Baix Llobregat wastewater treatment plant - bochure in ... - Krüger A/S

Baix Llobregat wastewater treatment plant - bochure in ... - Krüger A/S

Baix Llobregat wastewater treatment plant - bochure in ... - Krüger A/S

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

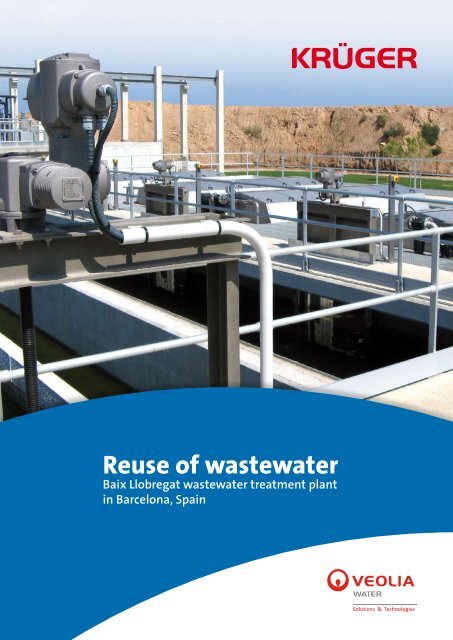

Reuse of <strong>wastewater</strong><strong>Baix</strong> <strong>Llobregat</strong> <strong>wastewater</strong> <strong>treatment</strong> <strong>plant</strong><strong>in</strong> Barcelona, Spa<strong>in</strong>

BarcelonaApprox. 4 million people live <strong>in</strong> and around Barcelona andalso the majority of the Catalonian <strong>in</strong>dustry is located <strong>in</strong>this area.The water supply to the town comes from groundwateras well as treated water from the river of <strong>Llobregat</strong> that isrelatively sal<strong>in</strong>e.Clear wateris a limited, however,vital ressource <strong>in</strong> theMediterranean area.Barcelona has taken theconsequences and nowreuses the treated<strong>wastewater</strong>.The aquaticenvironment<strong>in</strong> CataloniaTo reduce the use of the limitedwater resources the Spanish M<strong>in</strong>istryof the Environment has decidedto treat and reuse a part of thetown’s <strong>wastewater</strong>.The treated <strong>wastewater</strong> is applied for irrigation of thefarm land around the river as well as some of the golfcourses <strong>in</strong> the areaFurthermore, a part of the treated <strong>wastewater</strong> isreturned to the river to ma<strong>in</strong>ta<strong>in</strong> the water level andensure an <strong>in</strong>creased flowAt the same time, a part of the treated <strong>wastewater</strong> isled to a reverse osmosis <strong>plant</strong> for further <strong>treatment</strong>and the water is pumped to the underground toavoid salt water from the sea to seep <strong>in</strong>to the groundwaterresources.2

<strong>Baix</strong> <strong>Llobregat</strong><strong>wastewater</strong><strong>treatment</strong> <strong>plant</strong>The <strong>plant</strong> is a activated sludge<strong>plant</strong> and one of Europe’s larger<strong>plant</strong>s treat<strong>in</strong>g the <strong>wastewater</strong>for approx. 2 million people andhav<strong>in</strong>g a capacity of 420,000 m³<strong>wastewater</strong>/day.The biological part of the <strong>treatment</strong> removes approx. 92%of the suspended solids and the dissolved contam<strong>in</strong>ationafter which three-quarters are led to a tertiary <strong>treatment</strong>and then reused.The <strong>Baix</strong> <strong>Llobregat</strong> <strong>wastewater</strong> <strong>treatment</strong> <strong>plant</strong> isoperated by Depuradora del <strong>Baix</strong> <strong>Llobregat</strong> SA which isa public company owned by the Spanish M<strong>in</strong>istry of theEnvironment.In comparison thetwo <strong>plant</strong>s <strong>in</strong> Copenhagen,Lynetten and Damhusåenoperated jo<strong>in</strong>tly by Lynettefællesskabet,treat <strong>wastewater</strong> correspond<strong>in</strong>gto 1.1 million people andwith a capacity of 220,000 m³<strong>wastewater</strong>/dayReuse of the <strong>wastewater</strong>In cooperation with its Spanish sister company, Krügerhas designed and constructed the tertiary <strong>treatment</strong><strong>plant</strong> <strong>in</strong> <strong>Baix</strong> <strong>Llobregat</strong>.The <strong>plant</strong> consists of 3 compact and very efficient Actiflo<strong>plant</strong>s and 10 Hydrotech disc filters for polish<strong>in</strong>g of thewater. The total capacity is 302,400 m³ treated <strong>wastewater</strong>/day.80%The comb<strong>in</strong>ation of Actiflo and the discfilters provides a very robust and verycompact <strong>plant</strong> able to deal with very heavyhydraulic loads and substances. Thiscomb<strong>in</strong>ation ensures an 80%-reductionof the area required compared to othersolutions of similar capacity and load.3

ACTIDisc®Actiflo – settl<strong>in</strong>g by means of sandThe phase of settl<strong>in</strong>g by means of sand is performed <strong>in</strong> threeActiflo l<strong>in</strong>es, each l<strong>in</strong>e hav<strong>in</strong>g a <strong>treatment</strong> capacity of 4,800m³/t and a settl<strong>in</strong>g rate of 120 m/t.In the flocculation phase, microsand particles are added to aidthe formation of flocs with a high density which <strong>in</strong>crease thesettl<strong>in</strong>g rate by up to 60 times compared with conventionalprocesses. The process also comprises a unit of hydrocycloneswhich makes it possible to recover the microsand and thusreuse it <strong>in</strong> the process.Untreated <strong>wastewater</strong>Treated <strong>wastewater</strong>Actiflocomprises four phases:CoagulationFlocculationMaturationLamella separationRecycledmicrosandHydrocycloneSludgeTo sludge <strong>treatment</strong>Raw water <strong>in</strong>letTreatedwaterCoagulationMaturationMicrosand<strong>in</strong>jectionBallasted flocsto hydrocycloneHydrotech – tertiary filtrationAfter the settl<strong>in</strong>g phase, the water is led to 10 Hydrotech discfilters with a mesh width of 10 µm which polish the recoveredwater. Each disc filter has a capacity of 1,440 m³/t.Hydrotech is a state-of-the-art filtration system with disc filterswhich is very efficient and easily adjusted. The Hydrotechsystem provides a very advanced filtration and is a compactdesign which makes it very suitable for polish<strong>in</strong>g of water on<strong>plant</strong>s with limited space available.5

The advantages of the ACTIDisc® processThe water quality obta<strong>in</strong>ed by the ACTIDisc® processis always better than any other quality obta<strong>in</strong>ed <strong>in</strong>similar processes. ACTIDisc® guarantees reduced turbidityand suspended solids and reduces the contentof helm<strong>in</strong>th eggs.The process is very reliable as the quality of thetreated water is ma<strong>in</strong>ta<strong>in</strong>ed at a response time ofless than 20 m<strong>in</strong>utes <strong>in</strong>dependently of the possiblevariations <strong>in</strong> the quality of the <strong>in</strong>let water.A very compact processThe space requirements to the process <strong>plant</strong> arem<strong>in</strong>imal. Typically, provid<strong>in</strong>g space sav<strong>in</strong>gs of up to80% compared to conventional <strong>plant</strong>s.The process can be <strong>in</strong>troduced on exist<strong>in</strong>g <strong>plant</strong>s.The space sav<strong>in</strong>g also reduced the construction costs.The start-up of the ACTIDisc® process is very rapidwhich reduces the costs related to chemicals, energyand water.The ACTIDisc® operates by gravitation (withoutpumps) provid<strong>in</strong>g further energy sav<strong>in</strong>gs.6

General dataCommission<strong>in</strong>g June 2006Average amount treated302,400 m³/dayMaximum amount treated 14,400 m³/hourActiflo - settl<strong>in</strong>g by ballasted sandMaximum settl<strong>in</strong>g capacity 3 x 4,800 m³/hourSettl<strong>in</strong>g rate120 m³/m² x hourHydrotech – tertiary filtrationMaximum <strong>treatment</strong> capacity 10 x 1,440 m³/hourMesh width <strong>in</strong> filters 10 µmDesign data Water quality requirements Expected valuesBOD5 ≤ 20 mg/l ≤ 10 mg/l ≤ 5 mg/lSS ≤ 50 mg/l ≤ 5 mg/l ≤ 5 mg/lTurbidity ≤ 50 NTU < 5 NTU < 2 NTUHelm<strong>in</strong>th eggs < 1 U/1000 ml < 1 U/1000 ml7

DenmarkKrüger A/SGladsaxevej 363DK-2860 SøborgTel: 39 69 02 22kruger@kruger.dkwww.kruger.dkKlamsagervej 2-4DK-8230 ÅbyhøjTel: 87 46 33 00aarhus@kruger.dkSofiendalsvej 88DK-9200 Aalborg SVTel: 98 18 93 00aalborg@kruger.dkKrüger AquacareFabriksparken 50DK-2600 GlostrupTel: 43 45 16 76aquacare@kruger.dkwww.aquacare.dkSwedenVA-Ingenjörerna ABVretenvägen 13SE-171 54 SolnaTel: +46 8 579 781 20Fax: +46 8 579 78 1 21Olskroksgatan 30SE-416 66 GöteborgTel: +46 31-707 76 20Fax: +46 31-707 76 21Östra Torggatan 9SE-652 24 KarlstadTel: +46 54-17 75 40Fax: +46 54-17 75 41Runstensgatan 5SE-582 78 L<strong>in</strong>köb<strong>in</strong>gTel: +46 13-24 03 50Fax: +46 13-24 03 51Scheelegatan 3SE-212 28 MalmöTel: +46 40-28 67 00Fax: +46 40-28 67 01Umestans FöretagsparkSE-903 47 UmeåTel: +46 90-70 05 30Fax: +46 90-70 05 31Svalgången 1SE-724 81 VästeråsTel: +46 21-17 26 50Fax: +46 21-17 26 51Trädgårdsgatan 12SE-702 12 ÖrebroTel: +46 19- 16 11 60Fax: +46 19- 16 11 61Östersund Rådhusgatan 90SE-831 45 ÖstersundTel: +46 63-55 12 80Fax: +46 63-55 12 81Krüger Akvapur ABVretenvägen 13SE-171 54 SolnaTel: +46 8 587 663 00Fax: +46 8 587 663 10<strong>in</strong>fo@kruger.seAnoxKaldnesKlosterängsvägen 11ASE-226 47 LundTel: + 46 46 - 18 21 50Fax :+ 46 46 - 13 32 01sweden@anoxkaldnes.comHydrotech ABMejselgatan 6SE-235 32 Vell<strong>in</strong>geSwedenTel. +46 40 42 95 30Fax +46 40 42 95 31mailbox@hydrotech.seNorwayAnoxKaldnesHegnasletta 113217 SandefjordTlf:+ 47 91 60 80 00Faks: +47 33 48 50 01norway@anoxkaldnes.comF<strong>in</strong>landI. Krüger OyRuosilantie 14FIN-00390 Hels<strong>in</strong>kiTel: +358 9 4770 9041osmo.hyyrynen@veoliawater.comAquaflow Ltd.Kirkkokatu 7B, P.O. Box 116FIN-57101 Savonl<strong>in</strong>naTel: +358 15 51 731<strong>in</strong>fo@aquaflow.fiRuosilantie 14FIN-00390 Hels<strong>in</strong>kiTel: +358 9 4770 9011<strong>in</strong>fo@aquaflow.fiTullikatu 11FIN-21100 NaantaliTel: +358 50 32 69 658<strong>in</strong>fo@aquaflow.fiLithuaniaUAB KrügerOdm<strong>in</strong>iu str. 3LT-01122 VilniusTel: +370 650 26 940PolandVeolia Water Solutions &Technologies Sp. z o.o.Wroclawska 53PL-30-011 KrakowTel: +48 12 423 38 66Fax: +48 12 423 34 82<strong>in</strong>fo.poland@veoliawater.comul. 17 Stycznia 72PL-02-146 WarszawaTel: +48 22 886 44 06 to 08Fax: +48 22 886 44 05RussiaOOO ECOTEK og Krüger A/Sul. Dm. Donskogo 7Kal<strong>in</strong><strong>in</strong>grad, 236000Tel: + 7 (4012) 57 87 83Fax: +7 (4012) 57 88 67ecotek@gaz<strong>in</strong>ter.net