Wärtsilä Rudder Solutions - Energopac

Wärtsilä Rudder Solutions - Energopac

Wärtsilä Rudder Solutions - Energopac

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

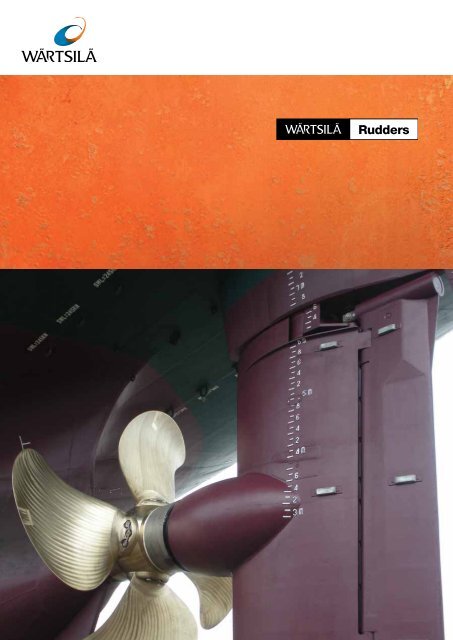

Courtesy of Finnlines Oy, photographed by Hannu Laakso.<strong>Energopac</strong> incorporated in model tests, photographed by HSVA.CFD capabilities within Wärtsilä are state-of-the-art.OPTIMIZINGENERGY EFFICIENCYWärtsilä is continuously looking to improvethe energy efficiency of its propulsionsolutions. In so doing, we aim to reduce fuelconsumption, lower the operational costs ofseagoing vessels, and, of course, cut back onemissions. We design our solutions to meetspecific customer requirements, utilizing ourextensive marine industry experience andstate-of-the-art, modern techniques, such asCFD (Computational Fluid Dynamics).Our high efficiency rudder technology dates back to the1990s when Wärtsilä started making energy-savingrudders. Since then more than 30 vessels have beenequipped with our energy-saving rudders, and all of themhave proven to be very successful in saving fuel. Forexample, the fuel consumption of a series of chemicaltankers has been reduced by 5% sailing at 17 knots.Another example is a series of general cargo vessels, withfuel savings of 4% at 23 knots.In 2009, two <strong>Energopac</strong> systems were delivered to a newbuilding project, and in early 2010 the first <strong>Energopac</strong> retrofitwas successfully installed. Another 12 <strong>Energopac</strong> systems are currently on order for delivery in 2010 and 2011.The Wärtsilä Propeller-<strong>Rudder</strong> System,<strong>Energopac</strong> has been designed to include thefollowing benefits:• improved energy efficiency and reduced fuelconsumption, thanks to integrated propellerand rudder design• excellent manoeuvrability• lower vibration levels and higher comfortonboard• reduced levels of emissionsENERGOPAC INTEGRATED PROPULSION ANDMANOEUVRING PERFORMANCEA vessel’s power efficiency level is dependentupon interaction between all the maincomponents. To achieve optimal performance,these need to form a single integrated design.This also holds true for the interaction betweenthe vessel’s propeller and rudder.<strong>Energopac</strong> is an optimized propulsion andmanoeuvring solution for coastal and seagoingvessels. Its key objective is to reduce a vessel’sfuel consumption and CO 2 emissions throughintegrating the propeller and rudder design.<strong>Energopac</strong> is tailored for each and every vesselto meet the customer’s specific requirements,and can thus be optimized for energy efficiency,without compromising manoeuvrability orcomfort.DESIGNED FOR PERFECTION<strong>Energopac</strong> was developed through co-operationbetween Wärtsilä’s propulsion specialists, andthe rudder experts at Becker Marine Systems.The combined experience and track record ofthese companies in optimizing ship efficiency isextensive, and is widely appreciated throughoutthe industry.2

CFD images show that streamlining the flow significantly reduces separation losses from the propeller hub.The combination of propulsion expertiseand vessel manoeuvring know-how forms thebackbone of this co-operation. The result isa sophisticated propulsion and manoeuvringsolution, designed and optimized for energyefficiency.The amount of fuel savings, when applying<strong>Energopac</strong>, depends very much on the vesseltype, its operational profile, and on the referencepropeller and rudder. We can give a goodestimation of the potential annual fuel savingsafter having examined the vessel’s design,together with alternative propulsion solutions, indetail.<strong>Energopac</strong> is then optimized according tothe specifics of the vessel. In-house, state-ofthe-artCFD (Computational Fluid Dynamics)capabilities are used for the engineering. CFDmakes it possible to customize the equipment forany vessel, and to tailor it to match the vessel’soperational profile and other specific needs.ENERGOPAC IN DETAIL<strong>Energopac</strong> comprises several components,which vary in design and dimension, andwhich are modified to integrate with eachother to serve the vessel in the most effectiveway possible. These include the propeller,a streamlined fairing cap, and a ruddersystem with a rudder bulb for efficiency. Theinteracting parts of the system are co-designedwith Becker Marine Systems<strong>Energopac</strong> includes a sophisticatedfull-spade flap rudder. Firstly, this providesexcellent rudder balance and manoeuvringperformance; and secondly it allows for asmaller overall rudder blade area, whichresults in lower rudder drag. Furthermore, itrequires only relatively small steering anglesto keep the vessel on course when in transitensuring that the rudder bulb stays in theshadow of the fairing cap wake in steeringcondition.3The KSR (King Support <strong>Rudder</strong>) system patentedby Becker is used to construct a slim rudder profile,thereby minimizing resistance and providing a strongand stiff rudder support. The KSR support systemenables the building of full spade rudders of anysize, and to suit the highest ship speeds. This allows<strong>Energopac</strong> to be installed on any size vessel, evenlarge or higher-speed vessels, which is truly unique.The asymmetric profile of the twisted leadingedge rudder is aligned perfectly with the propeller’srotating slipstream. This results in less accelerationat the rudder leading edge, making the rudder lessprone to propeller induced cavitation and recoveringa part of the rotational energy of the slipstream,improving the propulsion efficiency of the propellerruddersystem.The fairing cap and rudder bulb are specificallydesigned to reduce the separation losses behindthe propeller hub, and to increase overall efficiency.The propeller design is adapted to individualpropulsion requirements. However, the design

<strong>Rudder</strong> resistance (% of propeller thrust)25%20%15%10%5%Wärtsilä <strong>Energopac</strong>Standard semispade rudder0%100% 80% 60% 40% 20% 0% 20% 40% 60% 80% 100%<strong>Rudder</strong> steering force (% of prop. thrust)<strong>Energopac</strong> reduces flow separation behind the propeller hub and createsless drag than conventional rudder systems.Vibration level (amplitude in kPa)65432101.91.82.95.40.31.8Design configurationFull scale <strong>Energopac</strong>Model scale <strong>Energopac</strong>Improved propeller designReference design2.82.70.30.91.21.11st 2nd 3rdthVibration frequency (n harmonic of blade passage)Example arrangement of a typical <strong>Energopac</strong> solution, showing all the maincomponents.A standard propeller-rudder design compared with the improved designusing <strong>Energopac</strong>. The reduction in pressure pulses, due to a morehomogeneous water inflow into the propeller, results in lower vibration andincreased comfort onboard the vessel.is also optimized for both the rudder and therudder bulb, thereby enabling even greaterpropeller efficiency when applying <strong>Energopac</strong>.WORKING PRINCIPLESBy reducing the flow separation behind thepropeller hub, <strong>Energopac</strong> effectively reducesthe vessel’s fuel consumption. Extendedstudies show that for the same course-keepingcapabilities, <strong>Energopac</strong> creates less drag thanconventional rudder systems.The efficient design of the rudder bulb,particularly when integrated with the propellerand the rudder profile, streamlines the flow andsignificantly reduces separation losses from thepropeller hub. The impact is most noticeablewhen a large part of the rudder bulb is behindthe propeller hub. Thus, the highest fuel savingsare achieved when the vessel is in transit, sincethe rudder angles required for maintainingcourse are minimal.In course-keeping mode, <strong>Energopac</strong> hasproven to save fuel more effectively than aconventional system. In particular, when usingsmall forces for correction and steering tokeep the vessel on course, the difference inrudder resistance is significant. The high-liftperformance of <strong>Energopac</strong> requires smallersteering angles, and consequently reducesrudder resistance.EFFIENCY AND COMFORT COMBINEDHigh performance propeller designs are oftena compromise between increased efficiencyand reduced vibration levels. The applicationof <strong>Energopac</strong> gives the vessel’s designeror propulsion engineer greater freedom inoptimizing opposing requirements. <strong>Energopac</strong>allows for a propeller design that meets bothrequirements! It will increase propulsionefficiency and/or reduce vibration levels,according to preference. At Wärtsilä we have4the experience and know-how to advise ourcustomers on the best solution for their specificcombination of requirements.TYPICAL APPLICATIONS<strong>Energopac</strong> will effectively reduce the operationalcosts for any vessel with a considerable share offree sailing time in its operational profile. It worksvery well for propellers with a relatively largepropeller hub. The potential savings are largestfor vessels having highly loaded controllablepitch propeller systems, such as RoRo-vessels,ferries, container / multipurpose vessels, andvessels with an ice class notation. On suchships with larger propeller hub diameters, thehub losses are significant with a conventionalsystem. By applying <strong>Energopac</strong>, however, theselosses can largely be avoided. Furthermore,<strong>Energopac</strong> will also show a favourable returnon investment for any coastal or ocean-goingvessels with considerable transit times.

SAVING WITH ENERGOPACFuel savings with <strong>Energopac</strong> can be estimatedfor any application and are based on the vesseltype, the operational profile of the vessel, andthe reference propeller and rudder. Provensavings in the required power for a vessel’strial speed vary between 2% and 9%. As theactual reduction in power depends on thepropulsion alternatives, the following examplesgive the annual savings in fuel costs for eachpercentage point in power reduction (based onfuel prices applicable in May 2010):Power (% of MCR)1009080706050Conventional flapped rudder<strong>Energopac</strong>Case 1:A 20,000 dwt cargo vessel with an 8000 kWmain engine and a CPP installation will benefitgreatly from <strong>Energopac</strong> in terms of powerreduction. Depending on the operational profileof the vessel, the annual savings can be upto USD 35,000 for each percentage pointreduction in power. In the figure above, a fullscale comparison is made between standardBecker rudders and <strong>Energopac</strong>. In this figureresults of speed trial measurements are shownfor the same series of vessels, where 6 vesselshave been equipped with standard Beckerrudders and two with <strong>Energopac</strong>. As can beseen, the power savings vary from 0.5% at lowspeed up to 4% at maximum vessel speed. Indesign condition there is a 3.7% reduction in4080 85 90 95 100 105 110Speed (% of trial speed)Trial data General Cargo Vesselspower, resulting in annual savings of more thanUSD 120,000.Case 2:A RoPax ferry typically has a high powerdensity propulsion system with additionalnoise control requirements. This represents anexcellent case for considering <strong>Energopac</strong>. Withan installed power of around 25,000 kW anda twin screw CPP installation, <strong>Energopac</strong> cansignificantly reduce power requirements. Thefuel cost savings can exceed USD 100,000 ayear, per percentage point in power reduction.Case 3:LNG carriers sail long distances at relativelyhigh speeds. A vessel with a capacity of135,000 m 3 usually has 28,000 kW installedon a single fixed pitch propeller. Applying<strong>Energopac</strong> will save roughly USD 135,000 ayear in fuel, for each percentage point in powerreduction.5

Wärtsilä is a global leader in complete lifecycle power solutionsfor the marine and energy markets. By emphasising technologicalinnovation and total efficiency, Wärtsilä maximises the environmentaland economic performance of the vessels and power plants of itscustomers. Wärtsilä is listed on the NASDAQ OMX Helsinki, Finland.06.2010 / Bock´s Office / LitosetWÄRTSILÄ ® is a registered trademark. Copyright © 2010 Wärtsilä Corporation.