FLUID ENDS - COVER - Weir Oil & Gas Division

FLUID ENDS - COVER - Weir Oil & Gas Division

FLUID ENDS - COVER - Weir Oil & Gas Division

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Weir</strong> SPM’s Fluid End Repair Servicesgive customers the choice betweenpurchasing a new fluid end or repairingan existing fluid end to “like-new”condition.Program Advantages:Fluid ends are thoroughlyinspected by trained techniciansto determine the scope of workrequired to repair the cylinder.In the past, the only option for customers with cracked, washed or eroded fluid endswas to simply discard them. In an effort to offer customers an alternative todisposing of their equipment, <strong>Weir</strong> SPM has developed a process to return usedblocks as reconditioned fluid ends in "like-new" condition. <strong>Weir</strong> SPM has beenimplementing this process in select areas with great success. Now, all customers willhave the opportunity to evaluate the status of their fluid cylinders and have optionsof whether to replace or refurbish.• Fast turnaround.• Cost efficient alternative to purchase of new block.• Extends life of fluid end.• In depth reports given on status of cylinder andrepairs made.• Complete examination of fluid cylinder, includingtests that cannot be performed in the field.Refurbishment Process Includes:• Fluid cylinders completely cleaned and bead-blasted.(A chemical hot tank dip is required for excessivelydirty cylinders.)• Visual inspection of seat taper bores, valve lift washareas, packing bores, suction bores, discharge bores,and mounting flange for fretting.• 100% die penetration examination of the fluidcylinder internals.• 100% wet fluorescent magnetic particle inspectionof all thread bores.• Examination of all bores and thread boreconnections.• Examination of all valve seat bores and stand offdimensions.• Record of all visual findings and dimensional data onformatted reports.• Finalized reports for presentation to customer.• Customer evaluation to decide on scope of workdemanded.<strong>Weir</strong> SPM Fluid End RepairServices can repair commondamage found in used fluidends, such as corrosive wearand cylinder bore cracks, asseen to the left.<strong>Weir</strong> SPM utilizes state ofthe art machinery andwelding techniques in therepair of worn or crackedfluid cylinders.

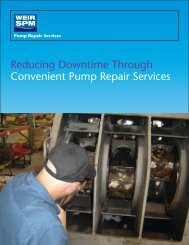

<strong>Weir</strong> SPM also offers a wide range ofpump repair services at its convenientlylocated service centers, or on-site throughthe use of its Mobile Recertification Units.<strong>Weir</strong> SPM is committed to providing our customers with the resources needed tomaximize the efficiency of their <strong>Weir</strong> SPM products, thus increasing productivityduring their operation. Well service pumps undergo great stresses during operation,particularly under harsh pumping environments. Care must be taken to make surethe pumps are maintained properly and repaired when needed.Therefore, <strong>Weir</strong> SPM has established select service centers capable of performing fullpump repair services. At these locations, <strong>Weir</strong> SPM's professionally trainedtechnicians perform complete pump repair services for all makes and models of wellservice pumps. Each pump repair service center can provide a wealth of services toallow the customer to have their equipment repaired as quickly as possible withmaximum convenience.<strong>Weir</strong> SPM offers pump repair services at several locations around the globe,strategically positioned to minimize the time pumps are out of service. <strong>Weir</strong> SPM alsooffers a fleet of Mobile Recertification Units that can provide fluid end maintenanceand basic pump repair services at the customer’s site for increased convenience andfast problem solving solutions.Pump RepairProcedures Include:• Disassembly of allcomponents• Inspection, includingmagnetic particle• Evaluation of Repairs• Cost Estimates• Repair utilizing skilled<strong>Weir</strong> SPM technicians• Test• Documentation toverify product quality• RepaintPump RepairFacilities:• Fort Worth, TX• Odessa, TX• Red Deer, AB, Canada• Aberdeen, Scotland<strong>Weir</strong> SPM7601 Wyatt DriveFort WorthTX 76108USATel: (817) 246 2461Fax (817) 246 6324www.weiroilandgas.com© 2008 <strong>Weir</strong> SPM V.2 08/08