Backflow protection devices - Watts Industries

Backflow protection devices - Watts Industries

Backflow protection devices - Watts Industries

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

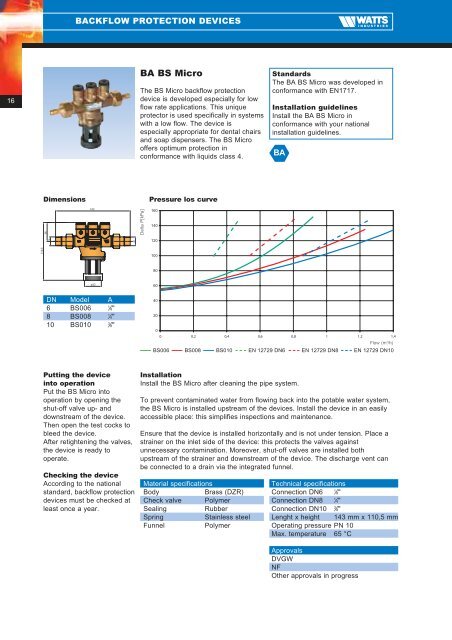

BACKFLOW PROTECTION DEVICES16BA BS MicroThe BS Micro backflow <strong>protection</strong>device is developed especially for lowflow rate applications. This uniqueprotector is used specifically in systemswith a low flow. The device isespecially appropriate for dental chairsand soap dispensers. The BS Microoffers optimum <strong>protection</strong> inconformance with liquids class 4.StandardsThe BA BS Micro was developed inconformance with EN1717.Installation guidelinesInstall the BA BS Micro inconformance with your nationalinstallation guidelines.BADimensionsPressure los curve36143Delta P[kPa]160140AA120110.510080ø32DN Model A6 BS006 1⁄8"8 BS008 1⁄4"10 BS010 3⁄8"60402000 0,2 0,4 0,6 0,8 1 1,2 1,4Flow (m 3 /h)BS006 BS008 BS010 EN 12729 DN6 EN 12729 DN8 EN 12729 DN10Putting the deviceinto operationPut the BS Micro intooperation by opening theshut-off valve up- anddownstream of the device.Then open the test cocks tobleed the device.After retightening the valves,the device is ready tooperate.Checking the deviceAccording to the nationalstandard, backflow <strong>protection</strong><strong>devices</strong> must be checked atleast once a year.InstallationInstall the BS Micro after cleaning the pipe system.To prevent contaminated water from flowing back into the potable water system,the BS Micro is installed upstream of the <strong>devices</strong>. Install the device in an easilyaccessible place: this simplifies inspections and maintenance.Ensure that the device is installed horizontally and is not under tension. Place astrainer on the inlet side of the device: this protects the valves againstunnecessary contamination. Moreover, shut-off valves are installed bothupstream of the strainer and downstream of the device. The discharge vent canbe connected to a drain via the integrated funnel.Material specificationsBodyBrass (DZR)Check valve PolymerSealingRubberSpringStainless steelFunnelPolymerTechnical specificationsConnection DN6 1⁄8"Connection DN8 1⁄4"Connection DN10 3 ⁄8"Lenght x height 143 mm x 110,5 mmOperating pressure PN 10Max. temperature 65 °CApprovalsDVGWNFOther approvals in progress