RELIANCE® 333 WASHER/DISINFECTOR - Steris

RELIANCE® 333 WASHER/DISINFECTOR - Steris

RELIANCE® 333 WASHER/DISINFECTOR - Steris

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

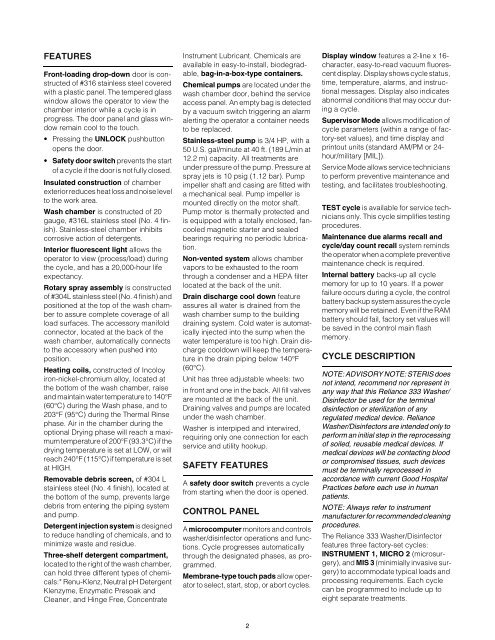

FEATURESFront-loading drop-down door is constructedof #316 stainless steel coveredwith a plastic panel. The tempered glasswindow allows the operator to view thechamber interior while a cycle is inprogress. The door panel and glass windowremain cool to the touch.• Pressing the UNLOCK pushbuttonopens the door.• Safety door switch prevents the startof a cycle if the door is not fully closed.Insulated construction of chamberexterior reduces heat loss and noise levelto the work area.Wash chamber is constructed of 20gauge, #316L stainless steel (No. 4 finish).Stainless-steel chamber inhibitscorrosive action of detergents.Interior fluorescent light allows theoperator to view (process/load) duringthe cycle, and has a 20,000-hour lifeexpectancy.Rotary spray assembly is constructedof #304L stainless steel (No. 4 finish) andpositioned at the top of the wash chamberto assure complete coverage of allload surfaces. The accessory manifoldconnector, located at the back of thewash chamber, automatically connectsto the accessory when pushed intoposition.Heating coils, constructed of Incoloyiron-nickel-chromium alloy, located atthe bottom of the wash chamber, raiseand maintain water temperature to 140°F(60°C) during the Wash phase, and to203°F (95°C) during the Thermal Rinsephase. Air in the chamber during theoptional Drying phase will reach a maximumtemperature of 200°F (93.3°C) if thedrying temperature is set at LOW, or willreach 240°F (115°C) if temperature is setat HIGH.Removable debris screen, of #304 Lstainless steel (No. 4 finish), located atthe bottom of the sump, prevents largedebris from entering the piping systemand pump.Detergent injection system is designedto reduce handling of chemicals, and tominimize waste and residue.Three-shelf detergent compartment,located to the right of the wash chamber,can hold three different types of chemicals:*Renu-Klenz‚ Neutral pH DetergentKlenzyme‚ Enzymatic Presoak andCleaner, and Hinge Free‚ ConcentrateInstrument Lubricant. Chemicals areavailable in easy-to-install, biodegradable,bag-in-a-box-type containers.Chemical pumps are located under thewash chamber door, behind the serviceaccess panel. An empty bag is detectedby a vacuum switch triggering an alarmalerting the operator a container needsto be replaced.Stainless-steel pump is 3/4 HP, with a50 U.S. gal/minute at 40 ft. (189 L/min at12.2 m) capacity. All treatments areunder pressure of the pump. Pressure atspray jets is 10 psig (1.12 bar). Pumpimpeller shaft and casing are fitted witha mechanical seal. Pump impeller ismounted directly on the motor shaft.Pump motor is thermally protected andis equipped with a totally enclosed, fancooledmagnetic starter and sealedbearings requiring no periodic lubrication.Non-vented system allows chambervapors to be exhausted to the roomthrough a condenser and a HEPA filterlocated at the back of the unit.Drain discharge cool down featureassures all water is drained from thewash chamber sump to the buildingdraining system. Cold water is automaticallyinjected into the sump when thewater temperature is too high. Drain dischargecooldown will keep the temperaturein the drain piping below 140°F(60°C).Unit has three adjustable wheels: twoin front and one in the back. All fill valvesare mounted at the back of the unit.Draining valves and pumps are locatedunder the wash chamber.Washer is interpiped and interwired,requiring only one connection for eachservice and utility hookup.SAFETY FEATURESA safety door switch prevents a cyclefrom starting when the door is opened.CONTROL PANELA microcomputer monitors and controlswasher/disinfector operations and functions.Cycle progresses automaticallythrough the designated phases, as programmed.Membrane-type touch pads allow operatorto select, start, stop, or abort cycles.Display window features a 2-line x 16-character, easy-to-read vacuum fluorescentdisplay. Display shows cycle status,time, temperature, alarms, and instructionalmessages. Display also indicatesabnormal conditions that may occur duringa cycle.Supervisor Mode allows modification ofcycle parameters (within a range of factory-setvalues), and time display andprintout units (standard AM/PM or 24-hour/military [MIL]).Service Mode allows service techniciansto perform preventive maintenance andtesting, and facilitates troubleshooting.TEST cycle is available for service techniciansonly. This cycle simplifies testingprocedures.Maintenance due alarms recall andcycle/day count recall system remindsthe operator when a complete preventivemaintenance check is required.Internal battery backs-up all cyclememory for up to 10 years. If a powerfailure occurs during a cycle, the controlbattery backup system assures the cyclememory will be retained. Even if the RAMbattery should fail, factory set values willbe saved in the control main flashmemory.CYCLE DESCRIPTIONNOTE: ADVISORY NOTE: STERIS doesnot intend, recommend nor represent inany way that this Reliance <strong>333</strong> Washer/Disinfector be used for the terminaldisinfection or sterilization of anyregulated medical device. RelianceWasher/Disinfectors are intended only toperform an initial step in the reprocessingof soiled, reusable medical devices. Ifmedical devices will be contacting bloodor compromised tissues, such devicesmust be terminally reprocessed inaccordance with current Good HospitalPractices before each use in humanpatients.NOTE: Always refer to instrumentmanufacturer for recommended cleaningprocedures.The Reliance <strong>333</strong> Washer/Disinfectorfeatures three factory-set cycles:INSTRUMENT 1, MICRO 2 (microsurgery),and MIS 3 (minimially invasive surgery)to accommodate typical loads andprocessing requirements. Each cyclecan be programmed to include up toeight separate treatments.2