new development in shot blasting machine. - Metalworld.co.in

new development in shot blasting machine. - Metalworld.co.in

new development in shot blasting machine. - Metalworld.co.in

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

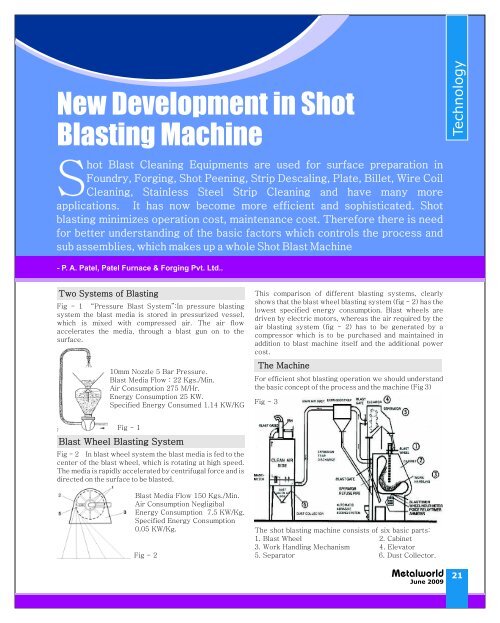

New Development <strong>in</strong> ShotBlast<strong>in</strong>g Mach<strong>in</strong>ehot Blast Clean<strong>in</strong>g Equipments are used for surface preparation <strong>in</strong>Foundry, Forg<strong>in</strong>g, Shot Peen<strong>in</strong>g, Strip Descal<strong>in</strong>g, Plate, Billet, Wire CoilSClean<strong>in</strong>g, Sta<strong>in</strong>less Steel Strip Clean<strong>in</strong>g and have many moreapplications. It has now be<strong>co</strong>me more efficient and sophisticated. Shotblast<strong>in</strong>g m<strong>in</strong>imizes operation <strong>co</strong>st, ma<strong>in</strong>tenance <strong>co</strong>st. Therefore there is needfor better understand<strong>in</strong>g of the basic factors which <strong>co</strong>ntrols the process andsub assemblies, which makes up a whole Shot Blast Mach<strong>in</strong>eTechnology- P. A. Patel, Patel Furnace & Forg<strong>in</strong>g Pvt. Ltd..Two Systems of Blast<strong>in</strong>gFig - 1 “Pressure Blast System”:In pressure blast<strong>in</strong>gsystem the blast media is stored <strong>in</strong> pressurized vessel,which is mixed with <strong>co</strong>mpressed air. The air flowaccelerates the media, through a blast gun on to thesurface.10mm Nozzle 5 Bar Pressure.Blast Media Flow : 22 Kgs./M<strong>in</strong>.Air Consumption 275 M/Hr.Energy Consumption 25 KW.Specified Energy Consumed 1.14 KW/KGThis <strong>co</strong>mparison of different blast<strong>in</strong>g systems, clearlyshows that the blast wheel blast<strong>in</strong>g system (fig - 2) has thelowest specified energy <strong>co</strong>nsumption. Blast wheels aredriven by electric motors, whereas the air required by theair blast<strong>in</strong>g system (fig - 2) has to be generated by a<strong>co</strong>mpressor which is to be purchased and ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong>addition to blast mach<strong>in</strong>e itself and the additional power<strong>co</strong>st.The Mach<strong>in</strong>eFor efficient <strong>shot</strong> blast<strong>in</strong>g operation we should understandthe basic <strong>co</strong>ncept of the process and the mach<strong>in</strong>e (Fig 3)Fig - 3Fig - 1Blast Wheel Blast<strong>in</strong>g SystemFig - 2 In blast wheel system the blast media is fed to thecenter of the blast wheel, which is rotat<strong>in</strong>g at high speed.The media is rapidly accelerated by centrifugal force and isdirected on the surface to be blasted.Blast Media Flow 150 Kgs./M<strong>in</strong>.Air Consumption NegligibalEnergy Consumption 7.5 KW/Kg.Specified Energy Consumption0.05 KW/Kg.Fig - 2The <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>e <strong>co</strong>nsists of six basic parts:1. Blast Wheel 2. Cab<strong>in</strong>et3. Work Handl<strong>in</strong>g Mechanism 4. Elevator5. Separator 6. Dust Collector.June 200921

TechnologyLet's take a close look at these six parts and see whatroleeach plays <strong>in</strong> the <strong>shot</strong> blast<strong>in</strong>g process.1. Blast Wheel :Abrasive particles are projected by centrifugal force fromvarious k<strong>in</strong>ds of turb<strong>in</strong>e wheels. The number of wheels<strong>in</strong>stalled <strong>in</strong> the mach<strong>in</strong>e depends on the type of jobs to be<strong>shot</strong> blasted and the rate of work. The wheel is the heart ofevery centrifugal <strong>shot</strong>-blast<strong>in</strong>g mach<strong>in</strong>e. Efficiency andclean<strong>in</strong>g effect depend to a great extent on the quality ofthe wheel and its <strong>co</strong>mponents.2. Cab<strong>in</strong>et :As high speed of abrasive particles (50-100 m/s) is<strong>in</strong>volved the articles to be <strong>shot</strong>-blasted have to be treated<strong>in</strong> closed, vibration free booth or cab<strong>in</strong>et made of strongsteel, l<strong>in</strong>ed with wear resistant alloy l<strong>in</strong>ers. Forma<strong>in</strong>tenance purpose proper <strong>in</strong>spection door andventilation are essential.3. Abrasive Re<strong>co</strong>very System and Elevator :The abrasives are re<strong>co</strong>vered at the bottom of the cab<strong>in</strong>etby means of a screw <strong>co</strong>nveyor and delivered to the base ofthe elevator, which then carries these to the separator.4. Separator :Before abrasives enters <strong>in</strong>to the blast wheel for reuse,these have to be cleaned of all <strong>co</strong>ntam<strong>in</strong>ants. This is therole of the air separator.5. Dust Collector :The last essential feature is the filtration, which retrievesdust laden air from the separator and cab<strong>in</strong>et ventilationsystem and discharges clean air <strong>in</strong>to atmosphere forpollution free environment.6. Work Handl<strong>in</strong>g :Various systems exist for <strong>co</strong>nvey<strong>in</strong>g the parts depend<strong>in</strong>gon the type, size and quality of the items to be treated.Tumblast Type Mach<strong>in</strong>e(Fig. A) :This design employs endless <strong>co</strong>nveyor beltmade of steel l<strong>in</strong>k and flats or rubber belt,which does not damage the job dur<strong>in</strong>gtumbl<strong>in</strong>g.Table Type Mach<strong>in</strong>e(Fig. B) :In this type of mach<strong>in</strong>e parts be<strong>in</strong>gcleaned must be positioned orrepositioned on the table to assure<strong>co</strong>mplete clean<strong>in</strong>g of the full surface.Blade Lock TypeControl Cage Small.Impeller Small.Monorail Hanger Type Mach<strong>in</strong>e(Fig. C) :In this type of mach<strong>in</strong>e, parts aresuspended on trees hung onhanger or special fixtures and arecarried <strong>in</strong>to the abrasive stream.Roller & Belt Conveyor Mach<strong>in</strong>e(Fig. D) :This picture shows plate, sheetor structural shape de-scal<strong>in</strong>gat high speed. Both upper andlower surfaces are <strong>shot</strong> blastedsimultaneously.Door Hanger Mach<strong>in</strong>e(Fig. E) :In this mach<strong>in</strong>e jobs arehung on the door. The partsare carried <strong>in</strong>to abrasivestream after clos<strong>in</strong>g thedoor. The parts aremounted <strong>in</strong> front of thewheel. On <strong>co</strong>mpletion of<strong>shot</strong> blast<strong>in</strong>g, door isopened and se<strong>co</strong>nd doorwith job hung enters thecab<strong>in</strong>et. In this type ofmach<strong>in</strong>e, one may get 30 to40% more production.Compare Old M Type Wheel (Fig-4)New High Power Wheels :With the need for <strong>in</strong>creased output it has be<strong>co</strong>me apparentthat 'Shot Blast Cycle' on the mach<strong>in</strong>e must be reduced <strong>in</strong>effort to give <strong>in</strong>creased output. We have <strong>in</strong>troduced NewRLM (Radialok) wheel, which throws more abrasive and<strong>co</strong>nsume less power. In this way one mach<strong>in</strong>e be<strong>in</strong>g able todo the work formerly required by two mach<strong>in</strong>es. The <strong>new</strong>wheel has large <strong>co</strong>ntrol cage and impeller mak<strong>in</strong>g itpossible to throw more abrasive and better and fasterclean<strong>in</strong>g.Old M Wheel(Fig-4)22June 2009

New RLM WheelBlade Self Lock<strong>in</strong>g.Control Cage Big.Impeller Big.New Abrasive Resistant L<strong>in</strong><strong>in</strong>g (Fig-8)Aga<strong>in</strong> due to the fact that moreabrasive is be<strong>in</strong>g thrown, it hasbe<strong>co</strong>me necessary to <strong>co</strong>mpletelyl<strong>in</strong>ed mach<strong>in</strong>es with abrasiveresistant material.This has been made possible by theuse of special high chrome alloymaterial. These are made <strong>in</strong>various sizes to provide <strong>co</strong>mplete<strong>in</strong>terlock<strong>in</strong>g l<strong>in</strong><strong>in</strong>g for most types of<strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>es.TechnologyWheel Unit (Fig - 6) :With this <strong>in</strong>creased amount of abrasive be<strong>in</strong>g thrown it hasbe<strong>co</strong>me necessary to have wheel, which are capable oflast<strong>in</strong>g a great deal, longer thantheir predecessor. This has beenmade possible by <strong>in</strong>troduction of<strong>new</strong> Hard Alloy Wheels.In addition it has been necessary to<strong>in</strong>crease the life of Blades, Impeller,Control Cage, L<strong>in</strong>ers and otherparts by us<strong>in</strong>g High Chrome Alloymaterial. This has been possibledue establishment of our <strong>new</strong>Foundry with Induction Furnace,Shell Mould<strong>in</strong>g Mach<strong>in</strong>e and HeatTreatment Facility. Very few equipment manufacturersunderstand importance of wheel and its parts.Wheel Unit L<strong>in</strong>ers (Fig - 7)The blast wheel is usually enclosed with<strong>in</strong> a hous<strong>in</strong>gserv<strong>in</strong>g as a safety guard and abrasive seal around rapidlyrotat<strong>in</strong>g wheel to m<strong>in</strong>imize wear on the hous<strong>in</strong>g, a series ofspecial alloy cast l<strong>in</strong>ers are <strong>in</strong>stalled <strong>in</strong>side the hous<strong>in</strong>g.Older wheel Fig-7 <strong>co</strong>nsisted of 21 l<strong>in</strong>ers where abrasivebounces <strong>in</strong> un<strong>co</strong>ntrolled manner. In our <strong>new</strong> RLM Fig-8)wheel only n<strong>in</strong>e l<strong>in</strong>ers are <strong>in</strong>stalled <strong>in</strong>side the hous<strong>in</strong>g.High chrome l<strong>in</strong>ers are approx. 25mm thick with labyr<strong>in</strong>thtype jo<strong>in</strong>ts provid<strong>in</strong>g and abrasive tight seal between thel<strong>in</strong>ers and very Long life.Alloy Perforated Plates :One of the biggest problem <strong>in</strong> the foundry <strong>in</strong>dustry has beenthat wire, chaplets and other material used for giv<strong>in</strong>gsupport to the mould gets <strong>in</strong> the elevator and separator, asthe perforated plates are not proper. We manufacture andsupply <strong>in</strong> High Chrome Alloy Steel with the result there isno wear or holes for wire to pass.Mould<strong>in</strong>g TechniqueMost popular mould<strong>in</strong>g technique used <strong>in</strong> India is greensand mould<strong>in</strong>g and About 80% of foundries use thistechnique. The drawback of this technology is that largeamount of sand, sticks on surface of the cast<strong>in</strong>gs, which areto be cleaned by <strong>shot</strong> blast<strong>in</strong>g.Foundry, us<strong>in</strong>g cupola has more sand <strong>co</strong>mpared toautomated foundries. Other technology like CO2 process,has 5 % to 10 % sand stick<strong>in</strong>g to cast<strong>in</strong>g because of badshak<strong>in</strong>g operation, poor property of mould and <strong>co</strong>retherefore <strong>shot</strong> blast<strong>in</strong>g is quite essential.There are number of items produced by Indian foundries.Some of them are impeller cast<strong>in</strong>gs. pump cast<strong>in</strong>gs, valvebodies & automobile or tractor <strong>co</strong>mponents like breakdrum, cyl<strong>in</strong>der head, hous<strong>in</strong>gs, fly wheel, manifold <strong>co</strong>vers,weigh<strong>in</strong>g from 5 kgs to 60 Kgs. or more. To clean thesecast<strong>in</strong>gs it takes 7 to 10 m<strong>in</strong>utes us<strong>in</strong>g S-550 (1.4mm) <strong>shot</strong>.Some other types of cast<strong>in</strong>gs when hanged on monorailtake 15-20 m<strong>in</strong>utes for a lot of 500 Kgs. or more.Most of the foreign foundries use No bake Process, WaxProcess and Foam Process. There is very little sand oncast<strong>in</strong>gs so most of the foreign <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>emanufacturers do not understand requirement of Indianfoundries . The <strong>co</strong>sts of foreign mach<strong>in</strong>es are 3 to 4 timesmore than Indian mach<strong>in</strong>es. Many imported mach<strong>in</strong>es havecartridge filters <strong>in</strong>stead of bag filter. The disadvantage ofcartridge filter is that <strong>in</strong> humid atmosphere sand sticks tothe paper. It can not handle heavy sand load with the resultit chockes frequently. The imported mach<strong>in</strong>es do not giveany production advantage and spare parts <strong>co</strong>st is very highJune 200923

TechnologyProperly designed <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>e will not only cleanthe cast<strong>in</strong>gs efficiently, but it will also satisfy the usersquality needs and also assure optimum productivity and thelowest possible operat<strong>in</strong>g <strong>co</strong>st.Abrasive Flow Control Valve (Fig-11)(soundabrator):The abrasive flow to each wheel isregulated to match the mechanicalcapacity of the abrasive reclaim<strong>in</strong>gsystem and must stay with<strong>in</strong> theAmperage capacity of Electric Motor.Enclosed air operated Soundabratorreduces noise level, which is below 85(Fig-11) dB and prevents leak<strong>in</strong>g of <strong>shot</strong>s and itis easy to ma<strong>in</strong>ta<strong>in</strong>.Shot Peen<strong>in</strong>g : (Fig-12)Shot peen<strong>in</strong>g is one of the application for <strong>in</strong>creas<strong>in</strong>g thefatigue life of various <strong>co</strong>mponents like Coil Spr<strong>in</strong>gs, LeafSpr<strong>in</strong>gs, Gears, Rack & P<strong>in</strong>ion, Torsion Bar, Connect<strong>in</strong>gRod, Crank Shaft widely used <strong>in</strong> auto <strong>in</strong>dustries. We SeeMany trucks broken down on the Road due to Fatiguefailure of axle Shaft or Spr<strong>in</strong>g, Sometime it results <strong>in</strong>Serious accidents. This Fatigue can be reduced byadoption of Shot Peen<strong>in</strong>g Process.Shot & Abrasive : (Fig-13).070”.0110”Effect of Shot Size on Impact & CoverageSHOT SIZEInches <strong>in</strong> (mm)0.18mm0.30mm.0170” 0.40mm.0230” 0.60mm.0280” 0.70mm.0330” 0.80mm.0390” 1.00mm.0460” 1.20mm.0550” 1.40mm.0660” 1.70mmApprox. ImpactValue14920335590150260440Approx. Nos. ofShots / ID82,00,00021,00,0007,45,0003,24,0001,92,0001,14,00068,00040,00024,00014,000Equiv. Size of<strong>in</strong> GritG-80G-50G-40G-25G-18G-16G-14G-12Shot Impact Value varies as the cube of the diameter (2:1 Size = 8.1Impact Value and 1:8 number of Shots / Ib). Consider<strong>in</strong>g Impact valueof 70 size <strong>shot</strong> as 1.Fig. 13(Fig-12)The impact Power and <strong>co</strong>verage of steel abrasive isgoverned by its mass and velocity <strong>in</strong> ac<strong>co</strong>rdance withequation of k<strong>in</strong>etic energy.Ke = ½ MV2 (Where Ke = K<strong>in</strong>etic Energy M=MassV=Velocity).The impact force delivered to the work piece will changeonly if the mass factor (i.e. the abrasive size) is altered.The relationship of abrasive size to both impact power and<strong>co</strong>verage is shown <strong>in</strong> figureThe e<strong>co</strong>nomy and performance of blast clean<strong>in</strong>g dependsupon the abrasives used. The proper size and type ofabrasives is most important. The follow<strong>in</strong>g three factorsshould be <strong>co</strong>nsidered while select<strong>in</strong>g the abrasivesa. Area of job surface these can cleanb. Quality of work producedc. Cost of the <strong>shot</strong>sChilled Iron ShotsThe <strong>shot</strong>s are manufactured by quench<strong>in</strong>g the stream ofmolten gray iron over high pressure water jet. Its hardnessis about 60 Rockwell C.Due to this hardness and quenchedstructure it fractures and dis<strong>in</strong>tegrates very quickly onimpact with the work surface. Due to greater amount ofdust produced <strong>in</strong> fractur<strong>in</strong>g process, the part cleaned bychilled iron <strong>shot</strong> does not have very good f<strong>in</strong>ish. Also thema<strong>in</strong>tenance <strong>co</strong>st is very high. This led to the <strong>in</strong>troductionof malleable iron-, cast steel-, cut wire-<strong>shot</strong>s and heattreated steel <strong>shot</strong>s.Heat-Treated Steel ShotsThe heat treated steel <strong>shot</strong>s are hav<strong>in</strong>g hardness of 45Rockwell C (424 Br<strong>in</strong>ell hardness). These are the mostsuitable for the <strong>shot</strong> blast<strong>in</strong>g mach<strong>in</strong>e.Sta<strong>in</strong>less Steel Shot & Cut Wire Shots (Fig. 13)Die casted <strong>co</strong>mponents manufactured from Alum<strong>in</strong>ium,Z<strong>in</strong>k & Magnesium Alloys required to be blasted forremov<strong>in</strong>g burr and also give asthetic value with aim toobta<strong>in</strong> even, sh<strong>in</strong>y f<strong>in</strong>ish on all sides. Many users prefersta<strong>in</strong>less steel <strong>shot</strong> as the <strong>co</strong>nsumption is one sixth of steel<strong>shot</strong>, carbon steel <strong>shot</strong> give dull grey f<strong>in</strong>ish, while sta<strong>in</strong>lesssteel imparts matt silver f<strong>in</strong>ish pleas<strong>in</strong>g to eye. Many autounits like Honda, Bajaj, Endurance are uses sta<strong>in</strong>less steel<strong>shot</strong>s.Conclud<strong>in</strong>g RemarksShot blast<strong>in</strong>g is no more an optional process <strong>in</strong> a foundry. Itprovides faster and better clean<strong>in</strong>g. It saves power, labour,space and also saves on cutt<strong>in</strong>g tools and permits better<strong>in</strong>spection, thus m<strong>in</strong>imiz<strong>in</strong>g the rejection of cast<strong>in</strong>gs. Apartfrom foundry it is also widely used <strong>in</strong> many other<strong>in</strong>dustries.Proper understand<strong>in</strong>g about the mach<strong>in</strong>e, its<strong>co</strong>nstruction and use enables us to improve its efficiencyand utility. Before Select<strong>in</strong>g the equipment it is necessary,to <strong>co</strong>nsider above po<strong>in</strong>ts, spare parts, availability, salesservices offered, and many other po<strong>in</strong>ts.24June 2009