Closed Circuit Coolers - Tasman Cooling Towers

Closed Circuit Coolers - Tasman Cooling Towers

Closed Circuit Coolers - Tasman Cooling Towers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LSWA & LRW Owner Advantages<br />

4<br />

Maintenance Free ZM Spray Nozzle Water Distribution System<br />

EVAPCO’S Zero Maintenance ZM Spray Nozzle remains<br />

clog-free while providing even and constant water distribution.<br />

The ZM nozzle provides reliable, scale-free evaporative cooling<br />

under all operating conditions continuously delivering 6 GPM<br />

to every square foot of coil plan area.<br />

The heavy duty nylon ZM Spray nozzles have a 1-5/16”<br />

diameter opening and a 1-1/2” splash plate clearance enabling<br />

EVAPCO to use 75% fewer nozzles. Furthermore, the fixed<br />

position ZM nozzles are mounted in corrosion-free PVC water<br />

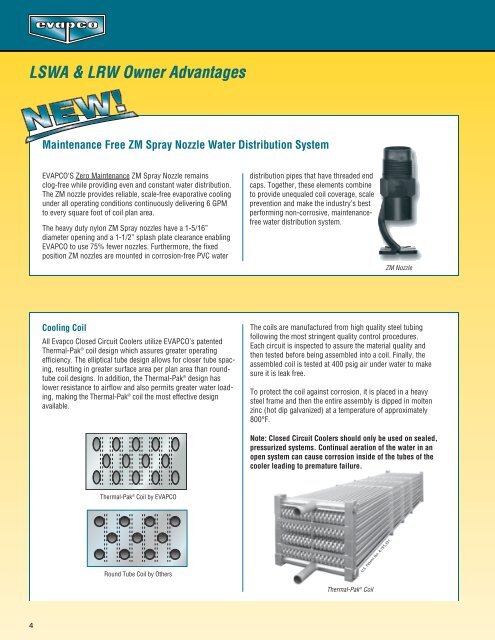

<strong>Cooling</strong> Coil<br />

All Evapco <strong>Closed</strong> <strong>Circuit</strong> <strong>Coolers</strong> utilize EVAPCO’s patented<br />

Thermal-Pak ® coil design which assures greater operating<br />

efficiency. The elliptical tube design allows for closer tube spacing,<br />

resulting in greater surface area per plan area than roundtube<br />

coil designs. In addition, the Thermal-Pak ® design has<br />

lower resistance to airflow and also permits greater water loading,<br />

making the Thermal-Pak ® coil the most effective design<br />

available.<br />

Thermal-Pak ® Coil by EVAPCO<br />

Round Tube Coil by Others<br />

distribution pipes that have threaded end<br />

caps. Together, these elements combine<br />

to provide unequaled coil coverage, scale<br />

prevention and make the industry’s best<br />

performing non-corrosive, maintenancefree<br />

water distribution system.<br />

The coils are manufactured from high quality steel tubing<br />

following the most stringent quality control procedures.<br />

Each circuit is inspected to assure the material quality and<br />

then tested before being assembled into a coil. Finally, the<br />

assembled coil is tested at 400 psig air under water to make<br />

sure it is leak free.<br />

To protect the coil against corrosion, it is placed in a heavy<br />

steel frame and then the entire assembly is dipped in molten<br />

zinc (hot dip galvanized) at a temperature of approximately<br />

800°F.<br />

Note: <strong>Closed</strong> <strong>Circuit</strong> <strong>Coolers</strong> should only be used on sealed,<br />

pressurized systems. Continual aeration of the water in an<br />

open system can cause corrosion inside of the tubes of the<br />

cooler leading to premature failure.<br />

Thermal-Pak ® Coil<br />

U.S. Patent No. 4,755,331<br />

ZM Nozzle