Topic : Common Structural Forms for High-rise Buildings in Hong Kong

Topic : Common Structural Forms for High-rise Buildings in Hong Kong

Topic : Common Structural Forms for High-rise Buildings in Hong Kong

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

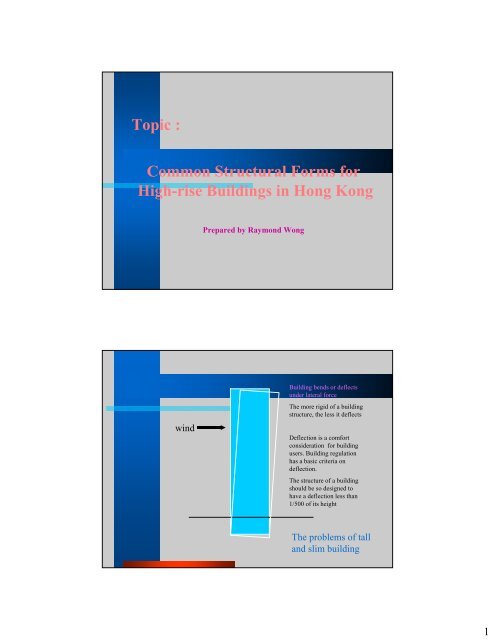

<strong>Topic</strong> :<strong>Common</strong> <strong>Structural</strong> <strong>Forms</strong> <strong>for</strong><strong>High</strong>-<strong>rise</strong> <strong>Build<strong>in</strong>gs</strong> <strong>in</strong> <strong>Hong</strong> <strong>Kong</strong>Prepared by Raymond Wongw<strong>in</strong>dBuild<strong>in</strong>g bends or deflectsunder lateral <strong>for</strong>ceThe more rigid of a build<strong>in</strong>gstructure, the less it deflectsDeflection is a com<strong>for</strong>tconsideration <strong>for</strong> build<strong>in</strong>gusers. Build<strong>in</strong>g regulationhas a basic criteria ondeflection.The structure of a build<strong>in</strong>gshould be so designed tohave a deflection less than1/500 of its heightThe problems of talland slim build<strong>in</strong>g1

Various deflection modes under w<strong>in</strong>d tunnel test<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK1. Column and beam (framed) structure <strong>in</strong> RCsometimes called framed build<strong>in</strong>gs which are structures<strong>for</strong>med by the framed elements usually <strong>in</strong> the <strong>for</strong>m ofcolumns and beams, as well as further strengthened asnecessary by the <strong>in</strong>troduction of rigid floor membranes andexternal walls.- Simple <strong>for</strong>mwork is required- lower cost of construction- easy to satisfy various spatial arrangement and shapes- may not be very able to cater <strong>for</strong> the structural needs oftall and slim build<strong>in</strong>gs- more suitable to construction low-<strong>rise</strong> or horizontalspreadbuild<strong>in</strong>gs such as schools, podium or carparkstructures2

Example oflayout designevolution from a5 x 3 grid systemExample of In-situ RC frame build<strong>in</strong>g3

<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK2. Load bear<strong>in</strong>g wall (shear wall) structure <strong>in</strong> RC- More complicated <strong>for</strong>mwork is required- cost of construction may <strong>in</strong>crease especially <strong>for</strong>build<strong>in</strong>g with more <strong>in</strong>ternal walls or <strong>in</strong> complicatedshape- the load bear<strong>in</strong>g walls can strengthen the rigidity of thebuild<strong>in</strong>g and able to resist build<strong>in</strong>g aga<strong>in</strong>st deflection- build<strong>in</strong>g examples: public build<strong>in</strong>gs such as theHarmony BlocksExample of load-bear<strong>in</strong>gwall structures4

<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK3. Load bear<strong>in</strong>g wall plus core wall structure- Complicated <strong>for</strong>mwork is often required especially <strong>in</strong><strong>for</strong>m<strong>in</strong>g the core- cost of construction is higher, especially <strong>for</strong> build<strong>in</strong>gswith complicated shape (e.g. lots of set-back or lightwells- has very strong rigidity to resist deflection- this is the most common structural <strong>for</strong>m <strong>for</strong> use <strong>in</strong> HK’sresidential build<strong>in</strong>gs due to:. walls between residential flats can be best used as aload bear<strong>in</strong>g wall (fire resistance is one reason). To fulfill build<strong>in</strong>g regulation <strong>for</strong> prescribed w<strong>in</strong>dowareas. To satisfy the rigidity of high-<strong>rise</strong> build<strong>in</strong>gsExample of load-bear<strong>in</strong>gwall structures with build<strong>in</strong>garea below 500 sq m5

Example of load-bear<strong>in</strong>g wall structures ofbuild<strong>in</strong>g area around 800 – 1000 sq mExample of load-bear<strong>in</strong>gwall structures withseveral blocks l<strong>in</strong>kedtogether to <strong>for</strong>m aconnected structure6

Structures <strong>in</strong>load-bear<strong>in</strong>g wallwith a RC core<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK4. RC Centre core plus a RC frame structure- Conf<strong>in</strong>e to more regularly shaped or build<strong>in</strong>gwith simpler layout, such as usual tower typebuild<strong>in</strong>gs- fair rigidity per<strong>for</strong>mance but may not besufficient <strong>for</strong> build<strong>in</strong>g higher than, say 50 storeys.- rigidity can be improved by the add<strong>in</strong>g <strong>in</strong> ofother stiffen<strong>in</strong>g members- plenty of w<strong>in</strong>dow areas (it is only a frame <strong>in</strong> theexternal face the build<strong>in</strong>g)- The <strong>in</strong>ternal core may have difficulty <strong>in</strong> gett<strong>in</strong>gnatural ventilation or sunlight.7

Example ofcored structurewith an externalframe <strong>for</strong> towertypeofficebuild<strong>in</strong>gVarious layout arrangement<strong>for</strong> build<strong>in</strong>g us<strong>in</strong>g core andouter frame structure8

Various layout arrangement<strong>for</strong> build<strong>in</strong>g us<strong>in</strong>g core andouter frame structureExample of cored structurewith an external frame –Central Plaza <strong>in</strong> Wanchai9

Example of cored structurewith an external frame –Langham Place <strong>in</strong> Mong KokIt is sometimes quitedifficult and costly toconstruct the RC core10

<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK5. Center core plus a outer core structure (tube <strong>in</strong> tube)- Formwork usually very complicated with the flooradded <strong>in</strong> at a second stage- build<strong>in</strong>g shape conf<strong>in</strong>ed to tubular <strong>for</strong>ms- area of w<strong>in</strong>dows limited due to the provision of astructurally strong external tube (wall)- quite strong <strong>in</strong> rigidity and be able to construct tovery tall structure- build<strong>in</strong>g examples – Hopewell Center (HK) or theprevious World Trade Center <strong>in</strong> New YorkExamples of tube-<strong>in</strong>-tube structures – Jard<strong>in</strong> House <strong>in</strong> Central11

Hopewell Centre <strong>in</strong> WanchaiExamples of a fram<strong>in</strong>g plan show<strong>in</strong>g the location/layout ofwalls, columns and beams12

<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK6. Steel frame structure- build<strong>in</strong>g is lighter than usual RC structure due to therelative higher weight/strength ration of steel- construction cost is lower especially <strong>for</strong> build<strong>in</strong>gsadopt<strong>in</strong>g high level of standardization- build<strong>in</strong>g is weak <strong>in</strong> rigidity due to steel is a moreflexible (elastic) material when compare to RC- additional stiffen<strong>in</strong>g elements <strong>in</strong> the <strong>for</strong>m of<strong>in</strong>ternal/external trusses, out-rigger or brac<strong>in</strong>g membersare often required to make the build<strong>in</strong>g structure morerigid- addition work is required to fire-protect the steelstructure- build<strong>in</strong>g examples: The Center, Ch<strong>in</strong>a Bank Build<strong>in</strong>gExamples of build<strong>in</strong>g constructed <strong>in</strong> pure structural steel frame13

Construction of <strong>Structural</strong> steel frame build<strong>in</strong>g<strong>Structural</strong> <strong>for</strong>ms suitable <strong>for</strong> build<strong>in</strong>gs <strong>in</strong> HK7. Composite structure (RC Core plus steel frame, hybridstructure)- build<strong>in</strong>g can be lighter than usual RC structure butwith a more acceptable rigidity than pure steelbuild<strong>in</strong>gs- construction cost is higher <strong>for</strong> the add<strong>in</strong>g <strong>in</strong> of a RCcore which requires a complicated <strong>for</strong>mwork system- it is time consum<strong>in</strong>g and more complicated to makeconnections between the RC and steel elements- It is even more difficult and costly if stiffen<strong>in</strong>gmembers are <strong>in</strong>troduced <strong>in</strong>to the build<strong>in</strong>g <strong>in</strong> order tomake it more rigid to resist deflection- Build<strong>in</strong>g examples: Time square, Manual Life Tower,Cheung <strong>Kong</strong> Center, IFC 1 and 214

Examples of composite structures15

More examples of composite structuresMore examples of composite structures16

The IFC 2Complicated stiffen<strong>in</strong>gelements <strong>in</strong>corporated <strong>in</strong>steel or compositebuild<strong>in</strong>g to improve therigidity of the structureCheung <strong>Kong</strong>CenterOutrigger system used<strong>in</strong> Cheung <strong>Kong</strong> Center17

The Cheung <strong>Kong</strong> CenterComplicated stiffen<strong>in</strong>g elements<strong>in</strong>corporated <strong>in</strong> steel or compositebuild<strong>in</strong>g to improve the rigidityof the structure18

Complicated stiffen<strong>in</strong>gelements <strong>in</strong>corporated<strong>in</strong> steel or compositebuild<strong>in</strong>g to improve therigidity of the structureCost idea of us<strong>in</strong>g RC, Steel and compositemethod <strong>in</strong> construct<strong>in</strong>g tall build<strong>in</strong>gs19

How to construct various <strong>for</strong>ms of <strong>Build<strong>in</strong>gs</strong><strong>Build<strong>in</strong>gs</strong> can be constructed or <strong>for</strong>med <strong>in</strong> a numberof ways, such as:1. In-situ manner us<strong>in</strong>g <strong>for</strong>mwork – <strong>for</strong> allre<strong>in</strong><strong>for</strong>ced concrete build<strong>in</strong>gs2. Prefabricated manner – <strong>for</strong> us<strong>in</strong>g part or all <strong>in</strong>precast concrete elements3. Prefabricated manner – us<strong>in</strong>g structural steelelements4. Hybrid manner – mak<strong>in</strong>g comb<strong>in</strong>ation of any ofthe above systemsConstruction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the wall structureus<strong>in</strong>g alum<strong>in</strong>um mouldsForm<strong>in</strong>g the wall structure us<strong>in</strong>gmanual-type timber <strong>for</strong>mwork20

Construction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the structure us<strong>in</strong>g largepanel-type <strong>for</strong>ms <strong>for</strong> walls or columnsConstruction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the wall structure us<strong>in</strong>gmechanical-operated <strong>for</strong>mwork systems21

Construction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the floor structure us<strong>in</strong>gtimber <strong>for</strong>mwork systemsConstruction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the floor structureus<strong>in</strong>g table <strong>for</strong>mwork – mostsuitable <strong>for</strong> office build<strong>in</strong>gs22

Construction of <strong>in</strong>-situ RC build<strong>in</strong>gsForm<strong>in</strong>g the floor structure us<strong>in</strong>gtable <strong>for</strong>mwork – floor be<strong>in</strong>gstrengthened by tension<strong>in</strong>g techniqueConstruction of prefabricated frame build<strong>in</strong>gHeadquarters build<strong>in</strong>g of<strong>Hong</strong> <strong>Kong</strong> Jockey ClubPodium – KCRKowloon Station23

Construction of prefabricated frame build<strong>in</strong>gUs<strong>in</strong>g precast elements as part of theexternal walls as well as the permanent<strong>for</strong>mwork <strong>for</strong> load-bear<strong>in</strong>g wallsAn external view of build<strong>in</strong>g –majority of external walls areconstructed <strong>in</strong> precast mannerAdvantageous features of framed structure1. Speedy construction due to simplicity <strong>in</strong> geometry –consist of only columns and beams (or partially by thefloor slab) as the ma<strong>in</strong> structural elements2. Very rigid and stable – able to resist tremendous vertical(dead load) and lateral loads (w<strong>in</strong>d)3. Reduced dead load – absent of thick shear wall etc.4. Roofed over at an earlier stage – every floor slab be<strong>in</strong>gf<strong>in</strong>ished becomes an cover to protect the lower floors fromsun and ra<strong>in</strong>5. Offer large unobstructed floor areas – without obstaclebetween columns6. Flexible utilization of space24

Advan. . features of framed structure (cont<strong>in</strong>ued)7. Adaptable to almost any shape8. Easily altered with<strong>in</strong> limits of frame– regular or non-regular grid system is very adaptable <strong>in</strong>spatial arrangement9. Offsite preparation possible – especially <strong>for</strong> prefabricatedconstruction us<strong>in</strong>g precast concrete or structural steelelements10. May be designed to accommodate movement11. Acceptable distribution of natural light – w<strong>in</strong>dow open<strong>in</strong>gscan be provided easily on eternal walls12. Easy to design structurally <strong>in</strong>clud<strong>in</strong>g computer design – aga<strong>in</strong>,due to simple geometryPr<strong>in</strong>ciple factors affect<strong>in</strong>g choice of frameProduction consideration• Availability of materials, labour and plant• Speed of construction• Availability of mechanical plantsArchitectural Design consideration• Size and shape of site• Conditions of site• Integration of mechanical elements• Architectural or aesthetic requirements25

Pr<strong>in</strong>ciple factors affect<strong>in</strong>g choice of frame<strong>Structural</strong> Design consideration• Foundation consideration• Standardization of members or design• Span and floor loads• Fire resistance requirement• Ma<strong>in</strong>tenance consideration• Integration of architectural & structural elementsFeatures of In-situ concrete frame constructionConstruction aspects1. Insitu concrete is <strong>in</strong>consistent <strong>in</strong> quality <strong>in</strong> per<strong>for</strong>mance –mix<strong>in</strong>g, delivery, plac<strong>in</strong>g and compact<strong>in</strong>g of concreterequire very tight quality control2. Overlapp<strong>in</strong>g <strong>for</strong>mwork, steel fix<strong>in</strong>g and concret<strong>in</strong>gprocess make site operations more difficult – these worksare to be done almost at the same time at the samelocation3. Formwork erection is often timely, expensive,environmental unfriendly and labour <strong>in</strong>tensive4. Increase a lot of wet-work – difficult to ma<strong>in</strong>ta<strong>in</strong> site <strong>in</strong> aclean and tidy environment26

Features of In-situ concrete frame constructionConstruction aspects – examples of problemImproper plac<strong>in</strong>g and compaction willserious lower the strength of concreteFeatures of In-situ concrete frame constructionConstruction aspects – examples of problemF<strong>in</strong>ish<strong>in</strong>g the concrete surface afterplac<strong>in</strong>g – improper f<strong>in</strong>ish will affectthe size and dimension of member27

Features of In-situ concrete frame constructionConstruction aspects – examples of problemExterior environmentInterior environmentIt is difficult to ma<strong>in</strong>ta<strong>in</strong> a clean and tidy site us<strong>in</strong>g <strong>in</strong>-situconcrete structure <strong>for</strong> the cast<strong>in</strong>g process is wet and dirtyFeatures of In-situ RC frame constructionConstruction aspects (cont<strong>in</strong>ue)5. Easier to allow <strong>for</strong> dimensional discrepancy – <strong>for</strong>mworkcan relatively easy to provide any ready dimension andshape6. Concrete is cheap, easy available and can be cast <strong>in</strong>tocomplicated shape7. Frame erection affected seriously by climatic condition – <strong>in</strong>w<strong>in</strong>dy day it is difficult to erect <strong>for</strong>mwork nor to placeconcrete8. Durability affect by heat, moisture or environmentalfactors – concrete is not so durable as most person th<strong>in</strong>k28

Features of <strong>in</strong>-situ RC frame construction (cont.)<strong>Structural</strong> characteristics and design aspects1. Concrete design more flexible and accurate than steelbecause of non dependence on standard sections2. Concrete frame easily damaged by build<strong>in</strong>g movements3. Problems of creep & shr<strong>in</strong>kage (cause damage to f<strong>in</strong>ishes)4. <strong>High</strong>er dead load and bigger structural elements5. Better fire resistance6. Durability sensitive to workmanship7. Overload<strong>in</strong>g cause irreversible structural damages8. Flexible <strong>in</strong> layout and shapeTypical case us<strong>in</strong>g traditionaltimber <strong>for</strong>mwork <strong>for</strong> framestructure <strong>in</strong> RC with loadbear<strong>in</strong>gwallsThe CCCU Build<strong>in</strong>g of CityU29

Features of structural steel construction<strong>Structural</strong> characteristics1. Steel has lower dead load (unless encased <strong>in</strong> concrete)2. Steel frame can easily to have the layout changed to suitnew design than concrete, especially requir<strong>in</strong>g alterationafter completion of the build<strong>in</strong>g.3. Easily accommodate build<strong>in</strong>g movements <strong>for</strong> steel is arelatively flexible material and have greater adaptability totake up stra<strong>in</strong> and de<strong>for</strong>mation4. However, it is weaker <strong>in</strong> fire resistance <strong>for</strong> steel will losestrength and de<strong>for</strong>m serious at higher temperature (at 600oCor above). This can be improved by apply<strong>in</strong>g fire resistantplaster30

Features of structural steel construction<strong>Structural</strong> characteristics (cont<strong>in</strong>ue)5. Beams usually shallower <strong>in</strong> size than <strong>for</strong> concrete Beams6. Sections <strong>in</strong> various convenient type and size thuseconomical <strong>in</strong> design and uses – refer to standard steelsections7. Produce larger deflection & de<strong>for</strong>mation (Bend) underw<strong>in</strong>d – this will cause uncom<strong>for</strong>t to users of build<strong>in</strong>g8. Steel has higher thermal expansion value9. Rust<strong>in</strong>g or corrosion problems – very strict anti-corrosiontreatment has to be appliedFeatures of structural steel construction (cont.)Construction aspects1. Quicker to erect and can be prepared offsite – <strong>in</strong>workshop/factory environment with good production andquality control2. Erection on site less affected by climatic conditions –without plac<strong>in</strong>g of concrete3. Longer and highly coord<strong>in</strong>ated plann<strong>in</strong>g – require long timeto make structural design, fabrication and delivery4. <strong>High</strong>er requirement <strong>in</strong> the control of dimensional accuracybe<strong>for</strong>e and dur<strong>in</strong>g construction (<strong>in</strong> fabrication and <strong>in</strong>erection31

Features of structural steel construction (cont.)Construction aspects5. Demand greater transportation or cranages provision6. Complicated quality assurance procedures – especially <strong>in</strong>the control of weld<strong>in</strong>g connection7. Difficult to make connection with rigid structures –especially <strong>in</strong> composite structure <strong>in</strong> which RC core structureis <strong>in</strong>volved8. More complex when build<strong>in</strong>g become more gigantic andtaller – due to the huge number of structural members, somemay be of very heavy section9. Induce more works at higher altitudeFeatures of structural steel constructionConstruction aspects – highlight of some problemsDelivery of structural steelmember by shipLarge member delivery to sitewait<strong>in</strong>g to hoist<strong>in</strong>g up <strong>for</strong> erection32

Features of structural steel constructionConstruction aspects – highlight of some problemsHoist<strong>in</strong>g of the structural steelmember to the upper floorFeatures of structural steel constructionConstruction aspects – highlight of some problemsConnect<strong>in</strong>g steel members with RCelement – an anchor frame may berequired <strong>for</strong> mak<strong>in</strong>g strong connection33

Features of structural steel constructionConstruction aspects – highlight of some problemsConstruct<strong>in</strong>g the composite floor<strong>in</strong> steel/RC composite structureTo connect floor to core wall –starter bars are to be providedwith<strong>in</strong> the core structureFeatures of structural steel constructionConstruction aspects – highlight of some problemsVery large component often <strong>in</strong>complicated shape34

Features of structural steel constructionConstruction aspects – highlight of some problemsHuge amount of structural membersmake erection very complicatedFeatures of structural steel constructionConstruction aspects – highlight of some problemsVery complex and gigantic framework as stiffen<strong>in</strong>g membersto the overall structure – Belt truss system, the IFC II35

Features of structural steel constructionConstruction aspects – highlight of some problemsVery complex and gigantic framework asstiffen<strong>in</strong>g members to the overall structure –Outrigger, Cheung <strong>Kong</strong> CenterFeatures of structural steel constructionConstruction aspects – highlight of some problemsThe existence of very complicated jo<strong>in</strong>t<strong>in</strong>g<strong>in</strong> steel structure36

Features of structural steel constructionConstruction aspects– highlight of some problemsRequired to per<strong>for</strong>m works atvery high altitudeFeatures of structural steel constructionConstruction aspects – highlight of some problemsWorkers work at high altitude37

Features of structural steel constructionConstruction aspects – highlight of some problemsConnect<strong>in</strong>g large and complicate shapedcomponents can be very difficultFeatures of structural steel constructionConstruction aspects – highlight of some problemsConcrete has to be trimmed to allowsteel to pass throughExamples of location where unmatched dimension caus<strong>in</strong>g problem38

Features of structural steel constructionConstruction aspects – highlight of some problemsRoof truss andthe deck<strong>in</strong>g noton the same levelExamples of location where unmatched dimension caus<strong>in</strong>g problem39