You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

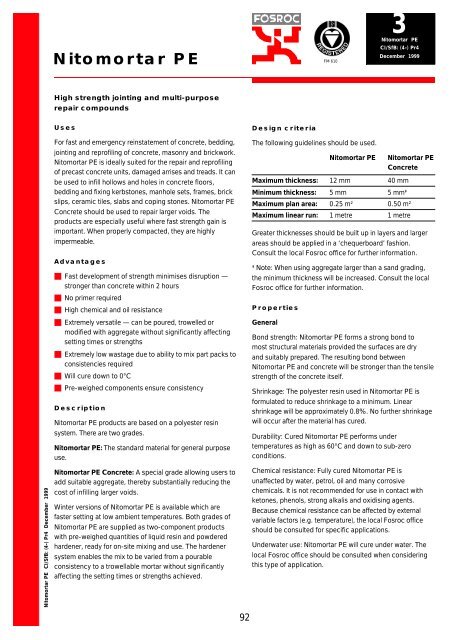

<strong>Nitomortar</strong> <strong>PE</strong>FM 6103<strong>Nitomortar</strong> <strong>PE</strong>CI/SfB: (4-) Pr4December 1999High strength jointing and multi-purposerepair compoundsUsesFor fast and emergency reinstatement of concrete, bedding,jointing and reprofiling of concrete, masonry and brickwork.<strong>Nitomortar</strong> <strong>PE</strong> is ideally suited for the repair and reprofilingof precast concrete units, damaged arrises and treads. It canbe used to infill hollows and holes in concrete floors,bedding and fixing kerbstones, manhole sets, frames, brickslips, ceramic tiles, slabs and coping stones. <strong>Nitomortar</strong> <strong>PE</strong>Concrete should be used to repair larger voids. Theproducts are especially useful where fast strength gain isimportant. When properly compacted, they are highlyimpermeable.Advantages■ Fast development of strength minimises disruption —stronger than concrete within 2 hours■ No primer required■ High chemical and oil resistance■ Extremely versatile — can be poured, trowelled ormodified with aggregate without significantly affectingsetting times or strengths■ Extremely low wastage due to ability to mix part packs toconsistencies required■ Will cure down to 0°C■ Pre-weighed components ensure consistencyDescription<strong>Nitomortar</strong> <strong>PE</strong> products are based on a polyester resinsystem. There are two grades.<strong>Nitomortar</strong> <strong>PE</strong>: The standard material for general purposeuse.Design criteriaThe following guidelines should be used.<strong>Nitomortar</strong> <strong>PE</strong>Maximum thickness: 12 mm 40 mmMinimum thickness: 5 mm 5 mm*<strong>Nitomortar</strong> <strong>PE</strong>ConcreteMaximum plan area: 0.25 m² 0.50 m²Maximum linear run: 1 metre 1 metreGreater thicknesses should be built up in layers and largerareas should be applied in a ‘chequerboard’ fashion.Consult the local Fosroc office for further information.* Note: When using aggregate larger than a sand grading,the minimum thickness will be increased. Consult the localFosroc office for further information.PropertiesGeneralBond strength: <strong>Nitomortar</strong> <strong>PE</strong> forms a strong bond tomost structural materials provided the surfaces are dryand suitably prepared. The resulting bond between<strong>Nitomortar</strong> <strong>PE</strong> and concrete will be stronger than the tensilestrength of the concrete itself.Shrinkage: The polyester resin used in <strong>Nitomortar</strong> <strong>PE</strong> isformulated to reduce shrinkage to a minimum. Linearshrinkage will be approximately 0.8%. No further shrinkagewill occur after the material has cured.Durability: Cured <strong>Nitomortar</strong> <strong>PE</strong> performs undertemperatures as high as 60°C and down to sub-zeroconditions.<strong>Nitomortar</strong> <strong>PE</strong> CI/SfB: (4-) Pr4 December 1999<strong>Nitomortar</strong> <strong>PE</strong> Concrete: A special grade allowing users toadd suitable aggregate, thereby substantially reducing thecost of infilling larger voids.Winter versions of <strong>Nitomortar</strong> <strong>PE</strong> is available which arefaster setting at low ambient temperatures. Both grades of<strong>Nitomortar</strong> <strong>PE</strong> are supplied as two-component productswith pre-weighed quantities of liquid resin and powderedhardener, ready for on-site mixing and use. The hardenersystem enables the mix to be varied from a pourableconsistency to a trowellable mortar without significantlyaffecting the setting times or strengths achieved.Chemical resistance: Fully cured <strong>Nitomortar</strong> <strong>PE</strong> isunaffected by water, petrol, oil and many corrosivechemicals. It is not recommended for use in contact withketones, phenols, strong alkalis and oxidising agents.Because chemical resistance can be affected by externalvariable factors (e.g. temperature), the local Fosroc officeshould be consulted for specific applications.Underwater use: <strong>Nitomortar</strong> <strong>PE</strong> will cure under water. Thelocal Fosroc office should be consulted when consideringthis type of application.92

3<strong>Nitomortar</strong> <strong>PE</strong>CI/SfB: (4-) Pr4December 1999Working timeTemperature <strong>Nitomortar</strong> <strong>PE</strong> <strong>Nitomortar</strong> <strong>PE</strong>Concrete5°C: 160 minutes 250 minutesWinter grade: 60 minutes15°C: 35 minutes 90 minutesWinter grade: 20 minutes25°C: 15 minutes 50 minutes35°C: 5 minutes 25 minutes<strong>Nitomortar</strong> <strong>PE</strong> ConcreteN/mm²Compressive strength gain: All grades of <strong>Nitomortar</strong> <strong>PE</strong> willdevelop strengths equivalent to mature concrete within a2 to 6 hour period at temperatures above 15°C. Typicalcompressive strength development is shown below.<strong>Nitomortar</strong> <strong>PE</strong>N/mm²Note: The performance of <strong>Nitomortar</strong> <strong>PE</strong> winter grade at 5°Cis similar to that of the standard grade at 20°C.Property at 20°C <strong>Nitomortar</strong> <strong>PE</strong> <strong>Nitomortar</strong> <strong>PE</strong>flowable Concrete*Compressiveconsistencystrength at 7 days(BS 6319, Pt 2): 100 N/mm² 100 N/mm²Flexural strength(BS 6319, Pt 3): 28 N/mm² 25 N/mm²Tensile strength(BS 6319, Pt 7): 14 N/mm² 12 N/mm²Young’s Modulusof Elasticity: 16 kN/mm² 23 kN/mm²Thermal conductivity: 1.0 Watt/m/°C —Coefficient ofthermal expansion: 30 x 10 – 6 per °C —* Note that the strengths quoted for <strong>Nitomortar</strong> <strong>PE</strong> Concretemay vary dependent on the type of aggregate selected.Mix design — <strong>Nitomortar</strong> <strong>PE</strong>Hardener:resin ratio Density Yield(volume) (weight) kg/m³ litres/kgTrowellable: 3.2 :1 4.2 :1 1,920 0.52Flowable: 2.5 :1 3.5 :1 1,840 0.54Fluid: 1.6 :1 2.0 :1 1,680 0.6093

3<strong>Nitomortar</strong> <strong>PE</strong>CI/SfB: (4-) Pr4December 1999are sensitive to resins, hardeners and solvents. Wearsuitable protective clothing, gloves and eye protection. Ifworking in confined areas, suitable respiratory protectiveequipment must be used. In case of contact with eyes, rinseimmediately with plenty of clean water and seek medicaladvice. In case of skin contact, remove immediately withresin removing cream followed by washing with soap andwater. Do not use solvent. In case of contact with eyes, rinseimmediately with plenty of clean water and seek medicaladvice. If swallowed, seek medical attention immediately —do not induce vomiting.Fire<strong>Nitomortar</strong> <strong>PE</strong> products are flammable. Keep away fromsources of ignition. No Smoking. In the event of fire,extinguish with CO 2or foam. Do not use a water jet.Flash point<strong>Nitomortar</strong> <strong>PE</strong> resin: 29°CFor further information, refer to the Product Safety DataSheet.Fosroc LimitedColeshill RoadTamworthStaffordshireB78 3TLTel 01827 262222Fax 01827 262444www.fosrocuk.com<strong>Nitomortar</strong> is the trade mark of Fosroc International LimitedImportant noteFosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of Goods and Services,copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation, specification or information it may give isaccurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly orindirectly arising from the use of its products, whether or not in accordance with any advice, specification, recommendation or information given by it.96