Great faith in Södra Timber

Great faith in Södra Timber

Great faith in Södra Timber

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

environment awareness<br />

attracts customers<br />

AD-Trä supplies customers all<br />

round Europe with wooden<br />

packag<strong>in</strong>g. The company competes<br />

successfully by adopt<strong>in</strong>g<br />

an environmental approach.<br />

pages 12–13<br />

Theme<br />

expanded range<br />

People are often time poor<br />

and the trend is for more<br />

ready f<strong>in</strong>ished products.<br />

<strong>Södra</strong> <strong>Timber</strong> now offers<br />

ready primed cladd<strong>in</strong>g<br />

panels. page 18<br />

<strong>Timber</strong>!<br />

A publicAtion from SödrA timber<br />

environment<br />

Stronger beams<br />

A new and better method of<br />

wet glu<strong>in</strong>g wooden beams<br />

is be<strong>in</strong>g developed at Växjö<br />

University <strong>in</strong> partnership with<br />

<strong>Södra</strong> <strong>Timber</strong> and others.<br />

pages 22–23<br />

#1<br />

2008

Contents #1 2008<br />

4–10<br />

Theme environment.<br />

19<br />

Surface treated panels<br />

popular.<br />

2 <strong>Timber</strong>!<br />

20<br />

11 New plant converts plane<br />

shav<strong>in</strong>gs <strong>in</strong>to pellets<br />

<strong>Södra</strong>Smart makes life<br />

easier.<br />

16 <strong>Södra</strong> <strong>Timber</strong> scores high on customer<br />

satisfaction<br />

16 <strong>Södra</strong> <strong>Timber</strong> opens new distribution<br />

centre<br />

22 Positive experiences from build<strong>in</strong>g<br />

large blocks <strong>in</strong> timber<br />

<strong>Timber</strong>! is a biannual magaz<strong>in</strong>e from <strong>Södra</strong> <strong>Timber</strong>.<br />

ediTorial sTaff Lars Edqvist, Åsa Wernersson and<br />

Alexander Åhréus<br />

graphic design Giv Akt AB, Växjö<br />

pr<strong>in</strong>T<strong>in</strong>g Växjö Offset, Växjö<br />

paper Munken Polar 120 g<br />

address <strong>Södra</strong> <strong>Timber</strong>, Skogsudden, SE-351 89 Växjö,<br />

Sweden<br />

responsible publisher Andreas Jonasson<br />

södra <strong>Timber</strong> produces sawn and planed wood<br />

products, primarily construction timber, at ten sawmills <strong>in</strong><br />

southern Sweden. All sawmills are specialised <strong>in</strong> terms of<br />

range and raw materials to optimise efficiency. Total annual<br />

production is more than 1.8 million cubic metres of sawn<br />

and planed timber products.<br />

<strong>Södra</strong> <strong>Timber</strong>’s ma<strong>in</strong> customers are the build<strong>in</strong>g materials<br />

trade and the construction-related timber <strong>in</strong>dustry.<br />

Key markets are Scand<strong>in</strong>avia, <strong>Great</strong> Brita<strong>in</strong>, Germany, the<br />

Netherlands, USA and Japan.<br />

Raw materials for all wood products from <strong>Södra</strong> <strong>Timber</strong><br />

are certified <strong>in</strong> accordance with Pan European Forest<br />

Certification.<br />

södra <strong>Timber</strong> is part of the <strong>Södra</strong> group. The Group<br />

has four other bus<strong>in</strong>ess areas <strong>in</strong> addition to the sawmill<br />

operation:<br />

• <strong>Södra</strong> Skog which supplies <strong>Södra</strong> mills with forest raw<br />

material<br />

• <strong>Södra</strong> Cell which is the world’s second largest producer<br />

of market pulp<br />

• Gapro which is one of Scand<strong>in</strong>avia’s lead<strong>in</strong>g producers of<br />

<strong>in</strong>terior wood products<br />

• <strong>Södra</strong> V<strong>in</strong>dkraft<br />

read more on www.sodra.com<br />

Bill<strong>in</strong>gsfors<br />

Värö<br />

Traryd<br />

Unnefors<br />

Växjö<br />

K<strong>in</strong>da<br />

Ramkvilla<br />

Långasjö<br />

Stockholm<br />

Åtvidaberg<br />

Mönsterås<br />

Orrefors<br />

Torsås

<strong>Timber</strong> – an excellent<br />

material <strong>in</strong> many ways<br />

<strong>Timber</strong> has fantastic properties <strong>in</strong> many ways. It is easy to work and build<br />

with, both as a construction material and for <strong>in</strong>terior fixtures and fitt<strong>in</strong>gs. It is<br />

also an ideal outdoor build<strong>in</strong>g material for gardens, fenc<strong>in</strong>g and deck<strong>in</strong>g.<br />

Peter Nilsson,<br />

President of <strong>Södra</strong><br />

<strong>Timber</strong>.<br />

<strong>Timber</strong> works well <strong>in</strong> professional<br />

construction while enthusiastic<br />

amateur DIYers can also<br />

obta<strong>in</strong> good results when us<strong>in</strong>g<br />

timber <strong>in</strong> various projects <strong>in</strong> the<br />

home.<br />

<strong>Timber</strong> also has very good<br />

qualities when we look at various<br />

environmental aspects. <strong>Timber</strong> is<br />

relatively efficient <strong>in</strong> terms of its<br />

low energy requirements. What’s<br />

more, grow<strong>in</strong>g trees lock <strong>in</strong> carbon<br />

dioxide which means build<strong>in</strong>g with<br />

timber is a means of stor<strong>in</strong>g carbon<br />

and <strong>in</strong> so do<strong>in</strong>g, helps reduce<br />

carbon dioxide <strong>in</strong> the atmosphere.<br />

With the recently resolved new EU<br />

Directive we are conv<strong>in</strong>ced that the<br />

use of timber <strong>in</strong> construction will<br />

<strong>in</strong>crease.<br />

meet<strong>in</strong>g the targets set by the<br />

EU on reduc<strong>in</strong>g carbon dioxide<br />

emissions will require the efficient<br />

use and usage of forest resources<br />

and here timber as a build<strong>in</strong>g material<br />

has a natural place.<br />

right now there is a surplus of<br />

timber products on the market and<br />

associated fall<strong>in</strong>g prices. However<br />

we believe this will be relatively<br />

temporary and that demand will<br />

start exceed<strong>in</strong>g supply <strong>in</strong> the near<br />

future.<br />

We are conv<strong>in</strong>ced our <strong>in</strong>dustry<br />

has a very bright future. Yet we<br />

need to ma<strong>in</strong>ta<strong>in</strong> a high tempo<br />

when it comes to cont<strong>in</strong>u<strong>in</strong>g to<br />

develop timber as a construction<br />

The properties of timber make it excellent to use <strong>in</strong><br />

numerous different contexts – by professionals and<br />

amateurs alike.<br />

material and various logistics solutions. Not<br />

least, we need to develop timber <strong>in</strong> comb<strong>in</strong>ation<br />

with other materials.<br />

We look forward to our cont<strong>in</strong>ued growth <strong>in</strong><br />

partnership with you our customer.<br />

<strong>Timber</strong>! 3

››<br />

Leif Gustavsson is the lead<strong>in</strong>g expert <strong>in</strong> Sweden<br />

on research <strong>in</strong>to the impact different construction<br />

materials have on the environment. He is Professor<br />

of Eco Technology and Environment Science at Mid<br />

Sweden University <strong>in</strong> Östersund.<br />

“Net emissions of carbon dioxide are lower when<br />

us<strong>in</strong>g timber <strong>in</strong> hous<strong>in</strong>g construction. And to ga<strong>in</strong> the<br />

full benefits of a lower carbon footpr<strong>in</strong>t with timber, it<br />

is also important to replace fossil fuels with wood waste<br />

from forestry fell<strong>in</strong>g and timber process<strong>in</strong>g,” he says.<br />

Four storey house<br />

In research<strong>in</strong>g the carbon dioxide equation <strong>in</strong> hous<strong>in</strong>g<br />

construction Gustavsson and his team have studied a<br />

four storey block with 16 apartments and 1,190 square<br />

metres of liv<strong>in</strong>g space. They used an actual timber apartment<br />

block at Välludden <strong>in</strong> Växjö, <strong>in</strong> the south of Sweden.<br />

They compared this with a hypothetical build<strong>in</strong>g <strong>in</strong><br />

concrete of identical size and function.<br />

There are four reasons why us<strong>in</strong>g timber has a<br />

smaller carbon footpr<strong>in</strong>t than the equivalent structure <strong>in</strong><br />

concrete:<br />

• Manufactur<strong>in</strong>g timber products requires less primary<br />

energy than produc<strong>in</strong>g concrete.<br />

• Waste wood can replace fossil fuels. Wood waste from<br />

fell<strong>in</strong>g, timber process<strong>in</strong>g and demolish<strong>in</strong>g hous<strong>in</strong>g<br />

can be used for energy purposes.<br />

• Cement production entails substantial emissions of<br />

carbon dioxide <strong>in</strong> the manufactur<strong>in</strong>g process through<br />

calc<strong>in</strong>ation. However concrete absorbs carbon dioxide<br />

via carbonisation as it weathers.<br />

• Carbon is stored <strong>in</strong> the timber frame for the entire<br />

lifetime of the build<strong>in</strong>g. This is a temporary ga<strong>in</strong>, but if<br />

more timber houses are built, these would hold more<br />

carbon.<br />

Clear difference<br />

Altogether, the calculations <strong>in</strong>dicate a clear difference<br />

<strong>in</strong> favour of timber hous<strong>in</strong>g. And this difference can be<br />

4 <strong>Timber</strong>!<br />

Theme: environment<br />

Lower carbon dioxide<br />

when build<strong>in</strong>g <strong>in</strong> timber<br />

Construct<strong>in</strong>g hous<strong>in</strong>g <strong>in</strong> timber rather than concrete is good for<br />

the environment.<br />

”We have studied the carbon dioxide emissions produced <strong>in</strong><br />

build<strong>in</strong>g an apartment block <strong>in</strong> timber compared with the correspond<strong>in</strong>g<br />

concrete framed build<strong>in</strong>g,” says Professor Leif Gustavsson.<br />

Build<strong>in</strong>g hous<strong>in</strong>g <strong>in</strong> timber rather than concrete means substantially lower carbon dioxide<br />

emissions.<br />

expressed <strong>in</strong> very specific terms: A one<br />

bedroom apartment with 72 square<br />

metres of floor space would generate<br />

11–15 tons less carbon dioxide emissions<br />

than the correspond<strong>in</strong>g apartment<br />

<strong>in</strong> a concrete structure.<br />

By multiply<strong>in</strong>g the number of<br />

apartments <strong>in</strong> apartment blocks be<strong>in</strong>g<br />

built <strong>in</strong> Sweden, we can obta<strong>in</strong><br />

a very rough estimate of the carbon<br />

dioxide ga<strong>in</strong>s that can be achieved by<br />

construct<strong>in</strong>g hous<strong>in</strong>g <strong>in</strong> timber rather<br />

than concrete.<br />

Today, timber framed apartment

emissions<br />

blocks are primarily be<strong>in</strong>g built<br />

<strong>in</strong> North America. It is clear that<br />

the construction <strong>in</strong>dustry can do<br />

a great deal to help on climate<br />

change.<br />

Is it not more expensive to<br />

build large timber frame hous<strong>in</strong>g<br />

compared to the concrete<br />

equivalent?<br />

“No, the construction costs<br />

for the block at Välludden came<br />

to SEK 19.1 million <strong>in</strong> 2004 values.<br />

An estimate of the production<br />

costs for a correspond<strong>in</strong>g<br />

concrete build<strong>in</strong>g po<strong>in</strong>ts to a<br />

cost of SEK 19.9 million. Which<br />

means it is possible to help the<br />

environment and save money,”<br />

says Gustavsson.<br />

However construction costs<br />

will vary depend<strong>in</strong>g on local<br />

circumstances and sometimes it<br />

is cheaper to use concrete.<br />

The concrete hous<strong>in</strong>g<br />

<strong>in</strong>dustry would argue that you<br />

have to take the whole life cycle<br />

of the house <strong>in</strong>to consideration,<br />

not just the construction phase.<br />

“We have done this. Our<br />

f<strong>in</strong>d<strong>in</strong>gs are fully comparable<br />

over the entire life cycle of the<br />

hous<strong>in</strong>g. We have also varied a<br />

number of parameters that affect<br />

the results, such as transport<br />

distances, type of cement, ballast<br />

material and carbonisation. We<br />

get similar results even when we<br />

factor <strong>in</strong> these k<strong>in</strong>ds of uncerta<strong>in</strong>ties,”<br />

claims Gustavsson.<br />

They have assumed that<br />

concrete and timber hous<strong>in</strong>g<br />

will both last 100 years. One<br />

factor that can affect lifespan<br />

is flexibility, or the possibility<br />

of chang<strong>in</strong>g the build<strong>in</strong>g<br />

usage and layout. <strong>Timber</strong><br />

offers advantages here too as a<br />

build<strong>in</strong>g material. It is easier to<br />

extend and change layouts <strong>in</strong><br />

timber frame apartment blocks<br />

compared with the concrete<br />

alternative.<br />

Leif Gustavsson is however<br />

also critical of the timber hous<strong>in</strong>g<br />

at Välludden. More could<br />

have been done <strong>in</strong> terms of<br />

energy efficiency.<br />

“There is every reason to use<br />

the knowledge that is available<br />

to construct good, highly energy<br />

efficient hous<strong>in</strong>g. If we factor<br />

<strong>in</strong> the effects of construct<strong>in</strong>g<br />

very energy efficient hous<strong>in</strong>g<br />

<strong>in</strong> timber that is heated by<br />

district heat<strong>in</strong>g, we can create<br />

new dwell<strong>in</strong>gs with a very good<br />

environmental performance.<br />

Professor Gustavsson feels this<br />

is a challenge that offers tremendous<br />

commercial potential for<br />

the Swedish timber <strong>in</strong>dustry.<br />

TexT: LARS EdqVIST<br />

PhoTo: TOMMy ANdERSSON<br />

illuSTraTioN: FREdRIKA OTTOSSON<br />

Professor leif Gustavsson’s research<br />

demonstrates that timber hous<strong>in</strong>g<br />

is better for the environment than<br />

concrete hous<strong>in</strong>g.<br />

<strong>Timber</strong>! 5

6 <strong>Timber</strong>!<br />

Theme: environment<br />

Environment th<strong>in</strong>k<strong>in</strong>g<br />

<strong>Södra</strong> <strong>Timber</strong>’s environment work starts <strong>in</strong> the forest.<br />

The environment is taken <strong>in</strong>to account at every stage,<br />

from the plant<strong>in</strong>g of sapl<strong>in</strong>gs to fell<strong>in</strong>g mature trees.<br />

Let us take you on a journey to the places where <strong>Södra</strong><br />

<strong>Timber</strong> gets its raw materials, like this forest outside<br />

Växjö <strong>in</strong> the south of Sweden. How do you actually conserve<br />

nature when you fell trees?<br />

››<br />

Production manager Nils Blomkvist is<br />

stand<strong>in</strong>g <strong>in</strong> a little pool of water and<br />

po<strong>in</strong>ts to a tall birch stump. We are at the fell<strong>in</strong>g<br />

place just north of Åseda.<br />

“This is a good example of a site where previous<br />

fell<strong>in</strong>g work did not taken <strong>in</strong>to account any<br />

particular concern for nature conservation. But<br />

we have now left a clump of birches that, together<br />

with the boggy ground, can provide a f<strong>in</strong>e home<br />

for local flora and fauna <strong>in</strong> the area,” says Blomkvist<br />

at the Norra Värends forestry area.<br />

Green driv<strong>in</strong>g licence<br />

Contractor and mach<strong>in</strong>ery operator Ve<strong>in</strong>e<br />

L<strong>in</strong>dqvist has a green driv<strong>in</strong>g licence. This means<br />

for <strong>in</strong>stance, that he appreciates the most important<br />

motives for environment protection and the<br />

preservation of different species.<br />

“These days this comes as naturally as breath<strong>in</strong>g.<br />

After all, we have been do<strong>in</strong>g this for years<br />

now,” says L<strong>in</strong>dqvist.<br />

When you are aware of what value this can<br />

offer, you also start th<strong>in</strong>k<strong>in</strong>g about what you can<br />

“We take the environment <strong>in</strong>to<br />

account at every stage of forestry,”<br />

expla<strong>in</strong>s Nils Blomkvist, production<br />

manager.<br />

The rowan tree <strong>in</strong> the<br />

middle of the clear<strong>in</strong>g<br />

will never be cut down.<br />

it can produce berries<br />

for birds <strong>in</strong> the forest for<br />

many years to come.<br />

do to take nature <strong>in</strong>to account. This can vary from<br />

place to place.<br />

At first, many landowners and lumberjacks<br />

were probably aga<strong>in</strong>st leav<strong>in</strong>g high stumps, dead<br />

trees and deciduous trees. It went aga<strong>in</strong>st the<br />

gra<strong>in</strong> as it were, not to clear everyth<strong>in</strong>g when fell<strong>in</strong>g<br />

so the site looked neat and tidy afterwards and<br />

prepar<strong>in</strong>g the ground for plant<strong>in</strong>g could then be<br />

done rationally.<br />

“Today it feels more natural with conservation,<br />

and I have no problems with this at all. Quite the<br />

reverse, I feel good when I th<strong>in</strong>k about the th<strong>in</strong>gs I<br />

am do<strong>in</strong>g on behalf of nature,” says L<strong>in</strong>dqvist.<br />

“I also feel most landowners agree with preserv<strong>in</strong>g<br />

biological diversity. Although at the same<br />

time I must also ensure that each landowner gets<br />

the best possible economic return.”<br />

That landowners are show<strong>in</strong>g a greater <strong>in</strong>terest<br />

<strong>in</strong> the environment is someth<strong>in</strong>g that area<br />

<strong>in</strong>spector Jörgen Filipsson has also noticed. His job<br />

<strong>in</strong>cludes visit<strong>in</strong>g landowners and agree<strong>in</strong>g fell<strong>in</strong>g<br />

contracts with them.<br />

“We only do green forestry plann<strong>in</strong>g today<br />

area <strong>in</strong>spector Jörgen Filipsson and contractor<br />

Ve<strong>in</strong>e l<strong>in</strong>dqvist survey the fell<strong>in</strong>g site. Which trees<br />

should we spare and which should we leave as<br />

high stumps?<br />

and the feedback from landowners<br />

is entirely positive,” says<br />

Filipsson.<br />

Forestry plann<strong>in</strong>g with targets<br />

for both timber production<br />

and nature conservation is an<br />

excellent plann<strong>in</strong>g tool.<br />

In black and white<br />

Filipsson feels that landowners<br />

with green forestry plans are<br />

proud when green plans have<br />

been established.<br />

“Once the plan has been<br />

established, the landowner has<br />

it <strong>in</strong> black and white which<br />

parts of his property are classed<br />

as be<strong>in</strong>g of great natural value.

at every stage<br />

“This wet area with sp<strong>in</strong>dly birches would not have been preserved if felled ten years ago. Now we have the opportunity to<br />

develop biological diversity <strong>in</strong> conserv<strong>in</strong>g it,” says production manager Nils Blomkvist.<br />

This can apply to e.g. “that f<strong>in</strong>e oak rise, or “this<br />

wonderful birch grove close to the forest mere”.<br />

These k<strong>in</strong>ds of th<strong>in</strong>gs often give the landowner a<br />

sense of pride,” says Filipsson.<br />

“There is also another aspect to this issue,” says<br />

Nils Blomkvist “which is that a green forestry plan<br />

is also a powerful document <strong>in</strong> f<strong>in</strong>ancial terms. The<br />

environment is money, not least <strong>in</strong> the years to come<br />

when it will have an ever <strong>in</strong>creas<strong>in</strong>g importance.”<br />

This k<strong>in</strong>d of f<strong>in</strong>ancial opportunity already<br />

exists for landowners today. PEFC certification is<br />

already available for develop<strong>in</strong>g susta<strong>in</strong>able private<br />

forestry with a good balance between forest<br />

production, environment and social <strong>in</strong>terests.<br />

Approved landowners that are PEFC certified<br />

by <strong>Södra</strong> ga<strong>in</strong> a higher settlement price for their<br />

forests. <strong>Södra</strong> <strong>Timber</strong> will deliver PEFC-certified<br />

timber to clients upon request.<br />

The great storms Gudrun and Per changed<br />

the landscape <strong>in</strong> these parts. Many of the earlier<br />

forestry plans became redundant because of these<br />

storms.<br />

“Unfortunately we have not had time to<br />

establish new green forestry plans as fast as we<br />

would like. But we hope to catch up. Right now<br />

there is about a one-year wait <strong>in</strong> our area,” says<br />

Blomkvist.<br />

Back at the fell<strong>in</strong>g place, Jörgen, Nils and Ve<strong>in</strong>e<br />

are look<strong>in</strong>g at the rowan tree that Ve<strong>in</strong>e spared<br />

from the fell<strong>in</strong>g.<br />

“Ten years ago we would never have saved a<br />

tree like this. Now it will be an eternal tree that<br />

will grow for many years and whose berries will<br />

be good food for the birds around here for a long<br />

time,” says Blomkvist.<br />

TexT ANd PhoToS: STEFAN GUSTAVSSON<br />

Factsheet<br />

Green forestry plan<br />

• A green forestry plan conta<strong>in</strong>s<br />

detailed <strong>in</strong>formation on a specific<br />

forest <strong>in</strong> a specific area. The plan<br />

should <strong>in</strong>clude advice on how<br />

the forest is to be managed to<br />

achieve a high yield allied to<br />

sound environment practice. The<br />

difference between this and early<br />

forestry plans is that it <strong>in</strong>cludes a<br />

nature conservation perspective.<br />

PeFC<br />

• PEFC stands for Programme for<br />

the Endorsement of Forest Certification<br />

Schemes. PEFC has been<br />

created to ensure the susta<strong>in</strong>able<br />

use of forests worldwide. <strong>Södra</strong><br />

jo<strong>in</strong>ed PEFC ten years ago. This<br />

means for <strong>in</strong>stance, that <strong>Södra</strong><br />

members can certify their property<br />

with <strong>Södra</strong> and thereby confirm<br />

they wish to pursue susta<strong>in</strong>able<br />

forestry. Certification has three<br />

strands, timber production, the<br />

environment and social <strong>in</strong>terests.<br />

Certification also assures buyers<br />

of timber and paper products that<br />

what they are purchas<strong>in</strong>g supports<br />

susta<strong>in</strong>able forestry.<br />

Green driv<strong>in</strong>g licence<br />

• The green driv<strong>in</strong>g licence was<br />

<strong>in</strong>troduced ten years ago to educate<br />

forestry workers on the most<br />

important motives for nature<br />

preservation and on important<br />

biological processes. Licence holders<br />

should be able to recognise<br />

different k<strong>in</strong>ds of nature of high<br />

value and possess a fundamental<br />

understand<strong>in</strong>g of cultural environment<br />

conservation <strong>in</strong> forests.<br />

In so do<strong>in</strong>g, they will then be<br />

able to make the correct nature<br />

preservation decisions. Everyone<br />

who works with <strong>Södra</strong> forests is<br />

required to have a green driv<strong>in</strong>g<br />

licence. This licence also entitles<br />

holders to work <strong>in</strong> PEFC certified<br />

forest properties.<br />

<strong>Timber</strong>! 7

8 <strong>Timber</strong>!<br />

Theme: environment<br />

Active efforts to reduce<br />

our carbon footpr<strong>in</strong>t<br />

<strong>Södra</strong> is actively engaged<br />

<strong>in</strong> reduc<strong>in</strong>g the<br />

impact of transport on<br />

the surround<strong>in</strong>g environment.<br />

One way is<br />

to m<strong>in</strong>imise driv<strong>in</strong>g<br />

empty trucks, which is<br />

achieved via so called<br />

return transport. Another<br />

way is to optimise<br />

and reduce fuel<br />

consumption.<br />

“Here we always use<br />

rail transport for longer<br />

distances and large volumes,”<br />

says says Göran<br />

Edvardsson, transport<br />

buyer at <strong>Södra</strong>.<br />

››<br />

Transport forms a large<br />

part of <strong>Södra</strong>’s operations.<br />

<strong>Timber</strong> lorries collect felled trees <strong>in</strong><br />

the forest, lorries, ships and tra<strong>in</strong>s<br />

delivery pulp, timber products and<br />

<strong>in</strong>terior wood products to customers<br />

all round the world. Transport<br />

is quite simply a necessity for<br />

<strong>Södra</strong>’s very existence. Yet transport<br />

has an environmental impact.<br />

Emissions from road traffic are<br />

<strong>Södra</strong> always uses rail for long distance shipments and large volumes.<br />

the biggest s<strong>in</strong>gle source of carbon dioxide<br />

emissions <strong>in</strong> Sweden.<br />

Various different ways<br />

<strong>Södra</strong> is work<strong>in</strong>g on several fronts to m<strong>in</strong>imise<br />

its carbon footpr<strong>in</strong>t.<br />

“One way is to m<strong>in</strong>imise driv<strong>in</strong>g empty<br />

lorries, by, for <strong>in</strong>stance, sign<strong>in</strong>g long-term<br />

agreements that offer hauliers opportunities<br />

to build up flows <strong>in</strong> the opposite direction to<br />

dest<strong>in</strong>ations close to <strong>Södra</strong> saw mills. We also

<strong>Södra</strong> is implement<strong>in</strong>g a range of measures and is <strong>in</strong>volved <strong>in</strong> several projects designed to reduce the environmental impact of transport <strong>in</strong> various ways.<br />

Göran edvardsson is<br />

a transport buyer at<br />

<strong>Södra</strong>.<br />

try to exchange timber<br />

with other companies,<br />

ma<strong>in</strong>ly pulp timber<br />

and saw mill chips, so<br />

the timber does not<br />

have to be transported<br />

long distances.<br />

Where possible we<br />

always use rail,” says<br />

Edvardsson.<br />

<strong>Södra</strong> <strong>Timber</strong><br />

shipments of timber<br />

products to The<br />

Netherlands are one<br />

such example. The timber is sent by road<br />

from <strong>Södra</strong> saw mills to Älmhult where the<br />

trailer is lifted onto the railway. Every day, a<br />

tra<strong>in</strong> leaves Älmhult for Herne <strong>in</strong> Germany<br />

close to the Dutch border, where the haulier<br />

Van Dieren Martitime BV has a term<strong>in</strong>al.<br />

The trailers are then transferred to lorries<br />

and shipped to the customer.<br />

“We send 3,500 trailers to The Netherlands<br />

each year. 2,500 of these go by rail.<br />

Each shipment saves 850 km on the roads.<br />

This means we reduce our ‘road miles’ by<br />

a total of over 2,000,000 km and with it our<br />

emissions by 1.2 tons of carbon dioxide,”<br />

adds Edvardsson.<br />

Around 40 percent of <strong>Södra</strong> <strong>Timber</strong> shipments<br />

go by boat.<br />

“A large proportion of this sea freight<br />

goes by shipp<strong>in</strong>g l<strong>in</strong>e where we are notified<br />

of the shippers available. However when we<br />

negotiate shipp<strong>in</strong>g contracts, we ensure that<br />

our suppliers comply with legal requirements<br />

and ask questions about the environment<br />

and quality, such as what oils are<br />

used,” says Edvardsson.<br />

<strong>Södra</strong> was also the first company <strong>in</strong> the<br />

world to fits its three long-term chartered<br />

merchant ships with catalytic converters.<br />

This reduced nitrogen oxide emissions by 95<br />

percent. S<strong>in</strong>ce 1997 the ships have also run<br />

on low sulphur oil, which means 70 percent<br />

lower sulphur emissions. They were the first<br />

ever vessels to be certified to the German<br />

Blue Angel environment label, which is<br />

comparable with the Nordic Swan mark.<br />

Tra<strong>in</strong>ed drivers<br />

<strong>Södra</strong> is also actively engaged <strong>in</strong> optimis<strong>in</strong>g<br />

fuel consumption. This is done with the<br />

aid of computerised logistics plann<strong>in</strong>g and<br />

fuel efficient vehicles. Driv<strong>in</strong>g <strong>in</strong> a more<br />

environment friendly way is another means<br />

of reduc<strong>in</strong>g emissions from road transport<br />

and someth<strong>in</strong>g <strong>Södra</strong> encourages.<br />

“We have tra<strong>in</strong>ed our own drivers <strong>in</strong><br />

”Heavy Eco Driv<strong>in</strong>g”. By driv<strong>in</strong>g more gently<br />

they reduce their fuel consumption.<br />

In cooperation with the Swedish Road<br />

Adm<strong>in</strong>istration and other companies with<br />

transport needs, <strong>Södra</strong> is a member of the<br />

Forum for Susta<strong>in</strong>able Transport project that<br />

seeks to make road transport safer and more<br />

environment friendly. The th<strong>in</strong>k<strong>in</strong>g is that <strong>in</strong><br />

commission<strong>in</strong>g transport, <strong>Södra</strong> should take<br />

responsibility for and make demands on its<br />

suppliers with regard to the development of<br />

susta<strong>in</strong>able transport.<br />

In order to further reduce its carbon<br />

footpr<strong>in</strong>t <strong>in</strong> the long-term, <strong>Södra</strong> is also<br />

<strong>in</strong>volved <strong>in</strong> several research projects on<br />

alternative fuels.<br />

<strong>Södra</strong>’s own haulage company is a good<br />

example of show<strong>in</strong>g it is possible to have a<br />

modern vehicle fleet with a low average age<br />

of just 2.4 years. Modern eng<strong>in</strong>es give off<br />

lower emissions.<br />

“We specify that all vehicles that operate<br />

on our behalf must run on bio diesel, use<br />

biodegradable hydraulic oil and have HA<br />

oil free tyres,” says Edvardsson.<br />

TexT: ÅSA WERNERSSON<br />

PhoToS: VAN dIEREN MARTITIME<br />

ANd ANdREAS LINdhOLM<br />

<strong>Timber</strong>! 9

10 <strong>Timber</strong>!<br />

Theme: environment<br />

Well-managed Swedish forests<br />

slow the greenhouse effect<br />

If half the world’s forests were managed like Swedish forests, we could<br />

counter the entire greenhouse effect. For carbon could then be locked<br />

<strong>in</strong>to an <strong>in</strong>creas<strong>in</strong>g stock of timber <strong>in</strong>stead of be<strong>in</strong>g given off <strong>in</strong>to the<br />

atmosphere as carbon dioxide. Achiev<strong>in</strong>g this would require significant<br />

<strong>in</strong>vestments, forestry management, political will and know-how.<br />

››<br />

Göran Örlander Head of<br />

Forestry Management at<br />

<strong>Södra</strong> and project leader Åsa Forss of<br />

the R&D department have analysed<br />

the significance of forests <strong>in</strong> reduc<strong>in</strong>g<br />

emissions of carbon dioxide <strong>in</strong>to the<br />

atmosphere. An estimated 7 billion<br />

tons of carbon are emitted each<br />

year from the burn<strong>in</strong>g of fossil fuels,<br />

cement production and deforest<strong>in</strong>g.<br />

Around four billion tons of this<br />

reaches the atmosphere annually. This<br />

raises its carbon dioxide content by<br />

over 0.5 percent a year.<br />

Big rise<br />

The ability of Swedish trees to capture<br />

carbon dioxide has grown over the<br />

past century.<br />

“The Swedish model for manag<strong>in</strong>g<br />

forests has enabled us to <strong>in</strong>crease forest<br />

growth by over one percent a year,”<br />

say Örlander and Forss who add<br />

“Around four billion hectares of<br />

the earth are covered by forests. Half<br />

of these could be managed <strong>in</strong> l<strong>in</strong>e<br />

with the Swedish model. If we could<br />

achieve a one percent growth there<br />

too, this would capture almost two<br />

billion tons of carbon a year.<br />

Every year, seven million hectares<br />

of forests are chopped down.<br />

Forests correspond<strong>in</strong>g to one third of<br />

Sweden’s forested area disappear each<br />

year. The situation is worst <strong>in</strong> South<br />

East Asia where almost one percent of<br />

forestland has disappeared every year<br />

<strong>in</strong> recent decades.<br />

Large scale <strong>in</strong>sect <strong>in</strong>festation,<br />

microbial attacks and extensive forest<br />

fires are a very big threat to the<br />

world’s forests. A large proportion of<br />

the 100 million hectares of forest damaged<br />

each year could have survived<br />

if action had been taken at an early<br />

stage.<br />

All preventative measures cost<br />

substantially less that the damage that<br />

would otherwise result.<br />

“If we could halt these negative<br />

trends of deforestation, damage and<br />

poorly managed forests, we could<br />

capture four million tons of carbon<br />

a year. If this could be done today, it<br />

would mean that the <strong>in</strong>crease <strong>in</strong> carbon<br />

dioxide <strong>in</strong> the atmosphere would<br />

be reduced,” says Örlander.<br />

However, it would take a further<br />

20–30 years before such measures had<br />

such a large effect that the rise could<br />

be stopped, based on the current level<br />

of carbon dioxide emissions.<br />

“The greatest environment benefit<br />

that forestry can offer <strong>in</strong> the long-term<br />

would be to produce renewable material<br />

and energy. We could then replace<br />

fossil fuels and materials that generate<br />

large emissions of carbon dioxide,<br />

such as cement, steel and alum<strong>in</strong>ium,”<br />

says Forss.<br />

“By us<strong>in</strong>g biofuels from forests<br />

the fossil raw materials could rema<strong>in</strong><br />

<strong>in</strong> the ground and be prevented from<br />

contribut<strong>in</strong>g to climate change. When<br />

we manufacture timber products from<br />

timber, this carbon dioxide will cont<strong>in</strong>ue<br />

to be locked <strong>in</strong>to our build<strong>in</strong>gs<br />

and not released <strong>in</strong>to the atmosphere<br />

for a very long time.<br />

Both Göran Örlander and Åsa<br />

Forss say it will require substantial<br />

<strong>in</strong>vestments to succeed. Which means<br />

the forestry <strong>in</strong>dustry must recognise<br />

the problem and make serious efforts<br />

to <strong>in</strong>crease usage of forestry raw materials<br />

and cut energy wastefulness.<br />

TexT: SVEN-ERIK PETERSSON<br />

PhoTo: ANdREAS LINdhOLM<br />

“<strong>in</strong>creas<strong>in</strong>g forest growth around the world could enable large quantities of<br />

carbon dioxide to be locked <strong>in</strong>to trees,” say Åsa Forss and Göran Örlander.

Långasjö now supply<strong>in</strong>g pellets<br />

The new pellet works at <strong>Södra</strong> <strong>Timber</strong>’s<br />

Långasjö saw mill makes pellets<br />

from plan<strong>in</strong>g shav<strong>in</strong>gs.<br />

››<br />

“This is enabl<strong>in</strong>g us to<br />

do our little bit on the<br />

energy and climate change issue.<br />

Pellets are a biofuel that is good<br />

for the environment. It also<br />

means less transport as pellets<br />

are more compact than loads of<br />

shav<strong>in</strong>gs, which largely consist<br />

of air, which further reduces our<br />

carbon footpr<strong>in</strong>t,” says Jonas<br />

Axelsson of <strong>Södra</strong> <strong>Timber</strong>.<br />

In December 2006 the board<br />

resolved to build a new pellet<br />

works at Långasjö.<br />

“It felt the right decision to<br />

take the next step <strong>in</strong> the process<strong>in</strong>g<br />

cha<strong>in</strong>. Pellets are an idea<br />

whose time has come, a biofuel<br />

that is good for the environment<br />

and that also saves on transport,”<br />

says Axelsson.<br />

Andritz Spout AS of Denmark<br />

was the ma<strong>in</strong> supplier.<br />

Installation began on 1 October<br />

and the works was ready for the<br />

first delivery on 14 January.<br />

“Production capacity is<br />

40,000 tons of pellets a year. The<br />

supplier guarantees the two<br />

presses can produce eight tons<br />

an hour. We reached full capacity<br />

<strong>in</strong> February,” adds Axelsson.<br />

Once the saw mill’s new<br />

plane shop is <strong>in</strong> production <strong>in</strong><br />

the first quarter of 2009, the<br />

shav<strong>in</strong>gs will go by conveyor<br />

“Pellets are an<br />

idea whose time<br />

has come as a<br />

biofuel that is<br />

good for the environment<br />

and<br />

also saves on<br />

transport,” says<br />

Jonas axelsson<br />

of <strong>Södra</strong> <strong>Timber</strong>.<br />

straight from the plane shop to<br />

the pellet works.<br />

“Until then we have to take<br />

the shav<strong>in</strong>gs from the exist<strong>in</strong>g<br />

plane shop to the pellet works<br />

by loader, which makes for a bit<br />

of extra work <strong>in</strong> this first year.”<br />

The pellet works is part of<br />

<strong>Södra</strong>’s eco energy drive and<br />

an example of the <strong>in</strong>creas<strong>in</strong>g<br />

importance of eco energy to the<br />

saw mill.<br />

“All energy <strong>in</strong>vestments are<br />

<strong>in</strong>terest<strong>in</strong>g. We are currently<br />

<strong>in</strong>vestigat<strong>in</strong>g the possibility of<br />

build<strong>in</strong>g pellet works at other<br />

saw mills. We are also look<strong>in</strong>g<br />

at towns where it would<br />

be possible to l<strong>in</strong>k saw mills to<br />

the district heat<strong>in</strong>g network, to<br />

convert waste heat <strong>in</strong>to energy.<br />

We are already supply<strong>in</strong>g the<br />

district heat<strong>in</strong>g networks <strong>in</strong> Kisa<br />

and Torsås,” says Axelsson.<br />

TexT: ÅSA WERNERSSON<br />

PhoToS: ÅSA WERNERSSON ANd<br />

JONAS AxELSSON<br />

<strong>Södra</strong> <strong>Timber</strong> offers CE labell<strong>in</strong>g on construction timber<br />

The EU has resolved that from 1 September<br />

2008 construction timber is to be CE<br />

labelled with<strong>in</strong> the EU.<br />

<strong>Södra</strong> <strong>Timber</strong> has adapted its operations<br />

which has <strong>in</strong>cluded an <strong>in</strong>vestment<br />

<strong>in</strong> strength sort<strong>in</strong>g equipment to comply<br />

with requirements and can therefore now<br />

offer customers CE labelled timber.<br />

Work to standardise timber prod-<br />

ucts with<strong>in</strong> the EU has been <strong>in</strong> progress<br />

for 20 years and has resulted <strong>in</strong> some<br />

forty standards. Several others are <strong>in</strong> the<br />

pipel<strong>in</strong>e.<br />

“There has been a demand for<br />

strength sorted timber for quite some<br />

time, but the EU directive will make it<br />

a legal requirement. This is positive as<br />

end users will be gett<strong>in</strong>g a well def<strong>in</strong>ed<br />

The first shipment from the new pellet works <strong>in</strong> långasjö left on 14 January.<br />

Factsheet<br />

• Total pellet production <strong>in</strong><br />

Sweden <strong>in</strong> 2007 was 1.5 tons<br />

of pellets. Production capacity<br />

is currently be<strong>in</strong>g expanded <strong>in</strong><br />

several parts of the country.<br />

• 1.5 million tons of pellets is<br />

the equivalent of 7.2 TWh. It<br />

could meet the electricity needs<br />

of over one million Swedish<br />

households.<br />

• One cubic metre of oil is the<br />

equivalent of 2.1 tons of pellets<br />

or three cubic metres.<br />

• Over 120,000 houses are<br />

heated by pellets <strong>in</strong> Sweden<br />

today.<br />

product. Which will make it easier to<br />

determ<strong>in</strong>e if a product possesses the<br />

desired properties. A new <strong>in</strong>dustry<br />

standard for products will also make it<br />

easier to compare products from different<br />

suppliers and different countries,” says<br />

Ted Wilhelmsson, Sales Director for The<br />

Netherlands.<br />

<strong>Timber</strong>! 11

Exact<strong>in</strong>g<br />

environment<br />

standards<br />

attractive for<br />

customers<br />

AD-Trä supplies wooden packag<strong>in</strong>g to companies<br />

<strong>in</strong> many parts of Europe.<br />

“We compete successfully by be<strong>in</strong>g more efficient<br />

and by liv<strong>in</strong>g up to high environment standards,”<br />

says Anders Danielsson, MD of AD-Trä.<br />

››<br />

The story of Anders Danielsson and<br />

AD-Trä is a classic tale of entrepreneurship<br />

that started on a small scale <strong>in</strong> his<br />

free time, and which has s<strong>in</strong>ce grown <strong>in</strong>to a<br />

very rational <strong>in</strong>dustry.<br />

“When I was a student <strong>in</strong> Luleå <strong>in</strong> the<br />

north of Sweden <strong>in</strong> the early 1990s, I earned<br />

money by driv<strong>in</strong>g round and collect<strong>in</strong>g surplus<br />

pallet collars and pallets from companies<br />

and deliver<strong>in</strong>g them to other companies<br />

that needed them,” he expla<strong>in</strong>s.<br />

Own manufactur<strong>in</strong>g<br />

After three years Anders term<strong>in</strong>ated his<br />

studies and moved back home to Småland<br />

<strong>in</strong> the south of Sweden to cont<strong>in</strong>ue his packag<strong>in</strong>g<br />

bus<strong>in</strong>ess. He quickly realised there<br />

were not enough used collars and pallets to<br />

meet demand and he therefore borrowed a<br />

factory on even<strong>in</strong>gs and weekends to start<br />

produc<strong>in</strong>g his own.<br />

“They then offered to sell me the equipment<br />

I was us<strong>in</strong>g at night and gave me<br />

six months to pay for them. To meet the<br />

payments I worked almost round the clock<br />

12 <strong>Timber</strong>!<br />

and moved back home with my parents. The<br />

equipment was paid for after six months<br />

and I was able to cont<strong>in</strong>ue to grow.<br />

Today, almost fifteen years later, AD-<br />

Trä is still a grow<strong>in</strong>g company with very<br />

rational production of wooden packag<strong>in</strong>g<br />

such as pallets and pallet collars. The company<br />

has customers <strong>in</strong> most of Europe and<br />

even <strong>in</strong> Ch<strong>in</strong>a.<br />

What is it that persuades e.g. companies<br />

<strong>in</strong> Spa<strong>in</strong> and Ch<strong>in</strong>a to turn to AD-Trä <strong>in</strong><br />

Växjö for its wooden packag<strong>in</strong>g needs?<br />

“S<strong>in</strong>ce the outset we have concentrated<br />

hard on be<strong>in</strong>g receptive to customer needs.<br />

Customers demand good prices, delivery<br />

when they want it, high quality and proper<br />

environmental awareness. We meet these<br />

requirements,” says Danielsson.<br />

In order to do so, AD-Trä has <strong>in</strong>vested <strong>in</strong><br />

very rational equipment, where most steps<br />

are managed by mach<strong>in</strong>e along a conveyor<br />

belt production l<strong>in</strong>e. This new equipment<br />

was supplied by Promatek of Kalmar,<br />

Sweden.<br />

“In order to work closely <strong>in</strong> further ref<strong>in</strong>-<br />

<strong>in</strong>g this equipment, AD-Trä has taken a stake<br />

<strong>in</strong> Promatek. By develop<strong>in</strong>g production<br />

equipment together, we can become even<br />

better at liv<strong>in</strong>g up to the demands of our<br />

customers,” expla<strong>in</strong>s Danielsson.<br />

<strong>Södra</strong> supplies<br />

AD-Trä only uses Swedish spruce <strong>in</strong> its<br />

products. As customers are <strong>in</strong>creas<strong>in</strong>gly<br />

us<strong>in</strong>g pallet collars for market<strong>in</strong>g purposes,<br />

it is important that the raw material is white<br />

and well planed. AD-Trä now pr<strong>in</strong>ts logos<br />

on pallet collars onl<strong>in</strong>e at a high tempo.<br />

To ensure satisfied customers, AD-Trä<br />

requires timber to be of the right quality and<br />

delivered when required.<br />

“The first four packs of pallet collar<br />

timber I bought came from <strong>Södra</strong>. S<strong>in</strong>ce<br />

then <strong>Södra</strong> has been my ma<strong>in</strong> supplier. We<br />

have a good relationship that gives me peace<br />

of m<strong>in</strong>d when it comes to both price and<br />

quality. We depend on even quality,” says<br />

Danielsson.<br />

AD-Trä gets most of its timber from<br />

<strong>Södra</strong> <strong>in</strong> Långasjö today. Anders Danielsson

Johan alvarsson, Joacim Sjöberg and Magnus angsås from <strong>Södra</strong> <strong>Timber</strong> have a good work<strong>in</strong>g relationship with anders Danielsson, MD of aD-Trä.<br />

is <strong>in</strong> contact with Anders Fransson, customer<br />

service manager at <strong>Södra</strong>, Långasjö<br />

on a weekly basis.<br />

“These days we take about three or four<br />

trucks a week. We are dependent on both<br />

large and punctual deliveries <strong>in</strong> order to<br />

keep our production l<strong>in</strong>e go<strong>in</strong>g. At the same<br />

time, we appreciate that <strong>Södra</strong> has the flexibility<br />

to enable us to order an extra delivery<br />

if required,” says Danielsson.<br />

<strong>Södra</strong>, Långasjö is a good supplier for<br />

AD-Trä from an environmental perspective,<br />

too.<br />

“They are close by, which means short<br />

transport journeys. That is not only better<br />

for the environment it also means low delivery<br />

costs,” notes Danielsson.<br />

He also stresses that he has be<strong>in</strong>g work<strong>in</strong>g<br />

closely with Magnus Angsås of <strong>Södra</strong><br />

for a long time. This helps ensure bus<strong>in</strong>ess<br />

deal<strong>in</strong>gs run smoothly.<br />

On the Swedish Board of Agriculture list<br />

The timber bought by AD-Trä is planed and<br />

KD certified, which means the timber is<br />

kiln-dried <strong>in</strong> Swedish Board of Agriculture<br />

approved kilns.<br />

“<strong>Södra</strong> are very good at plan<strong>in</strong>g, which<br />

is important for us. The timber is also dried<br />

<strong>in</strong> the correct way and KD certified. This<br />

means we are on the Swedish Board of<br />

Agriculture list of approved companies and<br />

can stamp all our products as ISPM 15 com-<br />

Factsheet / AD-Trä<br />

• Production is <strong>in</strong> Växjö, Sweden.<br />

• The company has 13 full-time employees.<br />

• In 2005 the company acquired its competitor,<br />

Steda Emballage <strong>in</strong> Hillerstorp.<br />

• Turnover <strong>in</strong> 2008 is expected to reach<br />

SEK 85 million.<br />

• In 2008 AD-Trä acquired a sharehold<strong>in</strong>g <strong>in</strong><br />

mach<strong>in</strong>ery supplier Promatek <strong>in</strong> Kalmar.<br />

• Customers <strong>in</strong> Sweden, Norway, Denmark,<br />

F<strong>in</strong>land, Germany, France, Italy, Spa<strong>in</strong> and<br />

Ch<strong>in</strong>a.<br />

• Read more at www.ad-tra.se<br />

pliant, which you have to have to export<br />

pallets and pallet collars without complications,”<br />

he adds.<br />

TexT: LARS EdKVIST<br />

PhoTo: JONAS LJUNGdAhL<br />

Read more about <strong>Södra</strong> and the packag<strong>in</strong>g<br />

<strong>in</strong>dustry on the next page.<br />

This is ISPM 15<br />

• ISPM 15 is an <strong>in</strong>ternational standard. It<br />

means the core of the timber is heated to<br />

at least 56 degrees Celsius for 30 m<strong>in</strong>utes.<br />

This heat<strong>in</strong>g is to kill any <strong>in</strong>sects that could<br />

damage the timber. In so do<strong>in</strong>g this prevents<br />

the spread of <strong>in</strong>sect pests and diseases to<br />

other countries.<br />

• To show that the timber has been heattreated<br />

<strong>in</strong> accordance with this standard, all<br />

pallets manufactured by AD-Trä are stamped<br />

as such.<br />

<strong>Timber</strong>! 13

<strong>Södra</strong> supplies 120,000 cubic metres of timber to the Swedish packag<strong>in</strong>g <strong>in</strong>dustry each<br />

year for the manufacture of pallets and pallet collars.<br />

<strong>Södra</strong> is develop<strong>in</strong>g its services<br />

to the Packag<strong>in</strong>g <strong>in</strong>dustry<br />

The packag<strong>in</strong>g <strong>in</strong>dustry is a<br />

strategic market for <strong>Södra</strong><br />

<strong>Timber</strong>.<br />

“It means we are adapt<strong>in</strong>g<br />

our services to suit our<br />

customers <strong>in</strong> this sector,”<br />

says Magnus Angsås of<br />

<strong>Södra</strong> <strong>Timber</strong>.<br />

Hav<strong>in</strong>g the packag<strong>in</strong>g <strong>in</strong>dustry as<br />

a strategic market means e.g. that<br />

<strong>Södra</strong> <strong>Timber</strong> can reserve certa<strong>in</strong><br />

volumes for this segment as early<br />

as the budget<strong>in</strong>g stage. Book<strong>in</strong>g<br />

volumes at such an early stage<br />

means the goods have been manufactured<br />

and available <strong>in</strong> stock<br />

when our customers need them.<br />

“Our customers are then able<br />

to know that they are strategically<br />

important for us and that we take a<br />

long-term approach when work<strong>in</strong>g<br />

with them. That they should<br />

view us as a secure and long-term<br />

supplier to the Swedish packag<strong>in</strong>g<br />

market irrespective of whether the<br />

market is good or bad,” says Joacim<br />

Sjöberg, <strong>Södra</strong> <strong>Timber</strong>.<br />

Today <strong>Södra</strong> <strong>Timber</strong> has over<br />

80 customers <strong>in</strong> the packag<strong>in</strong>g<br />

<strong>in</strong>dustry. Altogether, <strong>Södra</strong> supplies<br />

around 120,000 cubic metres of<br />

timber to the Swedish pack<strong>in</strong>g <strong>in</strong>dustry<br />

for the production of pallets<br />

and pallet collars.<br />

In order to become a lead<strong>in</strong>g<br />

supplier to packag<strong>in</strong>g manufacturers,<br />

<strong>Södra</strong> has <strong>in</strong>vested <strong>in</strong> develop<strong>in</strong>g<br />

services for them. What does<br />

this entail?<br />

“It means, for <strong>in</strong>stance, that<br />

we are pretty much spot on and<br />

flexible when it comes to deliveries.<br />

We have discovered that punctual<br />

deliveries are very important for<br />

14 <strong>Timber</strong>!<br />

packag<strong>in</strong>g manufacturers, and that<br />

sometimes unplanned additional<br />

deliveries are needed at short<br />

notice. We have the capacity to offer<br />

this,” says Angsås.<br />

Another element of this high<br />

level of service is that <strong>Södra</strong> also<br />

offers a large range with numerous<br />

dimensions. <strong>Södra</strong> can also offer<br />

products cut to precise sizes to customers<br />

who prefer to concentrate<br />

solely on pallet manufactur<strong>in</strong>g.<br />

Along with this high level of<br />

service, the drive to become a supplier<br />

to the packag<strong>in</strong>g <strong>in</strong>dustry also<br />

means that <strong>Södra</strong> has chosen not to<br />

be a packag<strong>in</strong>g manufacturer itself.<br />

“We do not want to compete<br />

with our customers,” says Sjöberg.<br />

The large <strong>in</strong>dustries that buy<br />

pallets and pallet collars also make<br />

high environment demands on the<br />

timber.<br />

“We have also chosen to be the<br />

leader <strong>in</strong> the environment area.<br />

Our customers can trust us to have<br />

taken the environment <strong>in</strong>to account<br />

at every stage from our own forestry<br />

to shipments to customers,”<br />

expla<strong>in</strong>s Johan Alvarsson, <strong>Södra</strong><br />

<strong>Timber</strong>.<br />

As <strong>Södra</strong> has plenty of sawmills<br />

deliveries need not be long distance<br />

either.<br />

“As a strategic market, the<br />

packag<strong>in</strong>g <strong>in</strong>dustry gives us the<br />

opportunity to become even better<br />

and a stronger supplier and at the<br />

same time it enables our customers<br />

to feel secure <strong>in</strong> the knowledge that<br />

we will stick with them through<br />

economic upturns and downturns,”<br />

says Angsås.<br />

TexT: LARS EdqVIST<br />

PhoTo: JONAS LJUNGdAhL<br />

Market und<br />

but light at<br />

The market for timber<br />

products has been turbulent<br />

for a while, but<br />

<strong>in</strong> the long term the<br />

world market looks<br />

bright, says Andreas<br />

Jonasson, Sales Director,<br />

<strong>Södra</strong> <strong>Timber</strong>.<br />

The market for timber products has been<br />

very turbulent <strong>in</strong> recent months. Supply has<br />

been exceed<strong>in</strong>g demand <strong>in</strong> Europe which<br />

has pushed prices down, while at the same<br />

time, the weak US market has reduced opportunities<br />

for the European sawn timber<br />

<strong>in</strong>dustry to export construction timber<br />

outside Europe. Six months ago I wrote<br />

that <strong>in</strong> the short term market growth will<br />

depend on when there is an upturn <strong>in</strong> the US<br />

market and how well production levels <strong>in</strong><br />

Europe can adapt. Unfortunately, the crisis<br />

has deepened <strong>in</strong> America and we cannot<br />

see any change ahead of the presidential<br />

election. However, production realignments<br />

<strong>in</strong> Europe, <strong>in</strong>clud<strong>in</strong>g Sweden, F<strong>in</strong>land and<br />

Germany, will have a stabilis<strong>in</strong>g effect on the<br />

timber products market.<br />

We expect demand for construction timber<br />

to rema<strong>in</strong> stable <strong>in</strong> Europe <strong>in</strong> 2008. While<br />

the construction cycle <strong>in</strong> Europe has been<br />

somewhat weak recently compared with the<br />

record years of 2006–2007, there cont<strong>in</strong>ues to<br />

be a high level of build<strong>in</strong>g <strong>in</strong> Europe. Build<strong>in</strong>g<br />

<strong>in</strong> Japan has picked up aga<strong>in</strong> to the level<br />

it was before the new build<strong>in</strong>g regulations<br />

were <strong>in</strong>troduced. As such, demand on the<br />

world market for timber products is at an<br />

acceptable level, if we exclude the USA.<br />

Tak<strong>in</strong>g a long-term approach to customer<br />

relationships has long been an important<br />

policy for <strong>Södra</strong> <strong>Timber</strong>. We do not th<strong>in</strong>k<br />

there is anyth<strong>in</strong>g to ga<strong>in</strong> from jump<strong>in</strong>g <strong>in</strong><br />

and out of bed with customers or markets.

er heavy pressure<br />

the end of the tunnel<br />

Over the past two years, there has been a shortage<br />

of timber products which has offered several<br />

opportunities to do more profitable bus<strong>in</strong>ess<br />

with new customers or markets, but we<br />

elected to take the long-term view and<br />

primarily sought to supply our loyal<br />

customers. We can now clearly<br />

see that we are gett<strong>in</strong>g the same<br />

long-term th<strong>in</strong>k<strong>in</strong>g back from our<br />

customers who choose to stay<br />

with <strong>Södra</strong> <strong>Timber</strong> even though<br />

several new suppliers are try<strong>in</strong>g<br />

to get a foothold with our customers.<br />

We appreciate this very<br />

much. We view our customers<br />

with<strong>in</strong> e.g. build<strong>in</strong>g suppliers,<br />

the hous<strong>in</strong>g and packag<strong>in</strong>g<br />

<strong>in</strong>dustries as strategically<br />

important to us, and where<br />

we are go<strong>in</strong>g to rema<strong>in</strong> <strong>in</strong> the<br />

long-term.<br />

<strong>in</strong> the long-term we cont<strong>in</strong>ue<br />

to rema<strong>in</strong> positive about market<br />

growth. The younger generation<br />

<strong>in</strong> the USA will have a big longterm<br />

need to build new homes.<br />

When you add <strong>in</strong> the P<strong>in</strong>e Beetle<br />

epidemic <strong>in</strong> Canada, which can<br />

eventually reduce sawn timber production<br />

<strong>in</strong> western Canada, this is bound to<br />

mean big <strong>in</strong>terest <strong>in</strong> import<strong>in</strong>g timber<br />

products from Europe. We also envisage<br />

<strong>in</strong>creas<strong>in</strong>g demand for imports <strong>in</strong> Asia,<br />

which can eventually have a big impact<br />

on the timber balance <strong>in</strong> the world.<br />

The new eu climate change targets will<br />

accelerate <strong>in</strong>vestments <strong>in</strong> the eco energy<br />

area. Eco energy <strong>in</strong>vestments are a top<br />

priority for <strong>Södra</strong> too, with 70 percent of<br />

<strong>Södra</strong>’s <strong>in</strong>vestment budget for 2008 earmarked<br />

for <strong>in</strong>vestment <strong>in</strong> eco energy such<br />

as w<strong>in</strong>d power, pellets and district heat<strong>in</strong>g.<br />

The grow<strong>in</strong>g eco energy sector will benefit<br />

the sawn timber <strong>in</strong>dustry with higher prices<br />

for by-products, although <strong>in</strong> the long-term, this<br />

could also require volumes for the eco energy<br />

area that squeezes access to certa<strong>in</strong> types of<br />

timber.<br />

ANdREAS JONASSON,<br />

Sales Director <strong>Södra</strong> <strong>Timber</strong><br />

High rise timber<br />

hous<strong>in</strong>g for Kalix<br />

◗ A high rise hous<strong>in</strong>g block <strong>in</strong> timber <strong>in</strong><br />

the centre of Kalix <strong>in</strong> the north of Sweden<br />

is at the plann<strong>in</strong>g stage. The block will<br />

conta<strong>in</strong> 20 flats.<br />

The project is a jo<strong>in</strong>t venture between<br />

several local build<strong>in</strong>g companies, Luleå<br />

University of Technology, Kalix Municipality<br />

and Västerbotten County Adm<strong>in</strong>istration<br />

Board.<br />

New arena <strong>in</strong> timber<br />

◗ In Sandviken 200 kilometres north of<br />

Stockholm an arena is be<strong>in</strong>g built for<br />

<strong>in</strong>door bandy and other sports. Instead of<br />

us<strong>in</strong>g the traditional steel, the arena is to<br />

be a glulam structure. One reason is that<br />

timber weighs much less than steel.<br />

The 92 metre long roof beams will be<br />

shipped <strong>in</strong> four sections and <strong>in</strong>stalled on<br />

site. Almost 1,200 cubic metres of glulam,<br />

or sixty lorry loads, will be used <strong>in</strong> the<br />

structure.<br />

The play<strong>in</strong>g area can be covered <strong>in</strong> ice,<br />

Astroturf and wooden floor<strong>in</strong>g. The arena<br />

will be ready for use <strong>in</strong> 2008.<br />

Eslöv looks to develop a<br />

hous<strong>in</strong>g estate <strong>in</strong> timber<br />

◗ The town of Eslöv <strong>in</strong> the south of<br />

Sweden is plann<strong>in</strong>g a hous<strong>in</strong>g estate <strong>in</strong><br />

timber. A ten-storey high gra<strong>in</strong> silo dat<strong>in</strong>g<br />

from 1917 has recently been converted<br />

<strong>in</strong>to residential hous<strong>in</strong>g. At the official<br />

open<strong>in</strong>g Eslöv local authority commissioner<br />

Cecilia L<strong>in</strong>d announced plans for<br />

a new residential neighbourhood and<br />

possibly an ideal homes exhibition 2011.<br />

She feels timber is both good for the<br />

environment and also a smart solution for<br />

construction projects.<br />

Eslöv is go<strong>in</strong>g to expand eastwards with<br />

some 1,000 new dwell<strong>in</strong>gs and the th<strong>in</strong>k<strong>in</strong>g<br />

is to comb<strong>in</strong>e this with a build<strong>in</strong>g<br />

and homes exhibition to mark the town’s<br />

centenary year 2011.<br />

Award for timber hous<strong>in</strong>g<br />

◗ A four storey timber block <strong>in</strong> Rydebäck<br />

<strong>in</strong> the south of Sweden has won an award<br />

for modern timber design excellence.<br />

Hous<strong>in</strong>g developer Derome is beh<strong>in</strong>d the<br />

block, and is now look<strong>in</strong>g to build even<br />

larger hous<strong>in</strong>g blocks <strong>in</strong> timber. The company<br />

owns land <strong>in</strong> the sought after Västa<br />

hamnen area of Malmö. The company is<br />

now plann<strong>in</strong>g a n<strong>in</strong>e storey block there.<br />

<strong>Timber</strong>! 15

A new distribution<br />

centre <strong>in</strong> Bill<strong>in</strong>gsfors<br />

<strong>Södra</strong> <strong>Timber</strong> is establish<strong>in</strong>g<br />

a distribution centre<br />

<strong>in</strong> Bill<strong>in</strong>gsfors <strong>in</strong> western<br />

Sweden. The ambition is<br />

to <strong>in</strong>crease sales to the<br />

builders merchant sector <strong>in</strong><br />

western Sweden.<br />

<strong>Södra</strong> <strong>Timber</strong>’s current distribution<br />

to this market is ma<strong>in</strong>ly <strong>in</strong> southern<br />

and south-eastern Sweden, and<br />

to enable expansion to the west of<br />

Sweden a physical base is needed.<br />

<strong>Södra</strong> <strong>Timber</strong> entered an agreement<br />

with the ARE Group <strong>in</strong> spr<strong>in</strong>g<br />

2007 to buy the closed Bill<strong>in</strong>gsfors<br />

Sågverks AB, which <strong>in</strong>cluded a<br />

50-hectare sawmill property <strong>in</strong><br />

Bill<strong>in</strong>gsfors. <strong>Södra</strong> has s<strong>in</strong>ce conducted<br />

a feasibility study regard<strong>in</strong>g<br />

the establishment of a sawmill <strong>in</strong><br />

Bill<strong>in</strong>gsfors.<br />

“It’s now clear that the area<br />

with warehouse and exist<strong>in</strong>g<br />

With effect from the year end,<br />

<strong>Södra</strong> <strong>Timber</strong> is tak<strong>in</strong>g a stake <strong>in</strong><br />

Uni4 Market<strong>in</strong>g, which markets<br />

Swedish timber goods on markets<br />

<strong>in</strong> North Africa and the Middle East.<br />

“We are acquir<strong>in</strong>g a m<strong>in</strong>ority<br />

hold<strong>in</strong>g <strong>in</strong> Uni4, <strong>in</strong> which SCA <strong>Timber</strong><br />

and Holmen <strong>Timber</strong> also have<br />

stakes,” says Peter Nilsson, MD of<br />

<strong>Södra</strong> <strong>Timber</strong>.<br />

Uni4 Market<strong>in</strong>g is the lead<strong>in</strong>g exporter of<br />

Swedish timber products to Morocco, Algeria,<br />

Egypt, Jordan, Saudi Arabia and Yemen. All<br />

these markets are characterised by young<br />

populations and relatively good growth, not<br />

least <strong>in</strong> the hous<strong>in</strong>g sector.<br />

The markets where Uni4 operates require<br />

specific expertise for sales, logistics, document<br />

handl<strong>in</strong>g and bank processes to present<br />

profitable options for Nordic manufacturers<br />

of timber products.<br />

“While we make a lot of sales on these<br />

markets, we appreciate it is very time consum<strong>in</strong>g<br />

and far away. Uni4 offers several<br />

Peter Nilsson, MD <strong>Södra</strong> <strong>Timber</strong> and Björn lagerqvist, Sales Manager<br />

for Sweden and Norway, be<strong>in</strong>g presented with flowers by<br />

Commissioner Per Jonsson, after the decision on the new distribution<br />

centre <strong>in</strong> Bill<strong>in</strong>gsfors.<br />

<strong>in</strong>frastructure is ideal for establish<strong>in</strong>g a new distribution<br />

centre. Wood products will be produced at our exist<strong>in</strong>g<br />

sawmills and transported to Bill<strong>in</strong>gsfors,” says Peter<br />

Nilsson, president of <strong>Södra</strong> <strong>Timber</strong>.<br />

The operation will be established dur<strong>in</strong>g the spr<strong>in</strong>gsummer<br />

period <strong>in</strong> read<strong>in</strong>ess for full operation <strong>in</strong> August.<br />

TexT: ÅSA WERNERSSON<br />

FoTo: ANNA NyBERG<br />

<strong>Södra</strong> <strong>Timber</strong> takes stake <strong>in</strong> Uni4<br />

16 <strong>Timber</strong>!<br />

advantages. Hav<strong>in</strong>g know-how all under one<br />

roof makes for a different k<strong>in</strong>d of cont<strong>in</strong>uity,<br />

and a better and more <strong>in</strong>tensive <strong>in</strong>terface with<br />

the market, which makes us more cost effective<br />

and more competitive,” says Nilsson.<br />

Uni4 Market<strong>in</strong>g expects to sell around<br />

300,000–350,000 cubic metres of timber products<br />

on its North African and Middle Eastern<br />

markets <strong>in</strong> 2008, with a turnover of SEK<br />

700–750 million.<br />

Chang<strong>in</strong>g job<br />

In connection with the part acquisition, <strong>Södra</strong><br />

<strong>Timber</strong>s salesman Lennart Antonsson is tak<strong>in</strong>g<br />

up a new position as Sales Director and<br />

buyer at Uni4 Market<strong>in</strong>g on 1 August.<br />

“That Lennart Antonson is jo<strong>in</strong><strong>in</strong>g Uni4<br />

Market<strong>in</strong>g feels very good. It offers us the<br />

opportunity to <strong>in</strong>troduce <strong>Södra</strong> to Uni4 Market<strong>in</strong>g<br />

<strong>in</strong> the best way, and also to take advantage<br />

of the bus<strong>in</strong>ess opportunities that arise<br />

at Uni4 <strong>in</strong> the future. Lennart knows a great<br />

deal about both these markets <strong>in</strong> North Africa<br />

and the Middle East and what opportunities<br />

<strong>Södra</strong> can offer.”<br />

<strong>Great</strong><br />

<strong>Södra</strong><br />

<strong>Södra</strong> <strong>Timber</strong><br />

has performed<br />

a wide rang<strong>in</strong>g<br />

customer survey<br />

for the very first<br />

time. It reveals<br />

that customers<br />

have great <strong>faith</strong><br />

<strong>in</strong> <strong>Södra</strong> <strong>Timber</strong><br />

and would<br />

recommend the<br />

company as a<br />

supplier. Customers<br />

are very<br />

satisfied with<br />

sales and customer<br />

service,<br />

but slightly less<br />

satisfied with<br />

deliveries.<br />

››<br />

<strong>Södra</strong> <strong>Timber</strong> wanted<br />

to f<strong>in</strong>d out what its<br />

customers thought of the<br />

company, and how they see us<br />

compared with other timber<br />

products suppliers. A random<br />

selection of large and small<br />

customers who buy regularly<br />

from us were <strong>in</strong>terviewed<br />

by phone <strong>in</strong> November. The<br />

<strong>in</strong>terviews were done <strong>in</strong> the<br />

customer’s own language. It<br />

was not just buyers that were

<strong>faith</strong> <strong>in</strong><br />

<strong>Timber</strong><br />

<strong>in</strong>terviewed, other people we <strong>in</strong>terface with,<br />

such as stock managers, were also <strong>in</strong>terviewed.<br />

Customers were given the option of<br />

rema<strong>in</strong><strong>in</strong>g anonymous but few chose to do<br />

so. 62 percent responded, which is a good<br />

result <strong>in</strong> this context.<br />

The survey was comprehensive and<br />

conta<strong>in</strong>ed a large number of questions <strong>in</strong> six<br />

ma<strong>in</strong> areas:<br />

• Deliveries<br />

• Products<br />

• Sales<br />

• Customer service<br />

• Compla<strong>in</strong>ts<br />

• <strong>Södra</strong> <strong>Timber</strong>’s image<br />

By way of summary, the survey revealed<br />

that customers are very satisfied when it<br />

comes to sales and customer service, but<br />

less so with deliveries. Confidence <strong>in</strong> <strong>Södra</strong><br />

<strong>Timber</strong> is high and many customers would<br />

recommend the company as a supplier.<br />

Act<strong>in</strong>g on the f<strong>in</strong>d<strong>in</strong>gs<br />

In order to track progress with the overall<br />

assessment of customers we have created<br />

a customer satisfaction <strong>in</strong>dex. This consists<br />

of three parts: comb<strong>in</strong>ed experience of<br />

<strong>Södra</strong> <strong>Timber</strong>, whether <strong>Södra</strong> <strong>Timber</strong> meets<br />

expectations and if the company is an ideal<br />

supplier.<br />

The <strong>in</strong>dex score was 72 <strong>in</strong> this <strong>in</strong>itial survey,<br />

which is a good result compared with<br />

other manufactur<strong>in</strong>g <strong>in</strong>dustries. As such, the<br />

survey will provide a base for subsequent<br />

development work on the market side. We<br />

are go<strong>in</strong>g to do regular surveys at two year<br />

<strong>in</strong>tervals <strong>in</strong> future.<br />

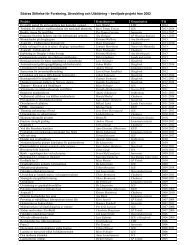

Customer Satisfaction Index (CSI)<br />

TexT: ÅSA WERNERSSON<br />

illuSTraTioN: JOhAN CASTOR<br />

Customer assessments<br />

of various aspects of<br />

<strong>Södra</strong> <strong>Timber</strong> have been<br />

summarised <strong>in</strong> a customer<br />

satisfaction <strong>in</strong>dex,<br />

CSi. The first <strong>in</strong>dex score<br />

was 72, which is a good<br />

result.<br />

<strong>Södra</strong> brand<br />

a high priority<br />