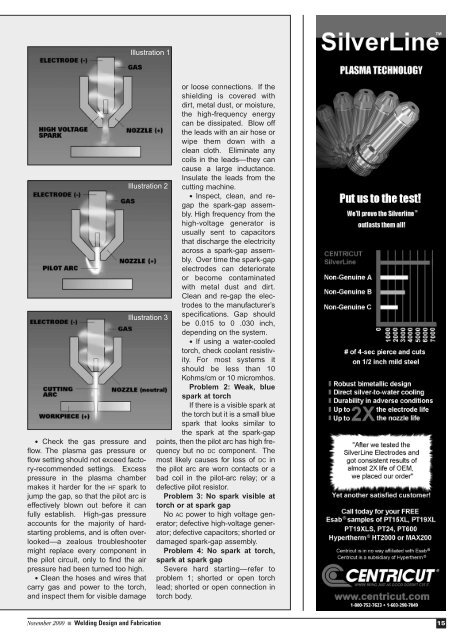

CLASSROOMWritten By: David J. Cook<strong>Centricut</strong> Technical Services DirectorTroubleshootingPAC Systems:Starting ProblemsWARNING! PAC system maintenanceand repair should only beattempted by those skilled in electricaltroubleshooting. PAC systemsuse high voltage and direct-current(DC) electricity. Electric shock caninjure or kill.Symptom: The torch fails to initiatethe cutting arc when all otherconditions for normal operation arecorrect—power supply energized,safety and parts-in-place interlockssatisfied, gas pre-flow at torch, andtorch within transfer distance.The sequence of operation for thetypical PAC system is as follows: Thestart-cut signal is sent to the powersupply to energize the system. Asolenoid opens, allowing gas flow tothe torch. The pilot-arc relay latches,activating open-circuit voltage (OCV)between the nozzle (+) and the electrode(-). A high-frequency (HF)spark (see illustration 1) is suppliedto the torch by a high-voltage generatorwith 3,000-10,000 V AC output.The high-frequency generator usuallyincludes a high-voltage transformer,capacitors, spark-gapassembly, and coil.The high-frequency spark ionizesthe gas flowing through the torch,making it electrically conductive.The ionized gas allows current flowbetween the electrode and nozzle.This current is limited to 20-40 A DCby the pilot resistor. The arc blowsout of the orifice and reattaches tothe face of the nozzle, forming a pilotarc (see illustration 2).The pilot arc forms the electricalpathway to the workpiece. If thetorch is within transfer distance, usually0.25 to 0.50 inch from thematerial, the pilot arc will transfer tothe plate since the plate is connectedto the positive pole of the DC circuitand is not limited by a resistor(see illustration 3). A current-sensingcircuit senses arc transfer, shutsoff the HF generator, and opens thepilot-arc relay.In simple terms, the torch needsthree ingredients to form a pilot arc:plasma gas, DC power, and AC highfrequency. With any of these ingredientsmissing, the torch will not fire,transfer, or cut.Troubleshooting startingproblemsWhen starting problems occur,the operator should first evaluate thepilot arc. He raises the torch severalinches above the material to providea good, clear view of the torch.He then signals the torch to fire.After several seconds of gas flow, apilot arc should form at the torch. Ahealthy pilot arc will sustain itself inthe air for several seconds. He looksfor an arc with a bright white-bluecolor that projects 0.25-0.50 inchfrom the end of the nozzle. The arcshould not spit and sputter or soundraspy; it should be smooth andsteady. He should test the pilot arca number of times in the air to see ifthe condition repeats.Problem 1: Hard StartingIf the pilot arc spits and sputtersbut fires intermittently, the problemmay be hard starting. Hard startingoccurs when the HF struggles tobreak down the high-pressurebarrier between electrode andnozzle. This can be caused byinsufficient HF or excessive gaspressure. Here are four steps toremedy hard starting.14Welding Design and Fabrication ■ November 2000

Illustration 1Illustration 2Illustration 3• Check the gas pressure andflow. The plasma gas pressure orflow setting should not exceed factory-recommendedsettings. Excesspressure in the plasma chambermakes it harder for the HF spark tojump the gap, so that the pilot arc iseffectively blown out before it canfully establish. High-gas pressureaccounts for the majority of hardstartingproblems, and is often overlooked—azealous troubleshootermight replace every component inthe pilot circuit, only to find the airpressure had been turned too high.• Clean the hoses and wires thatcarry gas and power to the torch,and inspect them for visible damageor loose connections. If theshielding is covered withdirt, metal dust, or moisture,the high-frequency energycan be dissipated. Blow offthe leads with an air hose orwipe them down with aclean cloth.Eliminate anycoils in the leads—they cancause a large inductance.Insulate the leads from thecutting machine.• Inspect, clean, and regapthe spark-gap assembly.High frequency from thehigh-voltage generator isusually sent to capacitorsthat discharge the electricityacross a spark-gap assembly.Over time the spark-gapelectrodes can deteriorateor become contaminatedwith metal dust and dirt.Clean and re-gap the electrodesto the manufacturer’sspecifications. Gap shouldbe 0.015 to 0 .030 inch,depending on the system.• If using a water-cooledtorch, check coolant resistivity.For most systems itshould be less than 10Kohms/cm or 10 micromhos.Problem 2: Weak, bluespark at torchIf there is a visible spark atthe torch but it is a small bluespark that looks similar tothe spark at the spark-gappoints, then the pilot arc has high frequencybut no DC component. Themost likely causes for loss of DC inthe pilot arc are worn contacts or abad coil in the pilot-arc relay; or adefective pilot resistor.Problem 3: No spark visible attorch or at spark gapNo AC power to high voltage generator;defective high-voltage generator;defective capacitors; shorted ordamaged spark-gap assembly.Problem 4: No spark at torch,spark at spark gapSevere hard starting—refer toproblem 1; shorted or open torchlead; shorted or open connection intorch body.November 2000 ■ Welding Design and Fabrication15