Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

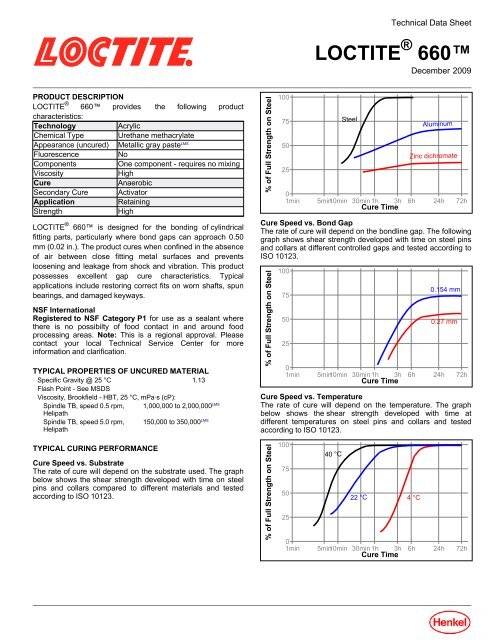

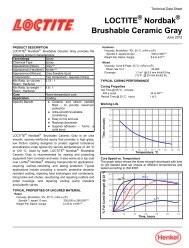

Technical Data Sheet<strong>LOCTITE</strong> ® 660December-2009PRODUCT DESCRIPTION<strong>LOCTITE</strong> ® 660 provides the following productcharacteristics:TechnologyAcrylicChemical Type Urethane methacrylateAppearance (uncured) Metallic gray paste LMSFluorescenceNoComponentsOne component - requires no mixingViscosityHighCureAnaerobicSecondary Cure ActivatorApplicationRetainingStrengthHigh<strong>LOCTITE</strong> ® 660 is designed for the bonding of cylindricalfitting parts, particularly where bond gaps can approach 0.50mm (0.02 in.). The product cures when confined in the absenceof air between close fitting metal surfaces and preventsloosening and leakage from shock and vibration. This productpossesses excellent gap cure characteristics. Typicalapplications include restoring correct fits on worn shafts, spunbearings, and damaged keyways.NSF InternationalRegistered to NSF Category P1 for use as a sealant wherethere is no possibilty of food contact in and around foodprocessing areas. Note: This is a regional approval. Pleasecontact your local Technical Service Center for moreinformation and clarification.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity @ 25 °C 1.13Flash Point - See MSDSViscosity, Brookfield - HBT, 25 °C, mPa·s (cP):Spindle TB, speed 0.5 rpm, 1,000,000 to 2,000,000 LMSHelipathSpindle TB, speed 5.0 rpm, 150,000 to 350,000 LMSHelipath% of Full Strength on Steel100755025Steel01min 5min10min 30min 1h 3h 6h 24h 72hCure TimeAluminumZinc dichromateCure Speed vs. Bond GapThe rate of cure will depend on the bondline gap. The followinggraph shows shear strength developed with time on steel pinsand collars at different controlled gaps and tested according toISO 10123.% of Full Strength on Steel10075502501min 5min10min 30min 1h 3h 6h 24h 72hCure Time0.154 mm0.27 mmCure Speed vs. TemperatureThe rate of cure will depend on the temperature. The graphbelow shows the shear strength developed with time atdifferent temperatures on steel pins and collars and testedaccording to ISO 10123.TYPICAL CURING PERFORMANCECure Speed vs. SubstrateThe rate of cure will depend on the substrate used. The graphbelow shows the shear strength developed with time on steelpins and collars compared to different materials and testedaccording to ISO 10123.% of Full Strength on Steel10075502540 °C22 °C01min 5min10min 30min 1h 3h 6h 24h 72hCure Time4 °C

TDS <strong>LOCTITE</strong> ® 660, December-2009Cure Speed vs. ActivatorWhere cure speed is unacceptably long, or large gaps arepresent, applying activator to the surface will improve curespeed. The graph below shows the shear strength developedwith time on zinc dichromate steel pins and collars usingActivator 7471 and 7649 and tested according to ISO10123.% of Full Strength on Steel10075502501min 5min10min 30min 1h 3h 6h 24h 72hCure TimeActivator 7471Activator 7649No activatorTYPICAL PROPERTIES OF CURED MATERIALPhysical Properties:Coefficient of Thermal Expansion,80×10 -6ISO 11359-2, K -1Coefficient of Thermal Conductivity, ISO 8302, 0.1W/(m·K)Specific Heat, kJ/(kg·K) 0.3Elongation, at break, ISO 37, %

TDS <strong>LOCTITE</strong> ® 660, December-20095. For Shrink Fitted Assemblies the adhesive should becoated onto the pin, the collar should then be heated tocreate sufficient clearance for free assembly.6. Parts should not be disturbed until sufficient handlingstrength is achieved.For Disassembly1. Apply localized heat to the assembly to approximately250 °C. Disassemble while hot.For Cleanup1. Cured product can be removed with a combination ofsoaking in a Loctite solvent and mechanical abrasionsuch as a wire brush.Loctite Material Specification LMSLMS dated September-1, 1995. Test reports for each batchare available for the indicated properties. LMS test reportsinclude selected QC test parameters considered appropriate tospecifications for customer use. Additionally, comprehensivecontrols are in place to assure product quality andconsistency. Special customer specification requirements maybe coordinated through Henkel Quality.StorageStore product in the unopened container in a dry location.Storage information may be indicated on the product containerlabeling.Optimal Storage: 8 °C to 21 °C. Storage below 8 °C orgreater than 28 °C can adversely affect product properties.Material removed from containers may be contaminated duringuse. Do not return product to the original container. HenkelCorporation cannot assume responsibility for product whichhas been contaminated or stored under conditions other thanthose previously indicated. If additional information is required,please contact your local Technical Service Center orCustomer Service Representative.Conversions(°C x 1.8) + 32 = °FkV/mm x 25.4 = V/milmm / 25.4 = inchesµm / 25.4 = milN x 0.225 = lbN/mm x 5.71 = lb/inN/mm² x 145 = psiMPa x 145 = psiN·m x 8.851 = lb·inN·m x 0.738 = lb·ftN·mm x 0.142 = oz·inmPa·s = cPNoteThe data contained herein are furnished for information onlyand are believed to be reliable. We cannot assumeresponsibility for the results obtained by others over whosemethods we have no control. It is the user's responsibility todetermine suitability for the user's purpose of any productionmethods mentioned herein and to adopt such precautions asmay be advisable for the protection of property and of personsagainst any hazards that may be involved in the handling anduse thereof. In light of the foregoing, Henkel Corporationspecifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for aparticular purpose, arising from sale or use of HenkelCorporation’s products. Henkel Corporation specificallydisclaims any liability for consequential or incidentaldamages of any kind, including lost profits. The discussionherein of various processes or compositions is not to beinterpreted as representation that they are free fromdomination of patents owned by others or as a license underany Henkel Corporation patents that may cover suchprocesses or compositions. We recommend that eachprospective user test his proposed application before repetitiveuse, using this data as a guide. This product may be coveredby one or more United States or foreign patents or patentapplications.Trademark usageExcept as otherwise noted, all trademarks in this documentare trademarks of Henkel Corporation in the U.S. andelsewhere.® denotes a trademark registered in the U.S.Patent and Trademark Office.Reference 0.4Henkel Americas+860.571.5100Henkel Europe+49.89.320800.1800Henkel Asia Pacific+86.21.2891.8863For the most direct access to local sales and technical support visit: www.henkel.com/industrial