Hoover Dam: - Elevator World

Hoover Dam: - Elevator World

Hoover Dam: - Elevator World

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

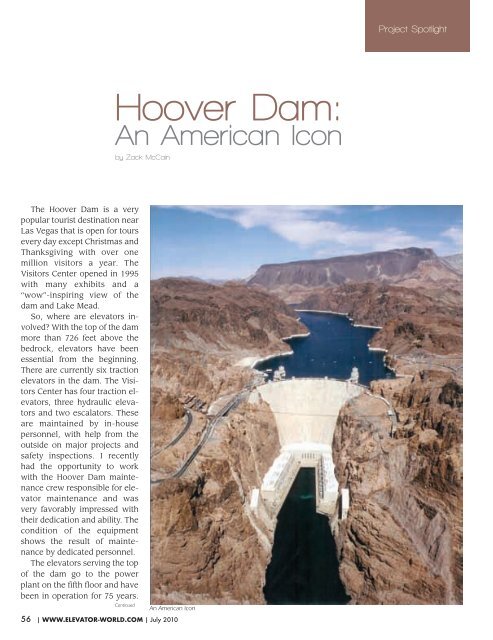

Project Spotlight<strong>Hoover</strong> <strong>Dam</strong>:An American Iconby Zack McCainThe <strong>Hoover</strong> <strong>Dam</strong> is a verypopular tourist destination nearLas Vegas that is open for toursevery day except Christmas andThanksgiving with over onemillion visitors a year. TheVisitors Center opened in 1995with many exhibits and a“wow”-inspiring view of thedam and Lake Mead.So, where are elevators involved?With the top of the dammore than 726 feet above thebedrock, elevators have beenessential from the beginning.There are currently six tractionelevators in the dam. The VisitorsCenter has four traction elevators,three hydraulic elevatorsand two escalators. Theseare maintained by in-housepersonnel, with help from theoutside on major projects andsafety inspections. I recentlyhad the opportunity to workwith the <strong>Hoover</strong> <strong>Dam</strong> maintenancecrew responsible for elevatormaintenance and wasvery favorably impressed withtheir dedication and ability. Thecondition of the equipmentshows the result of maintenanceby dedicated personnel.The elevators serving the topof the dam go to the powerplant on the fifth floor and havebeen in operation for 75 years.ContinuedAn American Icon56 | WWW.ELEVATOR-WORLD.COM | July 2010

Clockwise from top:Bridge under constructionOriginal driving machineMike Mahaney, facility maintenance supervisor at the historic<strong>Hoover</strong> <strong>Dam</strong>(l-r) Mahaney, George Wolfe and Charles Bullen with Otis 74-Dmachine, which has been in daily use for more than 75 years.(l-r) Demarco Brooks, Wolfe, Mahaney, James Crocker and Bullenhandle the day-to-day elevator and escalator maintenance, as wellas that for other plant equipment. They have outsideinspections and contract major work when needed.Generator level on Arizona sideJuly 2010 | ELEVATOR WORLD | 57

<strong>Hoover</strong><strong>Dam</strong>: AnAmericanIconContinuedInformation from Otis indicatedthat the layout for the originaldriving machine (Otis Machine-# 156993) was finalized on March13, 1935, and revised on June 6,1935. This was an Otis #72 machinewith a 13-CULG controllerand a 2B generator, a capacityThe dry side of the dam from the power generating platform on the Arizona side. Notice the two center elevatorshafts and penthouse protruding above the dam top. The shadow on the face of the dam is of the newbridge that is under construction to take traffic from the dam.of 4000-lb. and speed of 450fpm. The records indicate that itwas modernized in 1987 with aE401M direct drive, new platform,cab, doors and governor.Since these elevators are 75years old, there are plans to replacethem in the near future. Ididn’t see anything wrong withthe 75, but it might be a goodidea to give them a little restafter serving faithfully for thesemany years.All highway traffic ispresently routed across thedam creating a bottle neck and<strong>Hoover</strong> <strong>Dam</strong> Statistics◆ Height: 726.4 feet◆ Crest length: 1,244 feet◆ Crest width: 45 feet◆ Base width: 660 feet◆ 17 hydroelectric generating unitswith total capacity of 2,080megawatts◆ Lake Mead shoreline: 550 miles◆ Lake Mead length: 110 mileswhen full58 | WWW.ELEVATOR-WORLD.COM | July 2010Bullen with one of the Visitor Center traction-elevator driving machines; visitor traffic resultsin heavy use, and reliability and safety are paramount.

delays. There are also securityconcerns which prohibits itsuse by trucks. The new bridgeis under construction justbelow the dam. The photographof the bridge under constructionwas taken from thedam visitor balcony. The bridgeis scheduled for completion inNovember and will have awalking/bicycle path. Thisshould provide another “wow”-inspiring view of the dam andColorado River.The condition and reliabilityof the original elevator hoistmachines, which are in dailyuse, are testimony that propermaintenance is well worth thecost. This can only be accomplishedwith the dedication ofemployees from managementto the one who wields thewrenches. It was a pleasureand honor meeting and workingwith such dedicated persons.<strong>Hoover</strong> <strong>Dam</strong>: Civil Engineering Monument of the MillenniumU.S. President Herbert <strong>Hoover</strong> supported the construction of a high dam on the Colorado River to control its flowand reclaim farmland. He also advocated that the Boulder Canyon project be self supporting, financed through the saleof hydroelectric power. The total cost of the project (US$165 million) has been repaid with interest to the U.S. Treasurythrough the sale of power. To this day, the operation and maintenance of the facility continues to be solely supportedwith revenues from the sale of more than 4 billion kilowatt-hours a year. It has a generating capacity of 2,080megawatts. Perhaps its greatest contribution is the irrigation water it provides to more than one million acres of richfarmland in the U.S. and one-half million acres in Mexico. Recreation, considered by some to be a byproduct of <strong>Hoover</strong><strong>Dam</strong>, is important to local residents as well as tourists, with a 12-month season. There are also several wildlife refugesdeveloped on the lower Colorado River because of <strong>Hoover</strong> <strong>Dam</strong> and other dams that followed.Construction of <strong>Hoover</strong> <strong>Dam</strong> started in 1931, and the last concrete was poured in 1935, two years ahead of scheduleand under budget. The power plant began producing electricity in 1936. At the time the construction contract waslet by the Bureau of Reclamation, it was the largest contract that the U.S. government had ever awarded. No singlecontractor had the resources to undertake such a large innovative project. To bid the project, six major constructioncontractors formed a new company and called it “Six Companies Inc.” <strong>Hoover</strong> <strong>Dam</strong> was, without precedent, the greatestdam of its day. It is still receiving honors from the engineering world.In 1955, the American Society of Civil Engineers selected <strong>Hoover</strong> <strong>Dam</strong> as one of seven modern civil-engineering wondersof the U.S., and it has become an American icon, with between 1,000 and 4,000 visitors each day the year around.Original tool cabinet in machine roomA power plant generator rotor being repaired. Asmall Pelton generator, with horizontal shaft forplant electricity, can be seen in the upper right sideof photo.July 2010 | ELEVATOR WORLD | 59