Datteln 4 - Kraftwerk Datteln

Datteln 4 - Kraftwerk Datteln

Datteln 4 - Kraftwerk Datteln

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

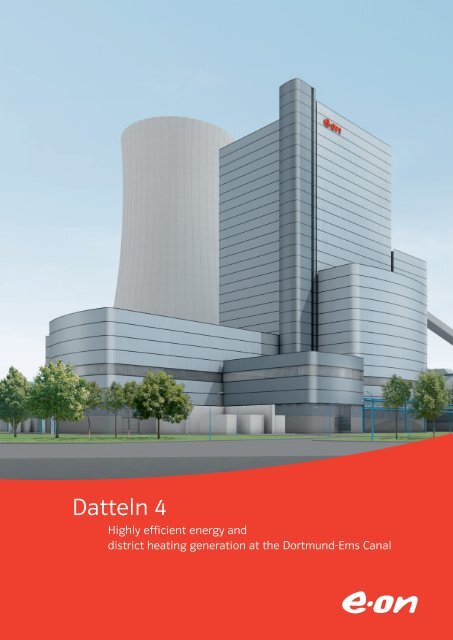

<strong>Datteln</strong> 4<br />

Highly effi cient energy and<br />

district heating generation at the Dortmund-Ems Canal

2<br />

<strong>Datteln</strong> 4 will be one of the most effi cient and powerful hard coal-fi red power plants in<br />

the world. This new power plant will go online with around 20 percent less fuel consumption<br />

than the older generation. This secures our energy supply and helps to protect the<br />

environment.<br />

We’re building the future

Why is E.ON building a new hard<br />

coal-fi red power plant?<br />

Why is the power plant so big?<br />

Why in <strong>Datteln</strong>?<br />

How will <strong>Datteln</strong> 4 affect the environment?<br />

3

4<br />

A good mix is necessary<br />

Big means affordable<br />

The right location<br />

Better for the environment

Energy from wind, sun and water power – can’t these cover all our energy needs? Unfortunately, the sun doesn’t shine<br />

every day, and the wind takes days off, too. The potential to generate power using hydroelectric dams has been largely<br />

exhausted in Germany. Hard coal-fi red power plants are still needed alongside other power generation methods in<br />

order to guarantee an affordable and secure supply. This is why E.ON is focusing on a balanced energy mix. The new<br />

<strong>Datteln</strong> 4 hard coal-fi red power plant is a part of this strategy.<br />

>> See page 6 for more on this topic<br />

Size provides a cost advantage in power generation. The higher the output of a power plant, the more affordable it is to<br />

operate, allowing us to sell power more cheaply. A high degree of effi ciency can be realized in large power plants. Today,<br />

we are able to generate twice as much electricity from one kilogram of hard coal as we were 50 years ago. This means<br />

lower emissions and a more careful use of resources. For this reason, large power plants will contue to form the backbone<br />

of our power generation capacity in the future.<br />

>> See page 7 for more on this topic<br />

Regions with a high population density – like the Ruhr area – need a lot of energy. However, it is not possible to store<br />

large amounts of electricity. We need to generate it exactly when it is needed. In addition, coal-fi red power plants require<br />

a strong logistics infrastructure, which is present at the <strong>Datteln</strong> location thanks to the present power plant facilities<br />

<strong>Datteln</strong> 1 through 3. These will be replaced by <strong>Datteln</strong> 4 because they have reached the end of their technical and economic<br />

lifetime. This means that this new build project will enable us to retain important jobs in the region for the coming<br />

decades.<br />

>> See page 12 for more on this topic<br />

The new power plant will have a net electrical effi ciency of over 45 percent. The simultaneous extraction of district heat<br />

means that over 60 percent of the potential energy in the fuel can be utilized. <strong>Datteln</strong> 4 will replace not only the existing<br />

power plants in <strong>Datteln</strong>, but another old facility in the Ruhr area as well, and E.ON has already shut down 1,800 MW<br />

of fossil-powered power plant output there. Even though the facility produces signifi cantly more energy than its predecessors,<br />

it will improve the region’s environmental footprint signifi cantly. The key is the improved efficiency and the<br />

decommissioning of the old, less efficient facilities. The new power plant will have a modern, multi-step fl ue gas<br />

purifi cation system. This will remove nitrogen oxides, dust and sulfur from the fl ue gas – and to a greater extent than<br />

what is currently required by law. The state environmental authority verifi es that the emission limit values are adhered<br />

to around the clock, 365 days a year.<br />

>> See page 14 for more on this topic<br />

5

6<br />

What energy mix makes sense?<br />

We need electricity for most of the things we do every day. But can't we meet all our<br />

energy needs using wind, water and solar energy? No, not reliably enough. Therefore<br />

E.ON relies on a balanced energy mix and invests into the development of innovative,<br />

climate-friendly technologies of the future at the same time.<br />

Energy mix 2009<br />

Power generation in Germany in 2009 currently amounts to a total<br />

of 597 billion kWh<br />

oil/gas 13 %<br />

renewables<br />

and others<br />

22 %<br />

42 % coal<br />

23 %<br />

nuclear<br />

energy<br />

It’s all about the mix<br />

All power generation resources have advantages<br />

and disadvantages. When deciding for or against<br />

a particular energy source, security of supply, price<br />

considerations and environmental sustainability<br />

come into equal play. In our view, it would be<br />

foolish to move away from a balanced energy<br />

mix – at least as long as it remains unclear how<br />

to sensibly replace fossil fuels.<br />

In Germany, E.ON generates in 2009<br />

a total of 112 Mrd. kWh<br />

oil/gas<br />

renewables<br />

and others<br />

4 %<br />

11 %<br />

coal 29 %<br />

Hard coal is and will remain an important energy<br />

source<br />

Hard coal will continue to be an important part<br />

of the energy mix in the future. Experts have calculated<br />

that the worldwide supply of coal will be<br />

enough to meet growing energy needs for several<br />

hundred years, even taking into account the continued<br />

growth of populous countries. In addition<br />

many countries in the world have considerable<br />

coal supplies. This allows them to avoid becoming<br />

dependent – as is the case with oil and gas – on<br />

single regions of the world that may be politically<br />

unstable.<br />

Yet the problem of CO 2 emissions from burning<br />

coal remains. This is why E.ON is focusing on<br />

increasing the energy effi ciency of thermal power<br />

plants like <strong>Datteln</strong>. Greater effi ciency always leads<br />

to less CO 2 per generated kilowatt hour (KWh).<br />

56 % nuclear<br />

energy

Effi ciency of hard coal-fi red power plants, worldwide comparison<br />

in % 1)<br />

60<br />

40<br />

20<br />

~ 30 35 36 38 40 > 45<br />

World USA Europe Germany E.ON today<br />

1) Average value for existing and new plants<br />

Less CO2 , higher effi ciency<br />

E.ON has set itself the goal of reducing its specifi c<br />

CO 2 in Europe by 2020 by 50 % compared to 1990<br />

– which is 10 years earlier than planned so far.<br />

The focus lies on the substantial expansion of<br />

renewable energies. Furthermore nuclear energy<br />

as well as highly effi cient hard coal- and gas-fi red<br />

power plants will make important contributions.<br />

And already today these power plants achieve<br />

outstanding degrees of efficiency in global comparison.<br />

<strong>Datteln</strong> 4<br />

starting<br />

in 2012<br />

<strong>Datteln</strong> 4 sets new standards<br />

By optimizing the system technology <strong>Datteln</strong> 4<br />

will be setting new benchmarks in terms of effi -<br />

ciency. The power plant will be able to exhibit an<br />

effi ciency of over 45 %. This represents a substantial<br />

increase over the German average. Extracting<br />

the district heat increases the effi ciency factor<br />

of the fuel used to over 60 %. To compare a Diesel<br />

motor achieves 35 %.<br />

Additionally, <strong>Datteln</strong> 4 will replace both the old<br />

power plant facilities <strong>Datteln</strong> 1 through 3, as well<br />

as other power plants in the Ruhr area. <strong>Datteln</strong> 4,<br />

with its high effi ciency rate and its low specifi c<br />

CO 2 output, will be used more than the older<br />

facilities, because effi ciently generated electricity<br />

is cheaper. This will push plants with lower<br />

effi ciency and higher CO 2 output out of the<br />

generation market. This represents a long-term<br />

victory for the environment.<br />

7

8<br />

<strong>Datteln</strong> 4

8<br />

10<br />

3<br />

2<br />

1<br />

5<br />

6<br />

7<br />

9<br />

4<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Boiler house<br />

Powerhouse<br />

Cooling tower<br />

Coal storage<br />

Flue gas purifi cation<br />

Outside air switching facility<br />

Flue ash silo<br />

Water supply and disposal<br />

Traction current converter<br />

Administrative building<br />

11

9<br />

How does the <strong>Datteln</strong> hard coal-fired po<br />

Power plant technology is not a mystery. Water, steam and coal are the most important<br />

elements in power generation. It all comes down to their interaction and the processes<br />

they undergo. The facility in <strong>Datteln</strong> 4 is a real powerhouse: compact and a high performer.<br />

Function diagram <strong>Datteln</strong> 4<br />

Technical data <strong>Datteln</strong> 4<br />

Electric output<br />

Water-steam cycle<br />

Cooling water cycle<br />

Flue gases<br />

Electricity for public supply<br />

Traction current<br />

District heat<br />

Net effi ciency (electrical)<br />

Fuel requirement<br />

Steam output<br />

Live steam parameters<br />

Flue gas capture<br />

MW: Megawatts t/h: Tons per hour<br />

air<br />

Flue gas<br />

purifi cation<br />

plant<br />

Supply<br />

1 Coaling station<br />

2 Ammonia (NH3) line<br />

3 Process and operating water<br />

4 Calcium carbonate<br />

Process<br />

5 Coal bunker<br />

6 Coal pulverizer<br />

7 Outside air<br />

8 Steam generator<br />

9 Live steam<br />

Boiler house<br />

1,100 MW gross<br />

1,055 MW net<br />

642 MW (50 Hz)<br />

413 MW (16.7 Hz)<br />

380 MW max.<br />

> 45 %<br />

360 t/h hard coal<br />

2,950 t/h<br />

6oo°C/285 bar<br />

Via a cooling tower<br />

Powerhouse<br />

10 High-pressure turbine<br />

11 Medium-pressure turbine<br />

12 Low-pressure turbines<br />

13 Generator<br />

14 Transformer<br />

15 Condenser<br />

16 Condensate pump<br />

17 Regenerative pre-heating<br />

18 Boiler feed pump<br />

19 De-asher<br />

20 Coarse ashes<br />

21 Feed water<br />

22 NOx removal: catalyst<br />

23 Dust removal: Electric fi lter<br />

24 Sulfur removal: SO2 washer<br />

25 Cooling water purifi cation<br />

26 Cooling water pump<br />

27 Cooling tower<br />

Waste<br />

28 Pulverized fuel ash as a<br />

cement additive<br />

29 Gypsum drainage<br />

30 Gypsum for industrial use

wer plant work?<br />

Coal delivery, boiler and turbine<br />

1 Coal storage<br />

2 Coal bunker<br />

3 Coal pulverizer<br />

4 Addition of outside air<br />

5 Boiler<br />

6 Combustion chamber<br />

The path to the boiler<br />

Barges deliver hard coal via the Dortmund-Ems<br />

Canal. They discharge their cargo in a purposebuilt<br />

E.ON harbor with the help of continual ship<br />

unloaders. Closed conveyor belt facilities transport<br />

the fuels to the coal storage (1) or directly into the<br />

coal bunker (2).<br />

Five coal pulverizers (3) grind the delivered hard<br />

coal to a fi ne dust. The coal dust is fi rst dried using<br />

hot air and then blown into the boiler’s combustion<br />

chamber. The grinding process results in a<br />

far greater coal surface area, leading to optimal<br />

combustion.<br />

Boiler house Powerhouse<br />

7 Pipelines<br />

8 Feed water<br />

9 Turbines<br />

10 Condenser<br />

11 Generator<br />

12 Transformer<br />

From steam to electricity<br />

The boiler house is where you will fi nd the stream<br />

generator itself (5). It consists of the combustion<br />

chamber (6) and a complex system of pipes (7).<br />

In normal operation the fi nely ground coal dust is<br />

burned at over 1,300 de grees Celsius in the combustion<br />

chamber. The resulting heat brings the water<br />

in the lines to a boil. The water is transformed into<br />

steam, which is then passed into the turbines at high<br />

pressure.<br />

The steam turbine (9) turns at 3,000 revolutions<br />

per minute. It consists of one high-pressure, one<br />

medium-pressure, and two low-pressure sections.<br />

There, blades transfer the steam’s energy onto the<br />

shaft. The turbine is linked to a generator (11), which<br />

transforms mechan ical energy into electrical energy<br />

– very simliar to a dynamo. The generated electricity<br />

is supplied into the grid through a transformer (12).

Cooling tower<br />

13 Condenser<br />

14 Dortmund-Ems Canal<br />

15 Cooling water purifi cation<br />

16 Cooling water pump<br />

17 Cooling tower<br />

As an inland location, <strong>Datteln</strong> 4 exhibits a very<br />

high degree of effi ciency. Over 45 percent of the<br />

energy in the coal is converted into electrical<br />

energy – this is high-performance technology.<br />

Water cools the steam<br />

Once the steam has gone through all the turbine<br />

stages, it turns back into water in the condenser<br />

(13) and begins its journey through the boiler<br />

again. This concludes the water-steam cycle. Only<br />

the water that evaporates out of the cool ing<br />

tower is removed from the Dortmund-Ems Canal<br />

(14). After heating in the condenser, the cooling<br />

water ends up in the natural draft cooling tower<br />

(17). This performs two functions: First, the cooling<br />

water transfers its heat to the air stream ing in<br />

from the bottom. Second, the cooling tower captures<br />

the purifi ed fl ue gases. This makes a second<br />

fl ue unnecessary.<br />

The cooling tower’s height of nearly 180 meters<br />

is needed in order to reach the desired plant effi -<br />

ciency of over 45 %. If we used smaller ventilator<br />

cooling towers, the plant effi ciency would diminish<br />

as a function of increased station supply, and<br />

fuel consumption and CO 2 emissions would rise.<br />

This means that an optimal cooling tower height<br />

also contributes to climate protection.

Flue gas purifi cation<br />

18 Ammonia<br />

19 Outside air<br />

20 NO x removal system<br />

21 Electric fi lter<br />

22 Pulverized fuel ash<br />

23 Calcium carbonate<br />

No-risk fl ue gas<br />

Before the fl ue gas enters the atmosphere, it is<br />

painstakingly purifi ed. It is especially important<br />

to remove sulfur dioxide (SO 2), nitrogen oxide<br />

(NO x) and dust. The purifi cation process has three<br />

phases: In the NOx removal system (20), catalysts<br />

convert the nitrogen oxide into the environmentally<br />

neutral substances water and nitrogen by<br />

means of ammonia (18) – air consists of 79 %<br />

nitrogen naturally.<br />

The next step in fl ue gas purifi cation is an electric<br />

fi lter (21) that captures pulverized fuel ash. This<br />

ash is collect ed in an ash bunker and sold to<br />

the construction industry, which uses it e.g. as a<br />

cement additive.<br />

24 Process water<br />

25 Sulfur removal system<br />

26 Gypsum drainage<br />

27 Gypsum<br />

The sulfur removal system (25) washes the fl ue<br />

gas. The sulfur dioxide reacts chemically with<br />

a limestone water mixture and oxygen. Gypsum<br />

and water are left over. The dried gypsum can<br />

then be used e.g. in the manufacture of gypsum<br />

plasterboard.<br />

10

12<br />

Who needs the energy from <strong>Datteln</strong>?<br />

Energy production is a traditional part of <strong>Datteln</strong>. Since 1964 the hard coal-fi red power<br />

plant in <strong>Datteln</strong> has supplied electricity to the Bahn, as well as district heating to the<br />

urban area, thus being an important economic factor for the city and region. As part of<br />

the pan-European supply grid, <strong>Datteln</strong> 4 contributes to making sure that energy is always<br />

there when you need it.<br />

Traditional location with a future<br />

The power plant units <strong>Datteln</strong> 1 – 3 as well as the<br />

power plant Shamrock in Herne will be at the end<br />

of their technical and economic lifetimes in the<br />

next few years. They need to be replaced with new,<br />

effi cient and more environmentally friendly facilities.<br />

E.ON is investing more than one billion Euros<br />

in the construction of the hard coal fi red power<br />

plant <strong>Datteln</strong> 4. At the same time the operation of<br />

the <strong>Datteln</strong> 4 power plant not only secures the jobs<br />

of the <strong>Datteln</strong> 4 employees, but many other jobs<br />

throughout the region as well.<br />

Electricity for the train<br />

A fi fth of the electricity used by Deutsche Bahn<br />

to run its trains comes from <strong>Datteln</strong>. In the future,<br />

this fi gure will rise to 25 %. Aside from district<br />

heating, the power plant units <strong>Datteln</strong> 1 through 3<br />

produce only 16.7 Hertz traction current.<br />

<strong>Datteln</strong> 4 generates the 50 Hertz electricity<br />

needed by the public supply grid. For this reason,<br />

it needs to be transformed into the 16.7 Hertz<br />

electricity needed by the train system. This will<br />

be done using a traction current converter facility<br />

to be built along with the power plant. With an<br />

output of 413 megawatts, it is the largest facility<br />

of its kind in the world, and is also the highestoutput<br />

feed current unit in Deutsche Bahn’s grid.<br />

Energy for the region<br />

In addition to traction current, the <strong>Datteln</strong> 4 power<br />

plant will be able to provide a total of 642 megawatts<br />

to the region’s public electricity grid. This<br />

means that the power plant will be utilized continuously<br />

and effi ciently.<br />

District heating for <strong>Datteln</strong> and the Ruhr area<br />

For over 40 years, the <strong>Datteln</strong> power plant has<br />

been rements with environmentally friendly district<br />

heating. The power plant presents a special type<br />

of environmental advantage: district heating is<br />

provided with low fuel requirements. The plant’s<br />

good overall energy profi le means that it saves a<br />

great deal of primary energy. In the Ruhr area, this<br />

leads to an additional improvement of the regional<br />

CO 2 footprint.<br />

Around 1,000 GWh environmentally friendly<br />

district heating will be produced by the new<br />

power plant <strong>Datteln</strong> 4. This provides around<br />

100,000 housing units with heating, and is the<br />

largest contribution of E.ON to grid supply in<br />

the region. The basis for this is the principle of<br />

com bined heat and power generation. Part of the<br />

steam used to turn the turbines and generate<br />

power is drawn off the turbine to be used for<br />

district heating. This increases the fuel effi ciency<br />

of the power plant to around 60 percent, and<br />

decreases the emissions in the Ruhr area. Altogether<br />

<strong>Datteln</strong> 4 will provide around 50 percent of the<br />

district heating and take over the supply of<br />

Recklinghausen, Herne and Bochum. Additionally<br />

the power plant is able to deliver district heating<br />

to Castrop-Rauxel and Dortmund-Bodelschwingh.<br />

Hereby <strong>Datteln</strong> 4 will be one of the ten largest<br />

heating power plants in Germany.

Social responsibility for the region<br />

E.ON has been operating at the <strong>Datteln</strong> location<br />

for many years. Over the years, we have become<br />

a part of the area, which in our view brings with it<br />

a certain measure of responsibility for the region.<br />

Support for children and youth has traditionally<br />

been a focal point of the E.ON Group’s regional<br />

involvement.<br />

This is why we support educational and social<br />

projects for children and youth on location. The<br />

projects range from fi eld trips to the <strong>Datteln</strong><br />

power plant to the “Energy for Kids” initiative,<br />

to setting up computer centers in elementary<br />

schools and providing fi nancial support to kindergardens<br />

and the channel festival in <strong>Datteln</strong>.<br />

Criticism is welcome in the Power Plant Forum<br />

Naturally, a new power plant cannot be built<br />

without questions or criticism. Exchanging<br />

opinions with our direct neighbors and the<br />

citizens of the region is important to us. To this<br />

end, we have created a platform that involves<br />

all interested parties – the “Power Plant Forum”.<br />

This forum is intended to resolved open and controversial<br />

issues. Proponents and critics will meet<br />

at regular intervals to exchange their opinions.<br />

This forum will address problems and solutions<br />

quite concretly: for instance, the reduction of the<br />

impact of construction site traffi ce on residents,<br />

the expansion of the measurement station network<br />

for environmental monitoring, or the further<br />

reduction of emissions and pollutants. You can<br />

fi nd up-to-date information on the Power Plant<br />

Forum in the internet at www.kraftwerksforumdatteln.de.<br />

13

14<br />

How are we protecting the environment?<br />

Building and operating a hard coal-fi red power plant always has some effect on the<br />

surrounding area. In order to lessen these effects, we exceed the legal environmental<br />

protection requirements in several respects.<br />

Environmental protection at your door<br />

Ever since we began planning this plant, strict<br />

environmental protection requirements have been<br />

at the forefront. In order to preserve the quality<br />

of life of neighboring residents, in addition to all<br />

the other aspects of environmental protection, we<br />

are going to do more in the way of protecting the<br />

environment at the <strong>Datteln</strong> 4 power plant than is<br />

required by law.<br />

One example is E.ON’s stated goal to furnish this<br />

industrial facility with an appealing exterior. Various<br />

architectural concepts were solicited and coordinated<br />

with the City of <strong>Datteln</strong> in this respect.<br />

Modern technology for clean living spaces<br />

In addition we have planned technical safety<br />

measures in many parts of the power plant. These<br />

help to reduce grime and environmental impacts,<br />

or to eliminate them entirely. For example, many<br />

parts of the coaling station are completely closed.<br />

This prevents dust from escaping as it does when<br />

coal is loaded in the open. In addition, the coal<br />

stock piles will be watered to keep dust down<br />

during dry weather.<br />

We have also selected the transportation routes<br />

to and from the power plant in such a way that<br />

environ mental impacts are minimized. Normally,<br />

coal reaches the power plant via canal barges.<br />

Substantial portions of the power plant’s byproducts,<br />

such as ash, also leave the power plant by<br />

barge. We will only use the existing rail link to<br />

transport materials in exceptional cases.<br />

Renaturing the Lippe wetlands

Renaturing to compensate for environmental<br />

impacts<br />

The construction of <strong>Datteln</strong> 4 requires a great<br />

deal of space. This area used to be covered in<br />

fi elds and forest. In order to maintain the environmental<br />

balance and to protect ecosystems, we are<br />

restoring nature in another area to compensate<br />

for the land used to build the power plant. In this<br />

case, we have decided to initiate a comprehensive<br />

project to “re-nature” the Lippe wetlands.<br />

A piece of untouched nature has sprung up directly<br />

adjacent to the power plant grounds: We have<br />

dug two ponds, where we settled the alpine newts<br />

that used to live on the grounds in old bomb<br />

craters. This newly created biome has tripled the<br />

alpine newt’s spawning opportunities.<br />

Permanent precise monitoring<br />

In order to determine the effects of the construction<br />

and operation of <strong>Datteln</strong> 4 precisely, E.ON<br />

has commissioned several expert opinions and<br />

measurements. Various research projects have<br />

been initiated to analyze the environmental<br />

effects of e.g. dust emissions, noise, cooling tower<br />

plumes and traffi c impacts. The measurement network<br />

used for emissions monitoring in the area<br />

surrounding the newly constructed power plant is<br />

among the most dense measurement networks in<br />

the Federal Republic of Germany.<br />

A regularly updated report compiles the signifi -<br />

cant results of the various research projects. This<br />

report is not only available to the technical authorities,<br />

but will also provide interested members<br />

of the general public with a comprehensive and<br />

detailed overview of the environmental situation<br />

in the area surrounding the power plant. We want<br />

to ensure as much transparency as possible in our<br />

monitoring report.<br />

<strong>Datteln</strong> 4 – the best-monitored power plant site<br />

How does pollutant monitoring work? Environmental<br />

monitoring around the new power plant began<br />

in August 2007. The system monitors how the<br />

construction site and the new power plant affect<br />

the environment. Current data from the period<br />

before the new power plant was built can later be<br />

compared to data generated while the new power<br />

plant is operating.<br />

The dense network of measurement sites to monitor<br />

air quality exceeds the requirements imposed<br />

by law. This makes <strong>Datteln</strong> one of the best-monitored<br />

power plant locations in Germany. In addition<br />

to air quality, we will also monitor noise generation,<br />

light pollution, the soil, the local climate, the<br />

water quality of the nearby stream, the groundwater,<br />

and the traffi c situation. Landscape monitoring<br />

is also included in the program.<br />

The results of the monitoring will be published<br />

semi-annually and can be viewed on the Internet<br />

at www.kraftwerk-datteln.com.<br />

15

16<br />

<strong>Datteln</strong> Energy Center<br />

In the <strong>Datteln</strong> Energy Center you’ll get a fi rsthand<br />

look at the various stages behind the planning<br />

and construction of the <strong>Datteln</strong> 4 power plant.<br />

We invite you to come and talk to us. The Energy<br />

Center is a good place for meetings and discussions,<br />

providing you with comprehensive information<br />

about the new power plant and the subject of<br />

energy.<br />

You can experience the fascination of power plant<br />

technology at the energy exhibit, test your skills as<br />

energy manager, and discover interesting details<br />

about power generation that you didn't know<br />

before.<br />

Feel free to visit our energy exhibit along with<br />

friends and colleagues, with your family or a group<br />

of students. You can also make the <strong>Datteln</strong> Energy<br />

Center the center of your own event.<br />

Where to learn more<br />

We heartily welcome you – we’re happy to have you!<br />

Treffpunkt Energie<br />

Zur Seilscheibe 8<br />

45711 <strong>Datteln</strong><br />

Opening hours<br />

Wednesdays from 10 to 5<br />

Saturdays from 10 to 5<br />

or by appointment<br />

T + 49 23 63-9 77-27 99<br />

F + 49 23 63-9 77-20 20<br />

E-Mail: treffpunkt-datteln@eon-energie.com<br />

www.kraftwerk-datteln.com<br />

<strong>Datteln</strong> Energy Center

E.ON ist Energie<br />

With nearly 90,000 employees, E.ON is one of the<br />

world's largest investor-owned power and gas<br />

companies. Every day, E.ON supplies<br />

30 million customers with electricity and gas,<br />

around the clock, in over 30 European countries.<br />

It is E.ON's aim to guarantee a secure, economical<br />

and environmentally friendly energy supply today<br />

and in the future. This challenge can only be met<br />

with innovative technology and a balanced energy<br />

mix. That is E.ON's mission.<br />

Further information on www.eon.com<br />

Imprint<br />

Publisher<br />

E.ON <strong>Kraftwerk</strong>e GmbH<br />

Concept and design<br />

wirDesign Berlin Braunschweig<br />

Image sources<br />

E.ON <strong>Kraftwerk</strong>e GmbH<br />

Lithography<br />

Rolf Neumann, Braunschweig<br />

Printer<br />

gutenberg beuys, Hannover<br />

as at<br />

March 2011

E.ON <strong>Kraftwerk</strong>e GmbH Treffpunkt Energie Zur Seilscheibe 8 45711 <strong>Datteln</strong> Germany<br />

T + 49 23 63-9 77-27 99 F + 49 23 63-9 77-20 20<br />

www.eon-kraftwerke.com www.eon.com<br />

www.kraftwerk-datteln.com<br />

EKW 03/2011