EQUALIZER Flow Control Devices Enhanced ... - Baker Hughes

EQUALIZER Flow Control Devices Enhanced ... - Baker Hughes

EQUALIZER Flow Control Devices Enhanced ... - Baker Hughes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

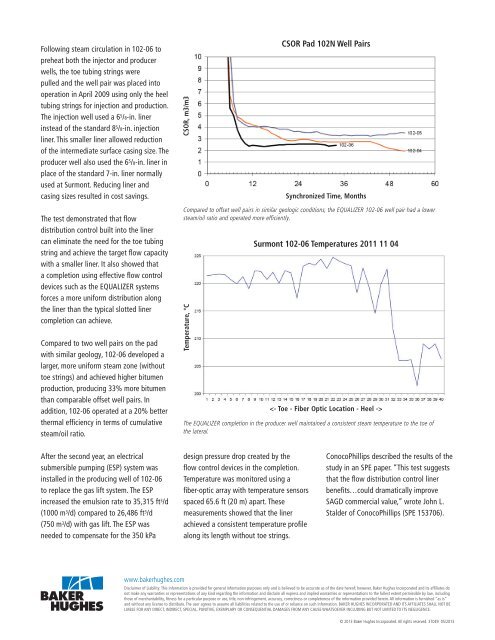

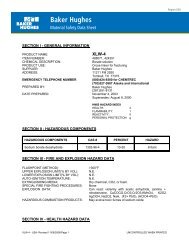

Following steam circulation in 102-06 topreheat both the injector and producerwells, the toe tubing strings werepulled and the well pair was placed intooperation in April 2009 using only the heeltubing strings for injection and production.The injection well used a 6 5 /8-in. linerinstead of the standard 8 5 /8-in. injectionliner. This smaller liner allowed reductionof the intermediate surface casing size. Theproducer well also used the 6 5 /8-in. liner inplace of the standard 7-in. liner normallyused at Surmont. Reducing liner andcasing sizes resulted in cost savings.CSOR, m3/m3CSOR Pad 102N Well PairsSynchronized Time, MonthsThe test demonstrated that flowdistribution control built into the linercan eliminate the need for the toe tubingstring and achieve the target flow capacitywith a smaller liner. It also showed thata completion using effective flow controldevices such as the <strong>EQUALIZER</strong> systemsforces a more uniform distribution alongthe liner than the typical slotted linercompletion can achieve.Compared to two well pairs on the padwith similar geology, 102-06 developed alarger, more uniform steam zone (withouttoe strings) and achieved higher bitumenproduction, producing 33% more bitumenthan comparable offset well pairs. Inaddition, 102-06 operated at a 20% betterthermal efficiency in terms of cumulativesteam/oil ratio.Compared to offset well pairs in similar geologic conditions, the <strong>EQUALIZER</strong> 102-06 well pair had a lowersteam/oil ratio and operated more efficiently.Temperature, °CSurmont 102-06 Temperatures 2011 11 04The <strong>EQUALIZER</strong> completion in the producer well maintained a consistent steam temperature to the toe ofthe lateral.After the second year, an electricalsubmersible pumping (ESP) system wasinstalled in the producing well of 102-06to replace the gas lift system. The ESPincreased the emulsion rate to 35,315 ft 3 /d(1000 m 3 /d) compared to 26,486 ft 3 /d(750 m 3 /d) with gas lift. The ESP wasneeded to compensate for the 350 kPadesign pressure drop created by theflow control devices in the completion.Temperature was monitored using afiber-optic array with temperature sensorsspaced 65.6 ft (20 m) apart. Thesemeasurements showed that the linerachieved a consistent temperature profilealong its length without toe strings.ConocoPhillips described the results of thestudy in an SPE paper. “This test suggeststhat the flow distribution control linerbenefits…could dramatically improveSAGD commercial value,” wrote John L.Stalder of ConocoPhillips (SPE 153706).www.bakerhughes.comDisclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, <strong>Baker</strong> <strong>Hughes</strong> Incorporated and its affiliates donot make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, includingthose of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided herein. All information is furnished “as is”and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BELIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.© 2013 <strong>Baker</strong> <strong>Hughes</strong> Incorporated. All rights reserved. 37049 05/2013