1-part Soft Elastic sealant For Building Joints - Arcon Supplies

1-part Soft Elastic sealant For Building Joints - Arcon Supplies

1-part Soft Elastic sealant For Building Joints - Arcon Supplies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

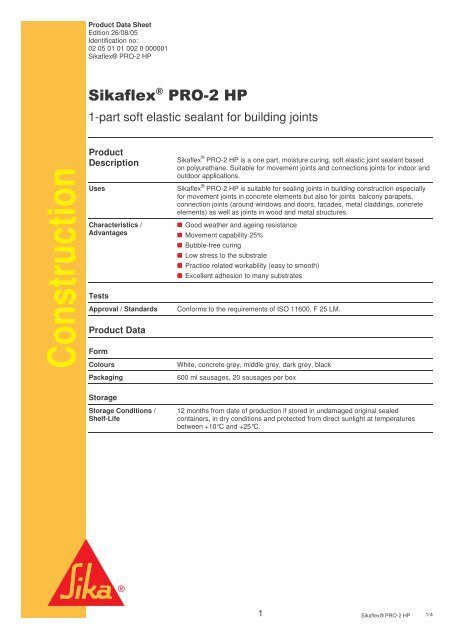

Product Data SheetEdition 26/08/05Identification no:02 05 01 01 002 0 000001Sikaflex® PRO-2 HP 1-<strong>part</strong> soft elastic <strong>sealant</strong> for building jointsConstructionProductDescriptionUsesCharacteristics /AdvantagesTestsApproval / StandardsProduct Data<strong>For</strong>mColoursSikaflex ® PRO-2 HP is a one <strong>part</strong>, moisture curing, soft elastic joint <strong>sealant</strong> basedon polyurethane. Suitable for movement joints and connections joints for indoor andoutdoor applications.Sikaflex ® PRO-2 HP is suitable for sealing joints in building construction especiallyfor movement joints in concrete elements but also for joints balcony parapets,connection joints (around windows and doors, facades, metal claddings, concreteelements) as well as joints in wood and metal structures. Good weather and ageing resistance Movement capability 25% Bubble-free curing Low stress to the substrate Practice related workability (easy to smooth) Excellent adhesion to many substratesConforms to the requirements of ISO 11600, F 25 LM.White, concrete grey, middle grey, dark grey, blackPackaging600 ml sausages, 20 sausages per boxStorageStorage Conditions /Shelf-Life12 months from date of production if stored in undamaged original sealedcontainers, in dry conditions and protected from direct sunlight at temperaturesbetween +10°C and +25°C.1 Sikaflex® PRO-2 HP 1/4

Technical DataChemical Base1-<strong>part</strong> polyurethane, moisture curing.Density ~ 1.3 kg/l (colour concrete grey) (DIN 53 479)Skinning TimeCuring RateMovement Capability 25%Joint Dimensions~ 60 - 120 minutes (+23°C / 50% r.h.)~ 2 - 3 mm/24 h (+23°C / 50% r.h.)Min. width = 10 mm / max. width = 35 mmSag Flow 0 mm, very good (DIN EN ISO 7390)Service TemperatureMechanical / PhysicalProperties-40°C to +70°CTear Strength ~ 7 N/mm (+23°C / 50% r.h.) (DIN 53 515)Shore A Hardness ~ 25 after 28 days (+23°C / 50% r.h.) (DIN 53 505)E-Modulus ~ 0.3 N/mm 2 at 100% elongation (+23°C / 50% r.h.) (DIN EN ISO 8340)~ 0.6 N/mm 2 at 100% elongation (-20°C)Elongation at Break ~ 800% (+23°C / 50% r.h.) (DIN 53 504)<strong>Elastic</strong> Recovery > 80% (+23°C / 50% r.h.) (DIN EN ISO 7389 B)SystemInformationApplication DetailsConsumption /Joint DesignThe joint width must be designed to accomodate the movement capability of the<strong>sealant</strong>, In general the joint width must be > 10 mm and < 35 mm. The width todepth ration of ~ 2 : 1 must be respected.Standard dimensions for concrete elements (as per DIN 18 540 / table 3):Joint Distance 2 m 2 - 3.5 m 3.5 - 5 m 5 - 6.5 m 6.5 - 8 mDesign Joint Width 15 mm 20 mm 25 mm 30 mm 35 mmMin. Joint Width 10 mm 15 mm 20 mm 25 mm 30 mmJoint Depth 8 mm 10 mm 12 mm 15 mm 15 mmMinimum joint width for joints around windows: 10 mm<strong>Joints</strong> must be properly dimensioned as changes are normally no longer feasibleafter construction. Basis for calculation of the necessary joint width are the technicalcharacteristic values of the joint <strong>sealant</strong> and the adjacent building materials, theexposure of the building elements, their construction and size.Joint Width 10 mm 15 mm 20 mm 25 mm 30 mmJoint Depth 8 mm 8 mm 10 mm 12 mm 15 mmJoint Length / 600 ml ~ 7.5 m ~ 4.5 m ~ 2.5 m ~ 1.6 m ~ 1.3 mSubstrate QualityThe stated values are indications onlyBackfilling:Use only close cell, <strong>sealant</strong> compatible foam backer rods e.g. high resiliencepolyethylene foam rod.Clean and dry, homogeneous, free from grease, dust and loose <strong>part</strong>icles.Paint, laitance and other poorly adhering <strong>part</strong>icles must be removed. Standardconstruction rules must be observed.2 2/4Sikaflex® PRO-2 HP

Substrate Preparation /PrimingSika ® Primer-3:<strong>For</strong> porous substrates e.g. concrete, aerated concrete and cement plaster.Flash off time: min. 30 minutes, max. 8 hoursSika ® Cleaner-205:<strong>For</strong> power coatings EP and PU coatings.Flash off time: 15 minutesSika ® Primer-215:<strong>For</strong> PVC and for mortar in connection joints between PVC and building.Flash off time: min. 30 minutes, max. 8 hoursSika ® Primer-35:<strong>For</strong> metals e.g. Aluminium, stainless steel, galvanised steel.Flash off time: min. 30 minutes, max. 8 hoursPrimers are only adhesion promoters. They neither substitute the cleaning of thesurfaces nor improve their strength significantly.<strong>For</strong> further information contact Sika ® Primer list.ApplicationConditions /LimitationsSubstrate TemperatureAmbient TemperatureSubstrate HumidityApplicationInstructionsApplication Method /ToolsCleaning of ToolsNotes on Application /LimitationsNotesLocal Restrictions+5°C min. / +40°C max.+5°C min. / +40°C max.DrySikaflex ® PRO-2 HP is ready to use.Insert Backing Rod to required depth. Insert cartridge into <strong>sealant</strong> gun and firmlyextrude Sikaflex ® PRO-2 HP into joint making sure that it is in full contact with thesides of the joint. Fill the joint, avoiding air entrapment. Sikaflex ® PRO-2 HP shouldbe tooled firmly against joint sides to ensure good adhesion.Masking tape should be used where sharp exact joint lines or exceptionally neatlines are required. Remove the tape whilst the <strong>sealant</strong> is still soft. Sleek joint for asmooth <strong>sealant</strong> surface .Clean all tools and application equipment with <strong>sealant</strong> remover / Sika ® Cleanerimmediately after use. Hardened / cured material can only be mechanicallyremoved.<strong>Elastic</strong> <strong>sealant</strong> must not be over painted in general!Sealant compatible coatings may cover the joint sides to max. 1 mm. Thecompatibility must be tested individually according to DIN 52 452-2.Colour deviations may occur due to chemicals, high temperature, UV-radiation(especially with colour shade whit). A change in colour does not influence thetechnical and protective performance of the product.Before using on other natural stone than granite contact our Technical Service.Do not use Sikaflex ® PRO-2 HP as glass sealer, in floor joints and in joints withpermanent water immersion.Do not use on bituminous substrates, natural rubber, chloropene, EPDM or onbuilding materials which might bleed oils, plastisicers or solvent.All technical data stated in this Product Data Sheet are based on laboratory tests.Actual measured data may vary due to circumstances beyond our control.Please note that as a result of specific local regulations the performance of thisproduct may vary from country to country. Please consult the local Product DataSheet for the exact description of the application fields.3 3/4Sikaflex® PRO-2 HP

ConstructionHealth and SafetyInformationProtective MeasuresEcologyTransportation ClassImportant NotesToxicityLegal NotesTo avoid rare allergic reactions, we recommend the use of protective gloves.Change soiled work clothes and wash hands before breaks and after finishing work.Local regulations as well as health and safety advice on packaging labels must beobserved.Refer to Material Safety Data Sheet.Refer to Material Safety Data Sheet.Residues of material must be removed according to local regulations. Fully curedmaterial can be disposed of as household waste under agreement with theresponsible local authorities.Detailed health and safety information as well as detailed precautionary measurese.g. physical, toxicological and ecological data can be obtained from the materialsafety data sheet.Refer to Material Safety Data Sheet.The information, and, in <strong>part</strong>icular, the recommendations relating to the applicationand end-use of Sika products, are given in good faith based on Sika's currentknowledge and experience of the products when properly stored, handled andapplied under normal conditions in accordance with Sika’s recommendations. Inpractice, the differences in materials, substrates and actual site conditions are suchthat no warranty in respect of merchantability or of fitness for a <strong>part</strong>icular purpose,nor any liability arising out of any legal relationship whatsoever, can be inferredeither from this information, or from any written recommendations, or from any otheradvice offered. The user of the product must test the product’s suitability for theintended application and purpose. Sika reserves the right to change the propertiesof its products. The proprietary rights of third <strong>part</strong>ies must be observed. All ordersare accepted subject to our current terms of sale and delivery. Users must alwaysrefer to the most recent issue of the local Product Data Sheet for the productconcerned, copies of which will be supplied on request.Sika LimitedWatchmeadWelwyn Garden CityHertfordshireAL7 1BQUnited KingdomPhone +44 1707 394444Telefax +44 1707 329129www.sika.co.uk, email: sales@uk.sika.com ISO 14001 ISO 90014 4/4Sikaflex® PRO-2 HP