industry<br />

■ Chemical industry<br />

■ Petrochemical industry<br />

■ Pharmaceutical industry<br />

Food industry ■ Breweries<br />

■ Dairies<br />

■ Sugar industry<br />

Energy ■ Power plants<br />

■ Air pollution control<br />

■ District heating<br />

Water/ Wastewater<br />

Applications<br />

■ Water works<br />

■ Sewage treatment<br />

■ Pump stations<br />

Others ■ Air conditioning and ventilation<br />

■ Ship building industry<br />

■ Steel mills<br />

■ Cement plants<br />

3

4<br />

Versions<br />

Part-turn actuator with<br />

AUMA MATIC integral<br />

controls<br />

Part-turn actuator with<br />

AUMATIC controls on<br />

wall bracket<br />

Definition of part-turn<br />

actuators according to<br />

ISO 5211<br />

A part-turn actuator is an actuator<br />

(actor), which transmits a torque to<br />

the valve for less than one full revolution.<br />

It need not be capable of withstanding<br />

thrust.

●Standard<br />

■Option<br />

<strong>Equipment</strong> / <strong>functions</strong><br />

Interfaces<br />

Service conditions<br />

<strong>Equipment</strong>/ Summary of <strong>functions</strong><br />

SG<br />

05.1 – 12.1<br />

SGR<br />

05.1 – 12.1<br />

SGExC<br />

05.1 – 12.1<br />

Description<br />

on page<br />

Open-close duty<br />

Modulating duty<br />

Swing angle adjustable<br />

Mechanical end stops<br />

Seating<br />

– Limit seating<br />

– Torque seating<br />

Overload protection<br />

DUO (Four train gear) limit switching<br />

Limit and torque switches<br />

– Tandem switch<br />

– Triple switch<br />

– Switches with gold plated contacts<br />

Magnetic limit and torque transmitter (MWG)<br />

Non-intrusive setting<br />

Position feedback/ torque feedback signal<br />

Mechanical position indicator<br />

Blinker transmitter for running indication<br />

Operating time adjustable<br />

Manual operation<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

■<br />

●<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

●<br />

■<br />

■<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

■<br />

●<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

●<br />

■<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

■<br />

●<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

●<br />

■<br />

■<br />

●<br />

6<br />

7<br />

8,14<br />

14<br />

8<br />

8<br />

8<br />

9<br />

10<br />

10<br />

10<br />

10<br />

10<br />

11<br />

12<br />

12<br />

14<br />

13<br />

16<br />

15<br />

Heater<br />

– in switch compartment<br />

– Motor heater<br />

●<br />

■<br />

●<br />

■<br />

●<br />

■<br />

13<br />

13<br />

Motors<br />

– 3-phase AC motors<br />

– 1-phase AC motors<br />

– DC motors<br />

●<br />

■<br />

■<br />

● ●<br />

■<br />

■<br />

15, 16<br />

15, 16<br />

15, 16<br />

15, 16<br />

Motor protection<br />

– Thermoswitches<br />

– PTC thermistor<br />

Integral controls<br />

●<br />

■<br />

■<br />

●<br />

■<br />

■<br />

■<br />

●<br />

■<br />

17<br />

17<br />

17<br />

21 - 23<br />

Electrical connections<br />

– AUMA plug/ socket connector<br />

– Double sealed<br />

– Plug/ socket connector for explosion-proof actuators<br />

– Plug-in terminal connection<br />

– Plug cover in special versions<br />

<strong>Valve</strong> attachment according to ISO 5211<br />

– Coupling<br />

– Coupling with bore<br />

●<br />

■<br />

■<br />

■<br />

●<br />

●<br />

■<br />

●<br />

■<br />

■<br />

■<br />

●<br />

●<br />

■<br />

●<br />

●<br />

■<br />

■<br />

●<br />

●<br />

■<br />

14, 18, 19<br />

18, 19<br />

18<br />

18, 19<br />

18, 19<br />

19<br />

15, 20<br />

15, 20<br />

20<br />

Ambient conditions<br />

– Enclosure protection IP67<br />

– Enclosure protection IP68<br />

– High temperature version<br />

– Low temperature version<br />

– Corrosion protection KN<br />

– Corrosion protection KS, KX<br />

– Version with cast iron housing<br />

Explosion protection<br />

EU Directives<br />

Functional tests<br />

●<br />

■<br />

■<br />

■<br />

●<br />

■<br />

■<br />

●<br />

●<br />

●<br />

■<br />

■<br />

●<br />

■<br />

■<br />

●<br />

●<br />

●<br />

■<br />

■<br />

●<br />

■<br />

■<br />

●<br />

●<br />

●<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24, 25<br />

26<br />

26<br />

5

6<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Type designation<br />

Version for modulating duty<br />

Explosion-proof part-turn actuator acc. to ATEX Directive 94/9/ EC<br />

Size (standard flange size according to EN ISO 5211)<br />

Device generation (SG x.2 for ship building, SG x.3 for lower torques)<br />

Open-close duty<br />

Input<br />

<strong>Valve</strong><br />

Actuator<br />

for open-close duty<br />

The usual valve positions in<br />

open-close duty are the end positions<br />

OPEN and CLOSED. Upon<br />

receiving an appropriate command<br />

the actuator moves the valve to one<br />

of the two end positions or, if necessary,<br />

to a pre-defined intermediate<br />

position.<br />

The valves are operated relatively<br />

seldom, the time intervals can span<br />

between a few minutes up to several<br />

months.<br />

<strong>Valve</strong> position<br />

trun<br />

t run max =15min(30min)<br />

Typical operation process in OPEN-CLOSE duty<br />

SGRExC 05.1<br />

Type of duty for part-turn<br />

actuators for open-close duty<br />

(SG, SGExC)<br />

AUMA part-turn actuators SG for<br />

open-close service are rated for<br />

short-time duty S2 - 15 min. The<br />

explosion-proof version SGExC are<br />

rated for S2 - 10 min. Description of<br />

the types of duty on page 7.<br />

t

Modulating duty<br />

Input signal from<br />

process controller<br />

Feedback signal<br />

to process controller<br />

<strong>Valve</strong> position<br />

Transmitter<br />

(Sensor)<br />

Positioner<br />

<strong>Valve</strong> position feedback<br />

Controlled variable<br />

Typical operation process in modulating duty<br />

Comparison short-time and intermittent duty<br />

<strong>Valve</strong><br />

Actuator<br />

for<br />

modulating<br />

duty<br />

Type of duty according to VDE 0530 / IEC 34-1<br />

Short-time duty S2<br />

The operation time at a constant load is short, so that<br />

thermal equilibrium is not reached. The pause is long<br />

enough for the machine to cool down to ambient temperature.<br />

The duration of the short-time operation is limited<br />

to 15 min (10 min, 30 min).<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

t<br />

The controlled variable in a modulating<br />

application is affected by many<br />

influences. A change of the reference<br />

input signal, pressure fluctuation<br />

in the pipeline and temperature<br />

variations influence the process in<br />

such a way that a frequent adjustment<br />

of the MOV is required. For<br />

sensitive modulating applications<br />

the starts may be in intervals of a few<br />

seconds.<br />

Therefore high demands are placed<br />

on actuators for this duty. Mechanical<br />

components and the motor must<br />

be designed appropriately to withstand<br />

a large number of operations<br />

with no decline in the required modulating<br />

accuracy.<br />

Type of duty for part-turn actuators<br />

for modulating duty (SGR)<br />

AUMA part-turn actuators SGR for<br />

modulating service are rated for<br />

intermittent duty S4 - 25 %.<br />

Intermittent duty S4<br />

The duty is a sequence of identical cycles which consist<br />

of starting time, operation time with constant load and<br />

rest period. The rest period allows the machine to cool<br />

down so that thermal equilibrium is not reached. The relative<br />

on- time at S4 - 25 % or S4 - 50 % is limited to 25 %<br />

and 50 % respectively.<br />

Permissible number of starts<br />

The max. permissible number of starts for all part-turn<br />

actuator sizes for modulating duty SGR 05.1 – SGR 12.1<br />

are 600 starts per hour [c/h].<br />

7

8<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Adjustable swing angle<br />

During manual operation the swing<br />

angle is limited via the internal end<br />

stops. If the customer requirements<br />

have not been mentioned in the<br />

order, the actuator is supplied with a<br />

swing angle of 90° The swing angle<br />

may be subsequently adjusted<br />

within a range of 80° – 110°. The<br />

operating time is extended or<br />

reduced accordingly.<br />

Seating<br />

Depending on the design of the valve<br />

to be operated, end position switching<br />

either limit seating, i.e. by measuring<br />

the valve travel completed, or<br />

torque seating, i.e. after reaching a<br />

defined torque. For this purpose, the<br />

Limit seating<br />

Speed<br />

Other swing angle ranges<br />

(option)<br />

On request the part-turn actuators<br />

may be supplied with different swing<br />

angle ranges.<br />

The following swing angle ranges<br />

are available:<br />

■ 30° – 40°<br />

■ 40° – 55°<br />

■ 55° – 80°<br />

■ 80° – 110° (standard)<br />

■ 110° – 160°<br />

■ 160° – 230°<br />

■ 230° – 320°<br />

The actuator runs at nominal output speed up to the set<br />

tripping point P. Due to the high reduction ratio and the<br />

consequently low output speeds (3.75 rpm at the shortest<br />

operating time 4 s for 90°) the overrun may be ignored.<br />

actuator is equipped with two independent<br />

measuring systems, i.e.<br />

limit switching and torque switching.<br />

The type of seating has to be taken in<br />

P<br />

Torque seating<br />

Set tripping torque<br />

Travel<br />

Travel<br />

OPEN CLOSED OPEN<br />

CLOSED<br />

Torque<br />

account both when setting the actuator<br />

and in the actuator control. However,<br />

the processing of signals for<br />

the two types of seating differs.<br />

After starting from the end position OPEN, the actuator<br />

runs in direction CLOSE. In end position CLOSED the<br />

torque increases within the valve seat until the actuator is<br />

automatically switched off after reaching the set value.

Adjustable torques<br />

Minimum and maximum tripping torques for part-turn actuators for open-close duty<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Size SG 05.1 SG 07.1 SG 10.1 SG 12.1<br />

min. [Nm] 100 120 250 500<br />

max. [Nm] 150 300 600 1 200<br />

Torques for part/turn actuators for modulating duty<br />

Size SGR 05.1 SGR 07.1 SGR 10.1 SGR 12.1<br />

min. tripping torque [Nm] 100 120 250 500<br />

max. tripping torque [Nm] 150 300 600 1 200<br />

Torque for modulating [Nm] 50 100 200 400<br />

Overload protection against torque peaks<br />

The torque switching, used for<br />

torque seating in the end position<br />

(see page 8), serves as overload<br />

protection for the entire travel, even<br />

in the case of limit seating.<br />

If excessive torque builds up at the<br />

obturator in an intermediate position,<br />

e.g. due to a trapped object, the<br />

torque switching trips after reaching<br />

the set tripping torque.<br />

After the controls have processed<br />

the torque switch signal accordingly,<br />

the motor will be switched off. As a<br />

result, valve and actuator are protected<br />

from damage.<br />

If the limit switch signals are processed<br />

accordingly in the controls,<br />

you can distinguish between a normal<br />

torque switch tripping at the end<br />

Torque<br />

OPEN<br />

Set tripping torque<br />

Travel<br />

positions and tripping in an intermediate<br />

position (fault) caused by<br />

over-torque.<br />

CLOSED<br />

9

10<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

DUO limit switching/ intermediate position switches (option)<br />

With DUO limit switching an additional<br />

switching point can be set for each<br />

direction of rotation (intermediate<br />

position switches). The switching can<br />

be set to any valve position between<br />

the end positions. The switch will<br />

remain operated from set tripping<br />

point to end position if not more than<br />

120 turns of the hollow output shaft<br />

are in between.<br />

Limit and torque switches<br />

Versions<br />

The switch signal can be used for<br />

any purpose, e.g. to:<br />

■ signal a certain valve position<br />

tripped<br />

not<br />

tripped<br />

OPEN<br />

direction<br />

With the help of the switches, the<br />

mechanically measured travel (i.e.<br />

number of turns) and torque are converted<br />

into usable signals for the<br />

actuator controls. The switches are<br />

integrated into the control unit which<br />

contains four switches in the basic<br />

version:<br />

■ one limit switch each for the end<br />

positions OPEN and CLOSED,<br />

■ one torque switch each for the directions<br />

OPEN and CLOSE.<br />

The limit switches are tripped when<br />

an end position is reached and the<br />

torque switches are tripped when the<br />

set tripping torque is exceeded.<br />

■ to start an additional actuator<br />

which is mounted on a bypass<br />

valve<br />

■ to start or switch off any unit, e.g. a<br />

pump<br />

Switching<br />

points<br />

<strong>Valve</strong> position<br />

CLOSE<br />

direction<br />

If the actuator is supplied with<br />

DUO limit switching two more limit<br />

switches for intermediate positions<br />

are available.<br />

To meet the high demands regarding<br />

reliability, AUMA uses specially<br />

developed high quality<br />

microswitches with a snap action<br />

mechanism.<br />

In the basic version the switch contacts<br />

are of silver. For voltages<br />

between 5 V and 50 V and low current,<br />

switches with gold-plated contacts<br />

are recommended.<br />

Application/ Description Type of contacts<br />

Single switch Standard (NC and NO contacts not galvanically isolated) 1 NC and 1 NO contact<br />

(1 NC and 1 NO)<br />

Tandem switches (option) For switching two different potentials. The switches have two compartments with<br />

galvanically isolated switches in a common sealed housing. The two switches are<br />

operated together; one switch is leading, which should be used for signalisation.<br />

Triple switches (option) For applications where three different potentials are to be switched. The switch<br />

consists of one single and one tandem switch.<br />

Switch rating<br />

Type of current Switch rating Imax<br />

30 V 125 V 250 V<br />

AC (ind. load) cos ϕ = 0.8 5 A 5 A 5 A<br />

DC (resistive load) 2 A 0.5 A 0.4 A<br />

with gold plated contacts<br />

(recommended for controls with low voltage)<br />

Voltage min. 5 V, max. 50 V<br />

Current min. 4 mA, max. 400 mA<br />

Technical data<br />

2 NC and 2 NO contacts<br />

(2 NC und 2 NO)<br />

3 NC and 3 NO contacts<br />

(3 NC and 3 NO)<br />

Enclosure protection IP 66<br />

Operation via lever<br />

Contact elements two snap action contacts<br />

Contact material Silver (standard)<br />

Gold (option)<br />

Mechanical lifetime min. 2 x 10 6 cycles

Magnetic limit and torque transmitter (MWG) (option)<br />

The magnetic limit and torque transmitter<br />

converts the mechanical values<br />

of limit and torque into continuous<br />

electronic signals.<br />

The simultaneous use of integral<br />

controls which evaluate the signals<br />

is a prerequisite for the use of the<br />

MWG. This variant does not require<br />

Absolute travel measurement –<br />

without battery<br />

The valve position is determined<br />

using a so called multi-turn-absolute<br />

encoder.<br />

Four shafts, each with a ratio of 8:1,<br />

are used to convert the travel into an<br />

electronic signal. Each valve position<br />

is assigned an unambiguous<br />

combination of the 4 shaft positions.<br />

Magnets and hall sensors register<br />

the shaft positions electronically.<br />

As soon as the power supply has<br />

been restored after a power failure,<br />

the current valve position is immediately<br />

available; a reference operation<br />

is not required. Position changes<br />

due to manual operation during<br />

power failure are registered by the<br />

MWG even without supply voltage. A<br />

battery is not required.<br />

Torque – continuously available<br />

The proven design of the sliding<br />

worm provides the mechanical principle<br />

of torque sensing. A torque at<br />

the output drive results in an axial<br />

movement of the sliding worm<br />

against the spring action. With a<br />

lever, the axial movement is transformed<br />

into a rotary movement. Hall<br />

sensors convert this movement into<br />

an electronic signal.<br />

any switches for limit positions or<br />

torque.<br />

Actuators with MWG have the following<br />

advantages.<br />

■ Non-intrusive setting is possible<br />

(see page 12)<br />

Torque signal<br />

to the controls<br />

Travel/ position signal<br />

to the controls<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

■ A torque signal is permanently<br />

available. It can be used for<br />

switching off at the set tripping<br />

torque. It can also be transmitted<br />

for external use, for example for<br />

torque monitoring at the valve.<br />

11

12<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Non-intrusive setting (option)<br />

If the actuator is equipped with<br />

a magnetic limit and torque<br />

transmitter (see page 11) and<br />

AUMATIC integral controls (see<br />

page 22) the actuator can be set<br />

non-intrusively. This means that the<br />

parameters can be set without having<br />

to open the actuator. Thereby<br />

several advantages are achieved:<br />

Position/ torque feedback signal (option)<br />

If the actuator is equipped with an<br />

MWG and AUMATIC integral controls,<br />

the valve position and the<br />

torque available in the valve are can<br />

be used as output signals. Even if<br />

there is no MWG installed in the actuator,<br />

the position of the valve can be<br />

transmitted as a continuous signal<br />

for remote position indication.<br />

Technical data potentiometer<br />

■ No tools are required for setting.<br />

■ The actuator need not be opened<br />

again after the electrical connection<br />

is completed. The electronic<br />

and mechanical components in<br />

the housing are well protected<br />

from ingress of water and dust.<br />

Position feedback is provided as an<br />

analogue feedback signal by:<br />

■ Precision potentiometer<br />

■ Electronic position transmitter<br />

RWG.<br />

Precision potentiometer Precision potentiometer in<br />

tandem version<br />

Linearity ≤ 1 %<br />

Output 0.5 W<br />

Resistance (standard) 0.2 kΩ 0.2/0.2 kΩ<br />

Resistance (option) 0.1 kΩ, 0.5 kΩ, 1.0 kΩ,<br />

5.0 kΩ<br />

Technical data RWG<br />

Output signal<br />

- 2-wire system<br />

- 3- or 4-wire system<br />

4 – 20 mA<br />

0/4 − 20 mA<br />

Supply voltage 24 V DC ±15% smoothed<br />

Lifetime min. 5 x 10 6 operations<br />

0.5/0.5 kΩ, 1.0/1.0 kΩ,<br />

5.0/5.0 kΩ, 0.2/5.0 kΩ<br />

■ The actuator can be set in potentially<br />

explosive atmospheres,<br />

without affecting the explosion<br />

protection.<br />

Electronic position transmitter<br />

RWG<br />

The actual position value is transmitted<br />

by a potentiometer and transformed<br />

by electronics into a current<br />

signal. Zero and span of the feedback<br />

signal can be easily adjusted by<br />

trimmer potentiometers.<br />

Inverse operation of the RWG is possible.<br />

Signal<br />

in mA 20<br />

4<br />

0<br />

0<br />

60<br />

Travel in %<br />

100<br />

Power supply unit for without<br />

integral controls<br />

For the voltage supply of all position<br />

transmitters we recommend the<br />

AUMA power supply unit PS 01.<br />

However, this unit must not be used<br />

in potentially explosive atmospheres<br />

or for intrinsically safe electric<br />

circuits.

Running indication (option)<br />

As an option the actuators are available<br />

with a blinker switch installed<br />

which can be used for the running<br />

indication. The contacts are available<br />

at the electrical connection.<br />

Heater<br />

Rating<br />

Technical data for heater in switch compartment<br />

Heater for actuators<br />

without integral controls<br />

Type of current Switch rating Imax<br />

30 V 125 V 250 V<br />

AC 5 A 5 A 5 A<br />

DC 2 A 0.5 A 0.4 A<br />

Heater in switch compartment<br />

(standard)<br />

Condensation in the actuator is possible<br />

due to wide fluctuation of the<br />

ambient temperature. The heater<br />

integrated in the control unit prevents<br />

this in general.<br />

The heater is rated for continuous<br />

duty. Therefore it should always be<br />

energized, but at the very least when<br />

the actuator is not operating.<br />

Heater for actuators with<br />

integral controls<br />

Heating element self-regulating PTC element Resistance type heater<br />

Voltage ranges 110 V – 250 V DC/AC<br />

24 V – 48 V DC/AC<br />

380 V – 400 V AC<br />

Output 5 W – 20 W 5 W<br />

24 V DC/AC<br />

(internal supply)<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Motor heater<br />

(option)<br />

For operation in extremely low temperatures<br />

AUMA strongly recommends<br />

the use of a motor heater.<br />

This applies to actuators in extreme<br />

low temperature version from<br />

– 50 °C. The heater prevents actuator<br />

starting problems caused by<br />

extremely cold temperatures.<br />

13

14<br />

Design principle<br />

Control unit<br />

2 Depending on the type of valve the actuator<br />

must be switched-off in the end position by<br />

limit or torque switches.<br />

For this purpose two independent measuring systems<br />

(limit switches and torque switches) are provided<br />

within the control unit. They measure the travel<br />

or the torque required at the output drive, respectively.<br />

The switches signalize to the actuator controls that<br />

the set tripping points have been reached, which<br />

then switch off the motor.<br />

The control unit may optionally be equipped with a<br />

magnetic limit and torque transmitter. The transmitter<br />

converts the mechanical parameters limit and<br />

torque into continuous electronic signals. In combination<br />

with the integral controls AUMATIC tripping<br />

points and tripping torques can be set non-intrusively,<br />

i.e. without using tools or opening the control<br />

unit.<br />

Electrical connection<br />

3 The connections for motor and control<br />

cables are made on a 50-pole AUMA plug/<br />

socket connector.<br />

If the plug/ socket is disconnected for maintenance<br />

work, the wiring remains undisturbed.<br />

The explosion-proof actuator types SGExC are provided<br />

with a special plug/ socket connector for explosion-proof<br />

actuators as a standard.<br />

Further information on page 14.<br />

1<br />

Mechanical position<br />

indicator<br />

The mechanical position<br />

indicator is used to indicate the<br />

valve position continuously.<br />

End stops<br />

4 During manual operation the internal end<br />

stops limit the swing angle. The significant<br />

advantage of the AUMA design is that the low input<br />

torque, not the high output torque acts against the<br />

end stops. Thereby high safety against damage due<br />

to overload is assured.<br />

3<br />

4<br />

1<br />

2<br />

6<br />

5<br />

7

Motor<br />

9<br />

An especially high starting torque is frequently<br />

required to unseat valves from the<br />

end position. The motors developed by AUMA fulfil<br />

this basic requirement.<br />

Apart from the predominantly used 3-phase AC<br />

motors, the actuators may also be equipped with<br />

1-phase AC motors. When using actuators with<br />

1-phase motors, the operating time can be adjusted.<br />

The motor is connected via an internal plug/ socket<br />

connector. This enables quick exchange of the<br />

motor, e.g. for change of output speed.<br />

Further information on page 16.<br />

8<br />

Gearing<br />

5 The well proven principle of worm gearing,<br />

combined with a planetary gear, is used to<br />

reduce the motor speed to the required actuator output<br />

speed. Self-locking is achieved by the worm<br />

gearing.<br />

The gear housing is filled with lubricant for the whole<br />

lifetime. A change of grease or re-lubrication is not<br />

necessary.<br />

9<br />

Design principle<br />

Manual operation<br />

8 For commissioning or in an emergency the<br />

part-turn actuator can be operated with the<br />

handwheel. Pull the handwheel until it disengages.<br />

The manual operation acts on the worm shaft due to<br />

an over-riding gear arrangement. The sliding worm<br />

which is used to determine the torque is located on<br />

the handwheel shaft.<br />

<strong>Valve</strong> attachment<br />

7 The valve attachment is according to EN ISO<br />

5211. On request, special connections are<br />

available.<br />

The gearbox can be positioned on the valve at every<br />

90°.<br />

Coupling<br />

6 The separate coupling facilitates the assembly<br />

of the actuator. It is placed on the valve<br />

shaft and secured against axial movement. Subsequently<br />

the actuator is fitted on the valve flange<br />

(Refer also to page 20).<br />

15

16<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

Motors<br />

Part-turn actuators SG 05.1 – SG<br />

12.1 may be equipped with 3-phase<br />

AC motors (standard), 1-phase AC<br />

motors (option), or DC motors<br />

(option). Part-turn actuators for mod-<br />

Standard voltages/ frequencies<br />

ulating duty SGR are only available<br />

with 3-phase AC motors. For actuators<br />

with 3-phase AC motors, the<br />

operating time may only be reached<br />

by replacing the motor or the plane-<br />

tary gear. For actuators with 1-phase<br />

AC motors, the operating time may<br />

be adjusted on site (see below).<br />

3-phase AC motors<br />

Voltage 1) [V] 220 230 240 380 400 415 440 460 480 500<br />

Frequency [Hz] 50 50 50 50 50 50 60 60 60 50<br />

1-ph AC motors<br />

Voltage [V] 110 – 120 220 – 240<br />

Frequency [Hz] 50/ 60 50/ 60<br />

DC motors<br />

Voltage [V] 24 110 220<br />

1) Permissible fluctuations ± 10 %<br />

Overvoltage may result in excessive temperature rise in the motor windings. In case of undervoltage the motor torque decreases in the ratio of<br />

the square of undervoltage divided the standard voltage. Larger voltage variations have therefore to be considered when sizing the actuator.<br />

Operating times<br />

If the actuators are equipped with the<br />

standard 3-phase AC motor, the<br />

operating time is invariably connected<br />

to the supply frequency and<br />

the reduction ratio. The operating<br />

time may only be subsequently<br />

changed by replacing the motor or<br />

the planetary gear.<br />

Operating times for a swing angle of 90°<br />

For part-turn, open-close duty actuators<br />

optionally equipped with a<br />

1-phase AC motor, the operating<br />

time may be adjusted within the set<br />

limits. Part-turn SGR actuators for<br />

modulating duty are only available<br />

with 3-phase AC motors.<br />

Size SG 05.1 SG 07.1 SG 10.1 SG 12.1<br />

with 3-phase AC motor at<br />

50 Hz [s]<br />

with 1-phase AC motor at<br />

50 Hz [s]<br />

4/ 5,6/ 8/ 11/ 16 /<br />

22/ 32<br />

with DC motor [s] 5 – 10<br />

10 – 20<br />

5,6/ 8/ 11/ 16/ 22/<br />

32<br />

11/ 16/ 22/ 32/ 45/<br />

63<br />

22/ 32/ 45/ 63<br />

5.6 – 45 11 – 90 11 – 90 22 – 180<br />

10 – 15<br />

20 – 30<br />

20 – 25<br />

40 – 50<br />

30 – 35<br />

60 – 70

Motor protection<br />

In order to protect the motor against<br />

overheating thermoswitches or PTC<br />

thermistors are embedded in the<br />

motor windings of the 3-phase AC<br />

and 1-phase AC motors. When integrated<br />

into the control circuit, they<br />

will protect the motor against damage<br />

due to excessively high winding<br />

temperature.<br />

Thermoswitches and PTC thermistors<br />

offer better protection than thermal<br />

overload relays, since the temperature<br />

rise is directly measured at<br />

the motor.<br />

The thermoswitches will interrupt the<br />

control circuit as soon as a winding<br />

temperature of 140 °C is exceeded.<br />

After cooling down to a temperature<br />

between 120 °C to 90 °C, the actuator<br />

can be switched on again.<br />

Motor temperature<br />

140 °C<br />

115 °C<br />

90 °C<br />

Tripping point<br />

Time<br />

Reset point<br />

Important! Failure to integrate the<br />

motor protection device into the controls<br />

voids the warranty for the<br />

motors.<br />

If the actuator is equipped with integral<br />

controls, the thermoswitches<br />

are automatically integrated.<br />

Delay time<br />

The delay time is the time from the<br />

tripping of the limit or torque switches<br />

to the motor power being removed.<br />

To protect the valve against excessive<br />

peak torques, the delay time<br />

should be as low as possible. This<br />

should be taken into account, especially<br />

if the actuators are controlled<br />

by a PLC. We recommend a delay<br />

time < 50 ms and to switch off the corresponding<br />

contactor directly by the<br />

limit or torque switch. Longer delay<br />

<strong>Equipment</strong>/ <strong>functions</strong><br />

times are possible provided the output<br />

speed, output drive type, valve<br />

type and the type of installation are<br />

considered.<br />

For the AUMA MATIC and AUMATIC<br />

integral controls the motor will immediately<br />

be switched off after tripping<br />

of a switch.<br />

Actuator type Thermoswitches PTC thermistors<br />

SG/SGR 05.1 – SG/SGR 12.1 1)<br />

Standard Option<br />

SGExC 05.1 – SGExC 12.1 1)<br />

Option Standard<br />

1) Also available with integral controls AUMA MATIC or AUMATIC; in this case the PTC tripping<br />

device is already integrated, if PTC thermistors are used.<br />

Rating of the thermoswitches<br />

AC voltage<br />

Switch rating<br />

(250 V AC)<br />

Imax<br />

cos ϕ = 1 2.5 A<br />

cos ϕ = 0.6 1.6 A<br />

DC voltage Switch rating<br />

Imax<br />

60 V 1 A<br />

42 V 1.2 A<br />

24 V 1.5 A<br />

17

18<br />

Interfaces<br />

Electrical connection<br />

AUMA plug/ socket connector<br />

Double sealed<br />

(option)<br />

As a standard, the actuators are<br />

equipped with an AUMA plug/<br />

socket connector for motor and<br />

control cables. This applies whether<br />

the actuator is equipped with integral<br />

controls or not.<br />

The double sealed connection is a<br />

sealed plug and socket which is fitted<br />

between the device housing and the<br />

plug/ socket connector. Even after<br />

removing the plug cover or if the<br />

cable glands do not seal properly the<br />

device will be protected against the<br />

ingress of dust or humidity.<br />

Plug/ socket connector with terminal board for explosion-proof actuators SGExC<br />

Explosion-proof actuators in versions<br />

SGExC with or without controls<br />

are designed with a ‘flameproof<br />

enclosure’. The sealed terminal<br />

board of this electrical connection<br />

ensures that the flameproof enclosure<br />

remains undisturbed even if the<br />

plug cover has been removed.<br />

The electrical connection between<br />

the terminal board and the electric/<br />

electronic components within the<br />

device is provided via a plug/ socket<br />

connector. The advantage of the<br />

modular design with plug-in connec-<br />

Plug-in terminal connection for explosion-proof actuators SGExC (option)<br />

Contrary to the plug/ socket<br />

connector, the customer connection<br />

is made on terminals which have<br />

been fitted to a terminal frame. The<br />

connection compartment has been<br />

enlarged. In terms of explosion protection<br />

this connection type has the<br />

same characteristics as the plug/<br />

socket connector.<br />

The significant advantage of this<br />

type of connection:<br />

Once connected, the wiring remains<br />

undisturbed, even if the actuator has<br />

to be removed from the valve, e.g. for<br />

maintenance purposes.<br />

tion is thereby also provided for explosion-proof<br />

actuators.<br />

The customer connection compartment<br />

is designated protection type<br />

‘increased safety’.<br />

By means of a protection cover, which<br />

is available as an option, the disconnected<br />

plug may be fitted to a wall to<br />

enable the operation of the plant<br />

under explosion-proof conditions.<br />

On request, these terminals can also<br />

be used for non-explosion-proof actuators.<br />

By means of a protection cover which<br />

is available as an option, the disconnected<br />

plug may be fitted to a wall to<br />

enable the operation of the plant<br />

under explosion-proof conditions.

Special connections<br />

For special customer requests plug/<br />

socket connectors of specified<br />

brands can be used.<br />

The plug cover of the standard version<br />

can be replaced by the following<br />

variants:<br />

Technical data<br />

AUMA plug/ socket connector<br />

Plug cover with<br />

■ removable lid<br />

■ enlarged terminal compartment<br />

■ enlarged terminal compartment<br />

and removable lid<br />

Interfaces<br />

Parking frame, protection cover<br />

These parts offer the facility to place<br />

the plug connector, while taken off<br />

the actuator, in a safe location on a<br />

wall. The open terminal compartment<br />

at the actuator can be closed<br />

with the protection cover. This prevents<br />

foreign matter, dust and water<br />

from entering the compartment while<br />

the plug connector is taken off.<br />

No. of contacts max. 6 (3 are available) 1 (leading contact) 50 pins/ sockets<br />

Designation U1, V1, W1, U2, V2, W2 according to VDE 1 to 50<br />

Connection voltage max. 750 V – 250 V<br />

Nominal current max. 25 A – 16 A<br />

Type of customer connection Screws Screw for ring lug Screws or crimping (option)<br />

Cross section max. 6 mm 2<br />

6 mm 2<br />

2.5 mm 2<br />

Technical data Motor power connections<br />

Material: Pin/ socket carrier Polyamide Polyamide Polyamide<br />

Contacts Brass Brass Brass, tin plated or gold plated (option)<br />

1) Protective earth Control pins<br />

Plug/ socket connector/ terminal board for explosion-proof actuators SGExC<br />

No. of contacts max. 3 1 38 pins/ sockets<br />

Designation U1, V1, W1 according to VDE 1 to 24, 31 to 40, 47 to 50<br />

Connection voltage max. 550 V – 250 V<br />

Nominal current max. 25 A – 10 A<br />

Type of customer connection Screws Screws Screws<br />

Cross section max. 6 mm 2<br />

6 mm 2<br />

1.5 mm 2<br />

Technical data Motor power connections<br />

Material: Pin/ socket carrier Araldite/ Polyamide Araldite/ Polyamide Araldite/ Polyamide<br />

Contacts Brass Brass Brass tin-plated<br />

1) Protective earth Control pins<br />

Plug-in terminal connection for explosion-proof actuators SGExC<br />

Terminals max. 6 (3 are available) 1 (leading contact) 50<br />

Designation U1, V1, W1 according to VDE 1 to 50<br />

Voltage max. 750 V – 250 V<br />

Current max. 25 A – 10 A<br />

Type of customer connection Screws Screws Cage clamp 2)<br />

Cross section max. 10 mm 2<br />

10 mm 2<br />

2.5 mm 2 Technical data Motor power connections<br />

flexible<br />

1) Protective earth Control pins<br />

Threads for conduit entries 3)<br />

Type Metric (standard) Pg (option)<br />

SG/ SGR 05.1 – 12.1 4)<br />

SGExC 05.1 – 12.1 4)<br />

2 x M25x1,5; 1 x M20x1,5 2 x Pg21; 1 x Pg13;5<br />

1) Suitable for copper wires. For aluminium wires please contact AUMA.<br />

2) Optional with screw connections.<br />

3) For delivery, sealed with plugs. Other thread sizes and thread types e.g. metric threads are possible on request.<br />

Cable glands can be supplied on request.<br />

4) Also valid for possibly available integral actuator controls.<br />

19

20<br />

Interfaces<br />

Wiring diagrams<br />

Terminal plans KMS<br />

The electrical details of the AUMA<br />

actuators are recorded in the KMS<br />

terminal plans. The terminal plan on<br />

the right shows the basic equipment<br />

and the normal version ‘clockwise<br />

closing’.<br />

For additional equipment see separate<br />

data sheet ‘Terminal plans<br />

KMS’.<br />

<strong>Valve</strong> attachment<br />

The flange sizes according to EN<br />

ISO 5211 as mentioned in the table<br />

are available. On request flanges<br />

with special dimensions can be provided.<br />

Coupling<br />

The separate coupling (refer to page<br />

15) can be supplied as follows:<br />

KMS TP 100 / 001<br />

Basic equipment SG<br />

Proposed wiring diagrams ASV<br />

If the control of the actuator is not<br />

provided via integral AUMA actuator<br />

controls, but via external controls,<br />

AUMA provides a variety of proposed<br />

wiring diagrams for the wiring<br />

of the actuator.<br />

To obtain the proposed wiring diagrams,<br />

please refer either to the<br />

AUMA catalogue, to our website on<br />

the Internet (www.auma.com), or<br />

contact us at AUMA.<br />

Type SG/ SGExC 05.1 07.1 10.1 12.1<br />

Flange Standard F05 F07 F10 F12<br />

sizes Special F07 F10 F12 F14<br />

■ unbored<br />

■ extended version<br />

■ finish machined as shown below<br />

Bore with keyway Square bore<br />

Bore with two-flats

Integral controls (option)<br />

with<br />

AUMA MATIC<br />

Part-turn actuators SG 05.1 – 12.1<br />

with<br />

AUMATIC<br />

Integral controls<br />

21

22<br />

Integral controls<br />

Which type of controls?<br />

AUMA MATIC<br />

AUMATIC<br />

The AUMA MATIC is the ideal<br />

control for open-close duty.<br />

Functions such as the<br />

automatic phase<br />

correction simplify<br />

commisioning. To<br />

operate the actuator<br />

on site the integral<br />

local controls<br />

can be used.<br />

The AUMATIC with<br />

microcontroller<br />

includes all <strong>functions</strong> of<br />

the AUMA MATIC. In<br />

addition, the AUMATIC<br />

has a variety of additional<br />

<strong>functions</strong> and the<br />

equipment has been<br />

considerably<br />

expanded:<br />

■ Non-intrusive setting (option)<br />

■ Adaptive positioner (option)<br />

■ Programmable signal relays<br />

■ Fieldbus interface (option)<br />

The following feedback signals are<br />

available: end positions reached, tripping<br />

torque exceeded, the selector<br />

switch position and a collective fault<br />

signal.<br />

An explosion-proof version of the<br />

AUMA MATIC is available.<br />

■ Display with plain text display<br />

■ Monitoring and diagnosis<br />

■ Logging of operating data<br />

■ Serial programming interface 1)<br />

The AUMATIC design: A modular<br />

system consisting of <strong>functions</strong>, communication<br />

interfaces and equipment<br />

elements, enables the combination of<br />

the ideal solution for every valve automation<br />

problem.<br />

An explosion-proof version of the<br />

AUMATIC is available.<br />

1) Please note, due to patent law the AUMATIC product with infrared interface on local controls must not be supplied to either the UK or Japan.<br />

This product without infrared interface does not infringe a patent and can be supplied to either country.<br />

Wall bracket<br />

The controls, also in explosion-proof<br />

version, can be mounted separately<br />

from the actuator on a wall bracket<br />

(see page 4). This is recommended<br />

if:<br />

■ limited space would restrict the<br />

access to directly mounted controls<br />

■ high ambient temperatures in the<br />

surroundings of the actuator could<br />

affect the electronics,<br />

■ heavy vibrations of the valve could<br />

influence the controls.<br />

Cable length<br />

The cable length between the actuator<br />

and the controls may be up to<br />

100 m.<br />

A separation of actuator and controls<br />

is also possible at a later date.<br />

Restrictions regarding cable length<br />

may apply depending on the equipment<br />

in the actuator, e.g. when an<br />

MWG is installed in the actuator (see<br />

technical data).<br />

On request, suitable cable sets can<br />

be obtained from AUMA.<br />

Further literature<br />

Detailed information can be found in<br />

the following brochures:<br />

■ Product description<br />

Actuator controls AUMATIC<br />

■ Product description<br />

Actuator controls AUMA MATIC

Advantages of integral controls (option)<br />

The aim in developing integral motor<br />

controls was to enable the customer<br />

Control cabinet<br />

Controls<br />

Controls<br />

Controls<br />

<strong>Process</strong> control system<br />

O. C. O. C.<br />

e.g. 400 V AC e.g. 400 V AC<br />

Local<br />

controls<br />

O. C.<br />

to save the high installation costs of<br />

external controls. This is highlighted<br />

PLC PLC<br />

Isolating<br />

switch<br />

Integral controls<br />

by the diagram below.<br />

A B C<br />

External controls (A)<br />

For actuators to be connected to<br />

external controls, the following must<br />

be considered:<br />

■ All actuator signals, e.g. the<br />

torque and limit switch signals,<br />

must be passed on to the external<br />

controls in the control cabinet.<br />

■ The control of the actuators via a<br />

reversing contactor combination<br />

has to be implemented and installed<br />

in the control cabinet.<br />

■ The local controls have to be implemented<br />

and mounted<br />

Fieldbus<br />

master<br />

I> I> I><br />

I><br />

Integral controls (B)<br />

Actuators with integral controls are<br />

supplied ready for use with local controls<br />

and switching elements.<br />

All electrical components, e.g. limit,<br />

torque and thermoswitches, as well<br />

as monitoring elements and possibly<br />

available position transmitters are<br />

integrated into the modern controls.<br />

This results in the following simplified<br />

systems:<br />

■ No extensive wiring in a control<br />

cabinet is required.<br />

■ Reliable and correct processing of<br />

the actuator signals. The immediate<br />

reaction of the controls prevents<br />

excessive torques from<br />

building up in the valve<br />

■ Actuator and controls are ideally<br />

adjusted to each other<br />

■ Standard wiring diagrams are<br />

available<br />

Supply<br />

Commands<br />

Signals<br />

Fieldbus cable (bidirectional)<br />

I> I><br />

Integral controls/<br />

Fieldbus (C)<br />

If the actuator controls are integrated<br />

in a fieldbus system, then the installation<br />

costs are further reduced. The<br />

commands and signals of all actuators<br />

(slaves) are transmitted to and<br />

from the master via a two-wire cable<br />

or via optical fibres. The space consuming<br />

input/ output boards, as well<br />

as their associate control cabinet<br />

sections, are no longer required.<br />

23

24<br />

Ambient conditions<br />

Enclosure protection<br />

IP 67<br />

AUMA part-turn actuators conform<br />

to enclosure protection IP 67 according<br />

to EN 60 529. IP 67 means protection<br />

against immersion up to max.<br />

1 m head of water for max. 30 minutes.<br />

Corrosion protection / Colour<br />

KN (standard)<br />

The standard AUMA corrosion protection<br />

KN is a high quality coating.<br />

This is suitable for outdoor installation<br />

and for slightly aggressive atmospheres<br />

with a low level of pollution.<br />

KS<br />

AUMA recommends this corrosion<br />

protection class when installing<br />

devices in occasionally or permanently<br />

aggressive atmospheres with<br />

a moderate pollutant concentration<br />

(e.g. in sewage treatment plants,<br />

chemical industry).<br />

KX<br />

AUMA recommends this corrosion<br />

protection class when installing<br />

devices in extremely aggressive<br />

atmospheres with high humidity and<br />

high pollutant concentration.<br />

Ambient temperatures<br />

IP 68<br />

AUMA part-turn actuators are available<br />

with improved enclosure protection<br />

IP 68 according to EN 60 529.<br />

IP 68 means protection against submersion<br />

up to 6 m head of water for<br />

max. 72 hours. During submersion<br />

up to 10 operations are permissible.<br />

Aluminium-free version<br />

All outside parts including the<br />

handwheel are either made of cast<br />

iron, spheroidal cast iron or stainless<br />

steel.<br />

This actuator version is designed for<br />

use in atmospheres which are highly<br />

corrosive to aluminium. This<br />

includes atmospheres with high<br />

humidity and maritime climate such<br />

as those present onshore, offshore<br />

or in desalination plants.<br />

In order to guarantee the enclosure<br />

protection IP 68, suitable cable<br />

glands have to be used. They are not<br />

part of the standard supply, but can<br />

be provided by AUMA, if ordered.<br />

Colour<br />

The standard colour of the finish<br />

coating is silver-grey (DB 701, similar<br />

to RAL 9007). Other colour are<br />

possible on request.<br />

Versions SG SGR SGExC<br />

Standard – 25 °C – + 80 °C 1) – 25 °C – + 60 °C – 20 °C – + 40 °C 2)<br />

Low temperature – 40 °C – + 60 °C – 40 °C – + 60 °C – 40 °C – + 40 °C<br />

Extr. low temperature – 50 °C – + 60 °C – – 50 °C – + 40 °C<br />

High temperature 3) Versions SG SGR SGExC<br />

Standard – 25 °C – + 80 °C 1) – 25 °C – + 60 °C – 20 °C – + 40 °C<br />

0 °C –+ 120 °C – –<br />

2)<br />

Low temperature – 40 °C – + 60 °C – 40 °C – + 60 °C – 40 °C – + 40 °C<br />

Extr. low temperature – 50 °C – + 60 °C – – 50 °C – + 40 °C<br />

High temperature 3) 0 °C –+ 120 °C – –<br />

1) With 3-phase AC motor up to + 80 °C, with 1-phase AC motor and/ or integrated RWG and/ or integral controls up to + 70 °C<br />

2) In special sizing up to + 60 °C possible<br />

3) Only possible with 3-phase AC motor

Explosion protection<br />

Lifetime<br />

Part-turn actuators for<br />

open-close duty SG/ SGExC<br />

One cycle is an operation from end<br />

position CLOSED to end position<br />

OPEN and vice versa for a swing<br />

angle of 90°.<br />

Type Cycles<br />

SG/ SGExC 05.1 20 000<br />

SG/ SGExC 07.1 20 000<br />

SG/ SGExC 10.1 15 000<br />

SG/ SGExC 12.1 10 000<br />

Mounting positions<br />

AUMA actuators (with or without integral<br />

controls) can be operated without<br />

restriction in any mounting position.<br />

For the installation of actuators in<br />

potentially hazardous or explosive<br />

areas, special protective measures<br />

are required. These are stipulated in<br />

the European Standards EN 50 014,<br />

50 018 and 50 019. The PTB<br />

(Physikalisch Technische Bundesanstalt,<br />

the German national<br />

test authority) as European<br />

test authority<br />

certifies the conformity<br />

of the equipment<br />

with the mentioned<br />

standards.<br />

The explosion-proof<br />

versions of the AUMA SGExC correspond<br />

to protection class II2G<br />

EEx de IIC T4.<br />

Part-turn actuators for modulating duty SGR<br />

The lifetime in operation hours (h)<br />

depends on the load and the number<br />

of starts. A high starting frequency<br />

will rarely improve the modulating<br />

accuracy. To reach the longest possible<br />

maintenance and fault-free<br />

Type Starts in<br />

million.<br />

min.<br />

Ambient conditions<br />

Certificates of conformity from<br />

national test authorities in other<br />

countries, e.g. CIS are also available.<br />

For the current versions of the<br />

certificates refer to the Internet<br />

under:<br />

www.auma.com (download section).<br />

operation time, the number of starts<br />

per hour chosen should be as low as<br />

permissible for the process. This can<br />

be achieved by setting the modulating<br />

parameters accordingly.<br />

Number of starts per hour for an<br />

expected lifetime based on min.<br />

operation hours 1)<br />

5.000 h 10 000 h 20 000 h<br />

Number of<br />

cycles<br />

max/h<br />

SGR 05.1 2,5 600 300 150 600<br />

SGR 07.1 2,5 600 300 150 600<br />

SGR 10.1 2,5 600 300 150 600<br />

SGR 12.1 2,5 600 300 150 600<br />

1) Based on the permissible torque for modulating duty according to ‘Technical Data SGR’<br />

and the type of duty S4 - 25 %<br />

25

26<br />

Other information<br />

EU-Directives<br />

Machinery Directive<br />

According to this directive, actuators<br />

are not complete machines. This<br />

means that a Certificate of<br />

Conformity is not possible. However,<br />

AUMA confirms with the Declaration<br />

of Incorporation (on the Internet<br />

under www.auma.com) that during the<br />

design stage the Standards mentioned<br />

in the Machinery Directive were<br />

applied.<br />

By mounting the actuator to other<br />

components (valves, pipelines etc.)<br />

a ‘machine’ within the meaning of the<br />

Directive is formed. Before commissioning<br />

this machine a Certificate of<br />

Conformity must be issued.<br />

Further literature<br />

■ Information<br />

Electric actuators for the installation<br />

in hazardous areas<br />

■ Information<br />

Electrical part-turn actuators<br />

SA/GS combinations<br />

■ Product description<br />

Electrical part-turn actuators for<br />

open-close and modulating duty<br />

AS(R) 6 – AS(R) 50<br />

■ Product description<br />

Actuator controls AUMA MATIC<br />

■ Product description<br />

Actuator controls<br />

AUMATIC<br />

Low Voltage, Electromagnetic<br />

Compatibility and ATEX Directive<br />

AUMA actuators fulfil the requirements,<br />

which has been proved in<br />

extensive tests. Therefore AUMA<br />

issued a Certificate of Conformity<br />

according to these Directives (on the<br />

Internet under www.auma.com).<br />

CE Mark<br />

Since AUMA actuators<br />

fulfil the requirements of<br />

the Low Voltage and EMC<br />

and the ATEX Directives, the actuators<br />

are marked with the CE-mark in<br />

accordance with the directives.<br />

■ Technical data<br />

AUMA part-turn actuators<br />

SG 05.1 – SG 12.1<br />

■ Technical data<br />

AUMA part-turn actuators for<br />

Modulating duty<br />

SGR 05.1 – SGR 12.1<br />

■ Technical data<br />

AUMA part-turn actuators<br />

SGExC 05.1 – SGExC 12.1<br />

Functional tests<br />

After assembly, all actuators are<br />

thoroughly tested according to<br />

AUMA’s inspection specification and<br />

the torque switching is calibrated.<br />

A final inspection record can be provided.<br />

The inspection records can be<br />

retrieved online via the Internet<br />

(www.auma.com).<br />

Furthermore, there are dimension<br />

sheets, proposed wiring diagrams<br />

and wiring diagrams available. The<br />

complete documentation is also<br />

available as PDF files under the Documents<br />

tab on the Internet under<br />

www.auma.com.

A<br />

Absolute encoder 11<br />

Actor 4<br />

Actuator controls 22 - 23<br />

Ambient temperatures 24<br />

Analogue feedback signal 12<br />

Applications 3<br />

ATEX Directive 26<br />

AUMA MATIC 4, 21 - 22<br />

AUMA plug/ socket connector 14,<br />

18 - 19<br />

AUMATIC 4, 12, 21 - 22<br />

B<br />

Blinker switch 13<br />

Bore with two-flats 20<br />

C<br />

CE Mark 26<br />

Certificate of Conformity 26<br />

Coating 24<br />

Collective fault signal 22<br />

Colour 24<br />

Conduit entries 19<br />

Control cabinet 23<br />

Control unit 10, 13 - 14<br />

Controls 4, 22 - 23<br />

Corrosion protection 24<br />

Coupling 15, 20<br />

Cycles 25<br />

D<br />

DC motor 16<br />

Declaration of Incorporation 26<br />

Definition of part-turn actuators 4<br />

Delay time 17<br />

Design principle 15<br />

Display 22<br />

Double sealed 18<br />

DUO limit switching 10<br />

DUO-limit switching 10<br />

E<br />

Electrical connection 14, 18<br />

EMC Directive 26<br />

EN ISO 5211 15, 20<br />

Enclosure protection 24<br />

End stops 8, 14<br />

EU-Directives 26<br />

Explosion protection 25<br />

External controls 23<br />

F<br />

Feedback signal 12, 22<br />

Fieldbus 22 - 23<br />

Fieldbus interface 22<br />

Flange size 20<br />

Frequencies 16<br />

Functional tests 26<br />

G<br />

Gearbox 15<br />

Gearing 15<br />

H<br />

Handwheel 15<br />

Heater 13<br />

I<br />

Integral controls 21, 23<br />

Intermediate position switches 10<br />

Intermittent duty 7<br />

L<br />

Lifetime 25<br />

Limit seating 8<br />

Limit switching 8, 10, 14<br />

Literature 22, 26<br />

Local controls 22 - 23<br />

Logging of operating data 22<br />

Low Voltage Directive 26<br />

M<br />

Machinery Directive 26<br />

Manual operation 8, 14 - 15<br />

Mechanical position indicator 14<br />

Modulating duty 7<br />

Motor protection 17<br />

Motors 15 - 17<br />

Mounting positions 25<br />

N<br />

Non-intrusive setting 11 - 12<br />

Number of starts 7<br />

O<br />

One-phase AC motor 15 - 16<br />

Open-close duty 6<br />

Operating time 15 - 16<br />

Overload protection 9<br />

P<br />

Parking frame 19<br />

Phase correction 22<br />

Plug/ socket 14<br />

Plug/<br />

socket connector 14 - 15, 18 - 19<br />

Plug/ socket connector with<br />

terminal board explosion-proof 18<br />

Position indicator 14<br />

Position transmitter RWG 12<br />

Positioner 22<br />

Potentiometer 12<br />

Power supply unit 12<br />

Precision potentiometer 12<br />

Protection cover 19<br />

PTB 25<br />

PTC thermistor 17<br />

PTC thermistors 17<br />

Index<br />

R<br />

Rating 13<br />

Reference input signal 7<br />

Running indication 13<br />

RWG 12<br />

S<br />

Selector switch 22<br />

Self-locking 15<br />

Short-time duty 6 - 7<br />

Signals 23<br />

Single switch 10<br />

Special connection 15<br />

Special connections 19<br />

Square bore 20<br />

Summary of <strong>functions</strong> 5<br />

Swing angle 8, 14, 16<br />

Switch 10<br />

Switch rating 10<br />

Switches 10<br />

T<br />

Tandem switches 10<br />

Technical data 9, 16<br />

Terminal connection 18 - 19<br />

Terminal plans 20<br />

Thermoswitches 17, 23<br />

Threads for conduit entries 19<br />

Three-phase AC motor 15 - 16<br />

Torque seating 8<br />

Torque sensing 11<br />

Torque switches 10 - 11<br />

Torque switching 8, 14<br />

Tripping torque 9<br />

Type designation 6<br />

Type of duty 6 - 7<br />

Type of seating 8<br />

V<br />

<strong>Valve</strong> attachment 15, 20<br />

W<br />

wall bracket 4<br />

Wiring diagrams 20<br />

Worm gearing 15<br />

27

Europe<br />

AUMA Riester GmbH & Co. KG<br />

Werk Müllheim<br />

DE-79373 Müllheim<br />

Tel +49 7631 809 - 0<br />

Fax +49 7631 809 - 250<br />

riester@auma.com<br />

www.auma.com<br />

Werk Ostfildern-Nellingen<br />

DE-73747 Ostfildern<br />

Tel +49 711 34803 - 0<br />

Fax +49 711 34803 - 34<br />

riester@wof.auma.com<br />

Service-Center Köln<br />

DE-50858 Köln<br />

Tel +49 2234 20379 - 00<br />

Fax +49 2234 20379 - 99<br />

Service@sck.auma.com<br />

Service-Center Magdeburg<br />

DE-39167 Niederndodeleben<br />

Tel +49 39204 759 - 0<br />

Fax +49 39204 759 - 19<br />

Service@scm.auma.com<br />

Service-Center Bayern<br />

DE-85748 Garching-Hochbrück<br />

Tel +49 89 329885 - 0<br />

Fax +49 89 329885 - 18<br />

Riester@scb.auma.com<br />

Büro Nord, Bereich Schiffbau<br />

DE-21079 Hamburg<br />

Tel +49 40 791 40285<br />

Fax +49 40 791 40286<br />

Stephan.Dierks@auma.com<br />

Büro Nord, Bereich Industrie<br />

DE-29664 Walsrode<br />

Tel +49 5167 504<br />

Fax +49 5167 565<br />

Erwin.Handwerker@auma.com<br />

Büro Ost<br />

DE-39167 Niederndodeleben<br />

Tel +49 39204 75980<br />

Fax +49 39204 75989<br />

Claus.Zander@auma.com<br />

Büro West<br />

DE-45549 Sprockhövel<br />

Tel +49 2339 9212 - 0<br />

Fax +49 2339 9212 - 15<br />

Karlheinz.Spoede@auma.com<br />

Büro Süd-West<br />

DE-69488 Birkenau<br />

Tel +49 6201 373149<br />

Fax +49 6201 373150<br />

Dieter.Wagner@auma.com<br />

Büro Württemberg<br />

DE-73747 Ostfildern<br />

Tel +49 711 34803 80<br />

Fax +49 711 34803 81<br />

Siegfried.Koegler@wof.auma.com<br />

Büro Baden<br />

DE-76764 Rheinzabern<br />

Tel +49 7272 76 07 - 23<br />

Fax +49 7272 76 07 - 24<br />

Wolfgang.Schulz@auma.com<br />

Büro Kraftwerke<br />

DE-79373 Müllheim<br />

Tel +49 7631 809 192<br />

Fax +49 7631 809 294<br />

Klaus.Wilhelm@auma.com<br />

Büro Bayern<br />

DE-93356 Teugn/Niederbayern<br />

Tel +49 9405 9410 24<br />

Fax +49 9405 9410 25<br />

Mathias.Jochum@auma.com<br />

AUMA Riester GmbH & Co. KG<br />

P. O. Box 1362<br />

D - 79373 Müllheim<br />

Tel +49 (0)7631/809-0<br />

Fax +49 (0)7631/809 250<br />

riester@auma.com<br />

AUMA Armaturenantriebe GmbH<br />

AT-2512 Tribuswinkel<br />

Tel +43 2252 82540<br />

Fax +43 2252 8254050<br />

office@auma.at<br />

AUMA (Schweiz) AG<br />

CH-8965 Berikon<br />

Tel +41 566 400945<br />

Fax +41 566 400948<br />

RettichP.ch@auma.com<br />

AUMA Servopohony spol. s.r.o.<br />

CZ-10200 Praha 10<br />

Tel +420 272 700056<br />

Fax +420 272 704125<br />

auma-s@auma.cz<br />

OY AUMATOR AB<br />

FI-02270 Espoo<br />

Tel +35 895 84022<br />

Fax +35 895 8402300<br />

auma@aumator.fi<br />

AUMA France<br />

FR-95157 Taverny Cédex<br />

Tel +33 1 39327272<br />

Fax +33 1 39321755<br />

servcom@auma.fr<br />

AUMA ACTUATORS Ltd.<br />

GB- Clevedon North Somerset BS21 6QH<br />

Tel +44 1275 871141<br />

Fax +44 1275 875492<br />

mail@auma.co.uk<br />

AUMA ITALIANA S.r.l.<br />

IT-20020 Lainate Milano<br />

Tel +39 0 2 9317911<br />

Fax +39 0 2 9374387<br />

info@auma.it<br />

www.auma.it<br />

AUMA BENELUX B.V.<br />

NL-2314 XT Leiden<br />

Tel +31 71 581 40 40<br />

Fax +31 71 581 40 49<br />

office@benelux.auma.com<br />

AUMA Polska Sp. zo. o.<br />

PL-41-310 Dabrowa Górnicza<br />

Tel +48 32 26156 68<br />

Fax +48 32 26148 23<br />

R.Ludzien@auma.com.pl<br />

www.auma.com.pl<br />

AUMA Priwody OOO<br />

RU-125362 Moscow<br />

Tel +7 095 787 78 21<br />

Fax +7 095 787 78 21<br />

aumarussia@auma.ru<br />

GRØNBECH & SØNNER A/S<br />

DK-2450 Copenhagen SV<br />

Tel +45 3326 6300<br />

Fax +45 3326 6301<br />

GS@g-s.dk<br />

IBEROPLAN S.A.<br />

ES-28027 Madrid<br />

Tel +34 91 3717130<br />

Fax +34 91 7427126<br />

iberoplan@iberoplan.com<br />

D. G. Bellos & Co. O.E.<br />

GR-13671 Acharnai Athens<br />

Tel +30 210 2409485<br />

Fax +30 210 2409486<br />

info@dgbellos.gr<br />

SIGURD SØRUM A. S.<br />

NO-1301 Sandvika<br />

Tel +47 67572600<br />

Fax +47 67572610<br />

post@sigurd-sorum.no<br />

INDUSTRA<br />

PT-2710-297 Sintra<br />

Tel +351 2 1910 95 00<br />

Fax +351 2 1910 95 99<br />

jpalhares@tyco-valves.com<br />

ISO 9001<br />

ISO 14001<br />

Certificate Registration No.<br />

12 100 4269<br />

12 104 4269<br />

For detailed information about AUMA products refer to the Internet:<br />

www.auma.com<br />

ERICHS ARMATUR AB<br />

SE-20039 Malmö<br />

Tel +46 40 311550<br />

Fax +46 40 945515<br />

info@erichsarmatur.se<br />

MEGA Endüstri Kontrol Sistemieri Tic. Ltd.<br />

Sti.<br />

TR-06460 Övecler Ankara<br />

Tel +90 312 472 62 70<br />

Fax +90 312 472 62 74<br />

megaendustri@megaendustri.com.tr<br />

Africa<br />

AUMA South Africa (Pty) Ltd.<br />

ZA-1560 Springs<br />

Tel +27 11 3632880<br />

Fax +27 11 8185248<br />

aumasa@mweb.co.za<br />

www.auma.co.za<br />

A.T.E.C.<br />

EG- Cairo<br />

Tel +20 2 3599680 - 3590861<br />

Fax +20 2 3586621<br />

atec@intouch.com<br />

America<br />

AUMA ACTUATORS INC.<br />

US-PA 15317 Canonsburg<br />

Tel +1 724-743-AUMA (2862)<br />

Fax +1 724-743-4711<br />

mailbox@auma-usa.com<br />

www.auma-usa.com<br />

AUMA Chile Respresentative Office<br />

CL- La Reina Santiago de Chile<br />

Tel +56 22 77 71 51<br />

Fax +56 22 77 84 78<br />

aumachile@adsl.tie.cl<br />

LOOP S. A.<br />

AR-C1140ABP Buenos Aires<br />

Tel +54 11 4307 2141<br />

Fax +54 11 4307 8612<br />

contacto@loopsa.com.ar<br />

Asvotec Termoindustrial Ltda.<br />

BR-13190-000 Monte Mor/ SP.<br />

Tel +55 19 3879 8735<br />

Fax +55 19 3879 8738<br />

atuador.auma@asvotec.com.br<br />

TROY-ONTOR Inc.<br />

CA-L4N 5E9 Barrie Ontario<br />

Tel +1 705 721-8246<br />

Fax +1 705 721-5851<br />

troy-ontor@troy-ontor.ca<br />

MAN Ferrostaal de Colombia Ltda.<br />

CO- Bogotá D.C.<br />

Tel +57 1 4 011 300<br />

Fax +57 1 4 131 806<br />

dorian.hernandez@manferrostaal.com<br />

www.manferrostaal.com<br />

PROCONTIC Procesos y Control Automático<br />

EC- Quito<br />

Tel +593 2 292 0431<br />

Fax +593 2 292 2343<br />

info@procontic.com.ec<br />

IESS DE MEXICO S. A. de C. V.<br />

MX-C.P. 02900 Mexico D.F.<br />

Tel +52 55 55 561 701<br />

Fax +52 55 53 563 337<br />

informes@iess.com.mx<br />

Multi-<strong>Valve</strong> Latin America S. A.<br />

PE- San Isidro Lima 27<br />

Tel +511 222 1313<br />

Fax +511 222 1880<br />

multivalve@terra.com.pe<br />

PASSCO Inc.<br />

PR-00936-4153 San Juan<br />

Tel +18 09 78 77 20 87 85<br />

Fax +18 09 78 77 31 72 77<br />

Passco@prtc.net<br />

Suplibarca<br />

VE- Maracaibo Edo, Zulia<br />

Tel +58 261 7 555 667<br />

Fax +58 261 7 532 259<br />

suplibarca@iamnet.com<br />

Asia<br />

AUMA (India) Ltd.<br />

IN-560 058 Bangalore<br />

Tel +91 80 2839 4655<br />

Fax +91 80 2839 2809<br />

info@auma.co.in<br />

AUMA JAPAN Co., Ltd.<br />

JP-210-0848 Kawasaki-ku,<br />

Kawasaki-shi Kanagawa<br />

Tel +81 44 329 1061<br />

Fax +81 44 366 2472<br />

mailbox@auma.co.jp<br />

AUMA ACTUATORS (Singapore) Pte Ltd.<br />

SG-569551 Singapore<br />

Tel +65 6 4818750<br />

Fax +65 6 4818269<br />

sales@auma.com.sg<br />

www.auma.com.sg<br />

AUMA Middle East Rep. Office c/o Al Ayman<br />

Ind. Eqpts.<br />

AE- Dubai<br />

Tel +971 4 3682720<br />

Fax +971 4 3682721<br />

auma@emirates.net.ae<br />

AUMA Beijing Representative Office<br />

CN-100029 Beijing<br />

Tel +86 10 8225 3933<br />

Fax +86 10 8225 2496<br />

mailbox@auma-china.com<br />

www.auma-china.com<br />

PERFECT CONTROLS Ltd.<br />

HK- Tsuen Wan, Kowloon<br />

Tel +852 2493 7726<br />

Fax +852 2416 3763<br />

joeip@perfectcontrols.com.hk<br />

DW Controls Co., Ltd.<br />

KR-153-803 Seoul Korea<br />

Tel +82 2 2113 1100<br />

Fax +82 2 2113 1088/1089<br />

sichoi@actuatorbank.com<br />

www.actuatorbank.com<br />

AL-ARFAJ Eng. Company W. L. L.<br />

KW-22004 Salmiyah<br />

Tel +965 4817448<br />

Fax +965 4817442<br />

arfaj@qualitynet.net<br />

BEHZAD Trading<br />

QA- Doha<br />

Tel +974 4433 236<br />

Fax +974 4433 237<br />

behzad@qatar.net.qa<br />

Sunny <strong>Valve</strong>s and Intertrade Corp. Ltd.<br />

TH-10120 Yannawa Bangkok<br />