H2prO HD Water Management Service - Baker Hughes

H2prO HD Water Management Service - Baker Hughes

H2prO HD Water Management Service - Baker Hughes

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

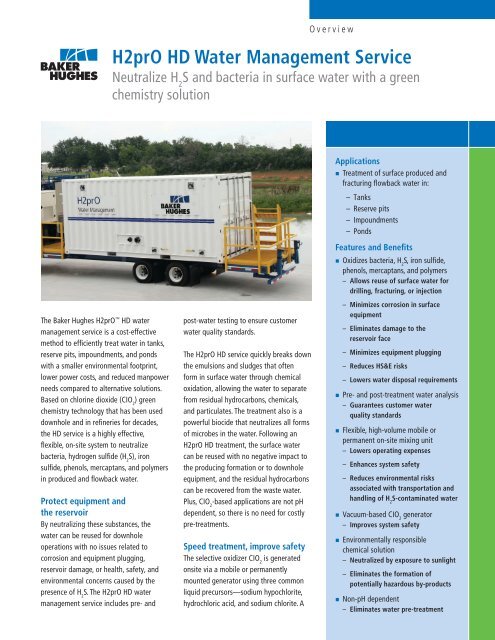

Overview<strong>H2prO</strong> <strong>HD</strong> <strong>Water</strong> <strong>Management</strong> <strong>Service</strong>Neutralize H 2S and bacteria in surface water with a greenchemistry solutionApplications• Treatment of surface produced andfracturing flowback water in:– Tanks– Reserve pits– Impoundments– PondsFeatures and Benefits• Oxidizes bacteria, H 2S, iron sulfide,phenols, mercaptans, and polymers– Allows reuse of surface water fordrilling, fracturing, or injectionThe <strong>Baker</strong> <strong>Hughes</strong> <strong>H2prO</strong> <strong>HD</strong> watermanagement service is a cost-effectivemethod to efficiently treat water in tanks,reserve pits, impoundments, and pondswith a smaller environmental footprint,lower power costs, and reduced manpowerneeds compared to alternative solutions.Based on chlorine dioxide (CIO 2) greenchemistry technology that has been useddownhole and in refineries for decades,the <strong>HD</strong> service is a highly effective,flexible, on-site system to neutralizebacteria, hydrogen sulfide (H 2S), ironsulfide, phenols, mercaptans, and polymersin produced and flowback water.Protect equipment andthe reservoirBy neutralizing these substances, thewater can be reused for downholeoperations with no issues related tocorrosion and equipment plugging,reservoir damage, or health, safety, andenvironmental concerns caused by thepresence of H 2S. The <strong>H2prO</strong> <strong>HD</strong> watermanagement service includes pre- andpost-water testing to ensure customerwater quality standards.The <strong>H2prO</strong> <strong>HD</strong> service quickly breaks downthe emulsions and sludges that oftenform in surface water through chemicaloxidation, allowing the water to separatefrom residual hydrocarbons, chemicals,and particulates. The treatment also is apowerful biocide that neutralizes all formsof microbes in the water. Following an<strong>H2prO</strong> <strong>HD</strong> treatment, the surface watercan be reused with no negative impact tothe producing formation or to downholeequipment, and the residual hydrocarbonscan be recovered from the waste water.Plus, CIO 2-based applications are not pHdependent, so there is no need for costlypre-treatments.Speed treatment, improve safetyThe selective oxidizer CIO 2is generatedonsite via a mobile or permanentlymounted generator using three commonliquid precursors—sodium hypochlorite,hydrochloric acid, and sodium chlorite. A– Minimizes corrosion in surfaceequipment– Eliminates damage to thereservoir face– Minimizes equipment plugging– Reduces HS&E risks– Lowers water disposal requirements• Pre- and post-treatment water analysis– Guarantees customer waterquality standards• Flexible, high-volume mobile orpermanent on-site mixing unit– Lowers operating expenses– Enhances system safety– Reduces environmental risksassociated with transportation andhandling of H 2S-contaminated water• Vacuum-based CIO 2generator– Improves system safety• Environmentally responsiblechemical solution– Neutralized by exposure to sunlight– Eliminates the formation ofpotentially hazardous by-products• Non-pH dependent– Eliminates water pre-treatment

vacuum-based CIO 2generator is used inthe <strong>H2prO</strong> <strong>HD</strong> service, which dramaticallyimproves system safety.With the fast chemical reaction time,concentrated solutions, and high CIO 2generation rates of the <strong>H2prO</strong> <strong>HD</strong> service,up to 200,000 BWPD (31,796 m 3 /d water)can be treated with a single unit. Unlikeother surface water treatment options, themobile CIO 2generator system can be setup very quickly—often in just one hour.Reduce environmental impactThe <strong>H2prO</strong> <strong>HD</strong> service also reducesthe environmental impact of oilfieldoperations. CIO 2, which is used to treatapproximately 30% of U.S. drinking water,does not form any hazardous by-products,and because it is neutralized by exposureto sunlight, it is not persistent in theenvironment. Also, by removing H 2S fromthe surface waste water, CIO 2eliminatesthe offensive odors and dangerous fumesassociated with H 2S.For more information on the<strong>Baker</strong> <strong>Hughes</strong> <strong>H2prO</strong> <strong>HD</strong> watermanagement service, contact your local<strong>Baker</strong> <strong>Hughes</strong> representative or visitwww.bakerhughes.com/watermanagement.<strong>Baker</strong> <strong>Hughes</strong> offers an integratedsuite of proven surface and subsurfacetechnologies to solve your specific watermanagement challenges.www.bakerhughes.comDisclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, <strong>Baker</strong> <strong>Hughes</strong> Incorporated and its affiliates donot make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, includingthose of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided herein. All information is furnished “as is”and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BELIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.© 2013 <strong>Baker</strong> <strong>Hughes</strong> Incorporated. All rights reserved. 36667 8/2013