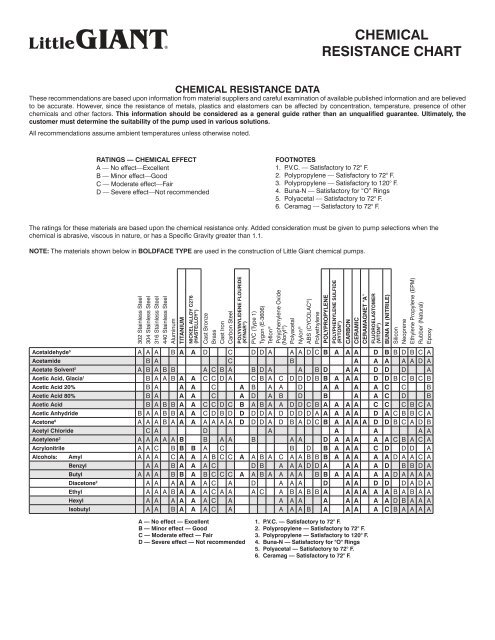

CHEMICAL RESISTANCE CHART - PEX Universe

CHEMICAL RESISTANCE CHART - PEX Universe

CHEMICAL RESISTANCE CHART - PEX Universe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylonCycolac (ABS)PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxyMethanol (See Alcohol Methyl)Methyl Acetate A A A A A B A A D A A D D D B B DMethyl Acrylate A A A D D B B D AMethyl Acetone A A A A A A A D A A D D D CMethyl Alcohol 10% A A C A C B A A A B A AMethyl Bromide A D A A A B D D D BMethyl Butyl Ketone A A D B A A D D C D A D BMethyl Cellosolve A A C B A A A D D D B D CMethyl Chloride A A D A A A A D A D A A D D A A A D D D C D AMethyl Dichloride D A A A A D D D D AMethyl Ethyl Ketone A A A A A A D D A D B A D D A A A A D D C D A D BMethyl Isobutyl Ketone 2 A A A D D A D B A D C A A A D D C D C D BMethyl Isopropyl Ketone A D B A A A D D B D B D BMethyl Methacrylate A A A D D D D D AMethylamine A A A D B B B D A A B AMethylene Chloride A A A A A A A C B D D A D A D D D A A D D D D D AMilk A A A A A C C D D A A A A B B A A A A A A B A A A AMolasses A A A A A A B A A A B A A B A A A A A A A AMustard A A A A B B C B A B B A B A A A A B C C ANaphtha A A A A A A A B B B A A C A D A A C D A A A A A B D D D D ANaphthalene B A B B A A C B A A D A D A D B A A A B D D D D ANickel Chloride A B D A A D D A A B A A B A B A A A A A A A A ANickel Sulfate B A B D A B C C D D A A A A A B A B A A A A A A A C ANitric Acid (10% Solution) A A A A D A A D D D A A B A A D D C B A D C B D A D D B D ANitric Acid (20% Solution) A A A D A A D D B A B A A D D D B A C D C D A D D D D BNitric Acid (50% Solution) A A A D A A D D B A B A A D D D C D C D A A D D D D DNitric Acid (Concentrated Solution) D B A B A B D D D D C A D D D D D D C D A C B D D D D DNitrobenzene 2 B A B C A B D B B D D D A D B C D D C B A A D D D D D D BOils: Aniline A A C A D A A D A D D C D A A A A D D B D AAnise A A A A A D ABay A A A A A A D ABone A A A A A A A A D ACastor A A A A A A A A A A A A A B A ACinnamon A A A A A A A D D ACitric A A D D A A A A A A A D AClove A A A A B A A A ACoconut A A B A A A A A A A A A A A D ACod Liver A A B A A C A A A A A B A D ACorn A A A B B A A A C A A A A A D C D ACotton Seed B A A A B B A C A A A A C A A A A A A D C D ACreosote 2 A A A D D A A A A B D D ADiesel Fuel (2D, 3D, 4D, 5D) A A A A D A A A A A A A A D D D AFuel (1, 2, 3, 5A, 5B, 6) A A A A A A A A D A B A A A B D D D AGinger A A A A A A A A AA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for "O" Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.7

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylon ®ABS (Cycolac ® )PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxyOils: Hydraulic (See Hydraulic)Lemon A A A D A A A D ALinseed A A A A A A A B A A C A A A A A A D D D AMineral A A A A A A A B A B A A B A A A A A A B D D AOlive A A A A B A B A A A A A A A A A C B D AOrange A A A A A A A A A A D APalm A A A B A A A A A A A D APeanut 3 A A A A A A A D A A A A D D APeppermint 2 A A A A D A A A D D APine A A A A D C B A A A A A A A D D ARape Seed A A A A A A A A B D D ARosin A A A A A A A A A A ASesame Seed A A A A A A A A A A A D ASilicone A A A A A A A A A A A A A A A ASoybean A A A B A A A A A A A A A D D ASperm A A A A A A A A A D ATanning A A A A A A A D ATurbine A A A A A A A C A A A A D D AOleic Acid B A A B B B B C C C A C A C B A B D C A A D B D D D D AOleum 25% A B D A D A A D D D D DOleum B A B C C B D D A D D A A C D D D D AOxalic Acid (cold) C A B A C C B B C D D A B A C C D A A A A A B C B A C AParaffin A A A A A A B B A A A B A A B A A A A A APentane A C C A B A B B A D A A D A A A A B D D APerchloroethylene 2 B A A A C B B A A D A D D A A A A C D D D D APetrolatum A A B B C C A D A A B A A A A B A D APhenol 10% B A A A B C B D A C A D A B D C D C CPhenol (Carbolic Acid) B A A A B C A B D D D A A C A C D D D B A A D A A D D D D BPhosphoric Acid (40% Solution) B A A D A A D D D A B A A D D C B A A B C D A D D B C APhosphoric Acid (40% - 100% Solution) C B B D B A D D D A B A A D D D C A A B D D A D D B C CPhosphoric Acid (Crude) D C C D C A D D D D A A D D D C A C D A D D B APhosphoric Anhydride (Dry or Moist) A A D D D A A D D D APhosphoric Anhydride (Molten) A A D D D D A A D D C D D APhotographic (Developer) C A C C A A D A A C B A A A A A A APhthalic Anhydride B A B B A B C C A A A CPicric Acid B A A C A D D D D A A A A A A A D A A APlating SolutionsAntimony Plating 130° F A A A A A A D A A A A D A BArsenic Plating 110° F A A A A A A A A C A A D A BBrass PlatingRegular Brass Bath 100° F A A A A A A A A C A A D A BHigh Speed Brass Bath 110° F A A A A A A A A D A A D A BBronze PlatingCopper Cadmium Bronze Bath R.T. A A A A A A A A C A A D A BCopper-Tin Bronze Bath 160° F A A A D A A A A D A A D B CCopper-Zinc Bronze Bath 100° F A A A A A A A A C A A A BCadmium PlatingCyanide Bath 90° F A A A A A A A A C A A A BA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for "O" Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.8

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylon ®ABS (Cycolac)PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxyCadmium PlatingFluoborate Bath 100° F A D A A A A D A D A B C BChromium PlatingChromic-Sulfuric Bath 130° F C A A A A D D A A C D D DFluosilicate Bath 95° F C C A A A D D A B C D D D DFluoride Bath 130° F D C A A A D D A B C D D DBlack Chrome Bath 115° F C A A A A D D A A C D D DBarrel Chrome Bath 95° F D C A A A D D A A C D D DCopper Plating (Cyanide)Copper Strike Bath 120° F A A A A A C B ARochelle Salt Bath 150° F A A A D A A A A D A A B CHigh Speed Bath 180° F A A A D A A A A D A A B CCopper Plating (Acid)Copper Sulfate Bath R.T. D A A A A A D A D A A A DCopper Fluoborate Bath 120° F D D A A A A D A D A B C DCopper (Misc.)Copper Pyrophosphate 140° F A A A A A A A A B A A A BCopper (Electroless) 140° F D A A A A A D A D D BGold PlatingCyanide 150° F A A A C D A A A A B A A A DNeutral 75° F C A A A A A A A A A A A AAcid 75° F C A A A A A A A A A A A AIndium Sulfamate Plating R.T. C A A A A A D A A A A A AIron PlatingFerrous Chloride Bath 190° F D A D D A A D C A A B D DFerrous Sulfate Bath 150° F C A A D A A D A A A A B DFerrous Am. Sulfate Bath 150° F C A A D A A D A A A A B DSulfate-Chloride Bath 160° F D A D D A A D A A A B C DFluoborate Bath 145° F D D B D A A D A D A B C DSulfamate 140° F D A B A A A D A A A A A ALead Fluoborate Plating C D A A A A D A D A B C ANickel PlatingWatts Type 115 - 160° F C A A D A A A A A A A A DHigh Chloride 130 - 160° F C A A D A A D A A A A B DFluoborate 100 - 170° F C D A D D A A D A D A B C DSulfamate 140° F C A A A A A A A A A A A AElectroless 200° F D A D D D A A D D BRhodium Plating 120° F D D D A A A D D A A A A B ASilver Plating 80 - 120° F A A A A A A A A B A A A ATin-Fluoborate Plating 100° F C D A A A A D A D A B C ATine-Lead Plating 100° F C D A A A A D A D A B C AZinc PlatingAcid Chloride 140° F D A D A A A D A A A A A AAcid Sulfate Bath 150° F C A A D A A D A A A A B DAcid Fluoborate Bath R.T. C D A A A D A D A B C AAlkaline Cyanide Bath R.T. A A A A A A A A D A A A APotash A A C A C B A B A B A B A A A A A A B B APotassium Bicarbonate A B C A B B D A A A A C A C B A A A A A A A B APotassium Bromide A A B C A B C D D A A A A A C B A C A A A A A A B AA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for “O” Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.9

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylon ®Cycolac (ABS ® )PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxyPotassium Carbonate B A A C A A C B B A A B A A B A B A A A A A A B A B APotassium Chlorate B A A A B A B B B B A A B A A B D B A A A A A A A B APotassium Chloride C A A B B A A C C B B A A A A A A B C B A A A A A A A A A APotassium Chromate B B A B A A A A C B A A D A A A B CPotassium Cyanide Solutions B A B A D A A D B B A A A A C A B A A C A B A A A A APotassium Dichromate B A A A A A B C B C A A A A C D B A A A A B A A A A APotassium Ferrocyanide B A A C B A C A A A A D A APotassium Hydroxide (50%) A B B B D C A D D C A D A B A A D A C B A A D A D B C A A C APotassium Nitrate B A B A B A B B B A A C A A B C B A C A A B A A A A APotassium Permanganate B A B B B B B B B B A A A A C D C B B A A A B A A B BPotassium Sulfate B A B B A A A B B B B A A A A A B C B A A A A A A C A A C APotassium Sulfide A A A B B B B B A A APropane (Liquified) 1 2 A A A A A A B D A D A A D A A A A D B D D APropylene Glycol B B A A B B B A B B B B A A A A C APyridine C B B B A D D A D D C B A A A D D D B D APyrogallic Acid B A A A B A B B B A A D A A A A A ARosins A A A A A B A C C A B A A A A A ARum A A A A A A A A A A A A ARust Inhibitors A A A A A A A A A A C ASalad Dressing A A B B D A A A A A A A A A ASea Water A A C A C A C D A A A A A B A A A A A A B B A A AShellac (Bleached) A A A A A B B A A A A A A A AShellac (Orange) A A A A A C C A A A A A A A ASilicone B A B A A A A A A A A A B A A A ASilver Bromide C C B D A C A ASilver Nitrate B A B A D A A D D D A A B A A C A B A A A A C A C A ASoap Solutions 1 A A A A C A B B B A B B A A A A B A A A A A A A B B C ASoda Ash (See Sodium Carbonate)Sodium Acetate B A A B B A B C C A A A A B A B A A A D D C A ASodium Aluminate B A C B B B C A A B A A A A A A A A B ASodium Bicarbonate B A A A A A B A C C A A B A A B A B B A A A A A A A C A A A ASodium Bisulfate A A A D B B C C D D A A B A A B C C B A A A A B A C A A ASodium Bisulfite A A A A B C D A A B A A B D B B A A A A A A C A A ASodium Borate B A A C A A C C C A A A A B ASodium Carbonate B A B B C A A B B B B A A B A A A A C B A A B A A A A A A ASodium Chlorate B A A B A B B C A A B A A D A B A A A A A D A A ASodium Chloride B A C B C A A B C B C A A B A A A A B B A A A A A A A C A A B ASodium Chromate A A A D B B B B A A D A A A A B B A A CSodium Cyanide B A A D A D D B B A A A A D C B A A A A A A D A A A ASodium Fluoride B C C C A A C D D D D A A C B D D D ASodium Hydrosulfite A A C C A A A A A A ASodium Hydroxide/Caustic Soda (20%) A A A D A A C D A A A B A A D C C B A A C D A A A D B A A ASodium Hydroxide/Caustic Soda (50%) A B D A A C D B D A B A A D C C C A B C D A D D D C A ASodium Hydroxide/Caustic Soda (80%) A D D A B C D C A B A A D C C C A B C D A B D D C B AA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for "O" Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.10

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylon ®ABS (Cycolac)PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxySodium Hypochlorite/Bleach 3 (to 20%) C C C C A A D D D A B A A D A B C C D A B A C D D B C BSodium Hypochlorite/Bleach D D D A A D D D A A A A A C C D B B C A ASodium Hyposulfate A A D D A C C CSodium Metaphosphate 2 A A A C C B B A B A D A A A A B A A ASodium Metasilicate A A B B C C A D A A A D A ASodium Nitrate B A A A A A B B C A B A A B A A B A B A A A A D C D B A C ASodium Perborate B C B C C B B A A B A A A A A B D B A C ASodium Peroxide B A A C B C C D C A A D D A A A C D B A C ASodium Polyphosphate (Mono, Di, Tribasic) A A D A A C A A B A A A A D A A ASodium Silicate B A B A C A B C C B A B A A C A A A A A A A A A ASodium Sulfate B A A C B A B B B A B A A A B A B A A A A A A A A C ASodium Sulfide B A B D A B D D A B A B A A B A B A A A A A C A A C ASodium Sulfite C C C A A C A A A A D A A A A A A A ASodium Tetraborate A A A B A A A A ASodium Thiosulphate (”Hypo”) A A A B A D D C B A A A C A A A A A A B A A C ASorghum A A A A A A A A A A ASoy Sauce A A A A D A A A A A A A A D AStannic Chloride D D D D A B D D D A A A A C A B A A A A D A A A AStannic Fluoborate A D A C A A A A AStannous Chloride D D C D A A D D D A A A D A B C D D A AStarch B A A A B C C A A A A A B A A A A A AStearic Acid 2 B A A A B A A C C C C A A B A A A A B D A A A A B D B B C AStoddard Solvent A A A A A A A A A B B A A D A D A A B D D A A A A B D D D D AStyrene A A A A A A A A A A A B D D D D D ASugar (Liquids) A A A A A A A B B A A A A B A A A A A A B A ASulfate Liquors C C B A C D A A A C ASulfur Chloride D D D D C D A C A A D A A D A C A D D D D CSulfur Dioxide 2 A A C A A B B B D B A D B D D C D A A A D D C B A D ASulfur Dioxide (dry) A A A A A A C A B D A A D A A D D D DSulfur Trioxide (dry) A A C A B B B A B A D D D B A A D D B C ASulfuric Acid (to 10%) D C C C A A D D D A A B A A D D B B A A A A A C D D C ASulfuric Acid (10% - 75%) 2 D D D D C B D D D A A B A B D D B C A B A A C A D D D D BSulfuric Acid (75% - 100%) D D B D A B A A D B C A A D D DSulfurous Acid C C B C C A B D D D A B A A D D B A B A A C D B B C ASulfuryl Chloride A A A ASyrup A A A A D A A A A B A A A A A A B A ATallow A A A A A A C A A A A ATannic Acid B A A A C A B B C C A A B A A B D B A A A A A D C A A A ATanning Liquors A A C A A A A B A B A A A A C ATartaric Acid B A B B C A B A C D D A A B A A B A B A A A A D C A A ATetrachlorethane A A A D A D A A A A A A D D D ATetrahydrofuran A A D D D A D D A D A A D C A A A D D D B D AToluene, Toluol 3 A A A A A A A A A A A D D A D A A D D D A A A A C D D D D D ATomato Juice A A A A C C C A A B A B A A A A A A A AA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for “O” Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.11

302 Stainless Steel304 Stainless Steel316 Stainless Steel440 Stainless SteelAluminumTITANIUMNICKEL ALLOY C276(HASTELLOY ® )Cast BronzeBrassCast IronCarbon SteelPOLYVINYLIDENE FLOURIDE(KYNAR ® )PVC (Type 1)Tygon (E-3606)Teflon ®Polyphenylene Oxide(Noryl ® )PolyacetalNylon ®ABS (Cycolac ® )PolyethylenePOLYPROPYLENEPOLYPHENYLENE SULFIDE(RYTON ® )CARBONCERAMICCERAMAGNET "A"FLUOROELASTOMER(VITON ® )BUNA N (NITRILE)SiliconNeopreneEthylene Propylene (EPM)Rubber (Natural)EpoxyTrichlorethane C A C A A C C A D A A A A D D D D D ATrichlorethylene 2 B A A B A A B A C B A D A D A C D D D C A A C A D D D D D ATrichloropropane A A D A D A A A A A ATricresylphosphate A B A A D A C C A A B D D A ATriethylamine A A B D A A A A D B ATurpentine 3 B A A C A B C B B A A B A D A A D B A A A A D D D D AUrine A A B C B A A A A B A A A A A D A AVegetable Juice A A A C D A A A A A A A B D D AVinegar A A A A D A A B B C D A A A A B A B B A A A A A A C B A C AVarnish (Use Viton for Aromatic) A A A A A A B C A D A A A A A A A B C D D AWater, Acid, Mine A A C C D C A B A D A B A B A A A A B B AWater, Distilled, Lab Grade 7 A A B A D A B A A A A A A A A A A A A B A A AWater, Fresh A A A A A C B D A B A A A A A A A A A A A A A B A A AWater, Salt A A B B C D A B A A A A A A A A A A B A A AWeed Killers A A C C A A A A A B C AWhey A A B A A A A A AWhiskey and Wines A A A A D B B D D A A A A A B A A A A A B A A A AWhite Liquor (Pulp Mill) A A A D C A A A D A A A A A A A AWhite Water (Paper Mill) A A A B A A A A A A AXylene 2 A A A A A A A A B A D A D A A D D D A A A A A D D D D D AZinc Chloride D D B B D A B D D D D A A A A C A B A A A A A A A A A AZinc Hydrosulphite A D D D A C A A A A A A AZinc Sulfate B A A A D A B B C C D A C B A A C A B A A A A A A A A C AA — No effect — Excellent 1. P.V.C. — Satisfactory to 72° F.B — Minor effect — Good 2. Polypropylene — Satisfactory to 72° F.C — Moderate effect — Fair 3. Polypropylene — Satisfactory to 120° F.D — Severe effect — Not recommended 4. Buna-N — Satisfactory for "O" Rings5. Polyacetal — Satisfactory to 72° F.6. Ceramag — Satisfactory to 72° F.NOTES12

NOTES17

18NOTES

NOTES19

Viton® is a registered trademark of Dupont Performance ElastomersTeflon® is a registered trademark of Dupont Performance ElastomersKynar® is a registered trademark of Arkema, Inc.Ryton® is a registered trademark of Chevron Phillips Chemical CompanyNoryl® is a registered trademark of General Electric CompanyForm 995516 - 07/09©2009 Franklin Electric Co., Inc.Little Giant® is a registered trademark of Franklin Electric Co., Inc.