ECOBOX Heat Recovery Unit - VES

ECOBOX Heat Recovery Unit - VES

ECOBOX Heat Recovery Unit - VES

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

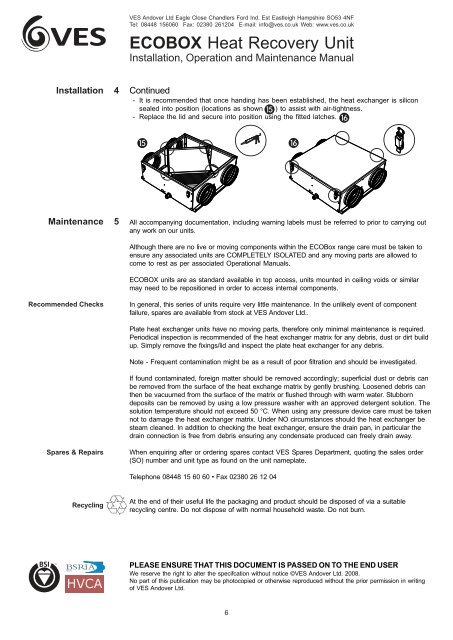

<strong>VES</strong><strong>VES</strong> Andover Ltd Eagle Close Chandlers Ford Ind. Est Eastleigh Hampshire SO53 4NFTel: 08448 156060 Fax: 02380 261204 E-mail: info@ves.co.uk Web: www.ves.co.uk<strong>ECOBOX</strong> <strong>Heat</strong> <strong>Recovery</strong> <strong>Unit</strong>Installation, Operation and Maintenance ManualInstallation 4Continued- It is recommended that once handing has been established, the heat exchanger is siliconsealed into position (locations as shown ) to assist with air-tightness.- Replace the lid and secure into position using the fitted latches.Maintenance 5All accompanying documentation, including warning labels must be referred to prior to carrying outany work on our units.Although there are no live or moving components within the ECOBox range care must be taken toensure any associated units are COMPLETELY ISOLATED and any moving parts are allowed tocome to rest as per associated Operational Manuals.<strong>ECOBOX</strong> units are as standard available in top access, units mounted in ceiling voids or similarmay need to be repositioned in order to access internal components.Recommended ChecksIn general, this series of units require very little maintenance. In the unlikely event of componentfailure, spares are available from stock at <strong>VES</strong> Andover Ltd..Plate heat exchanger units have no moving parts, therefore only minimal maintenance is required.Periodical inspection is recommended of the heat exchanger matrix for any debris, dust or dirt buildup. Simply remove the fixings/lid and inspect the plate heat exchanger for any debris.Note - Frequent contamination might be as a result of poor filtration and should be investigated.If found contaminated, foreign matter should be removed accordingly; superficial dust or debris canbe removed from the surface of the heat exchange matrix by gently brushing. Loosened debris canthen be vacuumed from the surface of the matrix or flushed through with warm water. Stubborndeposits can be removed by using a low pressure washer with an approved detergent solution. Thesolution temperature should not exceed 50 °C. When using any pressure device care must be takennot to damage the heat exchanger matrix. Under NO circumstances should the heat exchanger besteam cleaned. In addition to checking the heat exchanger, ensure the drain pan, in particular thedrain connection is free from debris ensuring any condensate produced can freely drain away.Spares & RepairsWhen enquiring after or ordering spares contact <strong>VES</strong> Spares Department, quoting the sales order(SO) number and unit type as found on the unit nameplate.Telephone 08448 15 60 60 • Fax 02380 26 12 04RecyclingAt the end of their useful life the packaging and product should be disposed of via a suitablerecycling centre. Do not dispose of with normal household waste. Do not burn.PLEASE ENSURE THAT THIS DOCUMENT IS PASSED ON TO THE END USERWe reserve the right to alter the specifcation without notice ©<strong>VES</strong> Andover Ltd. 2008.No part of this publication may be photocopied or otherwise reproduced without the prior permission in writingof <strong>VES</strong> Andover Ltd.6