You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

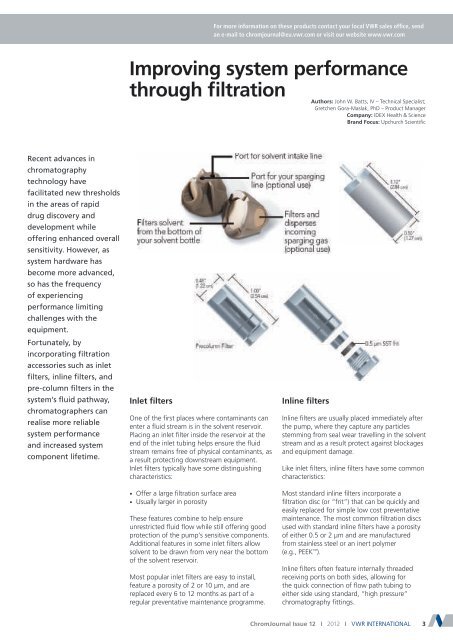

For more information on these products contact your local VWR sales office, sendan e-mail to chromjournal@eu.vwr.com or visit our website www.vwr.comImproving system performancethrough filtrationAuthors: John W. Batts, IV – technical Specialist;Gretchen Gora-Maslak, PhD – Product Managercompany: IDeX Health & ScienceBrand focus: Upchurch ScientificRecent advances inchromatographytechnology havefacilitated new thresholdsin the areas of rapiddrug discovery anddevelopment whileoffering enhanced overallsensitivity. However, assystem hardware hasbecome more advanced,so has the frequencyof experiencingperformance limitingchallenges with theequipment.Fortunately, byincorporating filtrationaccessories such as inletfilters, inline filters, andpre-column filters in thesystem’s fluid pathway,chromatographers canrealise more reliablesystem performanceand increased systemcomponent lifetime.Inlet filtersOne of the first places where contaminants canenter a fluid stream is in the solvent reservoir.Placing an inlet filter inside the reservoir at theend of the inlet tubing helps ensure the fluidstream remains free of physical contaminants, asa result protecting downstream equipment.Inlet filters typically have some distinguishingcharacteristics:• offer a large filtration surface area• Usually larger in porositythese features combine to help ensureunrestricted fluid flow while still offering goodprotection of the pump’s sensitive components.Additional features in some inlet filters allowsolvent to be drawn from very near the bottomof the solvent reservoir.Most popular inlet filters are easy to install,feature a porosity of 2 or 10 µm, and arereplaced every 6 to 12 months as part of aregular preventative maintenance programme.Inline filtersInline filters are usually placed immediately afterthe pump, where they capture any particlesstemming from seal wear travelling in the solventstream and as a result protect against blockagesand equipment damage.Like inlet filters, inline filters have some commoncharacteristics:Most standard inline filters incorporate afiltration disc (or “frit”) that can be quickly andeasily replaced for simple low cost preventativemaintenance. The most common filtration discsused with standard inline filters have a porosityof either 0.5 or 2 µm and are manufacturedfrom stainless steel or an inert polymer(e.g., PeeK ).Inline filters often feature internally threadedreceiving ports on both sides, allowing forthe quick connection of flow path tubing toeither side using standard, “high pressure”chromatography fittings.chromJournal Issue 12 I 2012 I VWR InteRnatIonal 3