cables & accessories.. - Kathrein - France

cables & accessories.. - Kathrein - France

cables & accessories.. - Kathrein - France

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ABOUT USBeing a subsidiary of a leading Group worldwide means to benefit from its notorietyand its power; It means to emphasize its regional and cultural characteristicsas well as its own competences and its flexibility; It also means to be conscious ofour responsibility toward future generations and bring our own contribution howevermodest it may be, to the durable development of our planet.As the French subsidiary of KATHREIN Group, it is our responsibility and our priorityto always serve and develop the best Telecom solutions that match the needsof the different actors within the mobile market.Being totally aware of the fast evolutions and the growing needs of the Middle-East and African mobile market, KATHREIN <strong>France</strong> now offers complete aerialsolutions to mobile operators and installation companies.Our know-how, our export-related experience, our technical support, as well asour ability to react immediately are the key assets which all together make us ableto answer, as perfectly as possible, your needs. We are also able to be at your sidefor your network and all your projects of sites roll-out, extension or optimization.Apart from Base Station Antennas for Mobile Networks, KATHREIN FRANCE alsosupplies RF equipment (feeder <strong>cables</strong>, coaxial connectors and jumpers), RF <strong>accessories</strong>(for aerials, clamps for feeder <strong>cables</strong>, cable trays, tools etc..), RF protectionsagainst lightning, as well as solutions for weatherproofing and isolation.KATHREIN FRANCE Export Team hopes that this new brochure “Cables, Connectorsand RF Accessories 2011” will bring you whole satisfaction.2

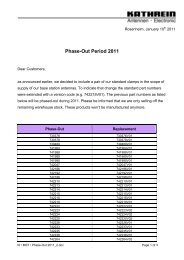

Quality & Environmental certificates3

PRODUCTS REFERENCESDescription References pagesFEEDERSFEEDER 1/2’’ HIFLEX CFC05019 p 8FEEDER 1/2’’ RIGID CFC05004 p 9NEW FEDEER 7/8’’ ULTRA LOW LOSS CFC05041 p 10NEW FEEDER 1-1/4’’ ULTRA LOW LOSS CFC05040 p 11NEW FEEDER 1- 5/8’’ ULTRA LOW LOSS CFC05034 p 12CONNECTORS COAX.7/16 MALE RIGHT 1/2’’ FLEXIBLE CRA05692 p 137/16 FEMALE RIGHT 1/2’’ FLEXIBLE CRA05082 p 137/16 MALE RIGHT ANGLE 1/2’’ FLEXIBLE CRA05206 p 137/16 MALE 1/2’’ RIGID CRA05982 p 137/16 FEMALE RIGHT 1/2’’ RIGID CRA05706 p 137/16 MALE RIGHT ANGLE 1/2’’ RIGID CRA05216 p 137/16 MALE RIGHT 7/8’’ RIGID CRA05717 p 137/16 FEMALE RIGTH 7/8’’ RIGID CRA05718 p 137/16 MALE RIGHT 7/8’’ CRA05720 p 137/16 FEMALE RIGHT 7/8’’ CRA05721 p 137/16 FEMALE RIGHT 1- 1/4’’ CRA05719 p 137/16 MALE RIGHT 1- 5/8’’ CRA05287 p 137/16 FEMALE RIGHT 1- 5/8’’ CRA05286 p 13JUMPERS7/16 MALE RIGHT/MALE RIGHT 0,50m HIFLEX 961 005 p 147/16 MALE RIGHT/MALE RIGHT 1m HIFLEX 961 010 p 147/16 MALE RIGHT/MALE RIGHT 1,5m HIFLEX 961 015 p 147/16 MALE RIGHT/MALE RIGHT 2m HIFLEX 961 020 p 147/16 MALE RIGHT/MALE RIGHT 2,5m HIFLEX 961 025 p 147/16 MALE RIGHT/MALE RIGHT 3m HIFLEX 961 030 p 147/16 MALE RIGHT/MALE RIGHT 4m HIFLEX 961 040 p 147/16 MALE RIGHT/MALE RIGHT 5m HIFLEX 961 050 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 0,50m HIFLEX 961 505 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 1m HIFLEX 961 510 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 1,50m HIFLEX 961 515 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 2m HIFLEX 961 520 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 2,50m HIFLEX 961 525 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 3m HIFLEX 961 530 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 4m HIFLEX 961 540 p 147/16 MALE RIGHT/MALE RIGHT ANGLE 5m HIFLEX 961 550 p 147/16 MALE RIGHT/MALE RIGHT 0,50m RIGID 962 005 p 157/16 MALE RIGHT/MALE RIGHT 1m RIGID 962 010 p 157/16 MALE RIGHT/MALE RIGHT 1,5m RIGID 962 015 p 157/16 MALE RIGHT/ MALE RIGHT 2m RIGID 962 020 p 157/16 MALE RIGHT/MALE RIGHT 2,5m RIGID 962 025 p 157/16 MALE RIGHT/MALE RIGHT 3m RIGID 962 030 p 157/16 MALE RIGHT/MALE RIGHT 4m RIGID 962 040 p 157/16 MALE RIGHT/MALE RIGHT 5m RIGID 962 050 p 15CABLE PREPARATION TOOL1/2’’ FLEXIBLE 960 085 p 191/2’’ RIGID 960 084 p 197/8’’ 960 064 p 191- 1/4’’ 960 123 p 19Description References pagesWRENCH HANDLES FOR CONNECTORS1/2’’ 950 002 p 207/8’’ 950 003 p 201- 1/4’’ 950 004 p 201- 5/8’’ 950 001 p 20CLAMPS FOR FEEDERSCLIP FOR FEEDER 1/2’’ ON PYLON A CORNIERE 960 053 p 24CLIP FOR FEEDER 1- 1/4’’ ON PYLON A CORNIERE 960 088 p 24CLIP FOR FEEDER 1- 5/8’’ ON PYLON A CORNIERE 960 087 p 241 FEEDER 1/2’’ HANGING ON FLAT AND ROUND CAC05300 p 251 FEEDER 7/8’’ HANGING ON FLAT ET ROUND CAC05301 p 251 FEEDER 1- 5/8’’ HANGING ON FLAT AND ROUNDREF TO ASKFOR1 FEEDER 1- 1/4’’ HANGING ON FLAT AND ROUNDREF TO ASKFOR2 FEEDERS 1/2’’ HANGING ON FLAT AND ROUNDREF TO ASKFOR2 FEEDERS 7/8’’ HANGING ON FLAT AND ROUND CAC05302 p 252 FEEDERS 1- 5/8’’ HANGING ON FLAT AND ROUND CAC05303 p 252 FEEDERS 1- 1/4’’ HANGING ON FLAT AND ROUNDREF TO ASKFOR3 FEEDERS 1/2’’ HANGING ON FLAT AND ROUNDREF TO ASKFOR3 FEEDERS 7/8’’ HANGING ON FLAT AND ROUND CAC05304 p 253 FEEDERS 1- 5/8’’ HANGING ON FLAT ET ROUNDREF TO ASKFOR3 FEEDERS 1- 1/4’’ HANGING ON FLAT AND ROUND CAC05315 p 256 FEEDERS COAX. 7/8’’ CAC05311 p 25HOISTING GRIPSPRE LACED FOR 1/2’’ 950 010 p 18PRE LACED FOR 7/8’’ 950 011 p 18PRE LACED FOR 1- 5/8’’ 950 012 p 18PRE LACED FOR 1- 1/4’’REF TO ASKFORWEATHERPROOFINGJUMPERS/ANTENNAS & FEEDERS/JUMPERS CAC05347 p 221/2’’ JUMPER TO 7/8’’ FEEDER CAC05348 p 221/2’’ JUMPER TO 1- 1/4’’ FEEDER CAC05350 p 221/2’’ JUMPER TO 1- 5/8’’ FEEDER CAC05351 p 22KITS D’ETANCHEITERUBAN BUTYL (0,50 m x 28 mm) & PLASTIC ELECTRICALSCOTCH (10 m x 15 mm)CAC05346 p 23COLLAR COLSONNON LOOSENING BLACK THROUGH JOINT 357 x 9100 PIECES BOX IN POLYAMID 12CAC05185 p 26UNIVERSAL EARTHING KITUNIVERSAL FOR FEEDER COAX 1/2’’ TO 7/8’’ 921 060 p 31SPECIFICALLY FOR FEEDER 7/8’’ 921 061 p 32SPECIFICALLY FOR FEEDER 1- 5/8’’ 921 020 p 32SPECIFICALLY FOR FEEDER 1- 1/4’’ 921 062 p 32BTS PROTECTIONEMP PROTECTION 900/1800/UMTS CRA05255 p 33GROUNDING BARGROUNDING BAR STAINLESS STEEL AISI 3004 (V2A) OUCUIVRE 9 X M8ROAD OF CHAINAGEFULL KIT : LIGHTNING ARRESTER, FLOW AND CROW’S-FOOT CONNECTORHOLE ENTRIES960 054 p 30REF TO ASKFORp 37MODULE 6x2 7/8’’ + STUFFING CAC p 271- 5/8’’ 960 086 p 194

EQUIPMENTTABLE OF CONTENTSFirst Part : RF Equipment Pages 06/07Hiflex Feeder cable 1/2” Page 08Rigid Feeder Cable 1/2” Page 09Feeder cable 7/8” Ultra-Low Losses Page 10Feeder cable 1-1/4” Ultra-Low Losses Page 11Feeder cable 1-5/8” Ultra-Low Losses Page 12Coaxial Connectors Références: Page 13Hiflex Jumpers Page 14Rigid Jumpers Page 157

FEEDER CABLE 1/2’’ HIFLEXCable with standard UV resistant PE jacket, halogen freeaccording to IEC 60754SPECIFICATIONSDesignInner conductorMaterial copper clad aluminium wireDiameter (mm) 3.55DielectricMaterial gas-injected cellular polyethyleneDiameter (mm) 9.0Outer conductorMaterial corrugated copper tubeDiameter (mm) 12.2JacketMaterial black polyethyleneThickness (mm) 0.65Diameter (mm) 13.5Mechanical specificationsMinimum bending radiussingle bending (cm) 315 repeated bends (cm) 4Maximum pulling strength (daN) 70Recommended temperature rangeStorage-70 to +85°CInstallation-40 to +60°COperation-55 to +85°CMaximum length per hoisting grip (m) 70Maximum hanger spacing 0.5Flat plate crush resistance (kg/mm) 1.7Bending moment (Nm) 2.7Weight (kg/km) 200(*) nominal values(**) Ambient temperature = 40°C; Temperature of innerconductor = 100°C;Reference :CFC 050191/2’’ hiflexElectrical specificationCharacteristic impedance (Ω) 50 ±1Nominal capacity (pF/m) 82Relative propagation velocity (%) 82Inductance (μH/m) 0.200DC-resistance at 20°Cinner conductor (Ω/km) 2.65outer conductor (Ω/km) 3.0RF peak voltage (kV) 1.13RF peak power (kW) 12.8Cut-off-frequency (GHz) 13.2Insulation resistance (MΩ.km) >>5000Attenuation [1] and power ratingFrequency(MHz)Attenuation at 20°C(*)(dB/100m)Mean powerrating(**) (kW)10 0.96 9.9020 1.37 6.9630 1.68 5.6680 2.79 3.42100 3.13 3.04150 3.88 2.46200 4.51 2.11300 5.60 1.70400 6.53 1.46450 6.96 1.37500 7.38 1.29600 8.15 1.17700 8.87 1.07800 9.55 1.00894 10.16 0.94960 10.57 0.901000 10.82 0.881500 13.62 0.701700 14.63 0.651800 15.12 0.631880 15.51 0.612000 16.08 0.592170 16.86 0.572200 17.00 0.562300 17.45 0.552400 17.89 0.532500 18.33 0.523000 20.42 0.474000 24.29 0.396000 31.21 0.318

FEEDER CABLE 1/2’’ RIGIDCable with standard UV resistant PE jacket, halogen freeaccording to IEC 60754SPECIFICATIONSDesignInner conductorMaterialcopper clad aluminium wireDiameter (mm) 4.8DielectricMaterialgas-injected cellular polyethyleneDiameter (mm) 12.4Outer conductorMaterialcorrugated copper tubeDiameter (mm) 13.7JacketMaterialblack polyethyleneThickness (mm) 1.1Diameter (mm) 16.0Mechanical specificationsMinimum bending radiussingle bending (cm) 715 repeated bends (cm) 12.5Maximum pulling strength (daN) 100Recommended temperature rangeStorage-70 to +85°CInstallation-40 to +60°COperation-55 to +85°CMaximum length per hoisting grip (m) 70Maximum hanger spacing 1Flat plate crush resistance (kg/mm) 1.9Bending moment (Nm) 3.5Weight (kg/km) 235[1] a = 0.2105b = 0.000625x (ƒ) = a . √ f + b . f [dB/100m](*) nominal values(**) Ambient temperature = 40°C; Temperature of innerconductor = 100°C;VSWR = 1.0; no solar loadingReference :CFC 050041/2’’ rigidCable with UV resistant, halogen free, low smoke, flameretardant jacket according to IEC 60754-2, IEC 60332-1-2, IEC 60332-3 Cat. C and IEC 61034-1+2Electrical specificationsCharacteristic impedance (Ω) 50 ±1Nominal capacity (pF/m) 76Relative propagation velocity (%) 88Inductance (μH/m) 0.190DC-resistance at 20°Cinner conductor (Ω/km) 1.48outer conductor (Ω/km) 2.04RF peak voltage (kV) 1.6RF peak power (kW) 25.6Cut-off-frequency (GHz) 9.8Insulation resistance (MΩ.km) >>5000Attenuation [1] and power ratingFrequency(MHz)Attenuation at 20°C(*)(dB/100m)Mean powerrating(**) (kW)10 0.67 11.7420 0.95 8.2730 1.17 6.7380 1.93 4.08100 2.17 3.64150 2.67 2.95200 3.10 2.54300 3.83 2.06400 4.46 1.77450 4.75 1.66500 5.02 1.57600 5.53 1.43700 6.01 1.31800 6.45 1.22894 6.85 1.15960 7.12 1.111000 7.28 1.081500 9.09 0.871700 9.74 0.811800 10.06 0.781880 10.30 0.772000 10.66 0.742170 11.16 0.712200 11.25 0.702300 11.53 0.682400 11.81 0.672500 12.09 0.653000 13.40 0.594000 15.81 0.506000 20.06 0.399

FEEDER CABLE 7/8’’STANDARDCable with standard UV resistant PE jacket,halogen free according to IEC 60754SPECIFICATIONSDesignInner conductorMaterialsmooth copper tubeDiameter (mm) 9.3Dielectricgas-injected cellular polyethyleneMaterialDiameter (mm) 23.5Outer conductorMaterialcorrugated copper tubeDiameter (mm) 25.0JacketMaterialblack polyethyleneThickness (mm) 1.4Diameter (mm) 28.0Mechanical specificationsMinimum bending radiussingle bending (cm) 1015 repeated bends (cm) 25Maximum pulling strength (daN) 150Recommended temperaturerangeStorage-70 to +85°CInstallation-40 to +60°COperation-55 to +85°CMaximum length per hoisting 70grip (m)Maximum hanger spacing 1.2Flat Plate Crush resistance(kg/mm)Bending moment (Nm) 11.6Weight (kg/km) 496CFC 05041 Feeder cable 7/8’’1.4 Bendingmoment (Nm)[1] a = 0.1107b = 0.000333x (ƒ) = a . √f + b . f [dB/100m](*) nominal values(**) Ambient temperature = 40°C; Temperature of innerconductor = 100°C;VSWR = 1.0; no solar loadingReference :Electrical specificationsCharacteristic impedance (Ω) 50 ±1Nominal capacity (pF/m) 75Relative propagation velocity (%) 89Inductance (μH/m) 0.187DC-resistance at 20°Cinner conductor (Ω/km) 1.34outer conductor (Ω/km) 1.0RF peak voltage (kV) 2.9RF peak power (kW) 86Cut-off-frequency (GHz) 5.1Insulation resistance (M Ω.km) >>5000Attenuation [1] and power ratingFrequency(MHz)Attenuation at 20°C(*)(dB/100m)Mean power rating(**)(kW)10 0.35 25.4620 0.50 17.9330 0.62 14.6080 1.02 8.85100 1.14 7.89150 1.41 6.40200 1.63 5.51300 2.02 4.46400 2.35 3.83450 2.50 3.60500 2.64 3.41600 2.91 3.09700 3.16 2.85800 3.40 2.65894 3.61 2.49960 3.75 2.401000 3.83 2.351500 4.79 1.881700 5.13 1.751800 5.30 1.701880 5.43 1.662000 5.62 1.602170 5.88 1.532200 5.92 1.522300 6.07 1.482400 6.22 1.452500 6.37 1.413000 7.06 1.274000 8.33 1.086000 - -10

FEEDER CABLE 1- 1/4’’STANDARDCable with standard UV resistant PE jacket, halogenfree according to IEC 60754SPECIFICATIONSDesignInner conductorMaterial corrugated copper tubeDiameter (mm) 13.6DielectricMaterialgas-injected cellular polyethyleneDiameter (mm) 33.5Outer conductorMaterial corrugated copper tubeDiameter (mm) 36.0JacketMaterial black polyethyleneThickness (mm) 1.5Diameter (mm) 39.0Mechanical specificationsMinimum bending radiussingle bending (cm) 2015 repeated bends (cm) 30Maximum pulling strength (daN) 200Recommended temperature range- Storage -70 to +85°C- Installation -40 to +60°C- Operation -55 to +85°CMaximum length per hoisting grip(m)70Maximum hanger spacing 1.4Flat plate crush resistance (kg/mm) 3.4Bending moment (Nm) 25Weight (kg/km) 830[1] a = 0.084b = 0.000461x(ƒ) = a . √ f + b . f [dB/100m](*) nominal values(**) Ambient temperature = 40°C; Temperature ofinner conductor = 100°C;VSWR = 1.0; no solar loadingReference :CFC 05040 Feeder cable 1- 1/4’’Electrical specificationsCharacteristic impedance (Ω) 50 ±1Nominal capacity (pF/m) 76Relative propagation velocity (%) 88Inductance (μH/m) 0.190DC-resistance at 20°C- inner conductor (Ω/km) 1.8- outer conductor (Ω/km) 0.5RF peak voltage (kV) 4.25RF peak power (kW) 180Cut-off-frequency (GHz) 3.3Insulation resistance (MΩ.km) >>5000Attenuation [1] and power ratingFrequency(MHz)Attenuation at 20°C(*)(dB/100m)10 0.27 39.7320 0.38 27.9030 0.47 22.6680 0.79 13.62100 0.89 12.12150 1.10 9.78200 1.28 8.39300 1.59 6.74400 1.86 5.76450 1.99 5.40500 2.11 5.09600 2.33 4.60700 2.55 4.22800 2.74 3.91894 2.92 3.67960 3.05 3.531000 3.12 3.441500 3.94 2.721700 4.25 2.531800 4.39 2.441880 4.51 2.382000 4.68 2.302170 4.91 2.192200 4.95 2.172300 5.09 2.112400 5.22 2.062500 5.35 2.013000 5.98 1.794000 - -6000 - -Mean power rating(**)(kW)11

FEEDER CABLE 1- 5/8’’ RIGIDSTANDARDCable with standard UV resistant PE jacket, halogenfree according to IEC 60754SPECIFICATIONSDesignInner conductorMaterial corrugated copper tubeDiameter (mm) 17.7Dielectricgas-injected cellular polyethyleneMaterialDiameter (mm) 43.0Outer conductorMaterial corrugated copper tubeDiameter (mm) 46.6JacketMaterial blackpolyethyleneThickness (mm) 1.7Diameter (mm) 50.0Mechanical specificationsMinimum bending radiussingle bending (cm) 2015 repeated bends (cm) 40Maximum pulling strength (daN) 250Recommended temperature rangeStorage-70 to +85°CInstallation-40 to +60°COperation -55 to +85°CMaximum length per hoisting grip (m) 70Maximum hanger spacing 1.5Flat plate crush resistance (kg/mm) 2.6Bending moment (Nm) 45Weight (kg/km) 1130[1] a = 0.061b = 0.000359x (ƒ) = a . √ f + b . f [dB/100m](*) nominal values(**)Ambient temperature = 40°C; Temperature of innerconductor = 100°C;VSWR = 1.0; no solar loadingReference :CFC 05034 Feeder 1- 5/8’’Cable with UV resistant, halogen free, low smoke, flameretardant jacket according to IEC 60754-2, IEC 60332-1-2, IEC 60332-3 Cat. C and IEC 61034-1+2Electrical specificationsCharacteristic impedance (Ω) 50 ±1Nominal capacity (pF/m) 75Relative propagation velocity (%) 89Inductance (μH/m) 0.190DC-resistance at 20°Cinner conductor (Ω/km) 1.37outer conductor (Ω/km) 0.39RF peak voltage (kV) 5.5RF peak power (kW) 302Cut-off-frequency (GHz) 2.7Insulation resistance (MΩ.km) >>5000Attenuation [1] and power ratingFrequency(MHz)Attenuation at 20°C(*)(dB/100m)Mean powerrating(**) (kW)10 0.20 51.5320 0.28 36.1730 0.34 29.3680 0.57 17.63100 0.65 15.68150 0.80 12.64200 0.93 10.84300 1.16 8.70400 1.36 7.43450 1.46 6.96500 1.54 6.56600 1.71 5.92700 1.87 5.43800 2.01 5.03894 2.14 4.72960 2.23 4.531000 2.29 4.431500 2.90 3.491700 3.13 3.241800 3.23 3.131880 3.32 3.052000 3.45 2.942170 3.62 2.802200 3.65 2.772300 3.75 2.702400 3.85 2.632500 3.95 2.573000 - -4000 - -6000 - -12

COAXIAL CONNECTORS7/16 F DT 7/8’’FEMALE STRAIGHT7/16 F DT 1- 5/8’’FEMALE STRAIGHT7/16 F DT 1- 1/4’’FEMALE STRAIGHT7/16 M CDE ½’’ FLEXIBLEMALE RIGHT ANGLED HI-FLEX 1/2’’References & SpecificationsCRA 05692CRA 05982CRA 05082CRA 05706CRA 05206CRA 05216CRA 05721CRA 05720CRA 05719CRA 05725CRA 05286CRA 05287Coaxial Connector 7/16 MALE STRAIGHT 1/2’’ FLEXIBLECoaxial Connector 7/16 MALE STRAIGHT 1/2’’ RIGIDCoaxial Connector 7/16 FEMALE STRAIGHT 1/2’’ FLEXIBLECoaxial Connector 7/16 FEMALE STRAIGHT 1/2’’ RIGIDCoaxial Connector 7/16 MALE RIGHT- ANGLED 1/2’’ FLEXIBLECoaxial Connector 7/16 MALE RIGHT- ANGLED 1/2’’ RIGIDCoaxial Connector 7/16 FEMALE STRAIGHT Clip 7/8’’ RIGIDRéférences:Coaxial Connector 7/16 MALE STRAIGHT Clip 7/8’’ RIGIDCoaxial Connector 7/16 FEMALE STRAIGHT 1-1/4’’ RIGIDCoaxial Connector 7/16 MALE STRAIGHT 1- 1/4’’ RIGIDCoaxial Connector 7/16 FEMALE STRAIGHT 1-5/8’’ RIGIDCoaxial Connector 7/16 MALE STRAIGHT 1-5/8’’ RIGID13

HIFLEX JUMPERSElectrical Specifications of Terminated Standard Jumper Cables :800-1000 MHz 1600-2000 MHz1 Return loss (VSWR) (typically) -32 dB (1.05: 1) -30 dB (1.06:1)Return loss (VSWR) (Min) -28 dB (1.08:1) -26 dB (1.1:1)2 Attenuation (per 100m) (Max) at 20°C11.2 dB (+0.03 dB for 17.0 dB (+0.03 dB forconnectors)connectors)3 Power Handling (Min) continuous 750 W 500 W4 Level of IMP (Intermodulation Products)2 unmodulated test tones each at +43 dBm (20 W)3nd or higher order IMP (typically) -118 dB (-161 dBc) -118 dBm (-161 dBc)(min) -107 dBm (-150 dBc) -107 dBm (-150 dBc)5 Impedance 50 Ω (+- 1.5 Ω) 50 Ω (+- 1.5 Ω)6 RF Voltage Rating (Peak) 1100 V 1100 V7 Velocity of Propagation 82% 82%8 Contact Potential (centre and outer conductors) no dissimilar metal interfacesMechanical and Environmental specifications:1 Temperature Range (Installation) -40°C…+60°C(Operating)-45°C…+85°C2 Relative humidity 10%…100%3 General Environmental Corrosion and UV resistant4 Minimum Bending Radius 30mm5 Connector Torque (nominal) 8 Nm (N types) 15 Nm (7/16 Types)6 Packaging Orange protection caps for connectors (standard)Design:All metal contact parts from connectors are silver plated. Their design is optimized to provide an extra low level ofintermodulation, excellent return loss values, and improved jumper cable performances.Excellent water tightness provided by the special connector design (O-ring in connector head). The over molding ofthe connector provides an additional mechanical stability.Easy, fast and reliable installation.References : References :Connector 7-16, 2 Male straight961 005 0,5 m961 010 1 m961 015 1,5 m961 020 2 m961 025 2,5 m961 030 3 m961 040 4 m961 050 5 mConnector 7-16, 1 Male straightand 1 male right angle 90°961 505 0,5 m961 510 1 m961 515 1,5 m961 520 2 m961 525 2,5 m961 530 3 m961 540 4 m961 550 5 m14

RIGID JUMPERSElectrical Specifications of Terminated Standard Jumper Cables :800-1000 MHz 1600-2000 MHz1 Return loss (VSWR) (typically) -38 dB (1.02: 1) -30 dB (1.06:1)Return loss (VSWR) (Min) -28 dB (1.08:1) -26 dB (1.10:1)*2 Attenuation (per 100m) (Max) at 20°C7.2 dB (+0.03 dB for 11.5 dB (+0.03 dB forconnectors)connectors)3 Power Handling (Min) continuous 1000 W 750 W4 Level of IMP (Intermodulation Products)2 unmodulated test tones each at +43 dBm (20 W)3nd or higher order IMP (typically) -122 dB (-165 dBc) -122 dBm (-165 dBc)(min) -112 dBm (-155 dBc) -112 dBm (-155 dBc)5 Impedance 50 Ω (+- 1 Ω) 50 Ω (+- 1 Ω)6 RF Voltage Rating (Peak) 1100 V 1100 V7 Velocity of Propagation 88% 88%8 Contact Potential (centre and outer conductors) no dissimilar metal interfaces*-24 dB (1.12:1) for angle connectorsMechanical and Environmental specifications:1 Temperature Range (Installation) -40°C…+60°C(Operating)-45°C…+85°C2 Relative humidity 10%…100%3 General Environmental Corrosion and UV resistant4 Minimum Bending Radius 70 mm (single) 125 mm (repeat)5 Connector Torque (nominal) 15 Nm -25 Nm6 Packaging Orange protection caps for connectors (standard)Design:All metal contact parts from connectors are silver plated. Their design is optimized to provide an extra low level ofintermodulation, excellent return loss values, and improved jumper cable performances.Excellent water tightness provided by the special connector design (O-ring in connector head). The over molding ofthe connector provides an additional mechanical stability.Easy, fast and reliable installation.References :Connector 7-16, 2 Male Straight962 005 0,5 m962 010 1 m962 015 1,5 m962 020 2 m962 025 2,5 m962 030 3 m962 040 4 m962 050 5 m15

RF ACCESSORIESSince the very beginning of the first base stations deployments almost 20 years ago, KATHREINand its technical specialists have been developing solutions and <strong>accessories</strong> that can bring mobileoperators and installation companies exactly what they need.There has been an increased development of products from high-performing technologies elaboratedstep by step, all over the past 20 years. Their easiness and their fast installation arehighly appreciated by most of the biggest service providers and mobile operators all over theworld.The following chapter is basically about all RF Accessories you need on a site, from <strong>accessories</strong>for Base Station Antennas, clamps for feeder <strong>cables</strong>, cable trays, to tools (stripping tools,wrench handles for connectors etc..). It will be a useful hand for technical engineers and specialists,and guarantee them a safe installation, while saving time.16

HOISTING GRIPSHoisting Grips are used to lift and hoist <strong>cables</strong> upto the top of the tower. Hoisting grips have an importanttin content, and are bronze-coated to providethe highest resistance to corrosion. Use onehoisting grip every 60 meters.SizeMaterialDesignIncludeSpecificitiesfrom 1/2’’ to 1-5/8” cableTinned bronzeMesh grip with single eye supportGrip, self-locking clip, tapepre-laced to make installation easierReferences :Available for 1/2’’, 7/8”, 1-5/8”and 1-1/4” feeder <strong>cables</strong>950 010 Tool 1/2’’950 011 Tool 7/8’’950 013 Tool 1-1/4’’950 012 Tool 1- 5/8’’18

STRIPPING TOOLSTool 7/8’’ Tool 1- 5/8’’Tool 1- 1/4’’Tool 1/2’’ Hi-FlexTool 1/2’’ rigidReferences :960 085 Tool ½’’ Hi-Flex960 084 Tool ½’’ Rigid960 086 Tool 1- 5/8’’960 064 Tool 7/8’’960 123 Tool 1- 1/4’’19

WRENCH HANDLE FOR CONNECTORSConnector Wrench sizemmMax. Wrench HeadThickness mmBack Nut TorqueNm½’’ rigid 19 7 207/8’’ 30 12 301- 1/4’’ 44 N/A 401- 5/8’’ 58 N/A 50References :During the connector tightening, Hold theconnector body fixed with the help of thetorque wrench.950 002 Connector 1/2’’950 003 Connector 7/8’’950 001 Connector 1- 5/8’’950 004 Connector 1- 1/4’’20

INSTRUCTIONS TO USESTRIPPING TOOLS 7/8’’21

PROTECTION OF CONNECTIONSGSCI closure system (Gel Seal for Coax Connectors)Feeders-Jumpers and Jumpers- AntennesThe GSIC closure system consists of in-line closures as well as closures used to sealAntenna/ Jumper, and Jumper/ Feeder. It is designed to provide water tightness, environmentaland mechanical protection for coaxial connectors. By providing a longtermand effective protection against water infiltration and other pollutants (IP68 acc.EN 60529), the gel guarantees a reliable and cost-effective solution.The GSIC closure system consists of the following components :- A wraparound central body molded from a UV-stabilized polymer.- A closing channel which is also molded from a UV-stabilized polymer.Sealing components :- The sealing is performed by a gel under compression- All sealing elements are integrated into the productReliable protection for temperature variation between -30°C and 60°C, without deteriorationof subsequent product performanceProtection against excessive cable bendingNo connector disunionKits are easy and quick to install, at temperatures of between -10°C and +45°CEasily removable and re-usableNo tape, mastics or tools required for installation and re-useUV resistant, and tested under extremely severe conditions, vibrations and temperature cycles (acc.ICE 60068-2-14 Test Nb).The reference CAC05347 can only beused with connectors DIN 7/16, maximumlength 60mm, maximum diameter 27mm,lowest distance between panel and connector: 45mmReferences :CAC 05347Antenna/ jumperCAC 05348 Jumper/ feeder cable 7/8’’CAC 05350 Jumper/ feeder cable 1- 1/4’’CAC 05351 Jumper/ feeder cable 1- 5/8’’22

WEATHERPROOFING KITComposition and technical specifications:ButylButyl tape (0.50m x 38mm)Electrical tapePlastic electrical tape(10m x 15mm)One kit guarantees the weatherproofing of:2 connectors 7/8’’ or 1 connector 1- 1/4’’ ou 1- 5/8’’Remove the protecting tape from the vulcanized rubber band (Butyl)Cover up all the connection, starting from the winding down below.Tighten steadily during the process.Continue the winding until you get 50 to 60 mm beyond the connector.Wind the plastic band in reverse of the Butyl winding.Cover up the Butyl with at least 3 layers of plastic band which must exceed an average of 25mm onboth sides of the rubber band.Stretch steadily during the winding of the first two layers, but do not stretch the last one. Press slowlywith hand on the winding to guarantee a safe adherence all around the connector.Reference :CAC 05346Weatherproofing Kit23

CLAMPS FOR 1/2’’ TO 1- 5/8’’ FEEDER CABLEClamps for feeder <strong>cables</strong> designed for towers ofangle-board typeSpecificities:MachiningComponentsTicknessAssemblingMechanical resistanceBlanked and press-formedFully tempered 301 stainless steel, hardened E40.8 to 1.5, according to the referenceStainless steel blind rivetTear-off cable side > 12 KgfTear-off angle iron side > 25 KgfCable Slip > 6 KgfFor <strong>cables</strong> with a diameter from 16to 50 mmMounting : 1 clip every meter atthe lowest.References :960 063 Clamps for 1/2’’ feeder <strong>cables</strong>960 053 Clamps for 7/8’’ feeder <strong>cables</strong>960 088 Clamps for 1- 1/4’’ feeder <strong>cables</strong>960 087 Clamps for 1- 5/8’’ feeder <strong>cables</strong>24

CLAMPS FOR 1 TO 6 FEEDERS CABLESFor flat and round with thickness between 3 and12mm. Calibrated saddlesMaterial :AISI 304 Stainless SteelGlass reinforced fiber P.A, U.V resistantColor : black (grey on request)References :CAC 05300 : Clamp for 1 feeder cable 1/2”CAC 05301 : Clamp for 1 feeder cable 7/8”CAC 05113 : Clamp for 1 feeder cable 1-1/4”CAC 05110 : Clamp for 1 feeder cable 1-5/8”References :CAC 05121 : Clamp for 2 feeder <strong>cables</strong> 1/2”CAC 05302 : Clamp for 2 feeder <strong>cables</strong> 7/8”CAC 05109 : Clamp for 2 feeder <strong>cables</strong> 1-1/4”CAC 05303 : Clamp for 2 feeder <strong>cables</strong> 1-5/8References :CAC 05119 : Clamp for 3 feeder <strong>cables</strong> 1/2”CAC 05304 : Clamp for 3 feeder <strong>cables</strong> 7/8”CAC 05315 : Clamp for 3 feeder <strong>cables</strong> 1-1/4”CAC 05316 : Clamp for 3 feeder <strong>cables</strong> 1-5/8”References :CAC 05122 : Clamp for 4 feeder <strong>cables</strong> 1/2”CAC 05120 : Clamp for 4 feeder <strong>cables</strong> 7/8”CAC 05319 : Clamp for 4 feeder <strong>cables</strong> 1-1/4”CAC 05318 : Clamp for 4 feeder <strong>cables</strong> 1-5/8”References :CAC 05124 : Clamp for 6 feeder <strong>cables</strong> 1/2»CAC 05311 : Clamp for 6 feeder <strong>cables</strong> 7/8»CAC 05317 : Clamp for 6 feeder <strong>cables</strong> 1-1/4»CAC 05123 : Clamp for 6 feeder <strong>cables</strong> 1-5/8»25

CABLE TIETechnical specificationsDescription Cable tieSize9 x 357 mmComposition Polyamide 12ColorblackConditioning 100 pcs boxesTighteningLowest diameter : 26 mmBiggest diameter : 92 mmReference :CAC 05185Cable tie26

WALL ENTRIESRanges from 1 to 12 feedersIP67 waterproof and fire resistant to REI 120For a tight sealing of <strong>cables</strong>Easy and quick mountingFixings <strong>accessories</strong> are includedElastic cushions on separate requestGrounding bar on requestDescriptionAISI 304 (V2A) steel plateBlack EPDM gasketElastic collarRemovable plastic PINAISI 304 Hose clamp for Collar (FAS)Sectorial cushions (GSR & GST)Round cushions (GR)Removable protective filmSilicon lubricant (LUS)Grounding bar on request (BEI)Reference :CAC 05310 Wall entriesModule 6 x 2 feeder <strong>cables</strong> (7/8’’)27

PROTECTIONThe lightning current is basically about a short and intense electromagnetic field (of double exponentialtype) that can damage equipment put at each ends of feeder <strong>cables</strong>, or cause a badfunctioning.Using components with new technologies of bad quality can easily increase the sensitivity ofelectrical and electronic equipment from lightning. Side protections limit troubles induced by thedischarge current, to a tolerable level for materials located in the extremities.Lightning arrester, surge protector, isolation systems are all rarely used directly. They are moreused as a whole system more or less complex and all put at the cable extremities, and close tothe equipment that need to be protected. They also need to be close, as much as possible, totheir inlet in buildings.These side protections can absolutely not damage the signal but indeed generate a safe flowpath for the lightning current to the ground, to avoid damages on the <strong>cables</strong>.Thanks to the large choice of side protections on the market, every cable type can easily bemounted with the perfect protection. The protection depends on the signal spread by the cable(tension, current, frequency). In specific cases, the designer has between several circuit typesthat he can use, and can consequently choose the circuit with the very best specifications heneeds to resolve his technical issues.This chapter will provide you with a complete range of products designed to protect your RFequipment against lightning, as well as weatherproofing solutions, for isolation matters.28

OF RF EQUIPMENTTABLE OF CONTENTSThird Part : Protection of RF Equipment Page 28/29Copper Grounding Bar Page 30Universal Earthing Kit Page 31Earthing Kits for 1/2’’, 7/8”, 1-1/4” & 5/8” Feeder Cables Page 32Lightning Arrester for GSM 900, 1800, and UMTS Page 33Lightning Arrester : Installation Instructions Page 34Basic Information for a safe Cell Site Page 35Protection of equipment upper extremities Page 36Cell Sites suffering from Lightning :How to provide a safe flowpath for the lightning current Page 3729

GROUNDING BARGrounding bar :AISI 304 STAINLESS STEELHoles :9 x M8Reference :960 054 Grounding bar30

Protection against lightningUNIVERSAL EARTHING KITFor any type of feeder cable.Kit in detail:1/ Contact bar of tin-plated copper2/ Tin-plated copper mesh3/ Connecting lug screw M84/ NAS self-agglomerating UV proof black color tape, for protection and sealing5/ P.E. insulated copper cable, length = 50cm, fire resistant CEI 20-22,Color : black (green and yellow on request)6/ Tinned copper lugsReference :921 060 Universal Earthing kit31

EARTHING KIT FOR FEEDER CABLE1/2’’, 7/8’’, 1- 1/4’’ & 1- 5/8’’Technical specifications:Compact structuresQuick and easy installationLightning tested (CESI)Low contact resistance < 1 mOhmWaterproof IP 67 (CESI)Corrosion resistantEnvironmental test (IEC 68-2-14)No extra taping neededRemove the section of the sheath with a knife.Take care not to damage the outer copper conductor of the cable.Carefully lubricate the cable sheet with special silicon lubricant S.Open the KMT contact slip and place it on the outer copper conductor of the cable.Close the steel shell and tighten the locking screw. Take care to well fit the rubber gasket on the cablejacket.Fix the cable lug of the grounding wire to the ground of the tower with the M8 screw and nut.References :921 000 Feeder Cable ½’’921 061 Feeder Cable 7/8’’921 020 Feeder Cable 1- 5/8’’921 062 Feeder Cable 1- 1/4’’32

LIGHTNING ARRESTER FORGSM 900, 1800, UMTSElectrical specifications:Power flow100 KA en onde 8/20 µs (1 fois)ROS 800 à 880 MHz < 1.08ROS 880 à 2500 MHz < 1.08ROS 2500 à 2600 MHz < 1.10Losses insertion < 0.05 dBConnection 7/16F (antenna side)7/16M (BTS side)Intermodulation < 160 dBcMecanical specifications:Length105 mmDiameter45 mmWeight525 gIP 67IEC 68 558521Ground connection on screw M5conductor 6 mm² minimumReference :CRA 05255lightning arrester33

LIGHTNING ARRESTER :INSTRUCTIONS FOR INSTALLATIONTo guarantee you the best protection you can find, the arrester has to bemounted as close as possible from the equipment that has to be protected(BTS…).This specific equipment needs to be mounted in a safe and well-coveredplace. For Outdoor protection, use weatherproofing kitRéférences: Références:34

BASIC INFORMATION FOR A SAFE SITEGeographical areaKeraunic levelThe study of a lightning protection requires a study of the local geographical conditions, especially theexposure degree of the structure to :- the lightning risk, to assess the “potential for risk”, useful in the specification of protection devices,- the winds, studying the structures architecture to determine the best mechanical design of the deviceKnowing the exact geographical position of the site to protect is determining for the keraunic level. Thekeraunic level Nk indeed expresses the number of days per year where thunder is heard at a given place.This level indicates the degree of protection (site strongly or not strongly exposed) and make possible tocalculate the lightning density Ng, which expresses the number of strikes per year per km².Wind directionKnowing the prevailing winds in thundery periods is less important than the keraunic level. But it can helpto change the position of each protection. Indeed, every calculation on lightning rods consider clap of thunderas vertical. However, they are lightly deflected by aerological phenomenon.Site geologyTwo factors have to be considered on a geological level.Ground resistanceIt is a determining point to take decision regarding the ground plugs size, which provides a safe flow pathfor the lightning current.Homogeneous Land surfaceIt is very important regarding the ground plug location; resistance between ground plugs will highly interferewith the differences of potential, included between buildings when lightning strikes.Site environment : building and surroundingsBuilding sizes (length, height, and width), terrace plans, towers and shelters positioning, and basically allheight measurements are necessary guidelines for the survey. The plan will have to include the indicationof the north, the surrounding facilities (water supply, electric power station).35

PROTECTION OF HEAD END EQUIPMENTPhenomenon:Lightning currents cause a short and intense electromagnetic field which is double exponential, that candamage head-end equipment connected to <strong>cables</strong>. Using high tech components from bad quality caneasily increase the severe impact of lightning on electrical and electronic equipment.Head-end equipment are involved to limit disturbances caused by lightning, until you get an acceptablelevel that head-end equipment can handle.Physical magnitudePeak value for 1 lightning strike 35 KATime of climb 100 ns to 100 µsTime10 µs to 100 msSpectrum1 KHz to 1 MHz (Maximum weight about 100 KHz)Main information on head-end equipmentLightning Arrester (association between spark gap and varistor)Surge Suppressor (transient voltage suppression diode)Isolation systems (slightly capacitive transformers or lines connected for microwave linksapplications).Lightning arrester, surge protector, isolation systems are all rarely used directly. They are more used as awhole system more or less complex and all put at the cable extremities, and close to the equipment thatneed to be protected.They also need to be close, as much as possible, to their inlet in buildings.These side protections can absolutely not damage the signal but indeed generate a safe flow path for thelightning current to the ground, to avoid damages on the <strong>cables</strong>.Thanks to the large choice of side protections on the market, every cable type can easily be mounted withthe perfect protection. The protection depends on the signal spread by the cable (tension, current, frequency).In specific cases, the designer has between several circuit types that he can use, and can consequentlychoose the circuit with the very best specifications he needs to resolve his technical issues.36

CELL SITES SUFFERING FROM LIGHTNINGHow to provide a safe flow path for the lightning currentPylon ProtectionLateral Fixing BracketsLightning Rod (Basic Metal Rod)Steel Strapping TapesMeplat 30x2mmEarthing KitOblong Test ClampCopper Square ClampsInspection HoleMeplat 30x2mmCrow-foot earthing systemConnectorCopper Ground Rod37

KATHREIN <strong>France</strong>7, rue des GardesF-91370 VERRIERES LE BUISSON<strong>France</strong>Tél. +33 1 69 53 64 53Fax +33 1 69 53 64 54www.kathrein.frkathrein@kathrein.frEn raison de l’évolution technique, KATHREIN se réserve le droit à toutmoment et sans préavis de modifier les caractéristiques techniquesannoncées pour ces produits et/ ou de cesser la fabrication de ceux-ci.