new development in shot blasting machine. - Metalworld.co.in

new development in shot blasting machine. - Metalworld.co.in

new development in shot blasting machine. - Metalworld.co.in

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

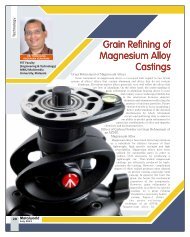

TechnologyProperly designed <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>e will not only cleanthe cast<strong>in</strong>gs efficiently, but it will also satisfy the usersquality needs and also assure optimum productivity and thelowest possible operat<strong>in</strong>g <strong>co</strong>st.Abrasive Flow Control Valve (Fig-11)(soundabrator):The abrasive flow to each wheel isregulated to match the mechanicalcapacity of the abrasive reclaim<strong>in</strong>gsystem and must stay with<strong>in</strong> theAmperage capacity of Electric Motor.Enclosed air operated Soundabratorreduces noise level, which is below 85(Fig-11) dB and prevents leak<strong>in</strong>g of <strong>shot</strong>s and itis easy to ma<strong>in</strong>ta<strong>in</strong>.Shot Peen<strong>in</strong>g : (Fig-12)Shot peen<strong>in</strong>g is one of the application for <strong>in</strong>creas<strong>in</strong>g thefatigue life of various <strong>co</strong>mponents like Coil Spr<strong>in</strong>gs, LeafSpr<strong>in</strong>gs, Gears, Rack & P<strong>in</strong>ion, Torsion Bar, Connect<strong>in</strong>gRod, Crank Shaft widely used <strong>in</strong> auto <strong>in</strong>dustries. We SeeMany trucks broken down on the Road due to Fatiguefailure of axle Shaft or Spr<strong>in</strong>g, Sometime it results <strong>in</strong>Serious accidents. This Fatigue can be reduced byadoption of Shot Peen<strong>in</strong>g Process.Shot & Abrasive : (Fig-13).070”.0110”Effect of Shot Size on Impact & CoverageSHOT SIZEInches <strong>in</strong> (mm)0.18mm0.30mm.0170” 0.40mm.0230” 0.60mm.0280” 0.70mm.0330” 0.80mm.0390” 1.00mm.0460” 1.20mm.0550” 1.40mm.0660” 1.70mmApprox. ImpactValue14920335590150260440Approx. Nos. ofShots / ID82,00,00021,00,0007,45,0003,24,0001,92,0001,14,00068,00040,00024,00014,000Equiv. Size of<strong>in</strong> GritG-80G-50G-40G-25G-18G-16G-14G-12Shot Impact Value varies as the cube of the diameter (2:1 Size = 8.1Impact Value and 1:8 number of Shots / Ib). Consider<strong>in</strong>g Impact valueof 70 size <strong>shot</strong> as 1.Fig. 13(Fig-12)The impact Power and <strong>co</strong>verage of steel abrasive isgoverned by its mass and velocity <strong>in</strong> ac<strong>co</strong>rdance withequation of k<strong>in</strong>etic energy.Ke = ½ MV2 (Where Ke = K<strong>in</strong>etic Energy M=MassV=Velocity).The impact force delivered to the work piece will changeonly if the mass factor (i.e. the abrasive size) is altered.The relationship of abrasive size to both impact power and<strong>co</strong>verage is shown <strong>in</strong> figureThe e<strong>co</strong>nomy and performance of blast clean<strong>in</strong>g dependsupon the abrasives used. The proper size and type ofabrasives is most important. The follow<strong>in</strong>g three factorsshould be <strong>co</strong>nsidered while select<strong>in</strong>g the abrasivesa. Area of job surface these can cleanb. Quality of work producedc. Cost of the <strong>shot</strong>sChilled Iron ShotsThe <strong>shot</strong>s are manufactured by quench<strong>in</strong>g the stream ofmolten gray iron over high pressure water jet. Its hardnessis about 60 Rockwell C.Due to this hardness and quenchedstructure it fractures and dis<strong>in</strong>tegrates very quickly onimpact with the work surface. Due to greater amount ofdust produced <strong>in</strong> fractur<strong>in</strong>g process, the part cleaned bychilled iron <strong>shot</strong> does not have very good f<strong>in</strong>ish. Also thema<strong>in</strong>tenance <strong>co</strong>st is very high. This led to the <strong>in</strong>troductionof malleable iron-, cast steel-, cut wire-<strong>shot</strong>s and heattreated steel <strong>shot</strong>s.Heat-Treated Steel ShotsThe heat treated steel <strong>shot</strong>s are hav<strong>in</strong>g hardness of 45Rockwell C (424 Br<strong>in</strong>ell hardness). These are the mostsuitable for the <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>e.Sta<strong>in</strong>less Steel Shot & Cut Wire Shots (Fig. 13)Die casted <strong>co</strong>mponents manufactured from Alum<strong>in</strong>ium,Z<strong>in</strong>k & Magnesium Alloys required to be blasted forremov<strong>in</strong>g burr and also give asthetic value with aim toobta<strong>in</strong> even, sh<strong>in</strong>y f<strong>in</strong>ish on all sides. Many users prefersta<strong>in</strong>less steel <strong>shot</strong> as the <strong>co</strong>nsumption is one sixth of steel<strong>shot</strong>, carbon steel <strong>shot</strong> give dull grey f<strong>in</strong>ish, while sta<strong>in</strong>lesssteel imparts matt silver f<strong>in</strong>ish pleas<strong>in</strong>g to eye. Many autounits like Honda, Bajaj, Endurance are uses sta<strong>in</strong>less steel<strong>shot</strong>s.Conclud<strong>in</strong>g RemarksShot blast<strong>in</strong>g is no more an optional process <strong>in</strong> a foundry. Itprovides faster and better clean<strong>in</strong>g. It saves power, labour,space and also saves on cutt<strong>in</strong>g tools and permits better<strong>in</strong>spection, thus m<strong>in</strong>imiz<strong>in</strong>g the rejection of cast<strong>in</strong>gs. Apartfrom foundry it is also widely used <strong>in</strong> many other<strong>in</strong>dustries.Proper understand<strong>in</strong>g about the mach<strong>in</strong>e, its<strong>co</strong>nstruction and use enables us to improve its efficiencyand utility. Before Select<strong>in</strong>g the equipment it is necessary,to <strong>co</strong>nsider above po<strong>in</strong>ts, spare parts, availability, salesservices offered, and many other po<strong>in</strong>ts.24June 2009