Quick Closing Non-Return Valve - hydrostec

Quick Closing Non-Return Valve - hydrostec

Quick Closing Non-Return Valve - hydrostec

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

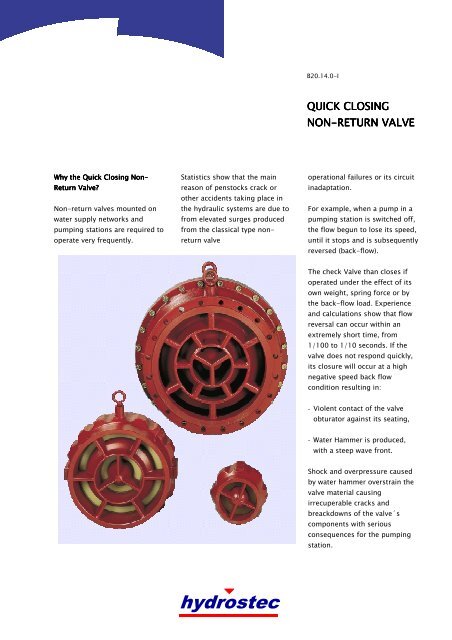

Basic requirements of a check<strong>Valve</strong>:- Shorter closing time limitingthe overpressure caused bysurging originated by the valveitself,- No vibration, and ability tooperate in maximum aperture,even at low flow speeds,- No bump operation withoutimpact or bumps on closure,- Operational durability andsafety.<strong>Quick</strong> <strong>Closing</strong> <strong>Non</strong>-<strong>Return</strong><strong>Valve</strong>meets all these requirementsbecause of its innovative designconception assuring:- Light weight obturator with lowinertia,- Short operation travel limited to1/10 of nominal diameter,- Obturator made ofpolyurethane to absorb theshock,- No mechanical parts,- Hydraulically optimized flowpassage section.<strong>Quick</strong> <strong>Closing</strong> <strong>Non</strong>-<strong>Return</strong><strong>Valve</strong>Advantages:- Prevents water hammer withhigh overpressure values,- Operates silently,- Damped closing due toobturator elasticity,- Good sealing in closed position,- Optimum hydraulic operation:flow partialization andconcentricity,- Small dimensions: valve width ~DN/2 (forDN ≥ 200mm - 8"),- No maintenance is necessary,- Simple technical design,- Operation in all installationpositions,- No wear in operation, thereforeno spare parts needed,- Wide range of diameters: DN 50to 1800 mm (2" to 72"),- Small disc valve stroke(~DN/10).Excellent dynamic response:Sample of overpressure recordstaken during water hammer testsof various types of valvesoperating under the identicalconditions (network pressure: 5bar);1- Single-flap valve,2- Multi-flap valve,3- <strong>Quick</strong> <strong>Closing</strong> No-<strong>Return</strong><strong>Valve</strong>.<strong>hydrostec</strong>

Type I Type II Type IIIFlow directionRef Designation Description Material (*)1 Body One-piece cast body in the form of profiledconcentric rings supported by spacersCast ironGG25 - GGG40 - GGG602 Ring seat (for Wafer type body)or counter flange (for flangedCast part with frame flaps and spring holder Cast ironGG25 - GGG40 - GGG60type)3 Obturator With longitudinal movement incorporating Polyurethaneprofiled concentric rings4 Helical spring Helps the disc valve closure Stainless steelAISI 3025 Thoroidal joint O-Ring Synthetic rubber(*) Other special material and lining may be supplied upon request.Range and dimensionsTypeDN PN Dimensions Weightmm inches 10 16 20 25 40 50 ∅A mm B mm Kg50 2" 91 50 180 3"142 80 2I 100 4" 174 100 6125 5" 210 125 11150 6" GG 25 246 150 17FlangedWafer200 8" 290 127 22250 10" 352 146 35300 12" 398 181 50II 350 14" 460 222 80400 16" 520 232 100450 18" 554 260 135500 20" 626 292 180600 24"900 435 500700 28" GGG 401120 500 800800 32" 1180 515 1000900 36" 1480 710 1700III 1000 40" GGG 60 1500 730 19001200 48" Upon Request 1890 900 34001400 56" 2205 1120 54001600 64" 2520 1352 81001800 72" 2850 1440 11850Used for water and other liquids up to 60 0 C (140 fahrenheit).<strong>hydrostec</strong>