Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

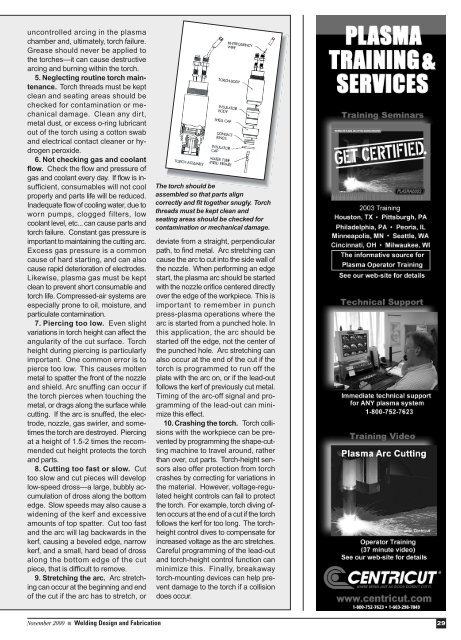

uncontrolled arcing in the plasmachamber and, ultimately, torch failure.Grease should never be applied tothe torches—it can cause destructivearcing and burning within the torch.5. Neglecting routine torch maintenance.Torch threads must be keptclean and seating areas should bechecked for contamination or mechanicaldamage. Clean any dirt,metal dust, or excess o-ring lubricantout of the torch using a cotton swaband electrical contact cleaner or hydrogenperoxide.6. Not checking gas and coolantflow. Check the flow and pressure ofgas and coolant every day. If flow is insufficient,consumables will not coolproperly and parts life will be reduced.Inadequate flow of cooling water, due toworn pumps, clogged filters, lowcoolant level, etc... can cause parts andtorch failure. Constant gas pressure isimportant to maintaining the cutting arc.Excess gas pressure is a commoncause of hard starting, and can alsocause rapid deterioration of electrodes.Likewise, plasma gas must be keptclean to prevent short consumable andtorch life. Compressed-air systems areespecially prone to oil, moisture, andparticulate contamination.7. Piercing too low. Even slightvariations in torch height can affect theangularity of the cut surface. Torchheight during piercing is particularlyimportant. One common error is topierce too low. This causes moltenmetal to spatter the front of the nozzleand shield. Arc snuffing can occur ifthe torch pierces when touching themetal, or drags along the surface whilecutting. If the arc is snuffed, the electrode,nozzle, gas swirler, and sometimesthe torch are destroyed. Piercingat a height of 1.5-2 times the recommendedcut height protects the torchand parts.8. Cutting too fast or slow. Cuttoo slow and cut pieces will developlow-speed dross—a large, bubbly accumulationof dross along the bottomedge. Slow speeds may also cause awidening of the kerf and excessiveamounts of top spatter. Cut too fastand the arc will lag backwards in thekerf, causing a beveled edge, narrowkerf, and a small, hard bead of drossalong the bottom edge of the cutpiece, that is difficult to remove.9. Stretching the arc. Arc stretchingcan occur at the beginning and endof the cut if the arc has to stretch, orThe torch should beassembled so that parts aligncorrectly and fit together snugly. Torchthreads must be kept clean andseating areas should be checked forcontamination or mechanical damage.deviate from a straight, perpendicularpath, to find metal. Arc stretching cancause the arc to cut into the side wall ofthe nozzle. When performing an edgestart, the plasma arc should be startedwith the nozzle orifice centered directlyover the edge of the workpiece. This isimportant to remember in punchpress-plasma operations where thearc is started from a punched hole. Inthis application, the arc should bestarted off the edge, not the center ofthe punched hole. Arc stretching canalso occur at the end of the cut if thetorch is programmed to run off theplate with the arc on, or if the lead-outfollows the kerf of previously cut metal.Timing of the arc-off signal and programmingof the lead-out can minimizethis effect.10. Crashing the torch. Torch collisionswith the workpiece can be preventedby programming the shape-cuttingmachine to travel around, ratherthan over, cut parts. Torch-height sensorsalso offer protection from torchcrashes by correcting for variations inthe material. However, voltage-regulatedheight controls can fail to protectthe torch. For example, torch diving oftenoccurs at the end of a cut if the torchfollows the kerf for too long. The torchheightcontrol dives to compensate forincreased voltage as the arc stretches.Careful programming of the lead-outand torch-height control function canminimize this. Finally, breakawaytorch-mounting devices can help preventdamage to the torch if a collisiondoes occur.November 2000 ■ Welding Design and Fabrication29