Cat HYDO (Hydraulic Oil) - Venequip

Cat HYDO (Hydraulic Oil) - Venequip

Cat HYDO (Hydraulic Oil) - Venequip

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

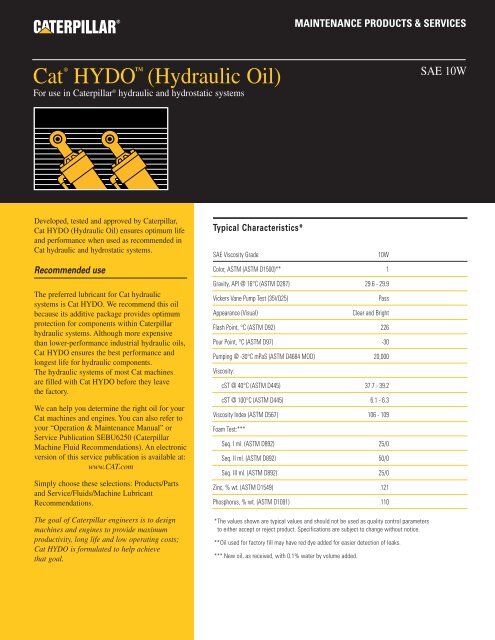

MAINTENANCE PRODUCTS & SERVICES® TM<strong>Cat</strong> <strong>HYDO</strong> (<strong>Hydraulic</strong> <strong>Oil</strong>)For use in <strong>Cat</strong>erpillar ® hydraulic and hydrostatic systemsSAE 10WDeveloped, tested and approved by <strong>Cat</strong>erpillar,<strong>Cat</strong> <strong>HYDO</strong> (<strong>Hydraulic</strong> <strong>Oil</strong>) ensures optimum lifeand performance when used as recommended in<strong>Cat</strong> hydraulic and hydrostatic systems.Recommended useThe preferred lubricant for <strong>Cat</strong> hydraulicsystems is <strong>Cat</strong> <strong>HYDO</strong>. We recommend this oilbecause its additive package provides optimumprotection for components within <strong>Cat</strong>erpillarhydraulic systems. Although more expensivethan lower-performance industrial hydraulic oils,<strong>Cat</strong> <strong>HYDO</strong> ensures the best performance andlongest life for hydraulic components.The hydraulic systems of most <strong>Cat</strong> machinesare filled with <strong>Cat</strong> <strong>HYDO</strong> before they leavethe factory.We can help you determine the right oil for your<strong>Cat</strong> machines and engines. You can also refer toyour “Operation & Maintenance Manual” orService Publication SEBU6250 (<strong>Cat</strong>erpillarMachine Fluid Recommendations). An electronicversion of this service publication is available at:www.CAT.comSimply choose these selections: Products/Partsand Service/Fluids/Machine LubricantRecommendations.The goal of <strong>Cat</strong>erpillar engineers is to designmachines and engines to provide maximumproductivity, long life and low operating costs;<strong>Cat</strong> <strong>HYDO</strong> is formulated to help achievethat goal.Typical Characteristics*SAE Viscosity Grade10WColor, ASTM (ASTM D1500)** 1Gravity, API @ 16°C (ASTM D287) 29.6 - 29.9Vickers Vane Pump Test (35VQ25)Appearance (Visual)PassClear and BrightFlash Point, °C (ASTM D92) 226Pour Point, °C (ASTM D97) -30Pumping @ -30°C mPaS (ASTM D4684 MOD) 20,000Viscosity:cST @ 40°C (ASTM D445) 37.7 - 39.2cST @ 100°C (ASTM D445) 6.1 - 6.3Viscosity Index (ASTM D567) 106 - 109Foam Test:***Seq. I ml. (ASTM D892) 25/0Seq. II ml. (ASTM D892) 50/0Seq. III ml. (ASTM D892) 25/0Zinc, % wt. (ASTM D1549) .121Phosphorus, % wt. (ASTM D1091) .110*The values shown are typical values and should not be used as quality control parametersto either accept or reject product. Specifications are subject to change without notice.**<strong>Oil</strong> used for factory fill may have red dye added for easier detection of leaks.*** New oil, as received, with 0.1% water by volume added.

<strong>Cat</strong> <strong>HYDO</strong> (<strong>Hydraulic</strong> <strong>Oil</strong>)Advanced formula for maximumperformance and protection<strong>Cat</strong> <strong>HYDO</strong> is formulated with a balanced additive system,including detergents, dispersants, rust inhibitors, anti-wear agentsand defoamers. It offers maximum protection against mechanicalwear, rusting and corrosive wear in <strong>Cat</strong> hydraulic and hydrostatictransmission systems. <strong>Cat</strong> <strong>HYDO</strong> is:• Field proven for consistent performance.• Approved and tested by <strong>Cat</strong> engineers.• An integral part of <strong>Cat</strong> machine hydraulic and hydrostaticsystems design.• Standard <strong>Cat</strong>erpillar worldwide factory-fill oil for mostmachine hydraulic systems.A proven balance of additives<strong>Cat</strong> <strong>HYDO</strong> contains:• Anti-wear Agents—Zinc dithiophosphate at 1200 ppm (typical)to minimize pump, motor and valve wear.• Emulsifiers—Disperse small amounts of water throughout theoil so water will not damage hydraulic system components.• Defoamers and Air Release Agents—Prevent the formation ofbubbles by reducing oil surface tension to quickly release aircontent to the atmosphere.• Anti-oxidants—Prevent the formation of sludge and corrosiveacids at high system temperatures and pressures.• Detergents/Dispersants—Keep components free of deposits,breaking up contaminants and holding them in suspension.• Excellent rust and corrosion inhibitors to protect metalscontaining iron or copper.S•O•S SM Services for early problem detection<strong>Cat</strong>erpillar recommends protecting your investment by usingS•O•S Services. Our S•O•S <strong>Oil</strong> Analysis program is theultimate detection and diagnostic tool for your equipment,helping you head off potential problems before they lead tomajor failures and costly unscheduled downtime.Acceptable SubstitutesIf <strong>Cat</strong> <strong>HYDO</strong> is not used, the following alternatives can beused in the hydraulic and hydrostatic systems of <strong>Cat</strong>erpillarmachines.*• <strong>Cat</strong> DEO TM (Diesel Engine <strong>Oil</strong>)• <strong>Cat</strong> TDTO TM (Transmission and Drive Train <strong>Oil</strong>)• <strong>Cat</strong> TDTO TMS TM (Transmission and Drive Train <strong>Oil</strong>—Transmission Multi-Season)• <strong>Cat</strong> MTO (Multi-Purpose Tractor <strong>Oil</strong>)• Commercial Heavy Duty Diesel Engine <strong>Oil</strong> with aminimum zinc content of 900 ppm. (Heavy Duty <strong>Oil</strong>s areidentified by API classifications CI-4**, CH-4**, CG-4,CF-4 or CF.)** However, <strong>Cat</strong> <strong>HYDO</strong> should not be used in place of any of theseother lubricants.** API CH-4 and CI-4 oils must also meet the requirements of <strong>Cat</strong>erpillarECF-1 (Engine Crankcase Fluid specification-1).4000 Hour <strong>Oil</strong> Change Intervals***The drain interval recommendation for <strong>Cat</strong> <strong>HYDO</strong> andalternatives is 4000 hours for all machine hydraulic systemcompartments where recommended for use. <strong>Oil</strong> that is notincluded in the alternatives list should be changed at 2000hours. <strong>Cat</strong> <strong>HYDO</strong> should not be used in hydraulic systemsthat contain friction material, except hydraulicexcavators.****Note: Refer to your Operation & Maintenance Manual orService Publication SEBU5250 (<strong>Cat</strong>erpillar Machine FluidsRecommendations) for “Lubricant Viscosities For AmbientTemperatures” recommendations.***For additional requirements, see IRM FLU01-02, “New RecommendedService Intervals for <strong>Hydraulic</strong> Systems on <strong>Cat</strong>erpillar Machines,” FormNumber PELE0824.****One example of an ineligible compartment is the integrated hydraulicand brake system on certain off-highway truck models.

MAINTENANCE PRODUCTS & SERVICESDo not use industrial hydraulic oilsIndustrial hydraulic oils may shorten hydraulic pump andcomponent life. Often referred to as “AW” (Anti-Wear) oil,these products typically omit or contain reduced levels of theadditive agents listed in this publication. Industrial hydraulicoils are usually formulated to separate water from the oil, adesired characteristic for stationary hydraulic systems.However, in earthmoving equipment this separated water willcause pump and component damage if it is suddenly drawnthrough the system from the tank as the machine moves.Furthermore, during freezing weather such water may formice, causing even more extensive damage.<strong>Cat</strong> <strong>HYDO</strong> contains emulsifier additives to disperse smallamounts of water throughout the system, minimizing waterdamage to hydraulic components.Avoid hydraulic oils with specifications that indicate they“separate,” “shed” or “release” water. These oils do notcontain emulsifiers.<strong>Cat</strong> <strong>HYDO</strong> contains emulsifiersKeep it cleanAlong with the use of proper hydraulic fluid, oil cleanliness isessential to achieving the full life of hydraulic systemcomponents. New hydraulic oil should be filtered to meet acleanliness of ISO 16/13 or lower when put into <strong>Cat</strong>erpillarmachines to achieve a machine operating cleanliness level ofISO 18/15 or lower. <strong>Hydraulic</strong> oil that has been removedduring a repair process must be filtered to a minimum of ISO16/13 before it is used to refill. Any used oil should bechecked using S•O•S <strong>Oil</strong> Analysis before it is reused.After repairs that involve exposing any hydraulic componentto the atmosphere or contamination, a clean-out hydraulicfilter should be installed. See your <strong>Cat</strong>erpillar dealer for partnumbers and more information. Also, an oil sample should betaken within several hours of returning the machine to serviceto assure an operating cleanliness level of ISO 18/15.<strong>Hydraulic</strong> oil zinc additive levels1200 ppm1000<strong>Oil</strong><strong>Oil</strong>Zinc (parts per million)750500500WaterWater250300<strong>Cat</strong> <strong>HYDO</strong>Industrial <strong>Hydraulic</strong> <strong>Oil</strong><strong>Cat</strong> <strong>HYDO</strong>Industrial <strong>Hydraulic</strong> <strong>Oil</strong>(Typical)Typical industrial hydraulic oils separate water and oil, which cancause valve sticking or excessive wear on your hydraulic system. <strong>Cat</strong><strong>HYDO</strong> disperses small amounts of water throughout the oil to ensureproper lubrication.A high level of zinc additives is essential for protecting pumps, motorsand valves from excessive wear. <strong>Cat</strong> <strong>HYDO</strong> contains more than twice asmuch zinc as typical (AW) industrial hydraulic oil to maximize yourhydraulic system’s life and performance.

MAINTENANCE PRODUCTS & SERVICES<strong>Cat</strong> <strong>HYDO</strong> (<strong>Hydraulic</strong> <strong>Oil</strong>)Use the best filters<strong>Cat</strong>erpillar fine-filtration hydraulic filters should be used afterrepairing or opening the hydraulic system and after each oilchange. Do not operate with fine filtration filters for more than100 hours as they will plug more readily than standard filters.We recommend using only <strong>Cat</strong>erpillar hydraulic filters on<strong>Cat</strong>erpillar machines because of their proven ability to trap andhold debris and their exceptional burst strength.Proper use for health and safetyAccording to toxicology information, <strong>Cat</strong> <strong>HYDO</strong> has little orno adverse effects if handled and used properly. No specialprecautions are suggested beyond attending to good personalhygiene and avoiding prolonged, repeated skin contact. Formore information, refer to the Material Safety Data Sheet,located on the Internet at:www.catmsds.comFor more information, see us todayor visit our Web site at www.CAT.comPEHJ0009© 2003 <strong>Cat</strong>erpillarPrinted in U.S.A.