Equipment/ functions - Process Valve Solutions

Equipment/ functions - Process Valve Solutions

Equipment/ functions - Process Valve Solutions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

14<br />

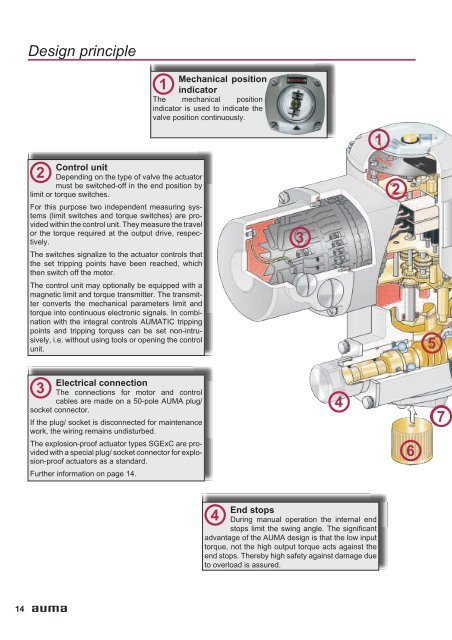

Design principle<br />

Control unit<br />

2 Depending on the type of valve the actuator<br />

must be switched-off in the end position by<br />

limit or torque switches.<br />

For this purpose two independent measuring systems<br />

(limit switches and torque switches) are provided<br />

within the control unit. They measure the travel<br />

or the torque required at the output drive, respectively.<br />

The switches signalize to the actuator controls that<br />

the set tripping points have been reached, which<br />

then switch off the motor.<br />

The control unit may optionally be equipped with a<br />

magnetic limit and torque transmitter. The transmitter<br />

converts the mechanical parameters limit and<br />

torque into continuous electronic signals. In combination<br />

with the integral controls AUMATIC tripping<br />

points and tripping torques can be set non-intrusively,<br />

i.e. without using tools or opening the control<br />

unit.<br />

Electrical connection<br />

3 The connections for motor and control<br />

cables are made on a 50-pole AUMA plug/<br />

socket connector.<br />

If the plug/ socket is disconnected for maintenance<br />

work, the wiring remains undisturbed.<br />

The explosion-proof actuator types SGExC are provided<br />

with a special plug/ socket connector for explosion-proof<br />

actuators as a standard.<br />

Further information on page 14.<br />

1<br />

Mechanical position<br />

indicator<br />

The mechanical position<br />

indicator is used to indicate the<br />

valve position continuously.<br />

End stops<br />

4 During manual operation the internal end<br />

stops limit the swing angle. The significant<br />

advantage of the AUMA design is that the low input<br />

torque, not the high output torque acts against the<br />

end stops. Thereby high safety against damage due<br />

to overload is assured.<br />

3<br />

4<br />

1<br />

2<br />

6<br />

5<br />

7