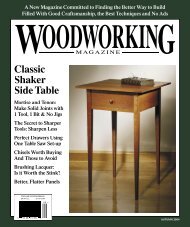

Classic Shaker Side Table - Popular Woodworking Magazine

Classic Shaker Side Table - Popular Woodworking Magazine

Classic Shaker Side Table - Popular Woodworking Magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sharpen a ChiselHere’s the secret: The less you sharpen, the keener your tool’s edges will become.TThere are two things you must learn to get yourchisels sharp enough for woodworking.The first is easy. Your cutting edge is the intersectionof two planes: the bevel and the faceof the tool. As the metal is abraded, the pointwhere those two planes intersect becomes finer,sharper and more durable. The ultimate goal ofsharpening is to make that point of intersectionas small as possible. The smaller that point of intersection,the sharper your edge will be.The second thing isn’t as obvious. Good sharpeningis more about learning to observe yourprogress than it is about rubbing a tool on a sharpeningstone. Ultimately, a good sharpener spendslittle time rubbing the tool and more time makingevery stroke count.If this sounds odd, think for a minute abouthow you viewed furniture before you startedwoodworking. Most non-woodworkers can seea piece of furniture as a whole form. But it takestraining to see the individual details (such asrecognizing inset doors that have perfect revealsall around) and to know what they mean (whichis good craftsmanship). As your woodworkingskills develop, your eye becomes more discriminating.At that point, creating fine furniture hasmore to do with seeing the details than with rippinglumber on a table saw.With sharpening, you must develop your eyeto know what a good edge looks and feels like.Once you know what sharp is and how to getthere, your edges will get better every time yousharpen. And you’ll spend less time at the stones.Ultimately, it should take you only five minutesto bring a dull edge back to perfection.The Right Sharpening KitBuying the right equipment is important. Somesystems are slow (oilstones), some need moremaintenance (waterstones) and some have peculiarities(such as the tendency of sandpaper toround over an edge). I have used every system,and after years of experimenting and sharpeninghundreds of edges, I’ve settled on a hybrid systemthat consists primarily of the following:■ A DMT diamond stone for removing metalquickly and truing my other sharpening stones(dmtsharp.com or 800-666-4368).■ A coarse waterstone (#800- or #1,000-grit)for shaping the tool’s secondary bevel.■ A fine waterstone (#6,000- or #8,000-grit)for polishing the secondary bevel and face.■ An inexpensive side-clamp honing guide.This list is a bit unusual because of what I’veincluded and what some may say is missing. Thehoning guide is a bit controversial, but it’s thekey to early success. Many excellent craftsmendispense with these “training wheels” and insistbeginners sharpen without it. However, withouthands-on instruction, most beginners will struggleneedlessly learning freehand technique. Producingyour first keen edge will take far morepractice. And your progress will be slower. Thehoning guide allows you to succeed on your firstor second try. And once you know what sharp is,you can then choose to use the guide or not.The second reason the above list is radical isbecause there is no medium-grit stone betweencoarse and fine. British craftsman and teacherDavid Charlesworth recently convinced me thatPHOTO BY AL PARRISHwoodworking-magazine.com ■ 11