Heading subheading Steam turbine and gas compressor repair ...

Heading subheading Steam turbine and gas compressor repair ...

Heading subheading Steam turbine and gas compressor repair ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

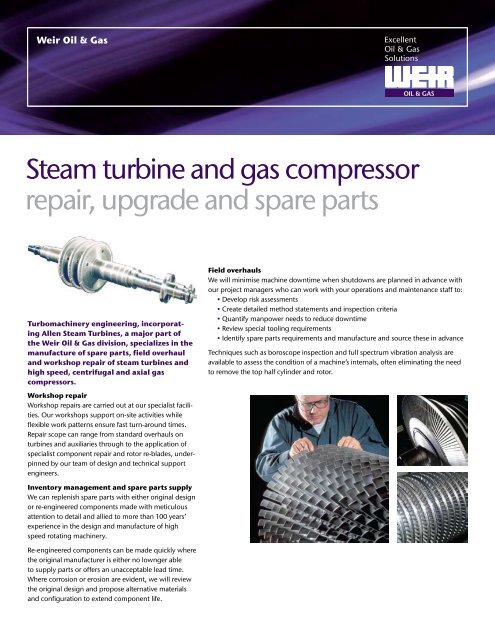

Weir Oil & GasExcellentOil & GasSolutions<strong>Steam</strong> <strong>Heading</strong> <strong>turbine</strong> <strong>and</strong> <strong>gas</strong> <strong>compressor</strong><strong>repair</strong>, <strong>subheading</strong> upgrade <strong>and</strong> spare partsTurbomachinery engineering, incorporatingAllen <strong>Steam</strong> Turbines, a major part ofthe Weir Oil & Gas division, specializes in themanufacture of spare parts, field overhaul<strong>and</strong> workshop <strong>repair</strong> of steam <strong>turbine</strong>s <strong>and</strong>high speed, centrifugal <strong>and</strong> axial <strong>gas</strong><strong>compressor</strong>s.Workshop <strong>repair</strong>Workshop <strong>repair</strong>s are carried out at our specialist facilities.Our workshops support on-site activities whileflexible work patterns ensure fast turn-around times.Repair scope can range from st<strong>and</strong>ard overhauls on<strong>turbine</strong>s <strong>and</strong> auxiliaries through to the application ofspecialist component <strong>repair</strong> <strong>and</strong> rotor re-blades, underpinnedby our team of design <strong>and</strong> technical supportengineers.Field overhaulsWe will minimise machine downtime when shutdowns are planned in advance withour project managers who can work with your operations <strong>and</strong> maintenance staff to:• Develop risk assessments• Create detailed method statements <strong>and</strong> inspection criteria• Quantify manpower needs to reduce downtime• Review special tooling requirements• Identify spare parts requirements <strong>and</strong> manufacture <strong>and</strong> source these in advanceTechniques such as boroscope inspection <strong>and</strong> full spectrum vibration analysis areavailable to assess the condition of a machine’s internals, often eliminating the needto remove the top half cylinder <strong>and</strong> rotor.Inventory management <strong>and</strong> spare parts supplyWe can replenish spare parts with either original designor re-engineered components made with meticulousattention to detail <strong>and</strong> allied to more than 100 years’experience in the design <strong>and</strong> manufacture of highspeed rotating machinery.Re-engineered components can be made quickly wherethe original manufacturer is either no lownger ableto supply parts or offers an unacceptable lead time.Where corrosion or erosion are evident, we will reviewthe original design <strong>and</strong> propose alternative materials<strong>and</strong> configuration to extend component life.

Our expertise in aerodynamics, rotordynamics,mechanical design <strong>and</strong> materials technology canimprove equipment reliability <strong>and</strong> availabilityUpgrading <strong>and</strong> re-rating plantOur expertise in upgrading <strong>and</strong> re-rating machinerymeans we can offer long term solutions to customersthat extend the operating life of their equipment.Our expertise covers a broad spectrum of turbomachinerydesign <strong>and</strong> analysis, including;• dynamics & structural engineers• aerodynamic & thermodynamic engineers• noise & vibration specialists• mechanical design engineers• materials engineersOur noise <strong>and</strong> vibration specialists will undertake onsitetrouble shooting which may involve in-situ balancingor might identify areas of concern to be rectifiedat the next outage. Where inherent problems exist ourdynamics, mechanical design <strong>and</strong> materials specialistswill work with you to create a solution.These disciplines can be integrated to provide a completere-rate service whether it is to up-rate or de-ratean existing machine for modified conditions, either forthe same site or where a machine is being relocated.Call us todayEdmonton4737, 97th StreetEdmonton, Alberta T6E 5W2T (780) 438-1122F (780) 437-5218Calgary2715, 18th Street N.E.Calgary, Alberta T2E 7E6T (403) 250-7000F (403) 250-2032Fort St. John10508, 89th AvenueFort St. John, British Columbia V1J 5P9T (250) 785-6627F (250) 785-4501www.weiroil<strong>and</strong><strong>gas</strong>.com Printed in Canada NA0017