Mapecem 202 Mapecem 202 - AltaPaints and Coatings

Mapecem 202 Mapecem 202 - AltaPaints and Coatings

Mapecem 202 Mapecem 202 - AltaPaints and Coatings

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

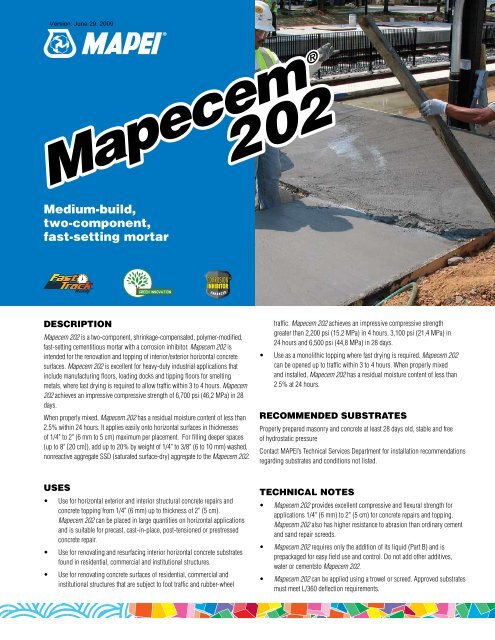

TM<strong>Mapecem</strong> ®<strong>202</strong>Medium-build,two-component,fast-setting mortarCORROSIONINHIBITORE N H A N C E DDESCRIPTION<strong>Mapecem</strong> <strong>202</strong> is a two-component, shrinkage-compensated, polymer-modified,fast-setting cementitious mortar with a corrosion inhibitor. <strong>Mapecem</strong> <strong>202</strong> isintended for the renovation <strong>and</strong> topping of interior/exterior horizontal concretesurfaces. <strong>Mapecem</strong> <strong>202</strong> is excellent for heavy-duty industrial applications thatinclude manufacturing floors, loading docks <strong>and</strong> tipping floors for smeltingmetals, where fast drying is required to allow traffic within 3 to 4 hours. <strong>Mapecem</strong><strong>202</strong> achieves an impressive compressive strength of 6,700 psi (46,2 MPa) in 28days.When properly mixed, <strong>Mapecem</strong> <strong>202</strong> has a residual moisture content of less than2.5% within 24 hours. It applies easily onto horizontal surfaces in thicknessesof 1/4" to 2" (6 mm to 5 cm) maximum per placement. For filling deeper spaces(up to 8" [20 cm]), add up to 20% by weight of 1/4" to 3/8" (6 to 10 mm) washed,nonreactive aggregate SSD (saturated surface-dry) aggregate to the <strong>Mapecem</strong> <strong>202</strong>.traffic. <strong>Mapecem</strong> <strong>202</strong> achieves an impressive compressive strengthgreater than 2,200 psi (15,2 MPa) in 4 hours, 3,100 psi (21,4 MPa) in24 hours <strong>and</strong> 6,500 psi (44,8 MPa) in 28 days.• Use as a monolithic topping where fast drying is required. <strong>Mapecem</strong> <strong>202</strong>can be opened up to traffic within 3 to 4 hours. When properly mixed<strong>and</strong> installed, <strong>Mapecem</strong> <strong>202</strong> has a residual moisture content of less than2.5% at 24 hours.RECOMMENDED SUBSTRATESProperly prepared masonry <strong>and</strong> concrete at least 28 days old, stable <strong>and</strong> freeof hydrostatic pressureContact MAPEI’s Technical Services Department for installation recommendationsregarding substrates <strong>and</strong> conditions not listed.USES• Use for horizontal exterior <strong>and</strong> interior structural concrete repairs <strong>and</strong>concrete topping from 1/4" (6 mm) up to thickness of 2" (5 cm).<strong>Mapecem</strong> <strong>202</strong> can be placed in large quantities on horizontal applications<strong>and</strong> is suitable for precast, cast-in-place, post-tensioned or prestressedconcrete repair.• Use for renovating <strong>and</strong> resurfacing interior horizontal concrete substratesfound in residential, commercial <strong>and</strong> institutional structures.• Use for renovating concrete surfaces of residential, commercial <strong>and</strong>institutional structures that are subject to foot traffic <strong>and</strong> rubber-wheelTECHNICAL NOTES• <strong>Mapecem</strong> <strong>202</strong> provides excellent compressive <strong>and</strong> flexural strength forapplications 1/4" (6 mm) to 2" (5 cm) for concrete repairs <strong>and</strong> topping.<strong>Mapecem</strong> <strong>202</strong> also has higher resistance to abrasion than ordinary cement<strong>and</strong> s<strong>and</strong> repair screeds.• <strong>Mapecem</strong> <strong>202</strong> requires only the addition of its liquid (Part B) <strong>and</strong> isprepackaged for easy field use <strong>and</strong> control. Do not add other additives,water or cementsto <strong>Mapecem</strong> <strong>202</strong>.• <strong>Mapecem</strong> <strong>202</strong> can be applied using a trowel or screed. Approved substratesmust meet L/360 deflection requirements.

<strong>Mapecem</strong> ®<strong>202</strong>2 • <strong>Mapecem</strong> <strong>202</strong> adheres well to existing properly preparedconcrete surfaces. Before application of <strong>Mapecem</strong> <strong>202</strong>,mechanically roughen concrete surface, saturatesurface-dry (SSD) <strong>and</strong> scrubcoat to ensure a securebond. Apply a bonding agent (Planibond ® 3C orPlanibond EBA [see respective Technical Data Sheets fordetails]) or <strong>Mapecem</strong> <strong>202</strong> as a scrubcoat to the properlyprepared surface. Quickly apply the <strong>Mapecem</strong> <strong>202</strong> mixwhile the scrubcoat is still wet. If scrubcoat dries beforeto placement of the mortar, it will become a bond breaker<strong>and</strong> the application will fail.• <strong>Mapecem</strong> <strong>202</strong> is not a construction grout, so itcannot be used for anchoring purposes or pouringinto formwork. Instead, use MAPEI's Planigrout ®740, Planigrout 750 or Planigrout 780 (see respectiveTechnical Data Sheets for details) for anchoring <strong>and</strong>Planitop ® 15 (see Technical Data Sheet for details) forpouring into formwork.• A waterproofing membrane, such as Mapelastic HPG(see Technical Data Sheet for details), can be appliedon top of <strong>Mapecem</strong> <strong>202</strong> in as few as 3 hours afterplacement.• <strong>Mapecem</strong> <strong>202</strong> can only be used between 45°F <strong>and</strong> 95°F(7°C <strong>and</strong> 35°C).Note: Cool, damp <strong>and</strong> humid conditions will slow therate of hydration <strong>and</strong> will cause the topping to retain ahigher moisture content for a longer period of time.INSTRUCTIONS1. Surface Preparation1.1 All substrates must be structurally sound, stable <strong>and</strong>solid, with all loose materials removed.1.2 Thoroughly clean the surface of any substance thatcould interfere with the bond of the installation material,including dirt, paint, tar, asphalt, wax, oil, grease,latex compounds, form release agents, laitance, loosetoppings, foreign substances <strong>and</strong> any other residues.1.3 Concrete surfaces must be mechanically profiled <strong>and</strong>prepared by shotblasting, s<strong>and</strong>blasting, waterjetting,scarifying or other engineer-approved methods to obtaina +/- 1/8" (3 mm) profile. Reference ICRI CSP St<strong>and</strong>ards7 to 9 for acceptable profile height.1.4 Concrete substrate <strong>and</strong> ambient room temperaturesmust be at least 45°F (7°C) <strong>and</strong> must not exceed95°F (35°C) before application. Temperatures must bemaintained within this range for at least 72 hours afterthe installation of <strong>Mapecem</strong> <strong>202</strong>.1.5 Do not apply over st<strong>and</strong>ing water or wet surfaces.2. Mixing2.1 Into a clean mixing pail, pour 4/5 of the required amountof cool liquid (Part B).2.2 Slowly add <strong>Mapecem</strong> <strong>202</strong> to the liquid while mixing,using a low-speed mixer. Next add the remaining 1/5 ofliquid to achieve the desired consistency. Mix for up to 4minutes, removing any unmixed powder <strong>and</strong> remix to asmooth, homogenous consistency.2.3 For extended mix, add 20% by weight (11 lbs. [4,99 kg])of washed, clean, SSD 3/8" (10 mm) pea gravel.2.4 Do not overmix. Overmixing can cause air entrapment,which could shorten pot life.2.5 Do not add water to material, or <strong>Mapecem</strong> <strong>202</strong> will notperform as specified.2.6 Do not mix more material than can be applied within a30-minute period.3. Application3.1 <strong>Mapecem</strong> <strong>202</strong> can be applied with a trowel or a screed,with or without formwork (screed rail), on a horizontalsurface. The maximum thickness neat is 2" (5 cm). Useextended mix for deeper repair patching up to 8" (20 cm)thick.3.2 When encountering exposed reinforcing steel bars, cleanbars <strong>and</strong> coat with Planibond 3C (see Technical DataSheet for details) to protect against corrosion <strong>and</strong> toimprove adhesion.3.3 Complete renovation by applying <strong>Mapecem</strong> 101 (seeTechnical Data Sheet for details) to the repair <strong>and</strong>adjoining area to provide a durable uniform appearance.4. CuringDo not wet-cure; however, protect the placed material fromexcessively hot or drafty conditions with wet burlap during thefirst 4 hours of curing. Excessive heat <strong>and</strong>/or wind could causepremature surface drying <strong>and</strong> result in cracking.5. CleaningWash h<strong>and</strong>s <strong>and</strong> tools promptly with water before materialhardens. Cured material must be mechanically removed.

TECHNICAL DATA (based on 73°F [23°C] <strong>and</strong> 50% relative humidity)Physical state.........................................................................................................PowderColor.....................................................................................................................GrayShelf life................................................................................................................1 year in original bag stored in a dry, heated,covered <strong>and</strong> well-ventilated placeMaximum aggregate size.......................................................................................3/32" (2,5 mm)Flammability..........................................................................................................Flame spread: 0Fuel contribution: 0Smoke development: 0Health <strong>and</strong> safety...................................................................................................Consult the Material Safety Data Sheet (MSDS) forsafe-h<strong>and</strong>ling instructions.<strong>Mapecem</strong> <strong>202</strong> (mixed)Mixing ratio (A:B = 8.9:1)Part A = powderPart B = liquid........................................................................................................0.71 U.S. gal. (2,69 L) of liquid per 55-lb. (25-kg) bagFlow (ASTM C230)................................................................................................116%Density..................................................................................................................131 lbs. per cu.ft. (2,10 kg per L)pH..........................................................................................................................12.3Slump ASTM C143 (CAN/CSA-A23.2-5C)............................................................9" (23 cm)Consistency of mix................................................................................................Trowel-grade mortarApplication temperature range...............................................................................45°F to 95°F (7°C to 35°C)Thickness per lift...................................................................................................1/4" to 2" (6 mm to 5 cm)Pot life...................................................................................................................30 minutesInitial set (ASTM C266).........................................................................................60 minutesFinal set (ASTM C266)..........................................................................................90 minutesOpen to traffic........................................................................................................After 4 hoursResistance to moisture...........................................................................................ExcellentCompressive strength – ASTM C109 (CAN/CSA-A5)4 hours.............................................................................................................> 2,200 psi (15,2 MPa)8 hours.............................................................................................................> 2,900 psi (20 MPa)1 day................................................................................................................> 3,100 psi (21,4 MPa)7 days...............................................................................................................> 4,950 psi (34,1 MPa)28 days.............................................................................................................> 6,500 psi (44,8 MPa)Flexural strength – ASTM C348 (CAN/CSA-A23.2-8C)4 hours.............................................................................................................> 450 psi (3,10 MPa)8 hours.............................................................................................................> 775 psi (5,34 MPa)1 day................................................................................................................> 1,200 psi (8,28 MPa)7 days...............................................................................................................> 1,400 psi (9,66 MPa)28 days.............................................................................................................> 1,500 psi (10,3 MPa)Modulus of elasticity – ASTM C46928 days...............................................................................................................2.6 x 10 6 psi (18,0 GPa)Slant/shear bond strength – ASTM C882 (modified)1 day................................................................................................................> 1,100 psi (7,59 MPa)7 days...............................................................................................................> 1,300 psi (8,97 MPa)28 days.............................................................................................................> 1,450 psi (10 MPa)Pull-out strength (rupture of concrete substrate) (CAN/CSA-A23.2-6B)3 days...............................................................................................................> 300 psi (2,07 MPa)7 days...............................................................................................................> 325 psi (2,24 MPa)28 days.............................................................................................................> 350 psi (2,41 MPa)Volume change – ASTM C157 (modified)28 days dry-cured............................................................................................-0.04%28 days wet-cured............................................................................................+0.015%Abrasion resistance – ASTM D4060, after 7 daysTaber H22-500 g, 200 cycles............................................................................0.89 gFreeze/thaw resistance – ASTM C666-A (CAN/CSA A23.2-9B), 300 cycles..........Very good – 100% durability factorResistance to de-icing salts – ASTM C672 (CAN/CSA A23.2-16C)......................Very good – 0 rating, no scalingPermeability to chlorides – ASTM C1<strong>202</strong> (AASHTO T277)...................................Good – 260 coulombs (very low)Packaging1 kit consisting of:Part A = powder (bag): 55 lbs. (25 kg)Part B = liquid (jug): 0.71 U.S. gal. (2,69 L); 6.17 lbs. (2,80 kg)Yield per 61.17-lb. (27,7-kg) kit............................................................................0.47 cu.ft. (0,0133 m 3 )APPROXIMATE Coverage/thickness* per 61.17-lb. (27,7-kg) kit...........1/4" (6 mm) = 23.4 sq. ft. (2,17 m 2 )1" (2,5 cm) = 5.6 sq. ft. (0,52 m 2 )2" (5 cm) = 2.8 sq. ft. (0,26 m 2 )* Coverage/thickness data shown are given for estimating purposes only. Actual job-site coverages may vary according to substrate conditions,type of equipment, thickness applied <strong>and</strong> application methods used.<strong>Mapecem</strong> ®<strong>202</strong>2

<strong>Mapecem</strong> ®<strong>202</strong>2 We proudly support the following industry organizations:Statement ofResponsibilityBefore using, user shall determine the suitability of theproduct for its intended use <strong>and</strong> user alone assumes allrisks <strong>and</strong> liability whatsoever in connection therewith. Anyclaim shall be deemed waived unless made inwriting to us within fifteen (15) days fromdate it was, or reasonably should have been,discovered.MAPEI Headquarters of the Americas1144 East Newport Center DriveDeerfield Beach, Florida 33442Phone: 1-888-US-MAPEI(1-888-876-2734)Technical Services1-800-992-6273 (U.S. <strong>and</strong> Puerto Rico)1-800-361-9309 (Canada)Customer Service1-800-42-MAPEI (1-800-426-2734)For the most current product <strong>and</strong>warranty data, visit www.mapei.com.Edition Date: June 11, 2009PR856 M22D_F09Evp © 2009 MAPEI Corporation.All Rights Reserved. Printed in the USA.