Food contact statement E250 G (Version 1.1) - Timcal

Food contact statement E250 G (Version 1.1) - Timcal

Food contact statement E250 G (Version 1.1) - Timcal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

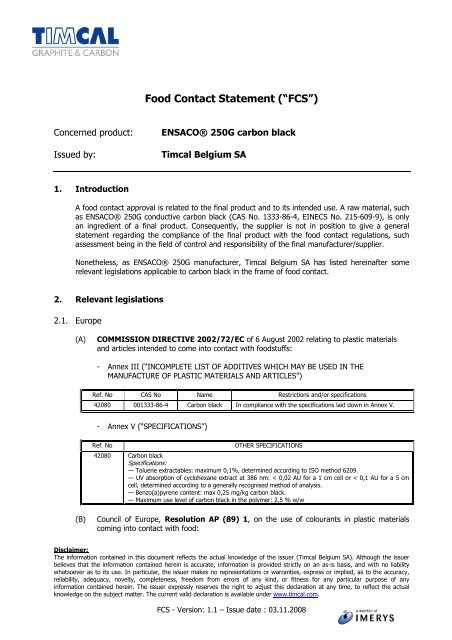

<strong>Food</strong> Contact Statement (“FCS”)Concerned product:Issued by:ENSACO® 250G carbon black<strong>Timcal</strong> Belgium SA1. IntroductionA food <strong>contact</strong> approval is related to the final product and to its intended use. A raw material, suchas ENSACO® 250G conductive carbon black (CAS No. 1333-86-4, EINECS No. 215-609-9), is onlyan ingredient of a final product. Consequently, the supplier is not in position to give a general<strong>statement</strong> regarding the compliance of the final product with the food <strong>contact</strong> regulations, suchassessment being in the field of control and responsibility of the final manufacturer/supplier.Nonetheless, as ENSACO® 250G manufacturer, <strong>Timcal</strong> Belgium SA has listed hereinafter somerelevant legislations applicable to carbon black in the frame of food <strong>contact</strong>.2. Relevant legislations2.1. Europe(A)COMMISSION DIRECTIVE 2002/72/EC of 6 August 2002 relating to plastic materialsand articles intended to come into <strong>contact</strong> with foodstuffs:- Annex III (“INCOMPLETE LIST OF ADDITIVES WHICH MAY BE USED IN THEMANUFACTURE OF PLASTIC MATERIALS AND ARTICLES”)Ref. No CAS No Name Restrictions and/or specifications42080 001333-86-4 Carbon black In compliance with the specifications laid down in Annex V.- Annex V (“SPECIFICATIONS”)Ref. NoOTHER SPECIFICATIONS42080 Carbon blackSpecifications:— Toluene extractables: maximum 0,1%, determined according to ISO method 6209.— UV absorption of cyclohexane extract at 386 nm: < 0,02 AU for a 1 cm cell or < 0,1 AU for a 5 cmcell, determined according to a generally recognised method of analysis.— Benzo(a)pyrene content: max 0,25 mg/kg carbon black.— Maximum use level of carbon black in the polymer: 2,5 % w/w(B)Council of Europe, Resolution AP (89) 1, on the use of colourants in plastic materialscoming into <strong>contact</strong> with food:Disclaimer:The information contained in this document reflects the actual knowledge of the issuer (<strong>Timcal</strong> Belgium SA). Although the issuerbelieves that the information contained herein is accurate, information is provided strictly on an as-is basis, and with no liabilitywhatsoever as to its use. In particular, the issuer makes no representations or warranties, express or implied, as to the accuracy,reliability, adequacy, novelty, completeness, freedom from errors of any kind, or fitness for any particular purpose of anyinformation contained herein. The issuer expressly reserves the right to adjust this declaration at any time, to reflect the actualknowledge on the subject matter. The current valid declaration is available under www.timcal.com.FCS - <strong>Version</strong>: <strong>1.1</strong> – Issue date : 03.11.2008

2Carbon Black should comply with any national requirement for food grade material.Furthermore, the toluene extractable fraction of carbon black should not in any case exceed0.15 % in accordance with the method described in section III, paragraph 5.(C)Synoptic Document, provisional list of monomers and additives notified to Europeancommission as substances which may be used in the manufacture of plastics or coatingsintended to come into <strong>contact</strong> with foodstuffs:Ref. No. 42080; SCF List: 3; EFSA/SCF_OP: under re-evaluation. Criteria purity shall beestablished. Carbon black should be free from aromatic hydrocarbons (CS/PM/2041).(D)Germany: BfR IX. (Colorants for Plastics and other Polymers Used in Commodities; as of01.06.1994):In colouring plastics with carbon black, no more than 2.5% (based on the colouredcomponent of the finished product) may be used as colorant. The carbon blacks usedmust comply with the “purity requirements for carbon black” contained in the 82 ndCommunication of the Bundesgesundheitsbl. 15 (1972) 268. BfR XXI. (Commodities based on Natural and Synthetic Rubber; as of 01.06.2007):- 2.1.3.1.2 Additives, processing aids:In the manufacture of finished products only the following substances and in the givenmaximum amounts (based on the finished product), may be added to the startingmaterials, including any that are pre-stabilised. When pre-cured or grafted rubber isused the amounts of additives already contained in these must also be taken intoaccount.- 2.1.3.1.2.1 Fillers:Carbon Black, … [omissum], but only for linings; for rubberised materials for silos andflexible containers for powdered foodstuffs only acetylene carbon black.The carbon blacks used must comply with the “Purity requirements for carbon blacks”laid down in Communication 82 of Bundesgesundheitsbl. 15 (1972) 268. Acetyleneblack must comply with DAB purity requirements for medical grade carbon. KTW (recommendations, part 1.3.13; carbon black named in section 1.3.13.2.1):May be used as a filler but with max. 30 percent by weight for application area A-C.(E) France: Circulaire No. 176 du 2 décembre 1959« Le noir de carbone ne doit pas donner un extrait benzénique supérieur à 0,1 % et doit êtreexempt de benzo 3-4 pyrène. » (« Carbon black shall not lead to a benzene extract above0.1% and should be exempt from benzo 3-4 pyrene » ; free translation by <strong>Timcal</strong> BelgiumSA).Disclaimer:The information contained in this document reflects the actual knowledge of the issuer (<strong>Timcal</strong> Belgium SA). Although the issuerbelieves that the information contained herein is accurate, information is provided strictly on an as-is basis, and with no liabilitywhatsoever as to its use. In particular, the issuer makes no representations or warranties, express or implied, as to the accuracy,reliability, adequacy, novelty, completeness, freedom from errors of any kind, or fitness for any particular purpose of anyinformation contained herein. The issuer expressly reserves the right to adjust this declaration at any time, to reflect the actualknowledge on the subject matter. The current valid declaration is available under www.timcal.com.FCS - <strong>Version</strong>: <strong>1.1</strong> – Issue date : 03.11.2008

4(B)Carbon Black (channel process ONLY) used as an indirect food additive:- 21 CFR, Section 175 (“Indirect food additives: adhesives and components of coatings”)C.F.R. Citation Substance Intended Use Limitations/Specifications21 C.F.R. § 175.105(“Adhesives”)CB (channel process)Used as components ofarticles intended for use inpackaging, transporting, orholding food.- 21 CFR, Section 177 (“Indirect food additives: polymers”)C.F.R. Citation Substance Intended Use Limitations/Specifications21 C.F.R. § 177.1650(“Polysulfide polymer– polyepoxy resins”)21 C.F.R. § 177.2410(“Phenolic resins inmolded articles”)CB (channel process)CB (channel process)Used as the food <strong>contact</strong>surface of articles intendedfor packaging,transporting, holding, orotherwise <strong>contact</strong>ing dryfood.Used as the food <strong>contact</strong>surface of molded articlesintended for repeated usein <strong>contact</strong> with nonacidfood.Use for <strong>contact</strong> with dry food.An appropriate sample of the finishedresin in the form in which it <strong>contact</strong>sfood, when subjected to ASTMmethod D968-81, “Standard TestMethods for Abrasion Resistance ofOrganic Coatings by the FallingAbrasive Tester”, shall exhibit andabrasion coefficient of not less than20 liters per mil of film thickness.Nonacid food refers to food with a pHabove 5.0.Finished molded articles containingthe phenolic resins shall be thoroughlycleansed prior to their first use in<strong>contact</strong> with food.3. Characteristics of ENSACO® 250G carbon black and compliance with therelevant legislationsWhile for conferring electrical conductivity to polymers ENSACO® 250G conductive carbon black iscommonly used in concentration between 10 to 30%, many national food <strong>contact</strong> regulationsrequest, as reported hereinbefore, purity requirements for carbon black as well as a maximumloading of usually 2.5 % - which concentration does not give an acceptable conductivity inpolymers.ENSACO® 250G carbon black’s purity level can be summarized as follows:- Toluene extract: < 0,1 % (measured by <strong>Timcal</strong> Belgium SA’s Quality Assurance Department).- UV absorption of cyclohexane extract @ 386 nm:

5BASED ON THE PURITY LEVEL INDICATED HEREINBEFORE, AND AS FAR AS THE EUROPEAN LEGISLATIONS ARECONCERNED, ENSACO® 250G COMPLIES, PROVIDED THAT THE CONCERNED LIMITATIONS/SPECIFICATIONS(SUCH AS, BUT NOT LIMITED TO, CONCENTRATION LIMITS) ARE RESPECTED, WITH THE COMMISSIONDIRECTIVE 2002/72/EC OF 6 AUGUST 2002 RELATING TO PLASTIC MATERIALS AND ARTICLESINTENDED TO COME INTO CONTACT WITH FOODSTUFFS, WITH THE GERMAN BFR IX AND XXI, THEFRENCH REGULATION (CIRCULAIRE N°176) AND THE COUNCIL OF EUROPE RESOLUTIONAP(89)1.Although the figures in <strong>Timcal</strong> Belgium SA’s possession show a high purity level of ENSACO® 250Gcarbon black, as reported hereinbefore, ENSACO® 250G carbon black does not fall ipso iure underthe definition of “carbon black” used in the US <strong>Food</strong> and Drugs regulations (“channel black” /“furnace black” / “high purity furnace black”). ENSACO® 250G carbon black is in fact produced bya partial combustion process, and differs from a “classic” furnace black due to different conditionsand set up used during its production, although the chemistry of the reaction (partial combustionprocess) is, to the best of <strong>Timcal</strong> Belgium SA’s actual knowledge and belief, quite similar to the oneused by a “classic” furnace process. Consequently, <strong>Timcal</strong> Belgium SA can not state that ENSACO®250G carbon black complies, pure or combined with other substances/compounds, with the US<strong>Food</strong> and Drugs regulations.Contact for any question related to the subject matter:Mrs. Patrizia AIELLOProducts compliance & Quality Systems Manager<strong>Timcal</strong> Ltd.CH-6743 Bodio (Switzerland)Tel.: +41(0)91/873 20 10Fax: +41(0)91/873 20 19@: p.aiello@ch.timcal.comDisclaimer:The information contained in this document reflects the actual knowledge of the issuer (<strong>Timcal</strong> Belgium SA). Although the issuerbelieves that the information contained herein is accurate, information is provided strictly on an as-is basis, and with no liabilitywhatsoever as to its use. In particular, the issuer makes no representations or warranties, express or implied, as to the accuracy,reliability, adequacy, novelty, completeness, freedom from errors of any kind, or fitness for any particular purpose of anyinformation contained herein. The issuer expressly reserves the right to adjust this declaration at any time, to reflect the actualknowledge on the subject matter. The current valid declaration is available under www.timcal.com.FCS - <strong>Version</strong>: <strong>1.1</strong> – Issue date : 03.11.2008