Tenable Screw Company Limited

Tenable Screw Company Limited

Tenable Screw Company Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

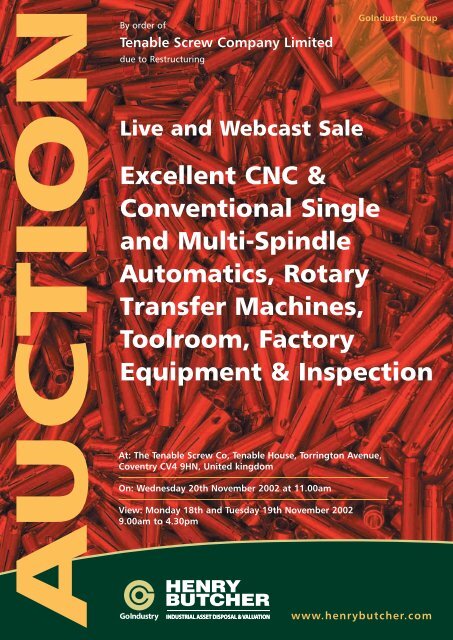

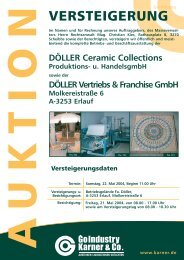

AUCTION<br />

By order of<br />

<strong>Tenable</strong> <strong>Screw</strong> <strong>Company</strong> <strong>Limited</strong><br />

due to Restructuring<br />

Live and Webcast Sale<br />

At: The <strong>Tenable</strong> <strong>Screw</strong> Co, <strong>Tenable</strong> House, Torrington Avenue,<br />

Coventry CV4 9HN, United kingdom<br />

On: Wednesday 20th November 2002 at 11.00am<br />

View: Monday 18th and Tuesday 19th November 2002<br />

9.00am to 4.30pm<br />

GoIndustry Group<br />

Excellent CNC &<br />

Conventional Single<br />

and Multi-Spindle<br />

Automatics, Rotary<br />

Transfer Machines,<br />

Toolroom, Factory<br />

Equipment & Inspection<br />

www.henrybutcher.com

Webcast available @ www.henrybutcher.com<br />

CNC Single Spindle<br />

Turning<br />

Index ‘ABC’ Single Spindle CNC Lathe,<br />

36mm bar dia, 2 x 8 Station Bi-<br />

Directional Turrets, Turret 1 with Driven<br />

Tooling and Synchronised Pick off,<br />

Synchronised Spindle with 2.5 Degree<br />

Indexing, 5 Spindle Rear End Drilling<br />

Attachment, Index ‘C200-4 (Siemens<br />

840C)’ Control, Schmid Magazine Bar<br />

Feed, Swarf Conveyor (1996)<br />

Tornos Bechler ‘DECO 13 basic’ 9 Axis<br />

CNC Sliding Head Automatics, 13mm<br />

Bar dia, 3 Spindle End Working<br />

Attachment, 3 Spindle Back Drilling<br />

Attachment, Tornos-Bechler Fanuc<br />

‘PNC DECO’ Control, Magazine Bar<br />

Feed (Choice of 2 and Both Lightly<br />

Used 2000 & 2001)<br />

Hitachi Seiki ‘CB20 Tricell’ CNC Super<br />

Productive Integrated Turning Cell,<br />

Twin 12 Station Upper Turrets, Twin<br />

Opposed Headstocks with 200mm dia<br />

Chucks, Single Bottom 6 Station<br />

Turret, ‘Seicos L Multi’ Control and<br />

Swarf Conveyor (1994)<br />

Hardinge ‘DV59’ Precision Lathe, with<br />

‘Omniturn’ CNC Controlled Slide,<br />

Traverses X=10.5”, Y=5.5”<br />

(Choice of 2, Retrofitted 1995)<br />

CNC<br />

Wickman 13/4” x 6 Spindle ‘Multiflex’ CNC<br />

Bar Automatic<br />

CNC<br />

Shimada ‘CN660/B6-27NC’ 27mm x 6 Spindle<br />

CNC Bar Automatic<br />

5<br />

1992<br />

6<br />

1991<br />

CNC<br />

Index ‘ABC’ Single Spindle CNC Lathe<br />

CNC<br />

2<br />

1<br />

Tornos Bechler ‘DECO 13 basic’ CNC Sliding Head Automatic<br />

1996<br />

Choice of 2<br />

2000 & 2001<br />

Register for the Catalogue Online @ www.henrybutcher.com

Webcast available @ www.henrybutcher.com<br />

CNC<br />

Hitachi Seiki ‘CB20 Tricell’ CNC Super Productive Integrated Turning Cell<br />

CNC<br />

3<br />

4<br />

Wickman 1” x 6 Spindle ‘Multiflex’ CNC Bar Automatic<br />

1994<br />

1995<br />

CNC Multi-Spindle<br />

Automatics<br />

Wickman 1” x 6 Spindle ‘Multiflex’ CNC<br />

Bar Automatic, NUM CNC Control,<br />

Fitted Pick Up and Back Chamfer,<br />

Threading Attachment, Frenco Tool<br />

Pre-setter (1995)<br />

Wickman 13/4” x 6 Spindle ‘Multiflex’<br />

CNC Bar Automatic, GE Fanuc ‘Power<br />

Mate’ Control, Fitted Pick Up and Back<br />

Chamfer, Threading Attachment, Swarf<br />

Conveyor (1992)<br />

Shimada ‘B6-27NC’ 27mm x 6 Spindle,<br />

4 Axis CNC Bar Automatic, 2 x CNC<br />

Controlled Slides, Fanuc ‘Series O-TT’<br />

Control, Cucchi Magazine Bar Feed &<br />

Swarf Conveyor (1991)<br />

Conventional Multi-<br />

Spindle Automatics<br />

Wickman ‘1” x 6F’ High Speed 6 Spindle<br />

Bar Automatic, 4000rpm, 4” Bar Feed<br />

Stroke, Bar Feed & Swarf Conveyor<br />

(1983)<br />

Wickman 1” x 6 Spindle Bar Automatics,<br />

3000rpm, 5” Bar Feed Stroke, Cucchi<br />

Magazine Bar Loader & Swarf<br />

Conveyor (Choice of 2, 1972 and 1978)<br />

Wickman 5/8” x 6 Spindle Bar<br />

Automatic, 5000rpm, Cucchi Magazine<br />

Bar Loader (Choice of 5 to 1977)<br />

Tornos-Bechler ‘BS20’ 21mm x 8 Spindle<br />

Bar Automatic, 6000rpm, 8 Cross<br />

Slides, fitted 2nd Operation 6 Station<br />

Machining Head and Transfer Arm,<br />

and Cucchi Magazine Bar Loader<br />

Tornos-Bechler ‘BS20’ 21mm x 8 Spindle<br />

Bar Automatic, 6000rpm, 8 Cross<br />

Slides, IEMCA ‘PRA40/33/P’ Magazine<br />

Bar Loader,<br />

Attachments - Machines fitted with a<br />

variety of Drives and Attachments to<br />

include Pick Up and Back Chamfer,<br />

Threading Drives and Attachments,<br />

Bottle Drives, Generating Attachments,<br />

Chasing Drives, High Speed Drilling<br />

Drives, Form Turning Slides, Spline<br />

Drives (See Catalogue for Machine By<br />

Machine Breakdown)<br />

Wickman ‘1” x 6F’ High Speed Bar Automatic<br />

or telephone the catalogue request line on +44 (0)117 930 4020<br />

7

Webcast available @ www.henrybutcher.com<br />

The Sale also includes a considerable<br />

number of attachments separate<br />

from the machines, which will be<br />

individually detailed in the catalogue.<br />

Conventional Sliding Head<br />

(Swiss Type) Automatics<br />

Tornos ‘R16’ 16mm Capacity, 3 Spindle<br />

Combined Attachment<br />

Tornos ‘R10’ 10mm Capacity, 3 Spindle<br />

Combined Attachment<br />

Bechler ‘B20’ 20mm Capacity, 3 Spindle<br />

Drilling Attachment (Choice of 3)<br />

Bechler ‘BR20’ 20mm Capacity, 3 Spindle<br />

Combined Attachment<br />

Strohm ‘125NAR’ 12.7mm Capacity,<br />

3 Spindle Combined Attachment<br />

(Choice of 2)<br />

Strohm ‘125S’ 12.7mm Capacity, 3<br />

Spindle Combined Attachment<br />

Petermann ‘P7’ 7mm Capacity, Azuma<br />

Autobar Magazine Bar Feeds,<br />

3 Spindle Combined Attachments,<br />

(Choice of 19)<br />

Petermann ‘10HS’ 10mm Capacity, 3<br />

Spindle Drilling Attachment<br />

Coil Fed Automatics<br />

Escomatic ‘D6S-R’ with Type ‘1A’ Turret,<br />

Double Back Drilling and Cross Drilling.<br />

Max capacity 6.35mm<br />

Escomatic ‘D6R’ with Type ‘1A’ 4 Position<br />

Turret. Max capacity 6.35mm<br />

(Choice of 2)<br />

Escomatic ‘D2’ Max capacity 4mm<br />

Rotary Transfer Machines<br />

Wirth & Gruffat ‘Convertible 128’ Rotary<br />

Transfer Machines, 8 working Stations<br />

including Loading (Choice of 2)<br />

Wirth & Gruffat ‘Convertible 126’ Rotary<br />

Transfer Machines, 6 Working Stations<br />

including Loading (Choice of 11)<br />

Wirth & Gruffat ‘Convertible 124’ Rotary<br />

Transfer Machine, 4 Working Stations<br />

Ackworthie ‘Vertomat V8’ Rotary<br />

Transfer Machines, 8 Working Stations<br />

(Choice of 6)<br />

Ackworthie ‘Vertomat V4’ Rotary<br />

Transfer Machines, 4 Working Stations<br />

(Choice of 11)<br />

Claude Fleury Horizontal Spindle Drilling<br />

Machine, 3 Heads and Indexing Table<br />

Attachments – The Catalogue details<br />

the head combinations on each<br />

machine, these include Horizontal,<br />

Vertical and Inclined Milling, Drilling<br />

& Threading Heads. There will be a<br />

quantity of additional attachments to<br />

be sold individually. For a Machineby-Machine,<br />

breakdown plus a<br />

comprehensive list of individual units<br />

see the catalogue.<br />

Wickman 1” x 6 Spindle Bar Automatic Wickman 5/8” x 6 Spindle Bar Automatic<br />

10<br />

Tornos Bechler ‘BS20B’ 21mm x 8 Spindle Bar<br />

Automatic<br />

Range of Sliding Head (Swiss Type) Automatics<br />

Choice of 2 Choice of 3<br />

Wirth & Gruffat ‘Convertible 126’ Rotary<br />

Transfer Machine<br />

Register for the Catalogue Online @ www.henrybutcher.com<br />

8<br />

1993<br />

9<br />

11<br />

13<br />

Choice of 11<br />

29 Machines

Webcast available @ www.henrybutcher.com<br />

12<br />

Wirth & Gruffat ‘Convertible 128’ Rotary Transfer Machine<br />

14 15<br />

Wirth & Gruffat ‘Convertible 124’ Rotary<br />

Transfer Machine<br />

Choice of 11<br />

16<br />

Ackworthie ‘Vertomat V4’ Rotary Transfer<br />

Machine<br />

Ackworthie ‘Vertomat V8’ Rotary Transfer<br />

Machine<br />

17<br />

Choice of 2<br />

Choice of 6<br />

Escomatic D6S-R Coil Fed Automatic<br />

Toolroom Machines<br />

Mecor CNC Camatic Machine<br />

EWAG ‘WS11’ Form Grinders (Choice of 3)<br />

Jones & Shipman ‘540P & 540’ Surface<br />

Grinders (Choice of 3)<br />

Jones & Shipman ‘1310’ EIU Cylindrical<br />

Grinder<br />

Jones & Shipman ‘310’ Tool & Cutter<br />

Grinder<br />

Myford ‘MG12’ Cylindrical Grinder<br />

Bridgeport ‘Series 1, 2HP’ Turret Head<br />

Milling Machine, 2 Axis DRO, Power<br />

Traverse, 42” x 9” Table and Slotting<br />

Attachment (1980)<br />

King Rich ‘KRV2000’ Turret Head Milling<br />

Machines, 2 Axis DRO, Power Traverses<br />

(Choice of 2)<br />

Induma Turret Head Milling Machine,<br />

42” x 9” Table<br />

Habegger ‘JH60’ CAM Slotting Machine<br />

Schaublin ‘135’ Precision Lathe,<br />

6.5” x 28”BC, 2 Axis DRO<br />

EMCO ‘Maximat Super 11’ Precision<br />

Lathe, 5” x 28”BC<br />

Harrison ‘M300’ 12”Dia x 42” BC SS &<br />

SC Gap Bed Lathe<br />

Colchester ‘Student’ Gap Bed Lathe,<br />

6” x 24”BC<br />

SIP ‘MP 5E’ Bridge Type Jig Boring<br />

Machine with DRO<br />

Delapena ‘Speedhone’ Horizontal<br />

Honing Machine<br />

Startrite ’18-T-10’ Vertical Bandsaw<br />

Startrite Vertical Bandsaw<br />

Agathon ‘175A’ Tool Lapping Machine<br />

Boremaster‘Tiplap’ Diamond Lapping<br />

Machine (Choice of 2)<br />

Arboga ‘ER825’ 24” Radial Drill<br />

Christen ’03-6’ Drill Point Grinder<br />

Gate-Velox 7 _” Power Hacksaw<br />

Invicta ‘4M’ Shaper<br />

Ewag Form Grinder<br />

or telephone the catalogue request line on +44 (0)117 930 4020<br />

18

Webcast available @ www.henrybutcher.com<br />

Second Operation<br />

Machines<br />

Adcock ‘1ESG’ horizontal production<br />

Milling Machine<br />

Hare ‘5BS’ 5 Ton Hydraulic Press<br />

(Choice of 2)<br />

Achol ‘Rotamill’ Rotary Milling Machine<br />

Centec ‘2A’ Horizontal Production Mill<br />

TMA ‘S-10’ Thread Rolling Machine<br />

Wickman Scrivenor ‘No O’ Centreless<br />

Grinder<br />

Estarta ‘301’ Centreless Grinder<br />

ERMA Bench Type Horizontal Milling<br />

Machines (Choice of 8)<br />

Smart & Brown ‘L4’ 2nd Operation<br />

Lathes (Choice of 2)<br />

Lorch Bench Lathes (Choice of 6)<br />

Maiden & Ris Ingold Bar End Chamfering<br />

Machines (Choice of 3)<br />

Pollard ‘130A/1, Meddings ‘MB10’ &<br />

Fobco Bench & Pillar Drills<br />

Herbert ‘Flashtap’ Tapping Machine<br />

Swarf Reclamation and<br />

Finishing Plant<br />

Petit Jean ‘Essomatic 2MD150’<br />

Automatic Swarf Separation and Oil<br />

Recycling Plant with Integral<br />

Centrifuge<br />

Alpasonic Automatic<br />

Cleaning/Degreasing Plant,<br />

Telemecanique PLC Control, F&R<br />

Cooling Unit (1989)<br />

Ris Ingold ‘M73’ Swarf Centrifuge<br />

(Choice of 2)<br />

ICI-Mond Degreasing Tank<br />

Walter Trowel ‘CN150’ Vibratory<br />

Deburrer (1991)<br />

Boulton ‘Vibromill’ Vibratory Deburrer<br />

Canning Twin Barrel Parts Deburrer<br />

Polyservice ‘P3C’ Vibratory Parts<br />

Deburrer (Choice of 4)<br />

Pickstone ‘HT6/95’ High Temperature N2<br />

Gas Injected Heavy Duty Oven<br />

Range of Oil Storage Tanks<br />

Schaublin ‘135’ Precision Lathe<br />

24<br />

19<br />

Jones & Shipman ‘540P’ Surface Grinder Jones and Shipman ‘1310’ Cylindrical Grinder<br />

Bridgeport ‘Series 1, 2HP’ Turret Milling<br />

Machine<br />

Petit Jean Swarf Reclaimation Plant<br />

King Rich ‘KRV3000’ Turret Milling Machine<br />

Register for the Catalogue Online @ www.henrybutcher.com<br />

20<br />

21 7a<br />

25

Webcast available @ www.henrybutcher.com<br />

Mitutoyo ‘PJ250’ Profile Projector<br />

CNC<br />

Demountable Bar Racks<br />

31<br />

Choice of 4<br />

Walter Trowell Vibratory Deburrer<br />

27 28<br />

39<br />

Mecor CNC Camatic Machine<br />

Ingersoll Rand ‘ML30’ Air Compressor<br />

1991<br />

Inspection<br />

Atlas Copco ‘GA75’ Air Compressor Dexion Racking<br />

Mitutoyo ‘PJ-250’ Profile Projectors<br />

(Choice of 4)<br />

Baty Shadowmaster ‘SM20XL’ Profile<br />

Projector. 20” Dia Screen. 2 Axis DRO<br />

Range of small parts inspection equipment<br />

Small Tools and General<br />

Factory Equipment<br />

Atlas Copco ‘GA75’ Packaged Air<br />

Compressor<br />

Ingersoll Rand ‘SSR-ML30’ Packaged Air<br />

Compressor<br />

Fluidair ‘Rotapak 105’ Packaged Air<br />

Compressor<br />

Range of Machine Related Tooling to<br />

include Machine Vices, Dividing Heads,<br />

Rotary Tables, Drills, Mills, Reamers etc<br />

Redirack and Dexion Boltless Pallet<br />

Racking<br />

Apex Storage System Double Sided Fir<br />

Tree Bar Racks<br />

Prat – Wilmat ‘RCL20’ Side Loading<br />

Warehouse Truck, 1900 kg Cap. (1987)<br />

Jungheinrich, Brit and Crown Pallet<br />

Trucks<br />

Vidmar Tooling Cabinets<br />

Quantity of Tipping & Swarf Skips<br />

Startrite ’18-T-10’ Vertical Bandsaw Hare ‘5BS’ Hydraulic Press<br />

or telephone the catalogue request line on +44 (0)117 930 4020<br />

26<br />

32<br />

29<br />

30<br />

33

Directions<br />

FROM M42<br />

Exit J6 and take A45 towards<br />

Coventry. Proceed for approximately<br />

8miles to the first roundabout and<br />

take the 4th Exit (returning back<br />

along A45). Proceed over bridge<br />

keeping in left lane and take slip<br />

road on left. Take next left into<br />

Torrington Avenue. Follow Torrington<br />

Avenue to first set of Traffic Lights<br />

and turn left. <strong>Tenable</strong> <strong>Screw</strong> is<br />

immediately on Right.<br />

FROM M1<br />

Exit J17 and take M45 towards<br />

Rugby / Coventry. At the end of the<br />

M45 take the A45 towards Coventry<br />

for approximately 10 miles and at<br />

the 5th roundabout (Canley Fire<br />

Station on Left) keep on A45 and<br />

proceed over bridge keeping in left<br />

lane and take slip nroad on left. Take<br />

next left into Torrington Avenue.<br />

Follow Torrington Avenue to Traffic<br />

Lights and turn left. <strong>Tenable</strong> <strong>Screw</strong> is<br />

immediately on Right.<br />

Important Notice<br />

Although information has been<br />

obtained from sources deemed<br />

reliable, Henry Butcher make no<br />

warranty or guarantee, expressed or<br />

implied, as to the accuracy of the<br />

information contained herein.<br />

34<br />

Internal Transport<br />

Small Tools and Equipment<br />

To utilise this service, register with Henry Butcher at<br />

www.henrybutcher.com<br />

where you can sign up for this auction.<br />

To learn more about how a webcast auction works, please go to<br />

the Support section on our homepage and choose “Webcast Instructions.”<br />

Conditions of Sale<br />

All goods will be sold in accordance<br />

with the auctioneers standard<br />

conditions of sale which will be<br />

detailed in the sale catalogue.<br />

Further information will be available<br />

on request.<br />

Webcast Helpline: +44 (0)20 7691 8293<br />

Catalogue Request Line: +44 (0)117 930 4020<br />

Fax: +44 (0)117 929 4267 email: sales@henrybutcher.com<br />

www.henrybutcher.com<br />

Clearance<br />

All lots must be cleared without fail<br />

by Tuesday 10th December 2002.<br />

Buyers Premium<br />

A Buyers Premium of 10% + VAT is<br />

charged to the Purchaser.<br />

Brownlow House, 50/51 High Holborn, London WC1V 6EG<br />

Tel: +44 (0)20 7405 8411 Fax: +44 (0)20 7405 9772<br />

email: sales@henrybutcher.com<br />

Local Service, Global Reach - 31 offices in 16 countries<br />

GoIndustry Worldwide • Henry Butcher International • Michael Fox International • Karner & Co • Appelboom<br />

35<br />

‘Webcast’ auction<br />

enables you to bid<br />

securely in<br />

real-time from<br />

the comfort of your<br />

own computer.