Datteln 4 - Kraftwerk Datteln

Datteln 4 - Kraftwerk Datteln

Datteln 4 - Kraftwerk Datteln

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

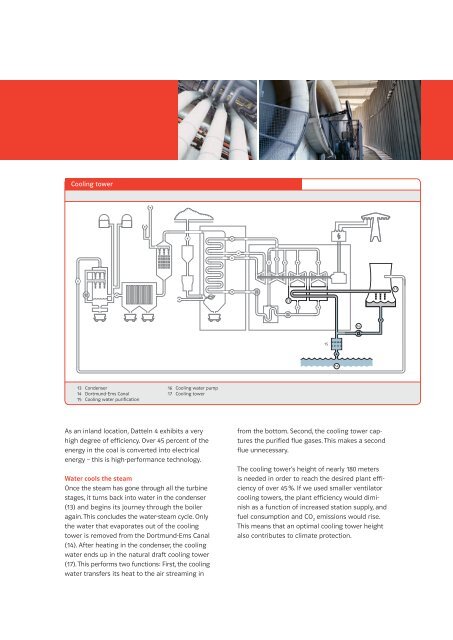

Cooling tower<br />

13 Condenser<br />

14 Dortmund-Ems Canal<br />

15 Cooling water purifi cation<br />

16 Cooling water pump<br />

17 Cooling tower<br />

As an inland location, <strong>Datteln</strong> 4 exhibits a very<br />

high degree of effi ciency. Over 45 percent of the<br />

energy in the coal is converted into electrical<br />

energy – this is high-performance technology.<br />

Water cools the steam<br />

Once the steam has gone through all the turbine<br />

stages, it turns back into water in the condenser<br />

(13) and begins its journey through the boiler<br />

again. This concludes the water-steam cycle. Only<br />

the water that evaporates out of the cool ing<br />

tower is removed from the Dortmund-Ems Canal<br />

(14). After heating in the condenser, the cooling<br />

water ends up in the natural draft cooling tower<br />

(17). This performs two functions: First, the cooling<br />

water transfers its heat to the air stream ing in<br />

from the bottom. Second, the cooling tower captures<br />

the purifi ed fl ue gases. This makes a second<br />

fl ue unnecessary.<br />

The cooling tower’s height of nearly 180 meters<br />

is needed in order to reach the desired plant effi -<br />

ciency of over 45 %. If we used smaller ventilator<br />

cooling towers, the plant effi ciency would diminish<br />

as a function of increased station supply, and<br />

fuel consumption and CO 2 emissions would rise.<br />

This means that an optimal cooling tower height<br />

also contributes to climate protection.