You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

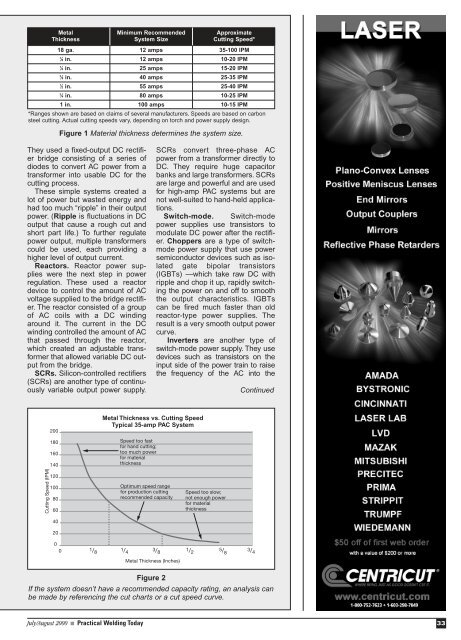

Metal Minimum Recommended ApproximateThickness System Size Cutting Speed*18 ga. 12 amps 35-100 IPM1⁄8 in. 12 amps 10-20 IPM1⁄4 in. 25 amps 15-20 IPM3⁄8 in. 40 amps 25-35 IPM1⁄2 in. 55 amps 25-40 IPM3⁄4 in. 80 amps 10-25 IPM1 in. 100 amps 10-15 IPM*Ranges shown are based on claims of several manufacturers. Speeds are based on carbonsteel cutting. Actual cutting speeds vary, depending on torch and power supply design.Figure 1 Material thickness determines the system size.They used a fixed-output DC rectifierbridge consisting of a series ofdiodes to convert AC power from atransformer into usable DC for thecutting process.These simple systems created alot of power but wasted energy andhad too much “ripple” in their outputpower. (Ripple is fluctuations in DCoutput that cause a rough cut andshort part life.) To further regulatepower output, multiple transformerscould be used, each providing ahigher level of output current.Reactors. Reactor power supplieswere the next step in powerregulation. These used a reactordevice to control the amount of ACvoltage supplied to the bridge rectifier.The reactor consisted of a groupof AC coils with a DC windingaround it. The current in the DCwinding controlled the amount of ACthat passed through the reactor,which created an adjustable transformerthat allowed variable DC outputfrom the bridge.SCRs. Silicon-controlled rectifiers(SCRs) are another type of continuouslyvariable output power supply.SCRs convert three-phase ACpower from a transformer directly toDC. They require huge capacitorbanks and large transformers. SCRsare large and powerful and are usedfor high-amp PAC systems but arenot well-suited to hand-held applications.Switch-mode. Switch-modepower supplies use transistors tomodulate DC power after the rectifier.Choppers are a type of switchmodepower supply that use powersemiconductor devices such as isolatedgate bipolar transistors(IGBTs) —which take raw DC withripple and chop it up, rapidly switchingthe power on and off to smooththe output characteristics. IGBTscan be fired much faster than oldreactor-type power supplies. Theresult is a very smooth output powercurve.Inverters are another type ofswitch-mode power supply. They usedevices such as transistors on theinput side of the power train to raisethe frequency of the AC into theContinuedCutting Speed (IPM)2001801601401201008060Metal Thickness vs. Cutting SpeedTypical 35-amp PAC SystemSpeed too fastfor hand cutting;too much powerfor materialthicknessOptimum speed rangefor production cuttingrecommended capacitySpeed too slow;not enough powerfor materialthickness402000 1/ 8 1/ 4 3/ 8 1/ 2 5/ 83/ 4Metal Thickness (Inches)Figure 2If the system doesn’t have a recommended capacity rating, an analysis canbe made by referencing the cut charts or a cut speed curve.July/August 2000 ■ Practical Welding Today33