Parking - Elevator World

Parking - Elevator World

Parking - Elevator World

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

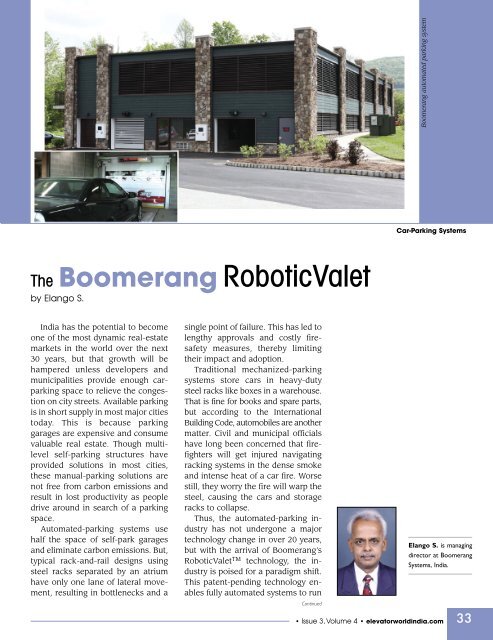

Boomerang automated parking systemCar-<strong>Parking</strong> SystemsThe Boomerang RoboticValetby Elango S.India has the potential to becomeone of the most dynamic real-estatemarkets in the world over the next30 years, but that growth will behampered unless developers andmunicipalities provide enough carparkingspace to relieve the congestionon city streets. Available parkingis in short supply in most major citiestoday. This is because parkinggarages are expensive and consumevaluable real estate. Though multilevelself-parking structures haveprovided solutions in most cities,these manual-parking solutions arenot free from carbon emissions andresult in lost productivity as peopledrive around in search of a parkingspace.Automated-parking systems usehalf the space of self-park garagesand eliminate carbon emissions. But,typical rack-and-rail designs usingsteel racks separated by an atriumhave only one lane of lateral movement,resulting in bottlenecks and asingle point of failure. This has led tolengthy approvals and costly firesafetymeasures, thereby limitingtheir impact and adoption.Traditional mechanized-parkingsystems store cars in heavy-dutysteel racks like boxes in a warehouse.That is fine for books and spare parts,but according to the InternationalBuilding Code, automobiles are anothermatter. Civil and municipal officialshave long been concerned that firefighterswill get injured navigatingracking systems in the dense smokeand intense heat of a car fire. Worsestill, they worry the fire will warp thesteel, causing the cars and storageracks to collapse.Thus, the automated-parking industryhas not undergone a majortechnology change in over 20 years,but with the arrival of Boomerang’sRoboticValet TM technology, the industryis poised for a paradigm shift.This patent-pending technology enablesfully automated systems to runContinuedElango S. is managingdirector at BoomerangSystems, India.• Issue 3, Volume 4 • elevatorworldindia.com 33

The Boomerang RoboticValet Continuedon concrete slabs in new or existing car parks, eliminatingthe structural and fire safety concerns that haveplagued automated parking in the past. Additionally,the omnidirectional RoboticValet can move laterallybeneath cars, decreasing retrieval time, eliminatingbottlenecks and single point of failure found in mechanizedrack-and-rail-parking systems.The Boomerang TM combines the space efficiency ofautomated parking with the peace of mind of a conventionalconcrete garage. Each is engineered with anample number of spacious, secure and convenientlylocated loading bays to quickly absorb peak trafficflows. After a driver exits the loading bay and identifiesthemselves at the kiosk, the external door closes andthe vehicle dimensions are measured. The inner doorthen opens and the Boomerang rolls under the car,which is parked over a tray, and gently lifts the car withthe tray.Other than the Boomerang’s patent-pending andlow-profile RoboticValet features, almost everythingelse about the system has been in use in factoriesaround the world for the past 30 years. The use of conventionalconcrete-slab construction resolves safetyconcerns that have plagued automated parking in thepast. As an omnidirectional robot, the Boomerang canturn on any floor, pass by other robots, park cars inboth parallel and perpendicular position, and workaround almost any obstacle. Its ability to slide undercars from the side enables 66% of the garage to be filledbefore requiring one car to be moved to retrieve another.The TrafficMaster TM software that coordinates theBoomerang’s movements can decrease retrieval timeby calling in other Boomerangs to assist. TrafficMasterintelligently navigates the path of the Boomerangaround obstacles. Each move of the Boomerang is optimizedto save time and energy. Remote retrievalprescheduling is a time-saving feature of the Traffic-Master software.The ability to simultaneously acquire multiple carsand move laterally to clear an exit path saves minutesfrom each multimove retrieval. If the adjacent space isnot empty, obstructing cars can be temporarily stagedin the center transit aisle and returned once the targetcar is on the lift. Unlike other automated parking systems,which require technicians wearing a safety harnessto repair broken machinery suspended high in theair, any building personnel can tow a disabledBoomerang out of the way in order to resume normaloperations.34ELEVATOR WORLD India • 3rd Quarter 2011 •TrafficMaster capabilitiesComparison between Boomerang and traditional automated systemsThe Boomerang

Car-<strong>Parking</strong> SystemsAutomated Car-<strong>Parking</strong> Systemby V. RajagopalanV. Rajagopalan is chairmanand managing directorof City Lifts India Ltd. Hehas been director/chairmanof City Lifts since its inceptionin 1985. He had his initialstint at Otis and ECE.With an electrical-engineeringbackground, he specializesin electric drives and controls for elevators.He has introduced innovations in the City Lift’sproducts to enable them to be considered environmentallyfriendly elevators. He has more than30 years of experience in the elevator industryAutomobiles are synonymouswith mobility and freedom. A car isdriven, on average, 2-3 hours perday, spending the remainder of itstime parked. Car parking has becomean important requirement forhigh rises. Buildings with inadequateparking find few tenants, contributingto the property’s eroding valueover the years. In cities, where spaceis at a premium and car ownership isgrowing, automated car-parkingsystems may be the best solution tomeet parking needs. In conventionalcar parking, about 35% of the area isconsumed by providing access toparking spaces. Automated systemsprovide more car slots in the samespace or, alternately, release morespace for better use with the samenumber of spaces offered by conventionalparking.A range of automated car-parkingsystems are available to suit variouscustomer needs. Tower parking systemsare best suited for areas wherefootprint is small and height is liberal.Systems such as cart parking,trolley parking (pallet and palletless)are best suited for areas withheight restrictions and a large footprint.The system can be constructedabove or below ground or withground at mid-entry level. Typically,a system must be planned at thebuilding’s design stage for it to be integratedwith other building services.Automated parking systems aretailored to suit the building configuration.In an automated car-parkingsystem, the car travels from the entrancein three coordinated directionsto reach the parking slot. Thesemovements are programmed andautomated with precision so carscan be parked or retrieved with definitecycle time.The planning process involveslaying out the slots based on thechosen system and deciding thenumber of entry and exit points.Traffic management at entry level36ELEVATOR WORLD India • 3rd Quarter 2011 •

Left: Vehicles stacked in the garage Below: Vehicle transported through system on a pallet Bottom: Automated parking entrancemust be planned to meet the peakhourhandling capacity. Peak-hourtraffic-handling capacity is based onthe application of the building,namely commercial, residential,parking when designing an efficientsystem.Automated parking has many advantagesover conventional parking,including:◆ Improved peak-hour handling capacity◆ Environmental friendliness — carsdo not idle in the parking bay◆ Absence of harmful smoke emissionreduces ventilation requirements.◆ Secure parking — no dents, damageor vandalism◆ Reduced infrastructure cost wherespace is at a premium◆ Handles high-traffic volume better,saving driver time◆ Provides fully integrated parkingand retrieval functions◆ Reduced traffic congestionshopping center, etc. and decides the ◆ Creates parking spaces wherequality of the system. The retrieval conventional parking does nottime of the farthest car should not permitexceed 2 min. Quality of parking ◆ High density, requiring less spacetakes precedence over quantity of and providing 50% more slotsContinued• Issue 3, Volume 4 • elevatorworldindia.com 37

AutomatedCar-<strong>Parking</strong>System Continued◆ Reduced lighting requirements◆ Use of radio-frequency identification(RFID) technology makes thesystem user friendly and savesregistration time.◆ Higher depreciation on investmentFinding a parking space in cities isposing more of a challenge. Forplanners and developers seeking solutions,automated systems providea new perspective. Architects canprovide new dimensions to car-parkingservices and aesthetically adaptit to the building’s architecture.Builders and developers have reservationsabout the return on investmentprovided by traditional carparking. The cost of planning, constructionand operation of automatedparking is lower than that ofconventional multilevel parking. Interms of cost, there is no real alternativeto an automatic-parking system,where large numbers of carsare parked or high-traffic volume isencountered. In India, the market isnew and still developing, with fewsystems in operation. In the absenceof a regulatory safety body, qualityand performance standards arebased on company standards. In theabsence of national standards, purchasersmust accept the suppliercountrystandards.City Lifts (India) Ltd. providescomplete vertical-transportation solutionsfor buildings. Apart from elevators,escalators and moving walks,the company provides medium- andlarge-capacity automated car-parkingsolutions. Recently, City Liftscommissioned an automated cartsystem with 390 cars for the AckrutiStar project in Mumbai. AnotherAckruti project with 650 cars is cur-38Ackruti StarELEVATOR WORLD India • 3rd Quarter 2011 •rently being installed, followed bymore upcoming projects. AckrutiStar received the Commercial Propertyof the Year award from RealtyPlus, India’s leading real-estate magazine.The award was given inrecognition of creating new benchmarksfor excellence in India’s realestateindustry.Ackruti Star’s car-parking systemis spread over three undergroundlevels, covering an area of 11,160m 2 . The system’s peak-hour handlingcapacity is 200 cars per hourwith eight drive-through entrances.The system is fully ventilated andequipped with a sprinkler system. Adouble-cart parking system is installedto utilize all available basementspace.The system was designed andmanufactured by M/s Samjung TechCo. Ltd., automated car-parking systemmarket leaders in South Korea.City Lifts installed the system andprovides maintenance service. Thetouch-screen operation panel displaysinfo rmation about the numberof vehicles parked, available slots,parking duration, etc., and reportson any breakdowns and maintenanceneeds. RFID registration isprovided for user-friendly operation.Each level of parking has stipulatedvehicle-height limits, and the systemmeasures the size of each vehicle,parking it accordingly. Optical sensorsprotect the system and automobilesfrom damage. Movements arecontrolled by inverter drives forsmooth operation. A standby generatoris provided for use in the eventof power failure.The automated car-parking marketis served by both domestic andinternational players. A wide selectionof systems is available, but abuyer must be clear about needs andrequirements to get the best solution.Automated car-parking systemscan be a cost-effective way to meetthe needs of urban parking.

Leading Manufacturerof Hydraulic ComponentsPISTONSPOWER UNITSRUPTURE VALVESCONTROL VALVESFULL RANGE OF ACCESSORIESCAR FRAMES FOR LOW PITAND HEADROOMMORIS Italia S.r.l.Via per Cadrezzate, 21/C21020 Brebbia (VA)Tel. +39 0332 984211Fax +39 0332 984280www.moris.it - E-mail: moris@moris.it

Car-<strong>Parking</strong> SystemsPuzzleP a r k i n gby Vijay KiledarVijay Kiledar works as asenior manager in theAuto <strong>Parking</strong> Division,with Kinetic Hyundai <strong>Elevator</strong>and Movement TechnologiesLtd. in Pune.Kiledar is an engineer with17 years of experience andhas been at the forefrontof design and development of car-parking systemsunder the “K-Park” brand from Kinetic Hyundai.He has experience in successful implementation ofvarious parking systems with a specialization inpuzzle and totary type of parking.Metropolitan cities cover merely2% of the world’s surface but support50% of its population; that is whatmakes real-estate expensive in ornear metros. It takes 375 sq. ft. topark one car, and most vehicles remainparked 95% of the time! However,the real problem is not movinga vehicle but parking one. With landscarce and available at an exorbitantprice, it has become imperative tomake the best use of available space.This has led to the birth of new parkingsolutions, and mechanized multilevelcar parking systems arecatching the imaginations of many.There is a tremendous market potentialfor parking systems. The industryis about six years old in India, andthere are about 10,000 mechanized/automated parking spaces presentlyoperating in India. About 70% ofpublic parking business is expectedto be government controlled. With thelimited resources at the government’sdisposal, they are primarily emphasizingthe need to implement parkingsystems on a build operate transfer/build own operate transfer basis.Kinetic Hyundai <strong>Elevator</strong> andMovement Technologies Ltd. is ajoint venture (JV) between Hyundai<strong>Elevator</strong> Co. of South Korea and theKinetic Group in India. The JV manufacturescar-parking systems in Indiaand sells, installs and maintains elevatorsand escalators manufacturedby Hyundai <strong>Elevator</strong>.Kinetic pioneered the business ofauto parking in India and offers acomprehensive auto parking solutionto help alleviate the increasingcar-parking problem. Its first installationdates back to 1998. The companyoffers customized solutions forparking in housing complexes, shoppingmalls, hotels, hospitals, airportsand public parking areas. It also has40ELEVATOR WORLD India • 3rd Quarter 2011 •

Technical Details/System SpecificationsModel and typeSSK 4000Maximum car size(with customized module)Length: 5,050 mmWidth: 1,650 mmHeight: 1,550 mmWeight: 1,500 kgVertical driving unitType: Wire rope and chainMotor: 1.5 kW X 4 P 1/90Speed: 4.4 mpmDrive: Geared motor with brakeHorizontal driving unitGeared motor: 0.18 kW X 4 PSpeed: 4.4 mpmDrive: Geared motor with brakePower sourceMain: 415 VAC, 3 PH, 50 HzLighting: 220 VAC, 1 PH, 50 HzOperationPush-button typeControlTouch screenSafety devicesEmergency-stop switch on operating panelPhoto sensorsFinal limit switchvarious installations of all types (i.e.,tower parking, puzzle, mini rotary,jack-type module, horizontal circulation)across the country.Puzzle-Type Car-<strong>Parking</strong> SystemsThe puzzle parking system workson principles similar to those of the“word puzzle” game. The lower palletsmove laterally and the upperpallets move vertically (in the case oftwo stage puzzle parking systems)and laterally and/or vertically (in thecase of multiple levels over ground,depending on the level). With thistype of arrangement, it is possible topark or remove any car from theparking system without taking anotherparked car out.The system is easy to operate dueto its simple construction. It is possibleto use various combinations toadapt to restricted spaces. It can beinstalled in driveways, basementsand rooftops. It is also very economicalto operate and maintain, and ittakes under 2 min. to park or removea car from the system.The puzzle parking system is asversatile as it is modular and can beinstalled progressively when theneed for additional parking arises. Themodules can be of single- or doublerowtype, with the number of layersvarying from two to four. The smallestmodule can take three cars, andthe largest can take 29. The puzzleContinued• Issue 3, Volume 4 • elevatorworldindia.com 41

PuzzleP a r k i n gContinuedrange permits near doubling of theparking capacity on a slab areawith a clear height of only about 12ft., near tripling with clear height ofabout 18 ft., or clear height of 12 ft.with pits a little under 7 ft. deep,near quadrupling with a clear heightof about 24 ft.The systems can be installed inbasements, under stilts, on openground and even on a terrace (subjectto it having been designed to takethe load of the cars and the parkingsystems). They come in modules ofvarious capacities to suit columngrid spacing and can be ordered andinstalled in phases. The motors usedin these are of low wattage (but withhigh gearing) and have low duty cycles.As a result, energy-consumptioncost is negligible. The connectedload of a module is low, and a 5 kVAgenerator will suffice to providebackup to a module – it can evenserve many such modules withchangeover switches. Furthermore,as long as power is available, it ispossible to manually bring a pallet toground level in case of breakdown toretrieve a parked car.4/3 Hydraulic Puzzle <strong>Parking</strong> System (07 Cars)4/3/3 Puzzle <strong>Parking</strong> System (10 Cars)4/3/3/3 Puzzle <strong>Parking</strong> System (13 Cars)42ELEVATOR WORLD India • 3rd Quarter 2011 •