High & Ultrahigh Vacuum Thin Film Deposition Technology

High & Ultrahigh Vacuum Thin Film Deposition Technology

High & Ultrahigh Vacuum Thin Film Deposition Technology

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>High</strong> & <strong>Ultrahigh</strong> <strong>Vacuum</strong><strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong> <strong>Technology</strong>VACUUM PRODUCTS CORPORATION

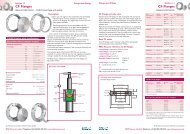

Frame 6 Electron Beam SourceMighty Source mounted on a 6-inch CF flangeXY Programmable Sweep Controllere-Vap ® Summary<strong>Vacuum</strong> coating technology has evolvedfrom an art form to a precise science overthe past 40 years. It is now commonplaceto evaporate metals, alloys, compoundsand polymers, and control their desiredthicknesses from mere atomic layers toactual microns.<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC produces state-of-the-art thin filmvacuum coating equipment. We currentlysupply users in the optical, metallurgical,medical, semiconductor, research &development, university and OEMmarketplace.Numerous applications include sunglasses,mirrors, laser optics, camera lenses, opticalfilters, infrared detectors, anti-reflectivecoatings, nano-technologies, medicaldevices, superconductors, telecommunications,automotive decorative trim,costume jewelry, corrosion resistantcoatings, stage & entertainment lighting,fiber optic coating, display technologiesand MEMs technology.The e-Vap ® Product LineMDC offers a wide range of choices andoptions. We understand that every vacuumsystem configuration may be different. Weoffer many standard off-the-shelfcomponents as well as customized designsto suit your particular deposition equipmentneed. The e-Vap ® product line supportstwo distinct evaporation methods: the firstbeing thermal or resistive evaporation andthe second being electron beamevaporation.Resistive EvaporationThe Re-Vap resistive sources are by farthe most economical and reliable methodof depositing thin films onto surfaces. Ingeneral terms, electric current passesthrough a resistive element that generatessufficient heat to melt and evaporatevarious coating materials. Materialscommonly evaporated include iron, nickel,aluminum, copper, tin, silver, gold andchrome. Three basic resistive elementdesigns are offered: filament coil, metal foiland oxide crucible types. Filament coildesigns are the most popular. All resistiveelements are relatively inexpensive andcan be discarded after each use or afterseveral uses.Electron Beam EvaporationMDC offers an unprecedented selection ofelectron beam evaporation sources andcontrol electronics. Electron beamevaporation is the most versatile means ofvacuum evaporation and deposition. Thistechnique allows the production of thin filmcoatings from pure elements, numerousalloys and compounds. Electron beamevaporation offers several advantages overcompeting processes including precisecontrol of low or high deposition rates,excellent material utilization, sequential &co-deposition and uniform low temperaturedeposition. It also offers relatively highevaporation rates, freedom from sourcecontamination, precise film compositionsand cooler substrate temperatures. Thematerials used for evaporation areavailable in near limitless shapes andforms, the most common being pellets,slugs and disks. Since the 1950s, thedevelopment of higher performance filmsand complex coating processes has beenobstructed by the lack of modern electronbeam evaporation equipment andtechnology. The e-Vap ® product line hastaken this challenge head-on and provideselectron beam evaporation sources andcontrol electronics that incorporate leadingedge technologies unmatched in theindustry.CVS <strong>High</strong> Voltage Power SupplyCopyright © 2005 MDC <strong>Vacuum</strong> Products CorporationReproduction in any manner, in whole or in part, in English orin other languages, is prohibited. All rights reserved.

<strong>Thin</strong> <strong>Film</strong><strong>Deposition</strong>Introduction 2Thermal EvaporationRe-Vap 900 4Re-Vap 3000 6Miniature Evaporation Systemse-Vap ® 100 10e-Vap ® 3000 12Mighty Source 14Modular Evaporation SourcesIndividual Source 17Horizontal Source Assembly 23Vertical Source Assembly 25Power Supplies 27Controls & MeasurementSource Control Module 28XY Programmable Sweep Controller 29<strong>Deposition</strong> Monitoring and Control 33Crucible Indexer 36Evaporation Source Accessories 37HF Emitter Assembly 41Ordering Information 43Index 441

e-Vap ®Introduction<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong><strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong><strong>Thin</strong> film deposition of metallic, insulating,conductive and dielectric materials playsan important role in a large number ofmanufacturing, production and researchapplications. Resistance heating, sputteringand electron beam are the processes mostwidely used. Techniques employed toperform these processes differ in degree ofsophistication and quality of film produced.A resistance heated evaporation source isrelatively simple and inexpensive, but thematerial capacity is very small. Sputterdeposition can be used to coat large areasand complex surfaces in productioncoating environments utilizing time andpower for rate control.Electron beam evaporation is the mostversatile means of vacuum evaporationand deposition. This technique allows theproduction of thin film coatings from pureelements, including most metals, as wellas numerous alloys and compounds.Electron beam evaporation offers severaladvantages over competing processesincluding precise control of low or highdeposition rates, excellent materialutilization, co-deposition and sequentialdeposition systems and a uniform lowtemperature deposition. Electron beamoffers higher evaporation rates, freedomfrom contamination, precise rate control atvery low deposition levels, precise filmcomposition and cooler substratetemperatures. The materials used forevaporation are available in near limitlessshapes and forms, the most commonbeing pellets, slugs and disks. Since theintroduction of electron beam evaporationin the 1950s, the development of higherperformance films and complex coatingprocesses has been delayed by the lack ofmodern electron beam equipment andtechnology. MDC’s e-Vap ® product linehas taken this challenge head-on andprovides electron beam evaporationsources and control electronics thatincorporate leading edge technologiesunmatched in the industry.<strong>Thin</strong> <strong>Film</strong> Applications<strong>Thin</strong> film applications requiring electronbeam evaporation are continuallyincreasing. Applications are found in themedical, metallurgical, telecommunication,micro-electronic, optical coating andsemiconductor industries. Electron beamevaporation sources are employed in theproduction of a multitude of low and hitechproducts including: sunglasses,camera lenses, optical filters, infrareddetectors, superconductors, automotivedecorative trim, costume jewelry, corrosionresistant surfaces and many others.Electron beam deposition is ideal forresearch and production applications dueto its widespread material availability,efficient material utilization and unmatchedfilm purity and uniformity.e-Vap ® Product LineThe e-Vap ® product line is as vast as theapplications requiring electron beamevaporation. Each and every e-Vap ®source is designed to meet or surpass thestringent requirements put forth by thevacuum coating world. As a leader andinnovator in this field, MDC holds variouspatents in electron-beam evaporationtechnology. Two notable patents includeU.S. patent numbers 5,418,348 and5,473,627. The first is for MDC’s uniqueelectron source design, which incorporateshigher material capacity with adramatically smaller source footprint. Thesecond, for an ingenious coolant deliverysystem incorporated into MDC’s UHV multipocketrotary sources. e-Vap ® electronbeam sources are available in six basicsizes, called Frames, which canaccommodate small research as well aslarge production coating requirements withcrucible capacities from 2cc to 400cc. Thesources are offered individually or ascomplete turn-key, flange-mountedsystems with all necessary serviceconnections, including fluid and electricalfeedthroughs. These state-of-the-artevaporation sources are powered andcontrolled with equally advanced solidstate switching power supplies, beamsweepers and control electronics. Thehighest rated power supply is capable of a15,000 Watt output at negative 10,000Volts, fits on a standard 19" rack, is only10-1/4" tall and weighs 100 pounds.Flange-mounted units are factoryassembled and tested including allfeedthroughs. A range of standard optionsinclude a watercooled collimator roof, astepper motor indexer and aprogrammable XY sweep controller.Miniature Evaporation SystemsMiniature evaporation systems include thee-Vap ® 100, a precision wire fed electronbeam source designed specifically fordepositing monolayer thin films in ultrahighvacuum environments. It can depositrefractory metals at an atomic level.e-Vap ® 3000 is a 2cc capacity, miniatureelectron beam evaporation system with a3kW power supply. This is a versatiledeposition tool used for thin film coatingprocesses in high and ultrahigh vacuumenvironments. The e-Vap ® 3000 systemevaporates virtually all rare earth refractoryand dielectric materials. It providesresearchers a simple, relatively low-costmeans of depositing high purity thin filmcoatings.Re-Vap resistive heater sources are alsopart of the miniature product line. Thesesources are available with filament boatsor coils and oxide crucibles. Re-Vap sources are by far the most economicalmethod of depositing thin films.Evaporation MaterialsMDC e-Vap ® sources are rugged, reliableand easy to maintain. Electron beamevaporation is an extremely versatilemeans of depositing uniform high-puritythin films. Capable of reaching elevatedtemperatures in excess of 3500°C,evaporation of virtually any material can beaccomplished.The Silica, Hafnia and Magnesium Fluoridematerials shown at right were producedusing an e-Vap ® power supply, e-Vap ®Source controller and e-Vap ®Programmable Sweep Controller with astandard figure-eight pattern at 200Hzsweep frequency. The continuous andsuperior performance of this arrangementpermits the routine evaporation of theseand other difficult materials.All dimensions in this catalog are given ininches unless specified otherwise.2 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®IntroductionMaterial SamplesTypical e-Vap ® InstallationSilica (SiO2)Fixed-Pocket UHV SourcewithManual ControlsRotary-Pocket UHV SourcewithAutomatic ControlsSubstrate FixtureCrystal SensorFeedthroughWater CooledRoofSilica (SiO2) Carousel SourceShutterHafnia (HfO2)Single-PocketSourceMulti-PocketSource<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Auto IndexerDrive<strong>Deposition</strong>Rate MonitorProgrammableX-Y Sweep<strong>Deposition</strong>Rate MonitorProgrammableX-Y SweepMagnesium Fluoride (MgF2)SourceControl ModuleSourceControl ModuleFilamentTransformerFilamentTransformerPower SupplyElectronic components fit on standard 19" rack. Filament transformer can bemounted remotely as shown or directly on source flange.MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-88173

Re-Vap Thermal Evaporation Systems<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Resistive Heater EvaporationFeatures■ 900W power supply■ 2-3/4" Del-Seal CF flange mount■ Ideal for organic material evaporation■ Contact factory for higher current modelsSpecificationsCoolingInput powerVoltage outputCurrent outputWeightDimensionsPower SupplyOutput CableAir cooled208 V ±10%, Single-phase, 50/60 Hz, 7 Amperes0 to 6 VAC0 to 150 A45lb16" W x 6" H x 12" L2 AWG x 10' LMDC’s Re-Vap resistive filament heater evaporation is an economicaland reliable method of depositing thin film coatings in vacuum.Current passing through a resistive element generates sufficientheat to melt and evaporate various coating materials. Materials commonlyevaporated using resistive heating include iron, nickel, aluminum,copper, tin, silver, gold and platinum. Re-Vap resistiveevaporation can be used for decorative metallizing as well asdemanding research applications. Three basic resistive elementdesigns are offered: filament coil, metal foil boat and oxide crucibletypes. Filament coil designs are by far the most popular. Re-Vap heater elements are economical and disposable. They can be discardedafter each use to prevent material contamination.coil. To minimize dripping of the molten material, the filament coiltemperature must be increased rapidly to 1200-1500°C. Using thistechnique, the molten material will climb or cling to the hot wire andvaporize efficiently. Another type of element coil is the filament basket,used to evaporate pellets or chips of materials which either sublimeor do not wet the filament wire upon melting. If wetting occurs,the coils of the basket are shorted and the temperature of the sourcedrops.Metal foil boat type resistive elements are yet another choice forsmall evaporation applications. Metal foil boats are made from thinrefractory metal stampings, usually tungsten, molybdenum or tantalum.These boats have dimples which hold the evaporation material.Their miniature size and small capacity make them ideal for smallevaporation jobs. Metal foil boats operate at very high temperaturesand may cause alloying to occur with certain types of evaporationmaterials. Wetting of the metal surface by the molten evaporant isdesirable in the interest of good thermal contact, however, themolten metal will lower the electrical resistance of the foil in the meltarea, thereby causing a drop in temperature. This problem can beeliminated by using a boat which has been coated with a thin layerof aluminum oxide. The oxide coating will not allow wetting of themolten metal evaporant to the metal foil element.Crucible heaters are an open circular wound filament which allowcrucibles to be inserted inside the windings. The crucibles are commonlymanufactured from alumina, carbon, quartz and boron nitride.Crucibles have insulating properties which form a thermal barrierbetween the filament and melt, allowing a uniform melt temperature.Crucible evaporation is very stable because of its uniform heating. Awide range of low to moderate temperature metals like palladium,tin, selenium, arsenic, indium and organic materials evaporate wellfrom crucibles. Crucibles are less prone to failure compared to metalfoil boats because of the complete isolation between the evaporantand the heater element, thus eliminating shorting or alloying.Re-Vap 900 Watt Power SupplyRe-Vap coiled filaments are typically three stranded tungsten wireslooped into coils. Multistrand filaments are generally used becausethey offer a greater surface area than single wire filaments. Underthese conditions, the evaporant charge should be small comparedwith the mass of the filament. The filament can hold up to 1 gram ofevaporant material which is formed into staple-like shapes and hungon the central helix of the tungsten filament. Upon melting, the evaporantwets to the filament and is held in place by surface tension.Spreading of the molten evaporant across the wire is desirable toincrease evaporation surface area. This is accomplished by distributingthe initial charge evenly over the entire length of the filament004221-2.7x3.64 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

Re-Vap Thermal Evaporation SystemsRe-Vap Source AssemblyDESCRIPTIONCOMPLETE SYSTEM 1900W POWER SUPPLYRESISTIVE SOURCE ASSEMBLY 2CONDUCTOR EXTENSION KITPOWER SUPPLY SPARE PARTS KITMETAL FOIL BOAT, TUNGSTENMETAL FOIL BOAT, TANTALUMMETAL FOIL BOAT, MOLYBDENUMCOATED FOIL BOAT, TUNGSTENCOATED FOIL BOAT, MOLYBDENUMFILAMENT COILFILAMENT BASKETOXIDE CRUCIBLE, ALUMINAOXIDE CRUCIBLE, BORON NITRIDEOXIDE CRUCIBLE, QUARTZREFERENCERH-900RH-PS-900RH-F-900RH-CEK-900RH-PSPK-900RH-MFB-900TURH-MFB-900TARH-MFB-900MRH-CFB-900TURH-CFB-900MRH-FC-900RH-FB-900RH-OC-900ARH-OC-900BNRH-OC-900QPARTNUMBER992626991256992625992619991257-08992624-01992624-02992624-03992623-01992623-02992622992621992620-01992620-02992620-03PRICE$34502450110024520172813252514172025201 Includes power supply and resistive source assembly.2 Includes filament coil heater element.Conductor Extension KitHeater ElementsResistive Heater Source AssemblyCoated Metal Foil Boat5.002.75Del-Seal CF Flange.77<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Filament CoilStandard Elements7.253.75Oxide CrucibleAcrylic<strong>High</strong>-VoltageShield2.75MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-88175

e-Vap ®Thermal Evaporation SystemsPower SupplyWeighs only20 poundsFeatures■ 3000 Watt output■ Designed for industrial / production applications■ Compact size - mounts underneath chamber■ <strong>High</strong> frequency switching power supply■ 5 or 10 Volt tap option■ Connects to Sigma or Inficon rate controllers —making it stand-alone capable■ CE compliant■ 6000 Watt stack optionPower Supply Specifications<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Re-Vap Power SupplyDescriptionMDC’s high powered Re-Vap resistive evaporation system is a highlyindustrial, robustly designed, economical method of depositing thin filmcoatings. The current passing through a resistive element (filament, boat,etc.) is produced by a unique high current, low voltage switch-mode highfrequency power supply that produces ample amounts of current needed toevaporate materials such as iron, nickel, aluminum, copper, silver, gold andplatinum. Silicon-monoxide, magnesium fluoride, as well as zinc selenideare readily evaporated.Re-Vap Power Supply & ControllerMDC has taken advantage of its extensive knowledge of high frequencysolid-state switching power supplies by incorporating that technology into apatent applied high-powered 3000 watt Re-Vap power supply. Tremendoussize and weight reductions are the result. With overall dimensions of 5" x 8"x 13" and a total weight of 20-pounds, the power supply can be mountedunderneath the vacuum coating system just inches away from the high currentfeedthroughs. The power supply is only one-eighth the size and onetenththe weight of a typical 3000 watt resistive power supply. Two uniqueadvantages include higher power efficiency and floor space savings. Powerefficiency is greater because the output cable length is reduced with aresulting lower power loss. The Re-Vap controller is a half-rack width displaymodule displaying the current, voltage, safety interlock and status/operationindicators. For automated coating processes, it may be connected to arate/thickness controller for precise control. Power can also be controlledthrough the front panel or with the hand-held remote control.CoolingInput powerPower outputOption:CableWeightDimensionsAir cooled208/220/240 VAC, Single-phase, 50/60 Hz, 25 Amperes0 to 5 VDC @ 600 amps0 to 10 VDC @ 300 amps6-foot cable included30 lb shipping5" W x 8" H x 13" DRe-Vap clamp, <strong>High</strong> Current feedthrough and Z-bar extensionsThe Re-Vap positive clamping method is universally designed for heavy useand quick-change capability. Thumbscrews are provided for fast installationof boats or filaments. Air-side clamping uses silver-plated battery clampstylehard copper connections designed for maximum surface contact andhigh current carrying capacity.The Re-Vap high current 3/4-inch feedthroughs are rated at 600 amps. Ituses high purity alumina ceramic as the dielectric material, which is hermeticallysealed to a flexible metal transition using vacuum grade braze alloysin a vacuum brazing furnace. Additionally, a removable snap-on groundshield provides protection from line-of-sight coating on exposed ceramicsurfaces. Re-Vap feedthroughs are fitted with Del-Base baseplate mountsin standard one-inch, 32mm or 34mm sizes for use in most vacuum coatingsystems, including Balzers and Leybold systems.Z-bar extensions are used in cases where normally an evaporation sourcecannot be positioned because of spacing limitations. The modular Z-bar extensions allow you to maneuver your evaporation sources around fixedequipment inside your vacuum coating system. Its versatility allows you touse them singularly or in multiples for those hard to reach locations.6 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Thermal Evaporation SystemsResistive Heater EvaporationRe-Vap typical source installation, shown with two Z-bars and boat clampsFeatures■ Industrial design■ Feedthroughs rated at 600 amps■ Removable snap-on ground shield protectsagainst coating build-up■ Z-bars allow installation of sources in difficult orhard to reach locations■ Z-bars may be used singularly or in multiples■ Clamp designed for virtually any type ofcommercial heater elements up to 1.25" wide■ Ultra positive clamping methodTypical Heater ElementsTypical Installation SchematicMetal Foil BoatRe-Vap rigid clampRe-Vap rigid clampZ-bar <strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>FilamentResistive sourceIn-vacuumshield1" Bolt hole mountfeedthroughSilver platedairside clampsBaffled Boat• Only one Z-bar shown ~ may be used inmultiplesRe-Vap clamp & Z-bar extensionStandard ElementsAll dimensions are given in inchesunless specified otherwise.MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-88177

e-Vap ®Thermal Evaporation SystemsResistive ControllerFeatures■ Front panel LED displays current and voltage■ On-Off switch■ Safety interlock■ Hand-held remote control■ Contact factory for CE complianceRe-Vap Resistive Controller<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>DescriptionThe Re-Vap Resistive Controller is designed for use with theRe-Vap 3000 Power Supply. The controller is a half-rack widthdisplay module displaying the current, voltage, safety interlock andstatus/operation indicators. For automated coating processes, itmay be connected to a rate/thickness controller for precise control.Power can also be controlled through the front panel or with thehand-held remote control. Cabling and connectors are provided.Ordering InformationResistive Controller SpecificationsConstructionCaseAluminum sheetReadoutLED displayMountHalf-rack standard electronics cabinetInput power110 volts, 50/60 HzWeight11 poundsDimensions8.5" W x 5.25" H x 14" DComplete SystemA complete Re-Vap 3000 system includes:• One 3000 watt power supply• One resistive controller• Two high current electrical feedthroughs, 1-inch bolt style• Two electrical airside clamps• Two Z-bars with bolts• Two rigid boat clamp assemblies• One metal foil boat heater elementDESCRIPTIONWTLBCOMPLETE SYSTEM 50POWER SUPPLY 30RESISTIVE CONTROLLER 10REFERENCERV-3000-SYSRV-3000-PSRV-3000-RCPARTNUMBER992970991301991303PRICE$61503000975Components may be purchased as a complete systemor individually.Metal Foil BoatFilamentBaffled BoatREFERENCEMETAL FOILFILAMENTBAFFLEDPARTNUMBER993037993038993039PRICE$161550Resistive heater elements are soldindividually.8 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Thermal Evaporation Systems<strong>High</strong> Current FeedthoughStandard 1" bolt mount1.50Hex1.00Metric style for 32mmand 34mm bolt mount1.613/8-16 UNC-2A 1-14 UNS-2A1.882.253.32 4.683/8-16 UNC-2A.75 dia.30 x 1.5mm thread.75 dia.REFERENCE1-IN. BOLT32MM BOLT34MM BOLT32MM - 1"PARTNUMBER992966993040993041991813PRICE$45045045095<strong>High</strong> current feedthroughs are availablefor mounting to baseplates inthree standard sizes. A removableshield protects ceramic insulatorfrom contamination during deposition.An adapter is available to mount a1-inch bolt feedthrough to a 32mmbolt hole. Adapter not shown.Two feedthroughs required. Soldindividually.2.125 dia.1.002.252.003.32 4.68Airside Clamps1.251.00REFERENCEPARTNUMBERPRICE$5.192.19 .94.25Fits 3/4"conductor.56 dia(2 places)1.002.00.375-16 bolt,nut andwasher (x2)1.75.63HCC-750 640070185Made of OFE copper with silverplate to minimize oxidation andcontact resistance. Two 9/16-inchholes are provided for fasteningeyelet-fitted power cables. Soldindividually.<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>.8132 places1.8752 places .3862 placesREFERENCEPARTNUMBERZ-BAR 992969PRICE$295.500Z-bar .500R .188 typ.2.8136.250R .812 typ.2.8131.6251.000MDC Z-bar extensions are usedwhere normally an evaporationsource cannot be positionedbecause of spacing limitations. Maybe used singularly or in multiplesfor hard to reach locations. Soldindividually.Boat ClampsRigid clamp1-1/4" width3-1/2" length.50F.25.250-20 Thread inHelicoil insertREFERENCEPARTNUMBERRIGID 992968-02PRICE$325Boat clamps use thumbscrews forfast installation of boats or filaments.Two boat clamps are required.Includes bolts. Sold individually.MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-88179

e-Vap ®Miniature Evaporation Systemse-Vap ® 100 SystemSpecificationsMeteringDigital Emission CurrentCoolingAir cooledInput power208 V ±10%, Single-phase, 50/60 Hz, 3 AmperesVoltage output2 kV DC negative polarityOutput RippleLess than 2% RMSVoltage Regulation 1%Current output0 to 0.05 AmperesEmission Current Regulation 1%Efficiency 85%Weight20lbDimensions19" W x 3.5" H x 18" LFeatures■ 100 Watt power supply■ Monolayer E-Beam deposition■ Precision control deposition rates■ 1mm wire feed mechanism, 2mm optional■ Refractory materials evaporation■ UHV compatible to 10 -11 Torr■ Bakeable to 250°C■ No water cooling required■ Mounted on 2-3/4" Del-Seal CF flangee-Vap ® 100 is a precision monolayer deposition source employed forevaporative coatings in UHV applications. Its unique design uses anelectron beam power source for thermionic emission and pinpointelectrostatic focusing of an electron beam onto a 1-millimeter diameterwire. The wire being evaporated is at ground potential and servesas the source anode, thus attracting electron bombardment. The constantstream of electrons heats the wire tip to its melting point forminga very small liquid ball, which is subsequently vaporized. The wireMonolayer <strong>Deposition</strong> Rates<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Li0.4LithiumNa0.4SodiumBe1.3BerylliumMg0.6MagnesiumNumbers indicate the time, in minutes, required to deposit one monolayer of the specified elements.<strong>Deposition</strong> rates are calculated at element melting point, using a substrate area of 1cm 2 , a source tosubstrate distance of 10cm and a vapor pressure of 10 -3 Torr. These values are intended as referenceonly, actual rates may vary from those listed.B2.2BoronAl1.2AluminumC2.8CarbonSi1.5SiliconNNitrogenPPhosphorusOOxygenSSulfurK0.3PotassiumCa0.6CalciumSc1.2ScandiumTi1.6TitaniumV2.0VanadiumCr2.0ChromiumMn1.7ManganeseFe2.1IronCo2.2CobaltNi2.2NickelCu2.1CopperZn0.9ZincGa1.8GalliumGe2.1GermaniumAsArsenicSeSeleniumRb0.4RubidiumSr0.7StrontiumY1.4YttriumZr2.1ZirconiumNb2.7NiobiumMo2.8MolybdenumTc3.0TechnetiumRu3.1RutheniumRh2.8RhodiumPd2.4PalladiumAg1.9SilverCd1.1CadmiumIn1.9IndiumSnTinSb1.4AntimonyTe1.4TelluriumCsCesiumBa0.8BariumLa1.7LanthanumHf3.0HafniumTa4.0TantalumW4.3TungstenRe4.4RheniumOs4.5OsmiumIr4.2IridiumPt3.7PlatinumAu2.9GoldHgMercuryTlThalliumPb1.7LeadBi1.7BismuthPo1.5PoloniumFr0.4FranciumRaRadiumAc2.0ActiniumLa1.7LanthanumCe2.6CeriumPr1.7PraseodymiumNd1.7NeodymiumPmPromethiumSm1.4SamariumEu1.0EuropiumGd1.8GadoliniumTb1.9TerbiumDy1.7DysprosiumHo1.8HolmiumEr1.8ErbiumTm1.6ThuliumYb1.4YtterbiumLu2.1LutetiumAc2.0ActiniumThThoriumPaProtactiniumU3.3UraniumNpNeptuniumPuPlutoniumAm2.1AmericiumCmCuriumBkBerkeliumCfCaliforniumEsEinsteiniumFmFermiumMdMendeleviumNoNobeliumLrLawrencium10 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Miniature Evaporation SystemsSourceAperture3.75TantalumShield,1.29" O.D.x 0.02" wallComplete SystemWire FeedAdapter2.75Del-Seal CFFlangeSource Assemblyis manually fed by a precision linear drive feedthrough, and must befed periodically as determined by source evaporation rates. The e-Vap ® 100 source evaporates high temperature refractory metalsincluding Tantalum, Molybdenum and Tungsten and most other materialsmanufactured in wire form. <strong>High</strong> temperature materials are notreadily evaporated using Knudsen or Effusion cells, making thee–Vap ® 100, because of its miniature size, an excellent PhysicalVapor <strong>Deposition</strong> (PVD) evaporation source. The elements table at leftdepicts calculated deposition rates for various pure materials.Thee-Vap ® 100 source is constructed with refractory metals for rapidequilibrium with minimal outgassing, to withstand elevated temperatureswithout the need for water cooling and to reduce the possibilityof contamination in sensitive UHV applications. The source has anoutgas mode to allow vacuum conditioning of the evaporation head.This degas feature allows heating of the e-Vap ® 100 head to driveoff any adsorbed contaminant. The source is mounted on a 2-3/4"Del-Seal CF flange. Power connections are made via four SHV coaxialconnectors clearly labeled for filament positive, filament negative,anode and screen inputs. Maintenance on the evaporation head ismade simple with easy replacement of all key components.The e-Vap ® 100 power supply incorporates all switching technologyfor the high-voltage and filament sections. This translates to a smallerand lighter package, greatly improved arc-suppression and betteremission current control. Arcs are suppressed in the order ofmicroseconds rather than the millisecond response in other 50/60Hzsystems. This, combined with lower levels of stored energy, preventthe molten tip of the evaporant rod from being “blown away” duringan arc, a common occurrence with older systems.7.451.63DESCRIPTIONCOMPLETE SYSTEM 1SOURCE ASSEMBLY100W POWER SUPPLYPOWER SUPPLY SPARE PARTS KIT2MM WIRE-FEED ADAPTERFILAMENT SET, 5 ea.1 Includes source and power supplyREFERENCEEV-100EV-SA-100EV-PS-100EV-PS-SPK-100EV-2MM-100EV-FIL-100SHVCoaxialFeedthroughsLinear MotionFeedthrough<strong>High</strong> TemperaturePARTNUMBER991029992458991192991257-07992589992596PRICE$13500377595003015560<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881711

e-Vap ®Miniature Evaporation Systemse-Vap ® 3000 System■ Includes water and electrical connections■ Evaporates refractory and dielectric materials■ CE compliantSpecifications<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MeteringCoolingInput powerVoltage outputOutput Ripple<strong>Deposition</strong> Rate vs Emission CurrentDigital Emission CurrentPower Supply: Air cooledSource: Watercooled225 V ± 25 V, Single-phase, 50/60 Hz, 18 Amperes5 kV DC negative polarityLess than 1% RMSVoltage Regulation .025%Current output0 to 0.6 AmperesEmission Current Regulation 0.25%Efficiency 85%WeightDimensions65lb19" W x 10.5" H x 19" LFeatures■ 3kW Switching technology power supply■ UHV compatible■ 2.75" Del-Seal CF flange mountMDC’s 3kW Electron Beam Source is a versatile and economicaldeposition tool used for thin film coating processes in high and ultrahighvacuum environments. The e-Vap ® 3000 system evaporatesvirtually all rare earth refractory and dielectric materials. It providesresearchers a simple, relatively low-cost means of depositing highpurity thin film coatings. The source is manufactured using all metalsealed gaskets, is extremely compact and has a high level ofruggedness, reliability and efficiency. The compact source designallows the entire source assembly to fit through a 2.75" Del-Seal CF port opening and eliminates internal water and electrical connections.This 3kW source is available free standing or as a completeturnkey system. The filament/emitter assembly has a heat-sink andfeatures a unique single piece high voltage insulator design. Theentire emitter assembly slides out for easy maintenance.A new 3kW Switching Power Supply is available to drive these miniaturesources. State-of-the-art switching technology renders a compactrack mountable power supply. The built-in source controller alsoemploys switching technology and provides extremely accurateThis graph represents stable rates (not maximum rates) @ 3kW with a source to substrate distance of 10 inches. These values are intended as reference only, actual rates may vary.1400Stable <strong>Deposition</strong> Rate in Å / min120010008006004002000SiOSiO 2HfO 2FeTiPdCoSiNiGeMoTaW0 100 200 300 400 500 600Emission Current in mA12 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Miniature Evaporation SystemsPower SupplySource AssemblySource Assembly2.75Acrylic<strong>High</strong>-VoltageShield3.757.257.872.75Del-Seal CFFlange• Source can be installed in a portwith 2-3/4" Del-Seal CF flangesSourcefits withina 1.38 insidediameter tube<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Source DetailFilament Detail2.75Del-Seal CFFlange9.002 ccCrucible.63 Source Face toFlange Center LineVap ® evaporation sources. These liners offer improved thermal stabilitywhile reducing the transfer of heat to the crucible. Liners providethe ability to easily and quickly switch evaporant materialswithout removing the crucible for cleaning. They also reduce powerrequirements to achieve specific evaporation rates. See page 39 fora detailed list of crucible liner materials.1 Includes source and power supplyDESCRIPTIONCOMPLETE SYSTEM 1SOURCE ASSEMBLY3000W POWER SUPPLYFILAMENT SET, 5 ea.ANODEBEAM FORMERBEAM FORMER INSULATORHIGH VOLTAGE INSULATORPOWER SUPPLY SPARE PARTS KITREFERENCEEV-CE-3000EV-SA-3000EV-PS-CE-3000EV-FIL-3000EV-A-3000EV-BF-3000EV-IBF-3000EV-IHV-3000EV-PS-SPK-3000PARTNUMBER992600992601991221992610991929991922990529991921991257-03PRICE$1740059851450060195155712530MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881713

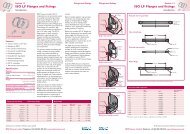

e-Vap ®Miniature Evaporation SystemsMODULAR SOURCE SERIESFeatures<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Descriptione-Vap ® Mighty Source 4 Pocket Evaporation SourcePractical, low-cost, and highly reliable electron beam depositionsources are the future as we know it today. MDC introduces the e-Vap ® “Mighty Source ”– a 4 pocket x 2cc rotary electron beamsource. Affordable and extremely compact, it stands just 2.4-inchestall by 4-inches long by 2.8-inches wide. Is there anything smallerout there? The Mighty Source is rated for 3 kilowatts of powerwhich makes it an ideal deposition tool for evaporating metals,oxides, metal-oxides, and magnetic materials. Designed into thesource body are two hermetically-sealed XY-axis sweep coils thatallow you to sweep the electron beam across the crucible pocket,resulting in the maximization of your coating process in terms ofmaterial stability and consistency. The Mighty Source design isspecifically tailored for the following uses – pilot production,lab/R&D applications, and the university marketplace. Its compactdesign features allow it to be mounted onto a 2-3/4-inch Del-SealCF flange or onto a 6-inch or 10-inch Del-Seal CF flange in eitherhorizontal or vertical configurations. To complete this product system,MDC also offers a 3kw power supply and low cost XY sweepcontroller.Specifications■ Ideal for evaporating metals, oxides, magneticmaterials and dielectrics■ Ideal for universities, lab/R&D, pilot productionusers■ Applications include metallization, MBE, nanotechnology,optics, microscopy and thin filmheads■ Rated for 3000 Watts of deposition power■ Four pocket x 2cc rotating crucible■ Ultra small footprint – total size is 2.4" H x 4.1" Lx 2.8" W■ A contained permanent magnet design producesa very small, highly dense beam spot■ XY sweep coils are included■ Crucible drive can be driven from any position –left, right, down, even angled■ Stand-alone, flange-mounted or turn-key assembliesare standard offerings■ Flange-mounts are installed on a 2.75-inch Del-Seal CF flange■ Turnkey assemblies are installed onto a 6-inchand 10 inch Del-Seal CF flange and include shutterand all electrical, water, and mechanicalfeedthroughs –ready to operate■ See the MDC web site for actual deposition ratedata on up to 27 different materials as well asdownloadable layout, e-drawings for the DesignEngineerMaximum Power3000 wattsOperating Voltage5000 voltsBeam Current600 milli-amperesCompatible <strong>Vacuum</strong>2 x 10E-8 torrWater Flow65 psi or .62 gpmXY Sweep Frequency0 – 50Hz, 1.0 ampsBeam Spot Size3-4 mmCrucible MaterialOFE copperBakeout Temperature150 o CCrucible Geometry 2.0 cc volume crucibles x 4Weight6 lbsDimensions2.4" H x 4.1" L x 2.8” W4 inchese-Vap ® Mighty Source Horizontal Source Assembly (6-inch CF flange)14 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Miniature Evaporation SystemsMODULAR SOURCE SERIESe-Vap ® Mini Sweep ControllerFlange Mounted Assemblies<strong>Deposition</strong> Rate Tablee-Vap ® 3kW Power Supply■ Complete turnkey assemblies -plug ‘n play■ Horizontal assembly is supplied on a 6" flange■ Vertical assembly is supplied on a 10" flange■ Water-cooled roofs are available as an option■ Different flange sizes are available upon request■ Physical dimensions are available atwww.mdcvacuum.com/3kw.htmor call 1-800-443-8817 for further details<strong>Deposition</strong> Rate vs PowerDepositin rate vs Power<strong>Deposition</strong> Rate (Å/sec25.020.015.010.05.0<strong>Deposition</strong> Rate vs. Emission CurrentNo Crucible Liners Used*AlTa 2 O 5TiCoGe0.00 100 200 300 400 500 600Emission Current (mA)Accelerating Voltage of 5.25 kVAll rates measured on a Crystal Rate Monitor at 10 inch crucible to sensor distance.*Indicates “with” crucible linerMoAlMATERIALAl*AlAl2O3AgCoCrCuGeHfHfO2InITOMoMgF2NbNiPdSiSi02TaTa 2O5TiTiO2WYZnSZnSeZrO2*with crucible linerSWEEP USEDYES OR NONoNoYesNoNoYesNoNoYesYesNoYesNoYesNoNoNoYesYesNoYesNoYesNoNoYesYesYesEMISSIONCURRENT (MA)500100100150200505003002501502002050010500300100300405001503001505001503010200DEPOSITION RATE(Å/SEC)4.528.08.013.09.013.02.23.07.09.018.010.08.57.01.03.050.01.025.08.07.020.07.58.040.010.040.010.0<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881715

e-Vap ®Miniature Evaporation SystemsMODULAR SOURCE SERIES☛ Power Supplies descriptionFigure 1e-Vap ® Mighty Source Vertical Source Assembly (10-inch CF flange)Figure 2Figure 3Mighty Source Details TableDESCRIPTIONREFERENCEPART #PRICEFIG<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Stand Alone Source3/4" Del Seal CF Flange (horizontal mount)10" Del Seal CF Flange (vertical mount)6" Del Seal CF Flange (horizontal mount)3KW Mini Sweep ControllerPower SupplyPower Supply (spare parts kit)Filament (pack of 5)AnodeBeam FormerBeam former Insulator<strong>High</strong> Voltage InsulatorEmitter Rebuild Kit 1 (Mighty Source)Crucible Seal Rebuild Kit (Mighty Source)Gasket (1/8” VCRFilament Clamp Sleeve*MS indicates Mighty Source Ref# EV-MS* (Mighty Source )Ref# EV-MS-F275-HRef# EV-MS-F1000Ref# EV-MS-F600HRef# Sweep-MSEV-PS-CE-3000EV-PS-SPK-3000EV-FIL-3000EV-A-3000EV-BF-3000EV-IBF-3000EV-IHF-3000Ref# ERK-MSRef# CSRK-MSCajon Fitting GasketFil Clamp Sleeve-MS1includes 2 filaments, high voltage insulator, beam form, fasteners993400993450993431993430991374991221991257-03992610991929991922990529991921993410993439042064993415550067501105010250149514500306019515571252507.50335123456789Figure 4Figure 6Figure 5Figure 7Figure 8Figure 916 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Modular Evaporation SourcesIndividual SourceMDC modular e-Vap ® sources are state-of-the-art electron-beamevaporation sources designed for the demanding and exacting worldof vacuum coatings. This unprecedented selection of electron-beamevaporation sources provides vacuum coating solutions for mostapplications including medical, metallurgical, telecommunications,micro-electronics and optics.Modular sources are offered in six standard frame sizes and are standalone components for maximum installation flexibility in existing vacuumsystems. For those desiring standard off-the-shelf solutions,complete horizontal and vertical flange mounted systems are alsoavailable. For a detailed presentation of horizontal and vertical turnkeycoating systems please refer to products beginning on page.Modular sources are fitted with direct watercooled crucibles. Selectmodels have indirectly cooled crucibles that allow the user to changecrucibles without interrupting the flow of water to the source andwithout having to disassemble the source. Modular sources areoffered with material capacities from 6cc to 400cc in a multitude ofpocket geometries and arrangements. They are available in bothfixed and rotary pocket mechanisms for high and ultrahigh vacuumenvironments. e-Vap ® modular sources are designed for optimumperformance with e-Vap ® power supplies, controls and electronics.Other essential components and hardware required for the installationof e-Vap ® modular sources are detailed starting on page.Contact the MDC technical sales engineers for custom electronbeamevaporation requirements.FeaturesFilament Assembly■ Filament is shielded from ion bombardment■ No shorting■ Longer filament life■ Reduced coating of ceramic insulators■ Reduced arcingEmitter Assembly■ 270° arc emitter module■ Heat sunk emitter■ Consistent electrostatic field■ Longer life anode and beam former■ Reduced filament distortion■ Modular plug-in emitter design■ Simple maintenance■ Simple filament replacement■ Minimal adjustment...only requires verification of filament toleranceOpen Cathode Design■ No space charging■ Increased emission■ Cooler operating filament...requires only 42 amps for 15 kWShielded <strong>High</strong> Voltage Ceramics■ Reduces coating of ceramic insulators■ Prevents arcing■ Unique high voltage insulator design...no screws to reduce dielectric breakdownBeam Sweep Coil Assembly■ Helmholtz design principle produces a uniformmagnetic field■ No tunneling■ Beam maintains constant density and shapewhen swept across crucibleMagnet Assembly■ Permanent magnets■ 270° arc beam deflection...with positive beam containment■ Reliable beam positioning■ No pole pieces■ Efficient magnetic field generation■ Beam travels vertically through crucibleCrucible Module / Replaceable Modules■ Capacity from 6cc to 400cc■ Complete flush-top design■ No condensate build up■ No contamination from flaking condensate■ Complete utilization of vapor cone during deposition...no shadowing■ Reduced cross-contamination during changes ofevaporant material<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881717

e-Vap ®Modular Evaporation Sources<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>Custom Sources and AssembliesCustom source and source assemblies can be designed to fit anexisting chamber or for a special application. Contact MDC fordetails regarding custom source assemblies or custom sources.Featurese-Vap ® Modular Evaporation SourcesCustom source and source assemblies■ Six Frame SizesCrucible / Pocket GeometryStandard configurations■ Single, Multipocket or Carousel Crucibles■ Custom Crucible configurations available■ Crucible sizes from 6cc to 400cc■ Power ratings from 6kW to 15kW■ Direct or indirect water coolingOptions■ Source Options are available-Consult with MDC for existingdesigns, availability and list prices.■ Single Pocket Sources (Frame 1 and Frame 2) UHV compatiblesources, volumes 7cc to 100 cc.■ UHV Rotary Mechanism (Frame 4 and Frame 5) allows forUHV operation of the multi pocket sources.■ Direct and Indirect Cooling (Frame 5 and Frame 6) optionfor both of these frame sizes. direct cooling allows for higherpower levels to be applied during deposition, the water sealmust be disturbed to change the crucible. Indirect coolingallows the crucible to be removed without disturbing the waterto vacuum seal, however maximum power levels are lower withindirect cooling.■ Custom Crucibles Can be machined with various pocketsizes and configurations depending upon your application. MDCwill manufacture any custom crucible that is required includiingsingle, four pocket, six pocket, pan carousel and bananas.Custom configurationsSingle-PocketCenteredMulti-Pocket 44@90°Multi-Pocket 66@60°Carousel360° Pan1x270°, 1@45°Shown above is one of many possibilities.Contact factory for special geometries.FRAME NUMBER VOLUME MAXIMUMSIZE OF POCKETS PER POCKET POWERREFERENCEPARTNUMBERPRICE$Standard Multi Pocket Sources that havebeen identified by our customers as themost popular sources are listed to the right.MDC is has made a commitment with subcomponentinventory to offer reduced leadtimes for standard multipocket sources.3 4 6cc 6kW4 4 6cc 6kW5 4 15cc 10kW5 4 25cc 10kW5 6 12cc 10kW5 1 150cc 10kW6 4 40cc 15kW6 4 75cc 15kW6 1 400cc 15kW6 6 40cc 15kWEV-4000-66EV-4000-66UHVEV-4000-1015EV-4000-1025EV-6000-1012EV-4000-150CAEV-4000-1540EV-4000-1575EV-4000-400CAEV-6000-15409916009917009919009918009921009925239924059924069931019931001050013750112251122511675112501422514625145251472518 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Modular Evaporation Sources8.2Frame 1SmallFixed PocketSpecificationsSource SizeSmallSource TypeFixed PocketMaximum Power15kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeSingle-Pocket 7, 15, 25 & 40ccX-Y Sweep Frequency 200HzEvaporation Rate of Aluminum50,000Å/min @14kW with a source tosubstrate distance of 250mmBeam Spot Size7mmCrucible Material OFE CopperBakeout Temperature200 ° CMaterialsUHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -11 TorrWater Flow3GPM and / or 65PSIG inlet-outlet differentialDimensions 6.60L x 4.90W x 2.10HWeight9 lbsREFERENCECRUCIBLEVOLUMEMAXIMUMPOWERPARTNUMBERPRICE$EV-1000-67EV-1000-1015EV-1000-1025EV-1000-15407cc15cc25cc40cc6kW10kW10kW15kW9905989905999905979906007850785078507850Frame 2SpecificationsSource SizeLargeSource TypeFixed PocketMaximum Power15kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeSingle-Pocket75 & 100ccX-Y Sweep Frequency 200HzEvaporation Rate of Aluminum50,000Å/min @15kW with a source tosubstrate distance of 250mmBeam Spot Size7mmCrucible Material OFHC CopperBakeout Temperature200 ° CMaterialsUHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -11 TorrWater Flow3GPM and / or 65PSIG inlet-outlet differentialDimensions 6.60L x 5.50W x 2.25HWeight10 lbsLargeFixed Pocket<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>REFERENCECRUCIBLEVOLUMEMAXIMUMPOWERPARTNUMBERPRICE$EV-1000-1575EV-1000-1510075cc100cc15kW15kW992250992430875011750MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881719

e-Vap ®Modular Evaporation SourcesFrame 3SmallRotary PocketSpecificationsSource SizeSmallSource TypeRotary PocketMaximum Power6kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeMulti-Pocket4x 6cc, 6x 3ccCarousel360°, 15ccX-Y Sweep Frequency 200HzEvaporation Rate of Aluminum8,000Å/min @6kW with a source tosubstrate distance of 250mmBeam Spot Size7mmCrucible Material OFHC CopperBakeout Temperature150 ° CMaterialsHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -8 TorrWater Flow2GPM and / or 65PSIG inlet-outlet differentialDimensions 5.32L x 5.12W x 2.46HWeight10 lbsREFERENCECRUCIBLEVOLUMEMAXIMUMPOWERPARTNUMBERPRICE$EV-4000-66EV-6000-664 X 6cc 6kW6 X 3cc 6kW9916009921661050010750Frame 4SmallUHV Rotary Pocket<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>SpecificationsSource SizeSmallSource Type UHV Rotary PocketMaximum Power6kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeMulti-Pocket4x 6ccX-Y Sweep Frequency 200HzEvaporation Rate of Aluminum8,000Å/min @6kW with a source tosubstrate distance of 250mmBeam Spot Size7mmCrucible Material OFHC CopperBakeout Temperature200 ° CMaterialsUHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -11 TorrWater Flow1.75GPM or 65PSIG inlet-outlet differentialDimensions 8.37L x 5.37W x 3.37HWeight17 lbsREFERENCECRUCIBLEVOLUMEMAXIMUMPOWERPARTNUMBEREV-4000-66UHV 4 X 6cc 6kW 991700PRICE$1375020 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Modular Evaporation Sources8.2Frame 5LargeHV & UHV Rotary PocketSpecificationsSource SizeLargeSource Type HV Rotary PocketUHV Rotary PocketMaximum Power10kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeMulti-Pocket 4x... 15, 25 & 30cc, 6x 12ccCarousel360° 150ccCombination Custom designs availableEvaporation Rate of Aluminum30,000Å/min @10kW with a source tosubstrate distance of 250mmX-Y Sweep Frequency 200HzBeam Spot Size7mmCrucible Material OFE CopperBakeout Temperature150 ° CMaterialsHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -8 TorrWater Flow3GPM and / or 65PSIG inlet-outlet differentialDimensions 6.20L x 5.62W x 3.25HWeight27 lbsREFERENCECRUCIBLE MAXIMUM COOLINGVOLUME POWERPARTNUMBERPRICE$EV-4000-1050EV-6000-1015UHVEV-4000-1025EV-4000-1030EV-6000-1012EV-4000-615iEV-4000-625iEV-4000-630iEV-4000-150CARiEV-4000-150CAR4 X 15cc4 X 15cc4 X 25cc4 X 30cc6 X 12cc4 X 15cc4 X 25cc4 X 30cc1 X 150cc1 X 150cc10kW10kW10kW10kW10kW6kW6kW6kW6kW10kWDirectDirectDirectDirectDirectIndirectIndirectIndirectIndirectDirect99190099270099180099240899210099252599250099258599250299252310500166251122511675116751143511500125501187511250<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881721

e-Vap ®Modular Evaporation SourcesFrame 6Extra-LargeRotary PocketSpecificationsSource SizeExtra-LargeSource TypeRotary PocketMaximum Power15kWOperating Voltage 6kV to 10kVFilament12VACCrucible Geometry / VolumeMulti-Pocket 4x... 40, 60 & 75cc, 6x 40ccCarousel360° 400ccCombination Custom designs availableX-Y Sweep Frequency 200HzEvaporation Rate of Aluminum50,000Å/min @15kW with a source tosubstrate distance of 250mmSource-Substrate Distance 250mmBeam Spot Size7mmCrucible Material OFE CopperBakeout Temperature150 ° CMaterialsHV CompatibleCompatible <strong>Vacuum</strong> 2x10 -8 TorrWater Flow3GPM and / or 65PSIG inlet-outlet differentialDimensions 8.50L x 6.87W x 3.50HWeight40 lbsREFERENCECRUCIBLE MAXIMUM COOLINGVOLUME POWERPARTNUMBERPRICE$<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>EV-4000-1540EV-4000-1560EV-4000-1575EV-6000-1525EV-6000-1450EV-4000-400CARiEV-4000-400CAREV-6000-640i4 X 40cc4 X 60cc4 X 75cc6 X 25cc6 X 40cc1 X 400cc1 X 400cc6 X 40cc15kWW15kW15kW15kW15kW6kW15kW6kWDirectDirectDirectDirectDirectIndirectDirectIndirect992405992400992406992599993100992720993101992674142251555014625155501472516625145251562522 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Modular Evaporation SourcesHorizontal Source AssemblyHorizontal Flange Mounted SystemFeatures■ UHV compatible system■ 8" or 10" Del-Seal CF flange mount■ Assembly includes rotary, linear and electricalfeedthroughs, clamps, linkages, water flow switchand water connections■ Manual, push-pull shutter■ <strong>High</strong> temperature, 300°C manual rotary drive on4 pocket models; blanked off on single pocket■ Flange seal surface to crucible centerline is 8" on8" Del-Seal CF■ Flange seal surface to crucible centerline is 10"on 10" Del-Seal CF■ Systems available with or without watercooledroofsUHV Single-Pocket Source10.00 with 10" Flange8.00 with 8" FlangeCoolingRoofCrucible Face to Flange Center Line0.30" Fixed on 8" Flange0.14" Fixed on 10" Flange1.38" Rotary on 10" Flange<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>10.75 Shutter Open8.75 Shutter ClosedSource/CrucibleWater LinesShown withUHV Rotary-Pocket SourceFrame Size 4Cooling RoofWater LinesShown with10" Del-Seal CFFlange14.0 with 10" Flange12.0 with 8" FlangeUHV Rotary-Pocket SourceManual ShutterLinear FeedthroughPocket IndexerRotary FeedthroughFilament Transformer<strong>High</strong> Voltage FeedthroughX-Y SweepInstrumentation FeedthroughGuide RodSupport BushingsMDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881723

e-Vap ®Modular Evaporation SourcesVertical Source AssemblyFeatures■ UHV compatible system■ 10.0" Del-Seal CF flange mount■ Assembly includes rotary and electricalfeedthroughs, clamps, linkages, water flow switchand water connections■ Shutter is fitted with a high temperature, 300°Cmanual rotary drive■ Flange seal surface to crucible centerline is 6"standard■ Systems available with or without watercooledroofsVertical Flange Mounted SystemCoolingRoof11.90<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>6.00UHV Single-Pocket SourceUHVSingle-PocketSource7.0010" Del-Seal CFFlangeVertical Flange Mount / Less Cooling RoofCooling RoofWater LinesSource/CrucibleWater LinesX-Y SweepInstrumentation FeedthroughManual ShutterRotary FeedthroughFilament Transformer<strong>High</strong> Voltage FeedthroughMDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881725

e-Vap ®Modular Evaporation SourcesVertical Flange Mounted SourceMDC has eliminated the difficulties of flange mounting electronbeam sources. The effort that goes into designing and fitting asource to a vacuum coating chamber has been done for you with theintroduction of standard vertical flange mounted evaporationsources. The flanged assembly includes one 7cc electron beamsource with all water and electrical connections. This type of flangemounted system is typically installed vertically through the bottomside of a chamber. The compact footprint of these flanged evaporationsystems requires only one port flange for installation. A popularoption commonly ordered with these systems is a water-cooled roof,which mounts directly above the e-Vap ® source. The water-cooledroof acts as a heat barrier between the source and substrate andalso prevents vapor condensation on chamber walls.The watercooled roof is fitted with a deposition port, angled towardsthe substrate, which yields excellent deposition uniformity, evenwhen source to substrate centerlines are offset. The single-pocketsource comes standard with a 7cc capacity crucible. The sameassembly can be fitted with larger capacity sources including 15, 25and 40cc versions. To order the larger volume crucible option addone of the three option numbers to the end of the assembly partnumber. Vertical systems purchased with a source control modulewill be fitted with flange-mounted filament transformers.MOUNTING FRAME SOURCE COOLING SOURCE WEIGHTFLANGE SIZE TYPE & VOLUME ROOF NUMBER POUNDSREFERENCEPARTNUMBERPRICE$10" DEL-SEAL 1 ONE POCKET 7cc NO 990598 5010" DEL-SEAL 1 ONE POCKET 7cc YES 990598 50EV-FMP-10VEV-FMP-10RV9925119925131475015500Optional Accessories<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>OPTION -01Pneumatic ShutterShutters mask off the vapor stream betweensource and substrate. Shutters are ideal forpre-melt or “soak” prior to deposition by blanketingthe evaporation material. Pneumaticshutters for vertical flanged assemblies cannotbe mounted on source flange, but can beinstalled through a secondary 1.33" Del-Seal CF port. This shutter is a two position shutterwhich includes a 120VAC solenoid.OPTION -06 TO -08Custom Crucible VolumeThe standard volume for a single-pocket crucibleis 7cc. For single pocket volumes of 15,25 or 40cc add option -06, -07 or -08 respectively.OPTION -04Custom Source PositionSource position is the distance from the sourceface to mounting flange seal face. This dimensionis standard at 6" for all vertical systems.Customer chamber layout or specificationsmay dictate a custom distance. Source positionsbetween 6" and 10" are optional andavailable at the price listed bellow. Dimensionsoutside these limits must be quoted separately.OPTION -05Custom Roof PortsWatercooled roofs have three ports. A mainport directly over the source, which is usedfor the deposition process. A second port forthe crystal sensor is used to monitor depositionrate. A third port provides direct visualinspection of the source and beam through achamber viewport. Each of these port locationscan be specified by the customer.DESCRIPTIONPNEUMATIC SHUTTER, TWO POSITIONCUSTOM SOURCE POSITIONCUSTOM COOLING ROOF PORTS15cc CRUCIBLE25cc CRUCIBLE40cc CRUCIBLEOPTIONNUMBER-01-04-05-06-07-08PRICE$15005001250CallCallCallWhen ordering e-Vap ® assembly options, please add the option number(s) to the end of thedesired assembly Part Number listed above. For example 992511-01-04-05-0826 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Modular Evaporation SourcesPower SuppliesFeatures■ 6kW, 10kW and 15kW models■ <strong>High</strong> frequency switching technology■ Excellent regulation■ Low stored energy■ Power efficiency greater than 85%■ Low ripple■ Rugged IGBT switches■ CE compliant■ Sequential or simultaneous operation of up tothree electron beam evaporation sourcesCVS-6 Power SupplySpecificationsMeteringDigital Voltage and Emission CurrentCoolingAir cooledInput power 208 V ±10%, Three-phase, 50/60 Hz, 30, 40, 60 Amperes400 V ± 5%, Three-phase, 50/60 Hz, 15, 20, 30 AmperesVoltage output1 to 10 kV DC, negative polarityVoltage RippleLess than 1% RMSVoltage regulation± 0.25% of full scale outputEfficiency 85%Cables From – To LengthInput power cord Facilities outlet – Power Supply 12'8 gauge ground wire Power Supply – Ground 12'Current output6 kW 0 to 0.6 Amperes10 kW 0 to 1.0 Amperes15 kW 0 to 1.5 AmperesWeightSee TableDimensions19" W x 10.25" H x 21" Le-Vap ® CVS Series Power Supplies are constructed using state-ofthe-artsolid state high frequency switching technology. They areoffered in three standard models rated for 6kW, 10kW and 15kW.CVS series power supplies are for use with the horizontal and verticalflange mounted systems detailed on the previous four pages, aswell as the e-Vap ® modular sources as detailed beginning on pageof this catalog. These power supplies are also compatible with mostcommercially available electron beam sources and are recommendedas upgrade power supplies in existing electron beam evaporationsystems.Power supply enclosures are fully interlocked for operator safety.e-Vap ® CVS Series Power Supplies can power and control up tothree electron beam sources. Source controls and X-Y Sweeps arenot included with power supplies and must be purchased separately.For ordering information please see the next three pages. Thee-Vap ® source control module also employs solid state high frequencyswitching technology and is designed to precisely controlemission current when used with e-Vap ® power supplies. MDC recommendsthe use of a high voltage grounding hook when servicingor working with all high voltage power supplies. Grounding hooks aredetailed on page of this catalog.POWERWEIGHTSUPPLY VOLTAGE POUNDS6kW 208 7510kW 208 9015kW 208 1006kW 400 7510kW 400 9015kW 400 100REFERENCECVS-6-2CECVS-10-2CECVS-15-2CECVS-6-4CECVS-10-4CECVS-15-4CEPARTNUMBER991240991275991242991193991245991246PRICE$153002257524750153002257524750<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881727

e-Vap ®Controls and MeasurementSource Control ModuleSource Control ModuleFeatures■ <strong>High</strong> frequency switching technology■ Improved emission stability over 60 Hz SCRcircuits■ Compact filament transformer■ Electrically isolated from high voltage unit■ Grounded and shielded filament transformeroffers improved safety over conventional designs■ Self contained emission current monitoring forindependent operation■ CE compliant■ Full remote control capability■ Touch screen programming■ PS/2 handheld mouse/trackball■ Rack mount brackets included<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>IndirectSpecificationsMeteringDigital Emission CurrentCoolingAir cooledInput power208 V ±10%, Single-phase, 50/60 Hz, 8 AmperesVoltage output12 VACCurrent output0 to 70 AmperesEfficiency 85%Cables From – To LengthInput power cord 1 Wall outlet – Source Control Module 7.5'Interface cable 1 Power Supply – Source Control Module 6'Secondary cable 1 Transformer – e-Vap ® Source 3'Control cable 2 Source Control Module – Transformer 12'Transformer input cable 2 Source Control Module – Transformer 12'<strong>High</strong> voltage cable 2 Power Supply – Transformer 12'WeightDimensionsDirect20 lb8.5" W x 5.25" H x 14" L1 Fixed length cables; not available in other lengths2 A 25-foot cable kit may be purchased separately; three cables are included in one kite-Vap ® CVS Source Control Modules are designed for use withe-Vap ® CVS Series Power Supplies. The source control module unitincludes filament transformer assembly, hand held mouse controland all necessary cables for hook-up with an e-Vap ® CVS PowerSupply. A maximum output current of 70 amperes assures sufficientpower to drive virtually any commercially available electron beamsource. e-Vap ® CVS Source Control Modules are available in threeinstallation packages, direct flange mount and two remote cablemounts. Direct flange mount packages are used on all MDC flangemounted evaporation systems. This package allows mounting of thefilament transformer to a high voltage feedthrough fitted with a2.75" Del-Seal CF flange. Filament transformer attachment isaccomplished by bolting the transformer housing via two of theflanges .250-28 bolts positioned 180° apart. The remote cablemount packages provide 36" of high voltage cable with OFE copperconnector lugs and an acrylic high voltage shield. This package istypically used with modular source installations where high voltageelectrical feedthroughs are fitted with 2-3/4 Del-Seal CF flanges,but limited space does not allow direct installation. The secondremote package is used on installations where high voltage are two1" feedthroughs.The source control module’s compact size occupies only half thewidth in a standard 19" electronics rack. To facilitate the installationinto a standard 19" rack, MDC offers half-rack spacers. However, ifthe source control module is purchased in conjunction with an e-Vap ® programmable X-Y sweep controller the two units can be fastenedtogether to form the standard 19" rack width and would notrequire the half-rack spacer.DESCRIPTIONWEIGHTPOUNDSDIRECT PACKAGE 10REMOTE PACKAGE 10REMOTE FOR 2-1" BOLT FT10HALF RACK SPACER 125-FOOT CABLE KIT 3REFERENCESCM2-DFM-CESCM2-RCM-CESCM2-RCM-1"BEV-HRSSCM-25FC-CEPARTNUMBER991364-01991364991364-02991062991287PRICE$56005750600512585028 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Controls and MeasurementXY Programmable Sweep Controllere-Vap ® XY Programmable Sweep Controller with mouseDescriptionThe next generation e-Vap ® Programmable Sweep Controller has takenelectron beam sweep capabilities to a higher level in versatility and practicality.It combines years of customer feedback with the latest advances in electronicstechnology. It possesses profound advancements from its predecessor interms of functionality and ruggedness. It is designed with both the coatingengineer and coatingoperator in mind. Electronbeam control is dynamicallyprecise allowing theuser optimum ability todeposit dielectrics andmetals in the mostdemanding of applications.The strength of the sweepcontroller lies in its abilityto easily adapt to differentevaporation processWelcome Screen Displayrequirements, using its many expandable sweep patterns. Four predefinedsweep patterns and up to 95 additional user-defined patterns can bestored. The predefined patterns include CIRCLE, SPIRAL, FIGURE 8, andLINE patterns. Each of the 95 user defined patterns may consist of upto 208 XY points with a different beam dwell time for each beam point.The user interface includes a large, vibrant color LCD display with sixfunction keys and a smooth rolling adjustment knob. A handheld PS/2device/trackball is provided which allows beam maneuverability forcrucible material preparation and evaporation. For computer-automatedvacuum systems, a detailed rear panel digital I/O port along with astandard RS-232 interface allows access to the most important sweeperfunctions and status signals. An optional interactive Windows program isavailable allowing desktop sweep pattern design and virtually unlimitedsweep pattern storage.Features■ Use with virtually any electron beam source■ Large color LCD display■ Store up to 99 sweep patterns (up to 95user programmable)■ Four pre-defined and highly expandablepatterns include CIRCLE, SPIRAL, FIGURE 8,and, LINE patterns■ PS/2 handheld mouse/trackball control included■ An audible alarm warns of possible fault conditions■ Ability to custom name each sweep pattern■ Ability to choose a crucible pocket number tocorrespond to specific sweep patterns and/orparameters such as beam centering orevaporation material specification■ Ability to custom name the sweep controlleritself for coating machine identification■ Expanded beam power-profile capabilitiesallow the user to control erosion of difficultto evaporate materials■ Customizable display color (foreground andbackground) to match your company colorsor coating machine colors■ Password option – requires a four digitpassword to access functions■ RS-232 interface■ Safety-interlocked■ All cabling included■ CE compliant■ Rack mounting brackets includedSpecificationsGraphic DisplayColor LCDInput Power100-120/200-240V, 50/60Hz, 3AMax Coil Output (sweep + dc bias)5 AmpsMax Sweep Frequency200 HzProgramming InterfacePushbutton, Digital I/O, or RS-232Mouse Remote InputPS/2Max Cable Length (18AWG)25 feet (7.6 meters)Weight11 lbsDimensions8.5" W x 5.25" H x 14” L, Rack-mountable<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881729

e-Vap ®Controls and MeasurementSweep Pattern TypesAll of these patterns may have their sweep characteristics andparameters highly modified. These parameters include SPEED, PHASE,and POWER PROFILE.SPEED is defined as the speed of which the beam travels to completeone cycle of a given pattern. The fundamental frequency of beam sweepis speed. SPEED settings are Fast, Medium, and Slow. Fast is consideredthe base time, Medium takes twice as long, and Slow takes fivetimes as long.PHASE is defined as angular pattern rotation per cycle. The pattern isrotated a few degrees after each sweep pattern cycle. PHASE settings areFast (50 degree steps), Medium (20 degree steps), Slow (10 degreesteps), and None.POWER PROFILE is defined as speed of the beam based on its distancefrom the center of the crucible. It allows the beam to sweep faster throughthe center of the crucible than at the outer edges. The parameter of apattern crossing a crucible too many times, thus resulting in “tunneling”of the material, may be adjusted to obtain “even” beam temperaturedistribution across the crucible surface. POWER PROFILE settings rangefrom 1 to 1/R 2 . A setting of 1 is considered as the beam dwell time, beingthe same for all points. A setting of 1/R 2 is considered the beam dwelltimes being four times greater on the outer edges of the crucible. Adjustingthe profile between 1 and 1/R 2 (twenty possible adjustments) is a newfeature for the sweep controller and adds coating process optimization tothis already valuable parameter.Select PatternCircle Pattern<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>The Select pattern allows the user to view patterns 1 through 99. Allpatterns may be started and/or edited from here as well.A CIRCLE pattern makes the beam sweep in concentric circles beginning atthe outer edge of the crucible and steps closer to the center of the cruciblewith each revolution. Upon reaching the center, a reverse cycle begins andthe beam sweep pattern continues.Spiral PatternFigure 8 PatternA SPIRAL pattern makes the beam sweep in a continuous spiral, beginning The FIGURE 8 pattern makes the beam sweep in a well-defined figure 8at the outer edge of the crucible and advancing toward the center and then path across the crucible.back out again.30 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Controls and MeasurementDisplay ModesLine PatternSystem ParametersA LINE pattern makes the beam sweep in a straight line across the crucible.As in all the predefined patterns (circle, spiral, figure 8 and line), the sweepamplitude, speed, phase, power profile, and XY offset can be readily adjusted.There is also easy access to selecting patterns and scrolling throughdifferent screen menus.User PatternThe System Parameter screen allows the XY offset to be adjusted andstored. Linearity and contrast adjustments can be implemented from here aswell. Foreground and background color selections can also be made fromthis screen and will affect all subsequent patterns. The maximum allowablesweep amplitude current can be set here for the pattern. You can alsodesignate the coating machine’s name as well as adjust the sensitivity of themouse from this screen.User Pattern<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>User Pattern: Ninety-six (96) user-defined patterns, completely customizableby the user, can be designed and stored into the sweep controller for instantaccess. Each of the user-defined patterns can contain up to 208 beamlocation points. Each point can possess its own dwell time ranging from1 to 100mS. Patterns can be designed via front panel or through RS-232. Ifdesigned via the front panel, a color interactive matrix panel is displayed foruser feedback. It displays a crucible-shaped area showing all selected points(see the Interactive Matrix Panel screen shown on the left.) Custom namingof the generated pattern, adding and deleting points/patterns, and modifyingdwell times is all done on this same screen. A new feature of the sweepcontroller allows the user to access the SPEED function as well. Choices areFast, Medium, and Slow.MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881731

e-Vap ®Controls and MeasurementCustomize the Pattern/Controller NameThe sweep controller has the ability to custom name each individual sweeppattern, whether pre-defined or user-defined. For example, when youchoose a specific pattern for a specific evaporation material, it may bedesirable to name the pattern after the evaporation material, such as“QuartzPattern” or “TitaniumPattern.”The sweep controller also has the ability to store a name for itself. If yourcoating machine is called “Coating Machine One,” you could customize thename of the sweep controller as, “CoatingMachine1.”The sweep controller also has the ability to assign a specific patternnumber (1 to 99) to a specific crucible number or crucible pocket. This isadvantageous for users who always have a certain evaporation material ina certain crucible pocket. This allows the user to have saved custom sweepand beam parameters for a given crucible pocket. This is beneficial sincemost deposition controllers have the ability to invoke crucible pocketsduring a coating cycle.Optical Coating Uniformity SolutionsHandheld PS/2 Mouse/TrackballRotary Pocket Evaporation Source with HF Emitter Assembly0<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>6030306090 901.0 0.8 0.6 0.4 0.2 0.0 0.2 0.4 0.6 0.8 1.0Maximize coating distribution with optimal sweep patternsThe XY Programmable Sweep Controller comes equipped witha handheld PS/2 mouse/trackball which allows activation, and XYoffsets and sweep amplitude adjustments from up to 6 feet away.• Sweep On/Off – click the left mouse button• DC On/Off – click the right mouse button• Edit XY Offset – roll the trackball in the desired direction• Edit Amplitude – highlight amplitude, roll the trackball up or down.Ordering InformationHidden Filament Emitter AssemblyDESCRIPTIONREFERENCEPARTNUMBERPRICE$XY PROGRAMMABLE SWEEP CONTROLLERHALF RACK SPACERXYS2-CEEV-HRS991344991062440012532 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation

e-Vap ®Controls and Measurement<strong>Deposition</strong> Monitoring and ControlDescriptionMDC offers a choice of four units with a range of capabilities frommonitoring the deposition process to controlling multiple depositionprocess or controlling co-deposition processes. The choices are tailoredfrom introductory / economical thin film deposition to fullprocess control for a production process. Co-deposition of materialsfrom multiple sources allows easier fabrication and investigation ofcomplex material compositions and layers. All of the monitors andcontrollers utilize proven 6 MHz quartz crystal sensor technology tomeasure the thin film deposition process.SQM-122C Screen ExampleSQM-160 Rate/Thickness MonitorThe SQM-160 measures thickness and deposition rate of the thinfilm deposition process. The base unit can monitor from 2 independentmeasurement channels. Four relays are available to controlsource and crystal shutters during the deposition process. Up tonine films can be stored in memory in the SQM-160, active film canbe easily changed from the front panel. All parameters can also beset from the front panel of the monitor. The SQM-160 is a monitoronly it is not capable of controlling the rate during deposition.The SQC-122 controls deposition rate and thickness in multi-layerthing film deposition processes. The controller was designed forease of use with six content sensitive Softkeys providing rapidaccess to frequently used data. The 122C memory will hold up to 25processes consisting of 250 layers and 25 materials. Cut / Copy/Paste Capabilities make it easy to modify or duplicate processesand layers. The controller has inputs for two crystal sensors, two 0-10 volt outputs are available to control the evaporation rate. Eightrelays and digital inputs can be independently assigned to over 40possible events, including pocket rotation and external process controls.A windows program for set up and data acquisition is alsoincluded with the controller.<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>SQM-222C Co <strong>Deposition</strong> ControllerSQM-122C Two Channel <strong>Deposition</strong> ControllerThe SQC-222C model of the controller includes software for co-depositioncontrol. The two crystal sensors and two outputs to controldeposition rate, along with special software features allow for codepositioncapability.MDC <strong>Vacuum</strong> Products Corporation www.mdcvacuum.com Phone 800-443-881733

e-Vap ®Controls and Measurement<strong>Deposition</strong> Monitoring and Controlcommunicate with digital I/O cards. The SQS-242 software packagesupports multiple cards, co-deposition, digital I/O , graphing, anddata logging.<strong>Thin</strong> <strong>Film</strong> <strong>Deposition</strong>SQM-242 Co <strong>Deposition</strong> Controller PCI CardThe SQM-242 is a thin film deposition controller and a standardPCI expansion card. Each SQM monitors from one to four crystalsensor inputs, and provides two control voltage outputs. Atypical single sensor deposition system is shown, the SQM-242card is installed in a computer, a quartz crystal sensor is connectedto the input and the output is connected to a power supply.The card will control the deposition rate and adjust the outputof the power supply for constant deposition rate. The basicSQM-242 card includes software that is easily modified toCrystal Sensor PackagesSQM-242 Co <strong>Deposition</strong> Controller SoftwareDESCRIPTIONSQM-160 TWO CHANNEL DEPOSITION MONITORSQM-122C TWO CHANNEL DEPOSITION MONITORSQM-22C TWO CHANNEL DEPOSITION MONITORSQM-242 TWO CHANNEL DEPOSITION MONITORSQS-242 CO DEPOSITION SOFTWAREREFERENCESQM-160SQC-122CSQC-222CSCM-242SQS-242PARTNUMBER9913669913099913679913279913281" Base-Plate Low Profile 2.75" Del-Seal CF Low Profile 2.75" Del-Seal CF Bakeable to 400°CPRICE$12952700315012951075This low profile sensor package includes sensor head,oscillator, 30" in-vacuum cable, 6" BNC cable, 10' BNCcable, a box of gold coated sensor crystals with 5crystals per box, two Swagelok ® compression fittingsand a 1" base-plate sensor feedthrough. Bakeable to180°C.This low profile sensor package includes sensor head,oscillator, 30" in-vacuum cable, 6" BNC cable, 10' BNCcable, a box of gold coated sensor crystals with 5crystals per box, two Swagelok ® compression fittingsand a 2.75" Del-Seal CF sensor feedthrough. Bakeableto 180°C.This bakeable sensor package includes a 400°C bakeablesensor head, oscillator, 30" in-vacuum cable, 6"BNC cable, 10' BNC cable, and a box of gold coated sensorcrystals with 5 crystals per box. Sensor head is preinstalled on a 2.75" Del-Seal CF flange, which includesthe sensor feedthrough.WEIGHTDESCRIPTION MOUNT POUNDSREFERENCEPARTNUMBERPRICE$LOW PROFILE SENSOR PACKAGE 1" BASEPLATE 5LOW PROFILE SENSOR PACKAGE 2.75" DEL-SEAL 5BAKEABLE SENSOR PACKAGE 2.75" DEL-SEAL 5SENSOR CRYSTALS, GOLD RATED BOX OF 10 5LPSP-1LPSP-275LPSP-HT-275CRP-500-11799131099131199163799113113751425197012034 Phone 800-443-8817 www.mdcvacuum.com MDC <strong>Vacuum</strong> Products Corporation