ZAXIS-5G series - CablePrice

ZAXIS-5G series - CablePrice

ZAXIS-5G series - CablePrice

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

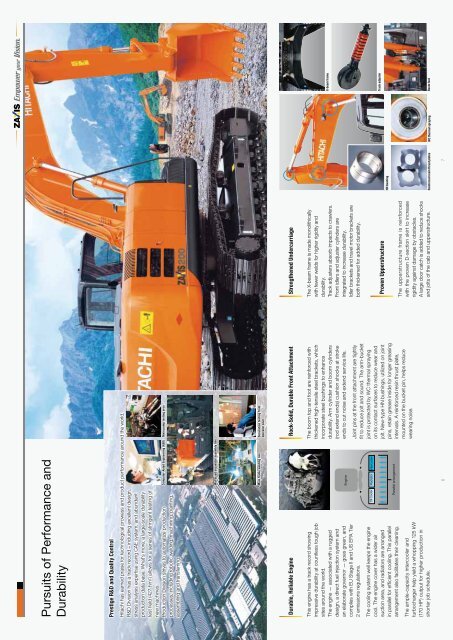

Pursuits of Performance andDurabilityPrestige R&D and Quality ControlHitachi has earned praise for technological prowess and product performance around the world.R&D Division has a track record – including excellent design,stress analysis expertise using CAE system, and abundantproduction data base. What’s more, a large-scale durabilitytest field (427 hm 2 ) allows for a <strong>series</strong> of stringent testing ofnew machines.Production Division strives to automatize productionprocesses, including robotic welding, machining, painting,assembling and transferring.Computer-Aided Engineering (AED) Main pump testing areaMid-sized excavator assembly lineMain frame welding line Simulation testing fromoperator seatDurable, Reliable EngineRock-Solid, Durable Front AttachmentStrengthened UndercarriageThis engine has a track record showingimpressive durability at countless tough jobsites around the world.The engine — associated with a ruggeddesign, a direct fuel injection system andan elaborate governor — goes green, andcomplies with EU Stage II and US EPA Tier2 emissions regulations.The cooling system well keeps the enginecool. The engine cover has a wider airsuction area, and radiators are arrangedin parallel for efficient cooling. This parallelarrangement also facilitates their cleaning.The ample-capacity intercooler andturbocharger help yield a whopping 125 kW(170 HP) output for higher production inshorter job schedule.EngineOil Cooler Radiator IntercoolerParallel arrangementThe boom top and foot are reinforced withthickened high-tensile steel brackets, whichincorporate steel bushings to enhancedurability. Arm cylinder and boom cylinders(rod extend ends) cushion shocks at strokeends to cut noise and extend service life.Joint pins at the front attachment are tightlyfit to reduce jolt and sound. The arm-bucketjoint is protected by WC thermal sprayingon its contact surfaces to reduce wear andjolt. New-type HN bushings, utilized on jointpins, retain grease inside for longer greasingintervals. A reinforced resin thrust plate,mounted on the bucket pin, helps reducewearing noise.The X-beam frame is made monolithicallywith fewer welds for higher rigidity anddurability.Track adjusters absorb impacts to crawlers.Front idlers and adjuster cylinders areintegrated to increase durability.Idler brackets and travel motor brackets areboth thickened for added durability.Proven UpperstructureThe upperstructure frame is reinforcedwith the proven D-section skirt to increaserigidity against damage by obstacles.A large door catch is added to reduce shocksand jolts of the cab and upperstructure.HN bushingReinforced resin thrust plates6 7WC thermal sprayingX-beam frameTrack adjusterBoom foot